Reducing acrylamide in bakery products

- Like

- Digg

- Del

- Tumblr

- VKontakte

- Buffer

- Love This

- Odnoklassniki

- Meneame

- Blogger

- Amazon

- Yahoo Mail

- Gmail

- AOL

- Newsvine

- HackerNews

- Evernote

- MySpace

- Mail.ru

- Viadeo

- Line

- Comments

- Yummly

- SMS

- Viber

- Telegram

- Subscribe

- Skype

- Facebook Messenger

- Kakao

- LiveJournal

- Yammer

- Edgar

- Fintel

- Mix

- Instapaper

- Copy Link

Posted: 23 May 2006 | Dipl.-LM-Ing.Achim Claus, Prof. Dr. Reinhold Carle and PD Dr.Andreas Schieber, University of Hohenheim, Institute of Food Technology, Section Plant Foodstuff Technology | No comments yet

Acrylamide is a food-borne toxicant mainly present in roasted, baked and deep-fried foods. To minimise acrylamide levels in bakery products, a comprehensive knowledge of the factors affecting its formation is indispensable. Based on this knowledge technological strategies may be developed.

Due to the potential carcinogenic properties of acrylamide1 the announcement of the Swedish National Food Authority and the University of Stockholm in April 2002 regarding findings of acrylamide in foodstuff initiated intense and rapid research efforts. Early investigations on the reaction pathways associated with the formation of acrylamide were continued by studies concerning its noxious effects. Besides metabolism and toxicology2,3, ways to minimise its levels in heat treated products are the subject of current studies.While efficient strategies for the reduction of acrylamide levels in potato products have been developed, bakery products are still a neglected field. This is quite surprising, considering that the consumption of French fries and potato chips is much lower than bakery products such as bread and bread rolls. In Germany per capita consumption of bakery products amounted to 86.3 kg in 2005, which is equivalent to an average daily intake of 236 g4. Thus, bakery products contribute approximately 25 per cent of the total acrylamide intake via the diet5. From this data it becomes evident that food pattern largely influences dietary intake of acrylamide. Since continuous intake of low acrylamide levels present in staple foods might even be more harmful than occasional consumption of food containing higher amounts, strategies solely considering highly contaminated food commodities will fail to reduce health risks. This article therefore provides a brief review of the occurrence of acrylamide in bakery products and includes recommendations for minimising its levels.

Acrylamide is a food-borne toxicant mainly present in roasted, baked and deep-fried foods. To minimise acrylamide levels in bakery products, a comprehensive knowledge of the factors affecting its formation is indispensable. Based on this knowledge technological strategies may be developed. Due to the potential carcinogenic properties of acrylamide1 the announcement of the Swedish National Food Authority and the University of Stockholm in April 2002 regarding findings of acrylamide in foodstuff initiated intense and rapid research efforts. Early investigations on the reaction pathways associated with the formation of acrylamide were continued by studies concerning its noxious effects. Besides metabolism and toxicology2,3, ways to minimise its levels in heat treated products are the subject of current studies.While efficient strategies for the reduction of acrylamide levels in potato products have been developed, bakery products are still a neglected field. This is quite surprising, considering that the consumption of French fries and potato chips is much lower than bakery products such as bread and bread rolls. In Germany per capita consumption of bakery products amounted to 86.3 kg in 2005, which is equivalent to an average daily intake of 236 g4. Thus, bakery products contribute approximately 25 per cent of the total acrylamide intake via the diet5. From this data it becomes evident that food pattern largely influences dietary intake of acrylamide. Since continuous intake of low acrylamide levels present in staple foods might even be more harmful than occasional consumption of food containing higher amounts, strategies solely considering highly contaminated food commodities will fail to reduce health risks. This article therefore provides a brief review of the occurrence of acrylamide in bakery products and includes recommendations for minimising its levels.

Acrylamide is a food-borne toxicant mainly present in roasted, baked and deep-fried foods. To minimise acrylamide levels in bakery products, a comprehensive knowledge of the factors affecting its formation is indispensable. Based on this knowledge technological strategies may be developed.

Due to the potential carcinogenic properties of acrylamide1 the announcement of the Swedish National Food Authority and the University of Stockholm in April 2002 regarding findings of acrylamide in foodstuff initiated intense and rapid research efforts. Early investigations on the reaction pathways associated with the formation of acrylamide were continued by studies concerning its noxious effects. Besides metabolism and toxicology2,3, ways to minimise its levels in heat treated products are the subject of current studies.While efficient strategies for the reduction of acrylamide levels in potato products have been developed, bakery products are still a neglected field. This is quite surprising, considering that the consumption of French fries and potato chips is much lower than bakery products such as bread and bread rolls. In Germany per capita consumption of bakery products amounted to 86.3 kg in 2005, which is equivalent to an average daily intake of 236 g4. Thus, bakery products contribute approximately 25 per cent of the total acrylamide intake via the diet5. From this data it becomes evident that food pattern largely influences dietary intake of acrylamide. Since continuous intake of low acrylamide levels present in staple foods might even be more harmful than occasional consumption of food containing higher amounts, strategies solely considering highly contaminated food commodities will fail to reduce health risks. This article therefore provides a brief review of the occurrence of acrylamide in bakery products and includes recommendations for minimising its levels.

Acrylamide formation and possible health implications

Acrylamide is not a contaminant such as, for example, dioxin, but a so-called ‘food-borne toxicant’ – a hazardous substance that is formed in a complex mechanism during roasting, baking or deep-frying of foods. Glycidamide, which represents the reactive metabolite, is formed via a cytochrome P450 mediated oxidation, presumably in the liver. The epoxy group of this molecule is highly reactive and may form adducts with the DNA, explaining the genotoxic potential of acrylamide.As shown in animal experiments, this reaction promotes mutations which may finally lead to cancer. Reaction with glutathione detoxifies acrylamide by blocking the reactive C-C double bond. Since acrylamide ingestion through food falls below neurotoxic dosages, its acute toxicity is negligible in human nutrition.

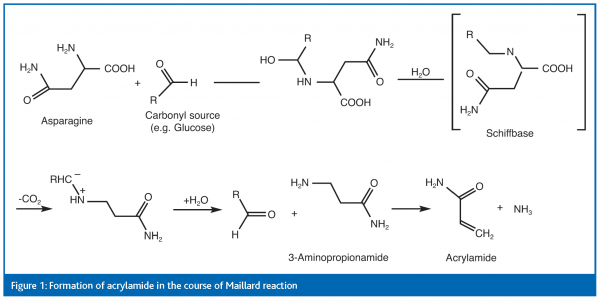

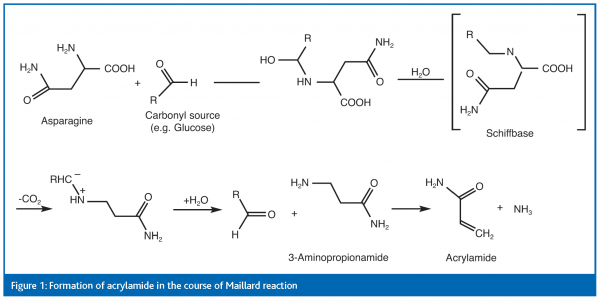

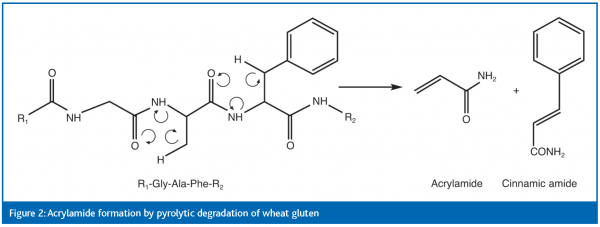

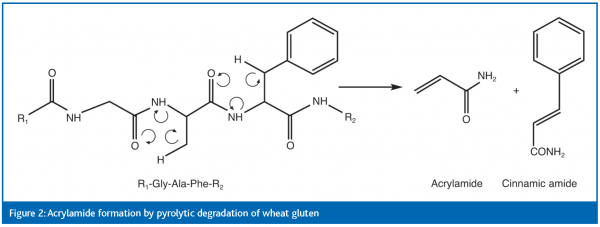

Using stable isotope labeling, various studies showed that acrylamide is formed in the course of Maillard reaction from asparagine and reducing sugars such as fructose, glucose and maltose (Figure 1) – the amino acid being the limiting precursor in bakery products6,7. Since this reaction requires temperatures above 120 °C and low moisture contents, only the crusts contribute to the acrylamide formation8.While the presence of carbohydrates has previously been considered a prerequisite for the formation of acrylamide, model studies have pointed out that acrylamide may also be generated by pyrolysis of the peptides carnosine and N-Benzoyl-Gly-Ala- Phe-NH29,10.Very recently, thermal degradation of isolated gluten proteins completely devoid of carbohydrates has also been demonstrated to generate acrylamide11, based on an electrocyclic domino reaction (Figure 2) which requires higher temperatures10. The latter mechanism is of particular interest from a technological point of view, since gluten proteins are essential in the bread making process.As a consequence, it appears that the formation of acrylamide in wheat-derived bakery products cannot be completely avoided. However, selection of suitable raw materials characterised by minimal levels of low molecular precursors, as well as optimisation of process parameters, may be an appropriate approach to the minimisation of acrylamide burdening.

Strategies for acrylamide reduction in bakery products

The toxicological consideration reveals that acrylamide levels in food shall be as low as reasonably achievable (ALARA). For this purpose, a strategic concept was agreed in Germany among the Federal Office of Consumer Protection and Food Safety (BVL), federal states, industry and the Federal Ministry of Consumer Protection, Food and Agriculture, which is based on signal values. In this concept, foodstuffs concerned are classified in commodity groups. Those foods which represent the top ten per cent most contaminated products in each group are identified, and the lowest acrylamide content within this group represents the new signal value. In general, a signal value of 1000 μg/kg should not be exceeded. If acrylamide contents are exceeding the signal value, food producers are obliged to take adequate actions to lower the contents. This concept has facilitated much research on acrylamide during recent years, resulting in a number of strategies for the reduction of acrylamide levels.

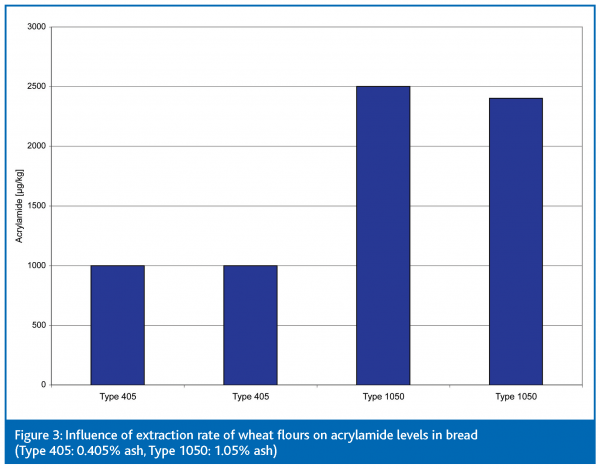

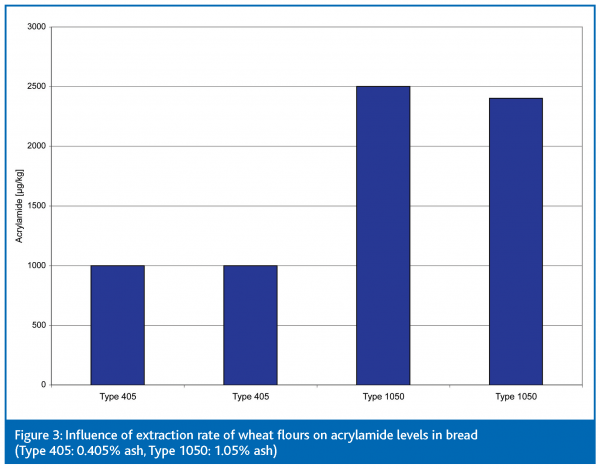

While several studies have indicated a strong influence of the potato cultivars and storage conditions on the acrylamide content of chips and French fries12,13, corresponding investigations of the effects of cereal cultivars on acrylamide levels in bakery products are rather limited14. Our own investigations revealed a significant impact of cultivar and fertilisation (unpublished data) due to variations in the asparagine and crude protein contents of the raw material. Therefore, acrylamide contents of bread and bread rolls can be considerably reduced through selection of suitable raw material. In agreement with the results reported by Haase et al. (2003) the ash content of the flour was shown to influence acrylamide contents in bakery products15 (Figure 3).While at that time no conclusive explanation could be given for this observation, our studies proved that flours high in ash are also characterised by significantly elevated amino acid contents, resulting in higher acrylamide levels in products produced thereof. Furthermore, flouring of the breads prior to baking elevates acrylamide contents significantly (Unpublished data).

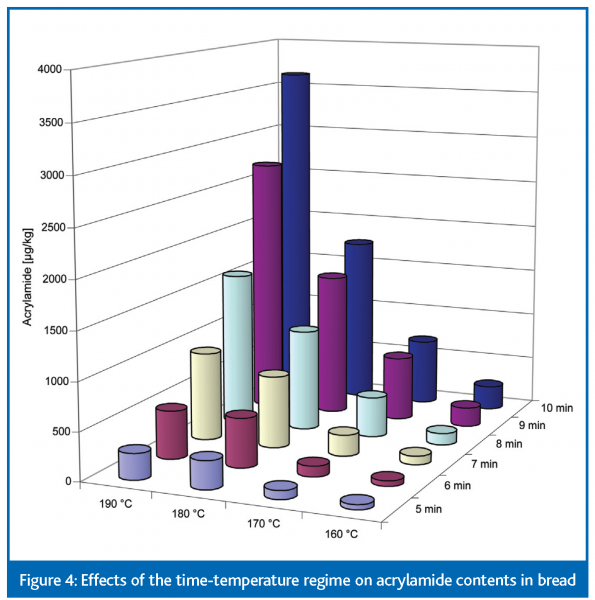

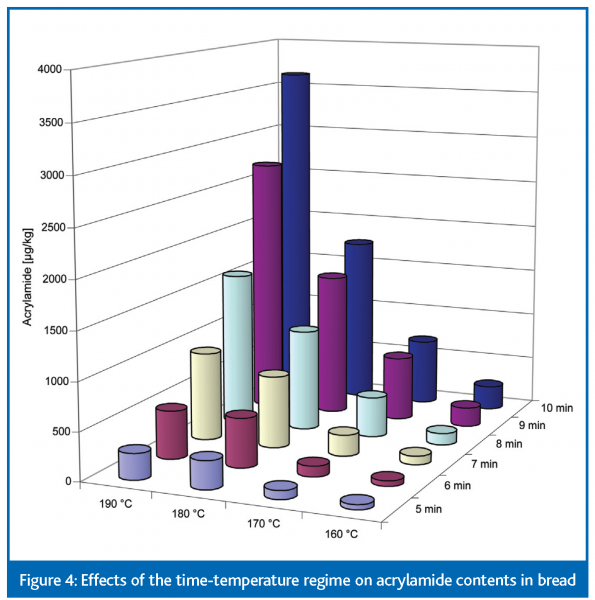

Besides the selection of suitable raw materials, optimisation of process parameters represents another means of reducing acrylamide levels which is of particular interest to food manufacturers. Since the extent of the Maillard reaction is time and temperature dependent, both parameters are strongly affecting acrylamide formation.As a consequence, elevated baking temperature and extended baking time increase acrylamide levels in the product. In order to obtain products that are low in acrylamide, while still being acceptable to the consumer, reduced temperatures and prolonged baking times should be given priority (Figure 4). However, it should also be noted that acrylamide is subject to partial degradation when the surface temperature exceeds 180 °C, probably due to polymerisation16.

Acrylamide formation not only depends on temperature, as such, but also on heat transfer to the product. For bread production two oven types are usually applied. In the traditional deck oven heat is transferred mainly by radiation, while air circulation is used in the convection oven. Compared to the situation in the deck oven, heat transfer is accelerated in the convection oven, which results in faster drying of the product surface and thus in facilitating acrylamide formation. Therefore, acrylamide levels in bread baked in a convection oven are usually higher than those in bread originating from conventional baking processes.

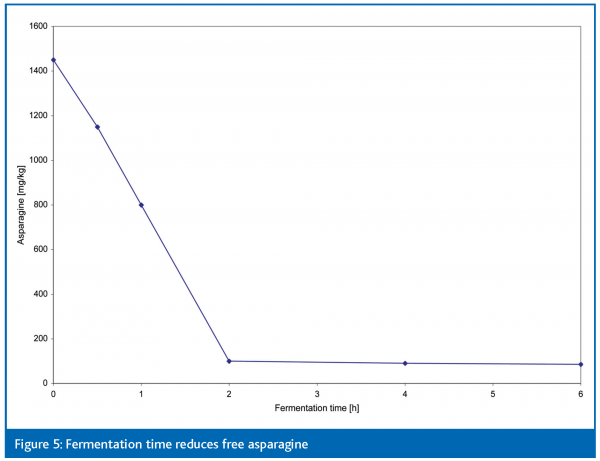

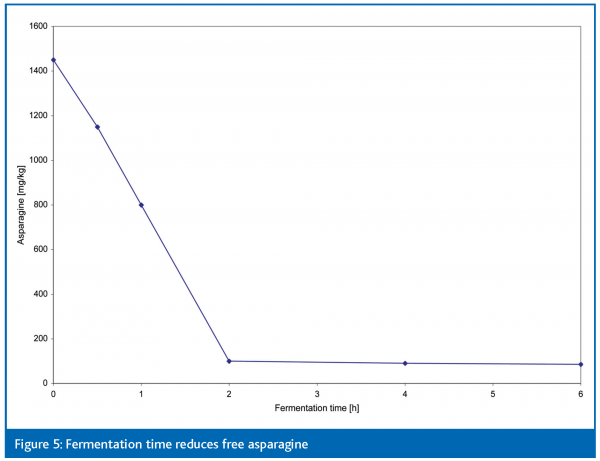

Leaching or blanching of potato slices has proven to be a very efficient strategy for reducing acrylamide in fried products, such as French fries and chips, due to the removal of precursors from the surface.While such treatment is not possible in the bread making process, contents of low molecular precursors in the dough may be efficiently reduced by fermentation17(Figure 5), which is attributed to the metabolism of reducing sugars and amino acids by the yeasts. Prolonged fermentation is suitable to lower acrylamide levels in bread. However, this treatment is limited since enzymatic starch degradation resulting in flat breads will begin after approximately 90 mins of dough fermentation.

The pH value of the dough is another factor affecting acrylamide formation. Since higher values with a maximum of approximately pH 8 lead to increased acrylamide levels18, lowering the pH values is an appropriate means to decrease acrylamide. This can be accomplished either by adding consumable acids such as citric acid or by lactic fermentation, as applied during sourdough preparation. The acidic medium leads to deamination of asparagine to yield aspartic acid, which is decarboxylated to acrylic acid9.

Modifications of conventional technologies may alter the sensory properties of products differing from traditional foodstuffs, which might result in poor consumer acceptance. Furthermore, changes to production lines may be associated with higher costs. Therefore, the addition of ingredients inhibiting acrylamide formation by reaction with precursors or acrylamide may be a more suitable route for food manufacturers. A spice preparation containing extracts of green tea, apples and onions (Flavomare®) has recently been demonstrated to reduce acrylamide levels in potato snacks by 50 per cent compared to the control group when the potato slices were immersed in a solution of this powder prior to frying19. The beneficial effects of this preparation were attributed to the flavonoids abundantly present in apples, tea leaves and onions, which may react with asparagine, thus preventing its reaction with reducing sugars. However, it is also conceivable that sulfur-containing compounds originating from onions react with the electrophilic center of acrylamide. Apart from crude plant extracts, sulfur-containing amino acids such as cysteine may also contribute to reduced levels of acrylamide via two pathways. First, such compounds may compete with asparagine for reducing sugars in the Maillard reaction. Second, the thiol groups may react with the double bond of acrylamide to yield cysteine-S-ß-propionamide. Based on these considerations, the addition of cysteine to flours and dough’s appears promising, especially since cysteine is a natural compound and an approved food additive. However, its application is limited because cysteine also reacts with gluten proteins, thus altering the rheological properties of the dough and the quality of bakery products, respectively. Furthermore, high dosages result in an unpleasant odour. In gingerbread production, dough leavening agents are crucial in order to obtain a porous product. Traditionally, ammonium hydrogencarbonate (NH4HCO3) is used for this purpose. However, it results in high acrylamide levels, probably because it activates reducing sugars by forming an amino sugar. If ammonium hydrogencarbonate is replaced by baking powder (NaHCO3), acrylamide levels are significantly lower20.

Concluding remarks

Since the first report on the presence of acrylamide in heat treated foodstuffs in April 2002 numerous studies concerning its formation have been initiated. Technological advances and optimised production strategies resulted in a considerable reduction of acrylamide levels especially in heat-treated potato products. However, provided that the toxicological consequences of the dietary intake of acrylamide, especially chronic incorporation, have not conclusively been assessed, further investigations are urgently needed to keep acrylamide contents as low as possible.

References

- Tareke, E., Rydberg, P., Karlsson, P., Eriksson, S., Törnqvist, M. (2000):Acrylamide: a cooking carcinogen? Chem. Res. Toxicol., 13, 517-522.

- Friedman,M. (2003): Chemistry, biochemistry, and safety of acrylamide.A review. J.Agric. Food Chem., 51, 4504-4526.

- Lingnert, H., Grivas, S., Jägerstad,M., Skog, K., Törnqvist, M.,Aman, P. (2002):Acrylamide in food:mechanisms of formation and influencing factors during heating of foods. Scand. J.Nutr., 46, 159-172.

- GMF, 2004. Bread consumption in Germany.Available: http://www.gmf-info.de Accessed April 2006.

- Svensson, K.,Abramsson, L., Becker,W., Glynn,A., Hellenas, K.-E., Lind, Y., Rosen, J. (2003): Dietary intake of acrylamide in Sweden. Food Chem. Toxicol., 41, 1581-1586.

- Stadler, R. H., Blank, I.,Varga,N., Robert, F., Hau, J., Guy, P.A., Robert,M.-C., Riediker, S. (2002):Acrylamide from Maillard reaction products.Nature, 419, 449-450.

- Mottram, D. S.,Wedzicha, B. L., Dodson,A. T. (2002): Acrylamide is formed in the Maillard reaction.Nature, 419, 448.

- Claus,A.,Weisz, G.M., Kammerer, D. R., Carle, R., Schieber,A. (2005):A method for the determination of acrylamide in bakery products using ion trap LC-ESIMS/ MS.Mol.Nutr. Food Res, 49, 918-925.

- Yaylayan,V.A., Perez, L. C.,Wnorowski,A.,O`Brien, J. (2004): The role of creatine in the generation of Nmethylacrylamide: a new toxicant in cooked meat. J. Agric. Food Chem., 52, 5559-5565.

- Buhlert, J., Carle, R.,Majer, Z., Spitzner, D. (2006): Thermal degradation of peptides and formation of acrylamide. Letters in Organic Chemistry, in press.

- Claus,A.,Weisz, G.M., Schieber,A., Carle, R. (2006): Pyrolytic acrylamide formation from purified wheat gluten and gluten supplemented wheat bread rolls.Mol.Nutr. Food Res, 50, 87-93.

- De Wilde, T., De Meulenaer, B.,Mestdagh, F., Govaert, Y., Ooghe,W., Fraselle, S., Demeulemeester, K.,Van Peteghem, C., Calus,A., Degroodt, J.-M.,Verhé, R. (2006): Selection criteria for potato tubers to minimize acrylamide formation during frying. J.Agric. Food Chem., 54, 2199-2205.

- Amrein, T.M., Bachman, S.,Noti,A., Biedermann,M., Ferraz Barbosa,M., Biederman-Brem, S., Grob, K., Keiser, A., Realini, P., Escher, F.,Amadó, R. (2003): Potential of acrylamide formation, sugars, and free asparagine in potatoes: a comparison of cultivars and farming systems. J.Agric. Food Chem., 51, 5556-5560.

- Springer,M., Fischer, T., Lehrack,A., Freund,W. (2003): Acrylamidbildung in Backwaren. Getreide Mehl Brot, 57, 274-278.

- Haase,N. u.,Matthäus, B.,Vosmann, K. (2003):Acrylamid in Backwaren, ein Sachstandbericht. Getreide Mehl Brot, 57, 180-184.

- Robert, F.,Vuataz, G., Pollien, P., Saucy, F.,Alonso,M.-I., Bauwens, I., Blank, I. (2004):Acrylamide formation from asparagines under low-moisture Maillard reaction conditions. 1. Physical and chemical aspects in crystalline model systems. J.Agric. Food Chem., 52, 6837-6842.

- Frederiksson, H., Tallving, J., Rosén, J., Åman, P. (2004): Fermentation reduces free asparagine in dough and acrylamide content in bread. Cereal Chem., 81, 650-653.

- Rydberg, P., Eriksson, S., Tareke, E., Karlsson, P., Ehrenberg, L., Törnqvist,M. (2003): Investigations of factors that influence the acrylamide content of heated foodstuffs. J. Agric. Food Chem., 51, 7012-7018.

- Fernández, S., Kurppa, L., Hyvönen, L. (2003): Content of acrylamide decreased in potato chips with addition of a proprietary flavonoid spice mix (Flavomare) in frying. Innov. Food Technol., 18, 24-26.

- Weißhaar, R. (2004):Acrylamid in Backwaren – Ergebnisse von Modellversuchen. Deut. Lebensm.-Rundsch, 100, 92-97.