Bran, bread and bubbles

- Like

- Digg

- Del

- Tumblr

- VKontakte

- Buffer

- Love This

- Odnoklassniki

- Meneame

- Blogger

- Amazon

- Yahoo Mail

- Gmail

- AOL

- Newsvine

- HackerNews

- Evernote

- MySpace

- Mail.ru

- Viadeo

- Line

- Comments

- Yummly

- SMS

- Viber

- Telegram

- Subscribe

- Skype

- Facebook Messenger

- Kakao

- LiveJournal

- Yammer

- Edgar

- Fintel

- Mix

- Instapaper

- Copy Link

Posted: 21 November 2005 | Grant M Campbell, Satake Centre for Grain Process Engineering, School of Chemical Engineering and Analytical Science, The University of Manchester | No comments yet

The greatest challenges facing the domestic chef or his/her industrial counterpart frequently concern the creation, retention and control of aerated structures in foods. Many food products – and most of the more high profile and attractive ones – derive their distinction and appeal from the incorporation and manipulation of bubbles: soufflé, champagne, ice cream, meringue – the list is, if not endless, certainly extensive!

The greatest challenges facing the domestic chef or his/her industrial counterpart frequently concern the creation, retention and control of aerated structures in foods. Many food products – and most of the more high profile and attractive ones – derive their distinction and appeal from the incorporation and manipulation of bubbles: soufflé, champagne, ice cream, meringue – the list is, if not endless, certainly extensive!

The greatest challenges facing the domestic chef or his/her industrial counterpart frequently concern the creation, retention and control of aerated structures in foods. Many food products – and most of the more high profile and attractive ones – derive their distinction and appeal from the incorporation and manipulation of bubbles: soufflé, champagne, ice cream, meringue – the list is, if not endless, certainly extensive!

Classic kitchen disasters resulting from lack of mastery of the bubbles, and reproduced in spectacular scale in food manufacturing plants, include sponge cake and soufflé catastrophes; egg whites refusing to whip; bread of low volume and poor appearance that falls apart when sliced or buttered, along with other failures such as loss of foam on beer, fizzy drinks that have gone flat, product size failing to fit into or to fill packaging, or the more mundane problems of simply poor, unacceptable or inconsistent structure and palatability.

Bubbles impart novelty to foods and enhance the pleasure of the eating experience and the profitability of the commercial product. Aerated foods represent the best of the chef or food technologist’s skill and are a compliment from the host – if you want to delight and impress your guests, you make them a soufflé; if you’re not bothered, you fry them an egg! A large part of the appeal of aerated foods is that they represent pure luxury – bubbles confer no nutritional benefit, and require costly effort and skill to incorporate into foods, but the unique and wondrous textures they impart are the height of dining magnificence. However, although bubbles are non-nutritive, aeration of foods does have health implications, as bubbles affect perceived satiety, contribute to reduction of portion sizes without adversely affecting pleasure or profitability (note the success of aerated chocolate bars), and influence dietary choices for or away from healthy foods.

The food industry is increasingly addressing the diet and health agenda and striving to create healthy versions of appealing foods, even within such unpromising and indulgent sectors as cakes, chocolate and confectionery. It is obvious, within the context of choosing a healthy diet, that a food product that is not consumed has no health consequence. Thus, the worthy ambition of creating healthy food choices cannot allow the sensory appeal of the food to be compromised. And where the sensory appeal derives, as it so often does, from the aerated structure, this means that a sound understanding of bubble behaviour is vital to creating healthy food products.

Nowhere is this more true that in relation to wholemeal and bran-enriched breads, where consumption (or avoidance) is directly related to the palatability and appeal of the aerated structure in comparison to white bread. (The same applies to other bakery goods that seek to offer high-fibre versions, such as cakes, biscuits, muffins and so-called flat breads, which are still significantly aerated.) Most of us should eat more bran and bread is a major vehicle for delivering bran into the diet. However, despite several decades of nutritional consensus and public education on the health benefits of fibre in general – and cereal brans (particularly wheat and oat bran) in particular – it is still the case that more than 70 per cent of bread consumed in the UK is white. Increased consumption of bran is arguably the single most significant dietary factor for enhancing the health of the nation, but achieving this important goal is hindered by the fact that bran adversely affects the aerated structure of bread. Bran damages bubbles in bread, so wholemeal breads are of lower volume, coarser texture, less soft and less palatable. Therefore, they are not consumed in great quantity and fail to deliver the significant health benefits resulting from more bran in the diet.

The health benefits of dietary fibre (of which wheat bran is a superior source) are well established in general, with specific claims (made with greater or lesser extents of certainty, and with qualifiers in relation to specific fibre products and with regard to efficacy for specific individuals) in relation to reduced incidences of: appendicitis, colon cancer, heart disease, obesity and other ailments, collectively referred to as the diseases of civilisation. However, it is still generally agreed that intakes of fibre and fibre-containing foods are well below recommended levels in Western countries, with a typical Western diet containing less than 20 g of dietary fibre per day, against the recommended daily intake of 25-35 g.

Having established that bran in the diet is beneficial, but that consumption is currently inadequate, it follows that facilitating the delivery of bran via products such as bread, through guidance to bakers and research in support of this, should be a priority. Van der Kamp (2003), reporting on the Dietary Fibre 2003 conference, advises that “the development of products that are attractive to consumers and underpinning research to this end is a key element in efforts to increase the intake of dietary fibre”. Indeed, guidance for bakers producing wholemeal breads has been forthcoming since the rise to prominence of the benefits of bran. Wholemeal bread quality can be improved through a number of strategies including addition of extra water, gluten, oxidants, surfactants, fat and lipoxygenase, and by pre-hydration or modification of the bran (e.g. through washing or fine grinding).

Alongside this practical guidance for producing acceptable wholemeal breads, studies have been undertaken to elucidate the mechanisms by which bran exerts its damaging effects on bubbles, in an attempt to understand and alleviate these negative effects. At least a dozen contributing factors have been identified, of which the major ones are dilution of the gluten protein, mechanical disruption of gluten films and starch gelatinisation at a lower temperature during baking (as a consequence of the increased water availability) giving less oven spring and lower loaf volumes. Additional mechanisms proposed by various workers include foam destabilisation by fatty acids and other small molecular weight compounds; reduction of fat levels by lipase activity; preferential removal of beneficial lipid fractions by absorption or hydrolysis; competition for oxygen by lipoxygenase during dough development; negation of the activity of some oxidising improvers; enzyme activity in the bran, to which we can add the possibilities of altered aeration during mixing and bubble growth dynamics during proving. Despite this lengthy list of contributing mechanisms, our detailed understanding of the interaction of bran with bubbles in bread is far from complete. Most research on breadmaking, including recent innovations such as the application of X-ray tomography to image bread structure during proving and baking (Whitworth, 2002), or the application of new dough rheometers such as the Dough Inflation System (Dobraszczyk, 1997), has focussed on white bread formulations. Meanwhile, the continued low consumption of wholemeal breads argues that the battle for the hearts, minds, palates and colons of the bread consuming public is not yet won.

With this in mind, the effects of the level and particle size of wheat and oat bran were investigated using the test bakery facilities at the New Zealand Institute for Crop and Food Research, and also using a sensitive new test of dough expansion capacity developed by the author, called Dynamic Dough Density (DDD). These studies aimed to address the mechanistic action of bran in bread by asking at what stage in the breadmaking process (i.e. during mixing, proving or baking) does bran exert its negative effects? Identifying when bran affects the bubbles helps our interpretation of how bran damages bread quality and how this damage may be alleviated.

For these studies, commercial wheat and oat bran samples were milled to different particle sizes and added to bread formulations at levels of 0, 7.5 and 15% for the wheat bran (i.e. substituting this percentage of the flour with bran), and 0, 10, 20 and 30% for the oat bran. (Oat bran is less ‘pure’ than wheat bran, hence the higher levels of incorporation.) Loaves were prepared using a laboratory scale mechanical dough development breadmaking process based on 125 g of flour. The specific volumes of baked loaves were measured as functions of particle size and bran level, and their maximum expansion capacity during proving measured using the DDD test.

In addition, the effects on optimum work input and water absorption were measured using a recording mixer. Particle size had no effect on optimum work input or water absorption for the doughs containing wheat bran, but had a major effect when oat bran was used, with smaller particles giving lower optimum work inputs and higher water absorptions.

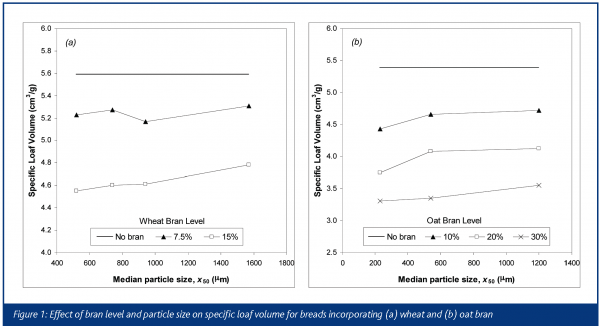

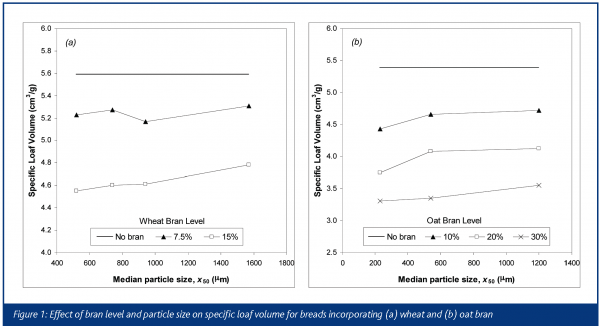

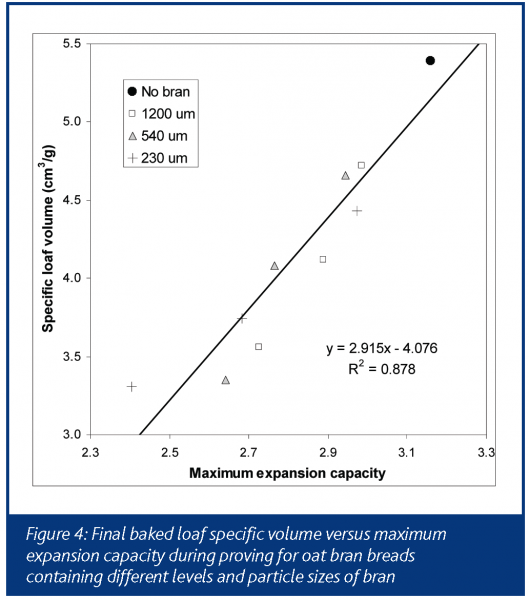

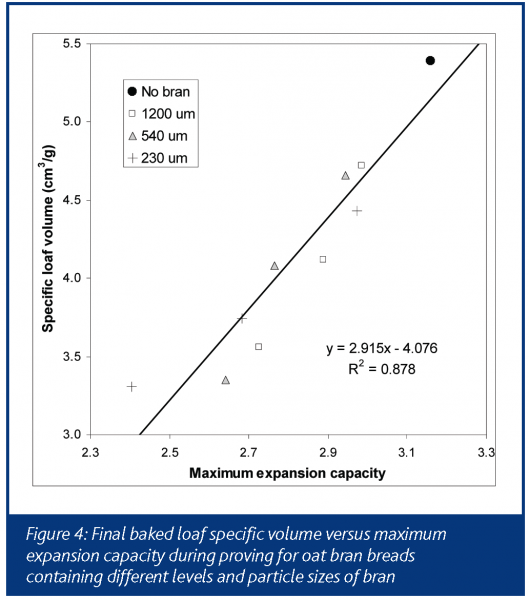

Figure 1 shows the effect of bran level and particle size on the specific loaf volumes for both the wheat and oat bran breads. In both cases, adding bran decreased specific loaf volume, while larger particles gave larger loaf volumes. However, finer particles gave finer baked loaf textures, as illustrated in Figure 2.

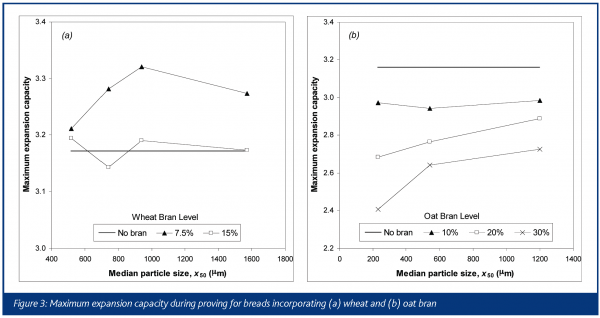

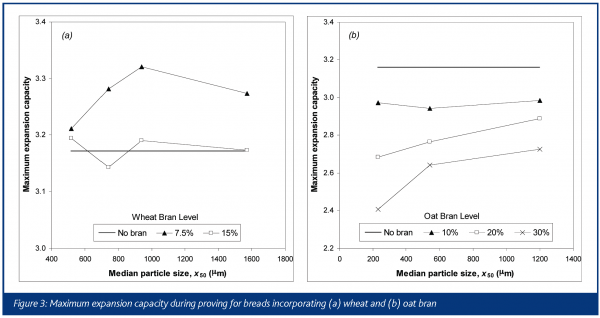

Figure 3 shows the maximum expansion during proving, as measured by the DDD test, for both the wheat and oat bran breads. For the oat bran breads, the pattern is very similar to that evident for the specific volume of final baked loaves. Figure 4 plots final baked loaf specific volume versus expansion during proving for the oat bran breads, showing a high correlation. By contrast, for the wheat bran breads, the correlation between maximum expansion during proving and specific volume of baked loaves was poor. For example, from Figure 3(a), adding 7.5% wheat bran appeared to have a slight strengthening effect on doughs during proving, giving slightly greater expansion capacity, while the expansion capacity for the 15% wheat bran breads was much the same as for breads with no bran. Despite this, the final baked loaf volumes were lower than for breads without bran. This implies that oat bran exerts its negative effects on bread during proving, whereas the adverse effects of wheat bran are created during baking. This conclusion therefore implies that wheat and oat bran damage bread quality via different mechanisms and that a solution for one type of bran might not work well for the other type.

Studying aerated foods, such as wholemeal breads, white breads or the numerous other examples listed above, from the perspective of the bubbles allows new insights and demands innovative developments that stimulate greater understanding and exploitation of this most versatile of food ingredients.

References

Campbell GM (2003) “The rise and rise of bubbles in bread.” New Food, Issue 1, 2003, 57-58,60

Dobraszczyk BJ (1997) “Development of a new dough inflation system to evaluate doughs.” Cereal Foods World 42, 516-519.

Whitworth MB (2002) “Development of bubble structure in bread dough.” Grain and Feed Milling Technology, 10-11.

van der Kamp J (2003) “New perspectives for dietary fibre research and development of novel research tools.” Cereal Foods World 48(5), 257-259.