Ingredients: Microencapsulation of food ingredients: still a field to be explored?

- Like

- Digg

- Del

- Tumblr

- VKontakte

- Buffer

- Love This

- Odnoklassniki

- Meneame

- Blogger

- Amazon

- Yahoo Mail

- Gmail

- AOL

- Newsvine

- HackerNews

- Evernote

- MySpace

- Mail.ru

- Viadeo

- Line

- Comments

- Yummly

- SMS

- Viber

- Telegram

- Subscribe

- Skype

- Facebook Messenger

- Kakao

- LiveJournal

- Yammer

- Edgar

- Fintel

- Mix

- Instapaper

- Copy Link

Posted: 10 September 2009 | Adem Gharsallaoui, Temporary Associate Professor, AgroSup Dijon (France) | 1 comment

The food industry uses more and more purified natural and synthetic fragile substances today, and consequently, there is an increased need to protect these ingredients. Functional food ingredients, such as flavours, vitamins or antioxidants, are sensitive to environmental stress during manufacturing, storage and consumption of the food product. Furthermore, loss of bioactivity can occur during digestion in the stomach and intestine. Microencapsulation is a useful tool to preserve the beneficial properties of these food ingredients and to control their release at both the right place and the right time.

The food industry uses more and more purified natural and synthetic fragile substances today, and consequently, there is an increased need to protect these ingredients. Functional food ingredients, such as flavours, vitamins or antioxidants, are sensitive to environmental stress during manufacturing, storage and consumption of the food product. Furthermore, loss of bioactivity can occur during digestion in the stomach and intestine. Microencapsulation is a useful tool to preserve the beneficial properties of these food ingredients and to control their release at both the right place and the right time.

The food industry uses more and more purified natural and synthetic fragile substances today, and consequently, there is an increased need to protect these ingredients. Functional food ingredients, such as flavours, vitamins or antioxidants, are sensitive to environmental stress during manufacturing, storage and consumption of the food product. Furthermore, loss of bioactivity can occur during digestion in the stomach and intestine. Microencapsulation is a useful tool to preserve the beneficial properties of these food ingredients and to control their release at both the right place and the right time.

Historically, microencapsulation of food ingredients has been employed since the 1930s to encapsulate flavours by spray-drying using acacia gum as the wall material. However, the increasing complexity of food products and the rapid growth in functional foods seen toward the end of the 1990s continues to push researchers and manufacturers to develop novel encapsulation strategies and processes. Microencapsulation has found widespread use in the cosmetic and pharmaceutical industries, but also in many food and beverage applications. Flavour encapsulation is the most well known application of this new technology in the food field. Flavour microencapsulation entraps very small amounts of flavouring compounds in a protective coating of another food grade material, creating micron-size capsules with a flavour profile suitable for a specific use in the food industry. For example, flavour-containing microcapsules can release the core material at the ideal time to provide the maximum impact for the consumer and/or develop a different flavour as the product is being chewed, or also, to formulate new flavour combinations.

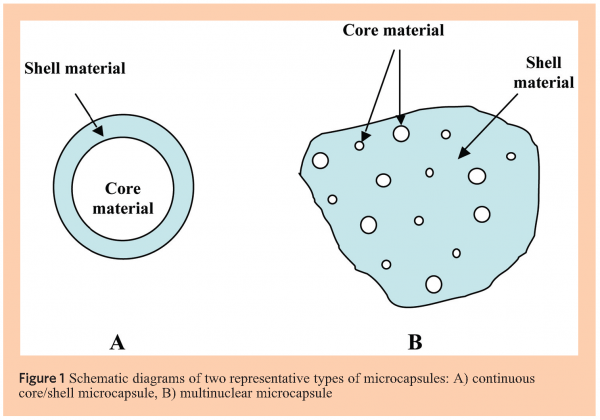

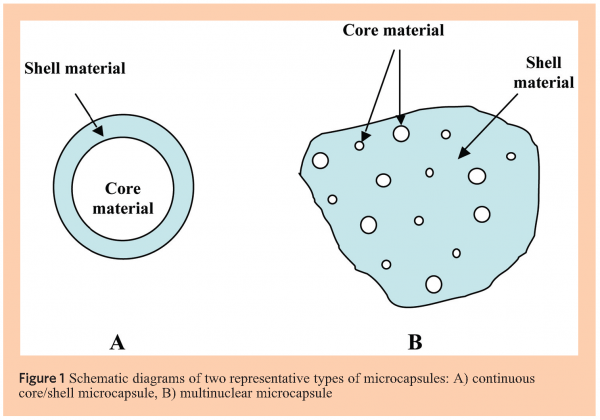

Microencapsulation can be defined as a process in which tiny particles or droplets are surrounded by a coating, or embedded in a homogeneous or heterogeneous matrix, to give small capsules with many useful properties. Microcapsules are small (1-1000 µm) and can have many morphologies. Particularly, food microcapsules are small particles that contain an active ingredient or core material surrounded by a coating or shell composed of materials including a variety of food grade polymers, carbohydrates, fats and waxes. These coatings play the role of a barrier that permits to avoid chemical reactions and/or enable controlled release of the ingredients. The core material may be composed of only one or several ingredients and the shell may be single or multi-layered.

Most important aims and advantages of microencapsulation

The current trend towards a healthier way of living and consumer interest in functional foods continues to increase and consequently, food companies are looking for ways to incorporate health-enhancing ingredients to their products. However, direct addition of active ingredients is often compromised by their degradation and the loss of their bioactivity during food processing and in the digestive tract. In addition, ingredients can react with components present in the food matrix, which may change the taste or colour of the final food product. More generally, six main reasons for applying microencapsulation in food industry can be outlined:

- Reduction of the core reactivity with environmental factors, e.g. temperature, humidity, interaction of other substances or UV radiation

- Reduction of evaporation or decrease of the transfer rate of the core material from the capsule to the surrounding environment

- Masking of certain properties of the active substances, e.g. microencapsulating minerals or vitamins in an appetising application can help children get their recommended intake of these supplements

- Promoting easier handling of volatile compounds, e.g. flavours

- Dilution of the core material when it should only be used in very small amounts, e.g. vitamins

- Control of the release of the encapsulated ingredient to ensure optimal timely and targeted dosage

In addition to food ingredients such as vitamins and flavours, microencapsulation can be extended to pharmaceuticals or even living cells that become important for a wide variety of applications and technologies, ranging from nutraceuticals to drug delivery and biomedical applications.

Microencapsulation methods

The microencapsulation technology used conditions the structure of the obtained microcapsules. Some processes produce microcapsules with a spherical geometry in which a continuous core region is surrounded by a continuous shell (Figure 1a). Other processes produce microcapsules with an irregular geometry that contain a number of small droplets or particles of core material dispersed in a matrix of shell material (Figure 1b)1:

- Processes producing A type microcapsules: Complex coacervation, polymer/polymer incompatibility, interfacial polymerisation in liquid media, in situ polymerisation, in-liquid drying, thermal and ionic gelation in liquid medial and desolvation in liquid media

- Processes producing B type microcapsules: Spray-drying, spray-chilling, fluidised bed, electrostatic deposition, centrifugal extrusion, spinning disk or rotational suspension separation, polymerisation at liquid/gas or solid/gas interface, pressure extrusion or spraying into solvent extraction bath and hot-melt extrusion

Although there are many techniques that have been developed to microencapsulate food ingredients, spray-drying is the most common technology used in the food industry due to low cost and available equipment. Application of the spray-drying process in microencapsulation involves three basic steps: (i) preparation of the dispersion or emulsion to be processed (ii) homogenisation of the dispersion and (iii) atomisation of the mass into the drying chamber. The short time exposition and the rapid evaporation of water keeps the core temperature below 40°C, in spite of the high temperatures generally used in the process (~180 °C).

Microstructure of dried microcapsules

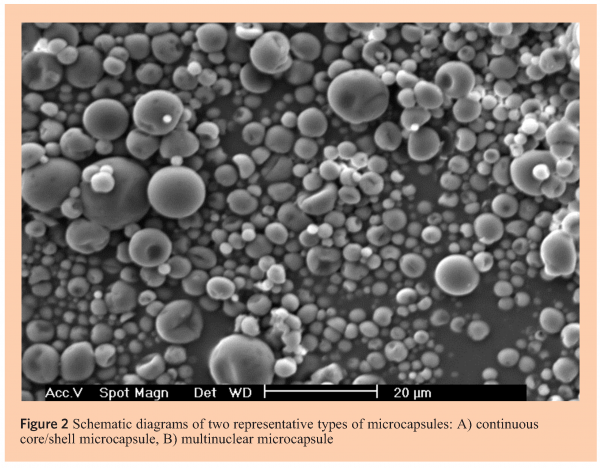

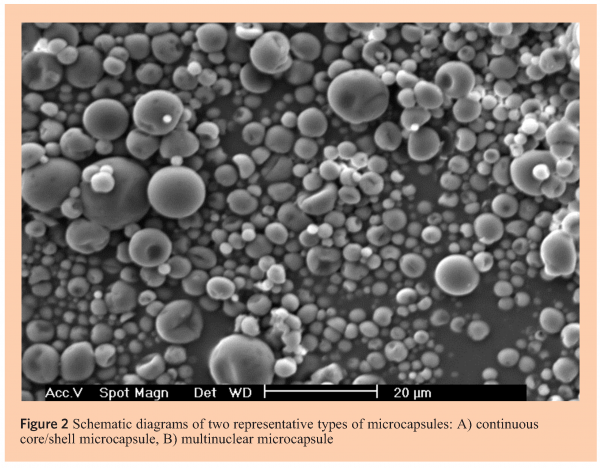

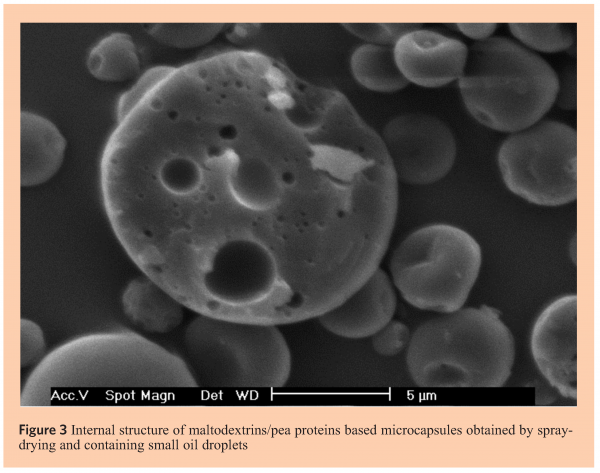

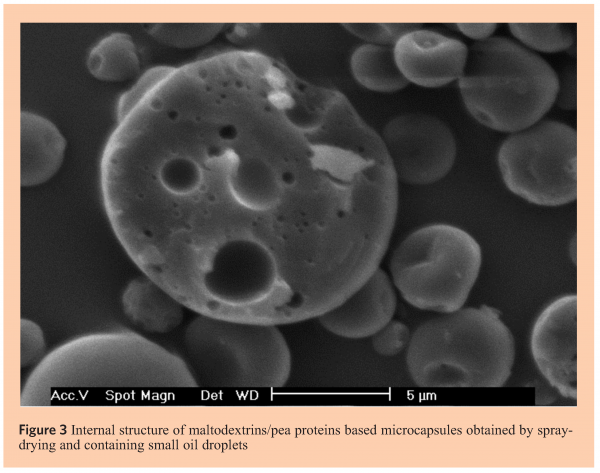

Scanning electron micrographs of the dry microcapsule powders obtained in our laboratory by spray-drying five weight-percent oil-in-water emulsions stabilised by pea proteins in presence of 11 per cent maltodextrins (Dextrose Equivalent 28) are presented in Figures 2 and 3. Dried microcapsules consisted of well-separated spherical particles, having homogeneous diameter repartition (2-10 µm) a rounded shape and smooth surface with no obvious dents (Figure 2). The internal structure of obtained microcapsules showed that oil was located in the form of small droplets embedded in the shell of the wall matrix as shown in Figure 3. A thicker shell matrix was observed and the microcapsule showed an air bubble (so called void) at the centre of the microcapsule. It has been reported that void formation is caused by expansion of air bubbles trapped inside the droplet. The mechanisms associated with the formation of these central voids are also related to the expansion of the particles during the drying process. Thus, void volume is known to increase when the viscosity of the feed emulsion or suspension increases.

Release modes

In addition to the stability of microcapsules to processing and storage, the selective setting of the wall matrix to a desired release mechanism and profile has an important role to play. An encapsulated food ingredient should be released from that encapsulating matrix in order to function within the food product at both the desired time and place. Because of the large number of different food applications, microencapsulation allows the realisation of a wide range of release profiles. The most significant modes of release are listed below:

- Dissolution: If the wall coating is composed of a water-soluble polymer, microcapsules design should take into account that the release can only occur at a particular pH, salt concentration or temperature. In this mode of release, the following steps could be optimised: wetting, swelling and permeation of the capsule material by water, dissolution and permeation of the encapsulated ingredient into the capsule material and diffusion of the ingredient into the food product bulk phase. e. g., pH-induced release of omega-3 fatty acids in the stomach

- Physical release: In this mode, to deliver their content, microcapsules should be broken physically. This is usually the case for ingredients that need to be released in the mouth. e.g. release of different flavours in a consecutive order when a chewing gum is chewed

- Thermal release: Some microencapsulation matrix compounds have high melting points or their chemical structures are sensitive to temperature increase. As a result, encapsulated ingredients can be released when the temperature conditions are modified. e. g. flavour release during cooking of the product or only when the product is heated in the consumer’s microwave

Examples of microencapsulated food ingredients

Microencapsulation of ingredients such as vitamins, flavours, pharmaceuticals or even living cells is becoming increasingly important for a wide variety of applications and technologies, ranging from functional foods to drug delivery and biomedical applications. Currently, essential interests are attributed to encapsulation of flavours, lipids and carotenoids among other ingredients. Microencapsulation of hydrophobic flavours is of great importance in the flavouring and food industries, since solid or liquid microencapsulated food flavour exhibits a good chemical stability and a controlled release. For example, l-Menthol, a cyclic terpene alcohol normally available in the form of crystals or granules was encapsulated in a wall system of maltodextrin and gum arabic. Other substances such as flavours of oregano, citronella and marjoram were successfully encapsulated by spray-drying in wall systems of skimmed milk powder and whey protein concentrate2.

In general, lipids are difficult to disperse in food products, in addition, especially polyunsaturated fatty acids are susceptible to oxidation, which results in off-flavours and toxic compounds. A fish oil (an oil rich in omega-3 polyunsaturated fatty acids) powder ingredient, with low off-flavour and extended shelf life was successfully manufactured using microencapsulation and was incorporated into a number of food products.

Lycopene, a molecule thought to decrease the risk of prostate cancer, was successfully microencapsulated by spray-drying using a wall system consisting of gelatine and sucrose3. The stabilisation of carotenoids in foods and foodstuffs against isomerisation or oxidation is very important because their degradation lowers the final product quality in terms of nutritional properties as well as colouration. Maltodextrins were found to be effective in protecting the carotenoids2.

However, some more specific applications of microencapsulation can be mentioned4:

- Baby foods: thanks to microencapsulation, many molecules can be incorporated into infant formula for composition closer to human milk

- Baked products: Unstable polyunsaturated fatty acids from fish oil are encapsulated to prevent oxidation and lipid breakdown, to withstand baking temperatures and then to preserve bioactivity

- Chewing gum: Controlled release and even alternating delivery of flavours and sweeteners creates a sensory experience with several dimensions

- Flavoured waters: water can be flavoured and fortified by using microencapsulated ingredients without compromising its clarity

- Leavening agents: Sodium bicarbonate and phosphates are microencapsulated to prevent activity in refrigerated and frozen dough. Their leavening power is released upon baking

- Nutrition bars: Microencapsulation technology enables delivery of many vitamins and minerals in nutrition bars with a release rate that depends on the consumer daily requirement

- Yogurt: Microencapsulation of lactic acid bacteria enables them to survive pasteurisation, moreover, probiotic microorganisms promoting digestive health can be protected through encapsulation from digestive degradation in the stomach and small intestine

Future trends

Despite the wide range of microencapsulated substances that have been developed and successfully marketed in the pharmaceutical and cosmetic industries, microencapsulation has found a smaller market place in the food industry. The technology is still far from being fully developed and the core material properties are often not preserved. Scientists consider that many new food ingredients will be available in a purified form within the next few years, including phytosterols, probiotics and prebiotics, new types of carotenoids and antioxidants, and polyphenols. Food ingredient companies should look for new innovative technologies to stabilise and protect these compounds and we think that microencapsulation will certainly play a crucial role in the enhancing of future product value and quality. However, if a microencapsulation company likes to be recognised as an expert in this innovative field, the following important factors should be taken into consideration in the selection of a microencapsulation technology: cost, microcapsule size and functions, severity of processing conditions, and potential interaction with other food components.

References

- Thies, C. (2001). Microencapsulation: what it is and purpose. In Microencapsulation of food ingredients. Leatherhead publishing, pp. 1-30

- Gharsallaoui, A., Roudaut, G., Chambin, O., Voilley, A. & Saurel, R. (2007). Applications of spray-drying in microencapsulation of food ingredients: An overview. Food Research International, 40(9), 1107-1121

- Shu, B., Yu, W., Zhao, Y., & Liu, X. (2006). Study on microencapsulation of lycopene by spray-drying. Journal of Food Engineering, 76, 664-669

- Poncelet, D. (2006). Microencapsulation: Fundamentals, Methods and Applications. In, Surface Chemistry in Biomedical and Environmental Science. Springer Netherlands, pp. 23-34

On-going researches round the world have led to a wide range of active agents – microencapsulated to achieve the desired properties. Whether it is making a smart fabric or a smart food microencapsulation is making things possible across many fields. The industry which foresees numerous applications for microencapsulation in the coming years is food and beverage industry.

Among many uses of microencapsulation in food and beverage industry some are

To entrap natural compounds,

Better handling (e.g. liquid to powdered form)

Controlled release of the active compound

Add textural or visible effects

Mask undesired taste

Prolong shelf life,

Preserve nutrients from degradation in gastrointestinal tract

And infuse nutrients, probiotics.

Microencapsulated products are majorly used by these industries:

Bakery and confectionary

Dairy and Frozen desserts

Snacks and convenience Foods

Functional and Fortified Food

Meat , Poultry and sea food

Beverages

Others