Viscosity measurements in food products and manufacturing

- Like

- Digg

- Del

- Tumblr

- VKontakte

- Buffer

- Love This

- Odnoklassniki

- Meneame

- Blogger

- Amazon

- Yahoo Mail

- Gmail

- AOL

- Newsvine

- HackerNews

- Evernote

- MySpace

- Mail.ru

- Viadeo

- Line

- Comments

- Yummly

- SMS

- Viber

- Telegram

- Subscribe

- Skype

- Facebook Messenger

- Kakao

- LiveJournal

- Yammer

- Edgar

- Fintel

- Mix

- Instapaper

- Copy Link

Posted: 27 October 2014 | Sarab Sahi | No comments yet

Viscosity is an important property of fluid foods. It is defined as the internal friction of a liquid or its ability to resist flow. The internal friction in a fluid can be easily demonstrated by observing a liquid that has been vigorously stirred to create a vortex. Once the stirring has stopped the speed of the vortex is gradually reduced and rotation of the liquid eventually stops. This happens as a result of the frictional force within the liquid and this force has to be overcome in order for the liquid to flow.

People often use the expression ‘thin’ or ‘water-like’ for liquids that have low viscosity and ‘thick as treacle’ for liquids with high viscosity. Viscosity of a liquid is an important parameter as it can be used as an indicator of quality by the consumer, in some instances a thicker liquid being thought of as superior quality when compared to a thinner product.

Viscosity is also a characteristic of the texture of food. This means that the viscosity of a product must be controlled and measured in production so that each batch is consistent from day to day.

Liquid food systems can be highly shear-sensitive and the structure can break down with the application of shear, as is the case during mixing or when pumped through pipes. There are a number of characteristic behaviours that can be observed.

Newtonian behaviour is displayed by simple liquids consisting of small molecules that do not interact or form any connected structure. However, it must be pointed out that long chain polymers at low concentration can also show Newtonian behaviour. An easy way to demonstrate Newtonian behaviour is to double the shear stress during a viscosity test and this should result in doubling of the shear rate. If this is not observed then the liquid is non-Newtonian.

The viscosity of some fluids is dependent on the rate used to shear the material, a high rate of shear making the fluid thinner compared with the fluid that was sheared more slowly. This is referred to as time independent (steady state) flow and materials showing this type of behaviour are called pseudoplastic. Another type of viscous behaviour exhibited by fluid foods and polymer systems is thixtropy which is again shear-thinning of the material with increasing rates of shear, but is also dependent on the duration of shear. Put in another way, the material shows thinning behaviour with time when it is sheared at a constant rate. In such liquids the time delay needed for the viscosity to change suggests that a certain amount of time is needed to re-arrange or align the structural components that results in decrease in the viscosity of the test material.

Generally speaking, fluids with larger, more complex, molecules will have higher viscosities. This is particularly true for the long chain polymers that are found in foods such as proteins, starches, hydrocolloids or gums, etc. Another striking property of these materials is that they consist of numerous chemical groups (hydroxyl groups, anionic groups etc.) along the length of the polymer chain that are water loving or hydrophilic and hence can bind water molecules. The polymer chains can also become entangled with one another, forming networks that are able to trap and immobilise water. The viscosity of water is low as the molecules are small.

Viscosity is also dependent on concentration and the relationship is not usually linear. For example, a small increase in concentration of a hydrocolloid may increase viscosity a little, but once a critical concentration is exceeded the viscosity can increase exponentially. Typical rate of addition of starch to achieve significant viscosity of a liquid would be in the region of four to five per cent. Hydrocolloid systems, on the other hand, have greater water-binding properties and can generate viscosities at lower concentrations, for example 0.5 to one per cent.

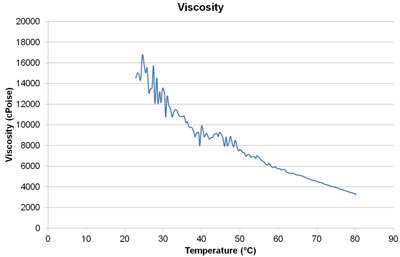

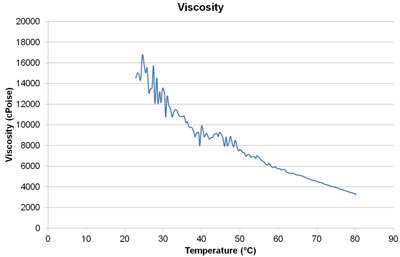

Figure 1

Temperature has a major effect on viscosity; the viscosity decreasing significantly with increase in temperature. As the temperature increases the molecules in the liquid move about more, and therefore spend less time in contact with each other, thus the internal friction of the liquid decreases. This is demonstrated in Figure 1, which shows the change in viscosity of a pre-gelled starch solution as the temperature was increased from 20 to 80°C. Because the viscosity of food is highly affected by temperature the test conditions to measure viscosity should be tightly controlled. To achieve accurate measure the sample temperature should be controlled within ±0.5°C and this can be achieved by placing the test sample in a thermostatically controlled water bath.

There are numerous instruments available to the food industry to measure viscosity for quality control and thus ensure that products made are of consistent quality. A very simple instrument that is used in the food industry is the Bostwick consistometer, which determines the consistency of a food by measuring the distance it flows under its own weight. Typical food products measured include tomato ketchup, tomato puree, pureed baby foods, jams, etc. to name a few. Samples that stick to the instrument or are highly viscous and do not flow sufficiently in 30s are not suitable for this instrument. The main drawback to this instrument is that factors other than viscosity, such as surface tension of the material, can influence the results, but it is a useful method to provide quick and easy quality control for a number of foods.

Rotational viscometers measure the torque required to turn a spindle in a sample of fluid at a known speed. These commonly-used viscometers are capable of measuring Newtonian and non-Newtonian fluids in a wide viscosity range. The spindle can be rotated at a fixed speed or at different speeds over time so that the viscosity can be measured over a range of shear rates. A number of different configurations of measuring systems are available, such as concentric cylinders, parallel plates and cone and plate. Which one to choose depends on the consistency of the material being tested. For less viscous, pourable liquids the concentric cylinder would be applicable, whereas for more viscous products parallel plates or cone and plate geometry would be more suited. For gelled systems, such as thick-set yoghurts, some viscometers can be fitted with T-bar and a stand that continually moves the probe into the sample cutting a helical shape into the sample. This avoids the potential problem of channels being created in such samples when measured with a spindle rotating in a fixed position.

Capillary viscometers, also known as U-Tube or Ostwald, measure the time for a fluid to pass between two points of a capillary tube under the force of gravity. This type of viscometer is only suited to low viscosity Newtonian fluids. Capillary viscometers are highly sensitive to temperature and so the capillary is usually immersed in a water bath. Based on the same principle, the Falling Sphere Viscometer measures the time it takes for a sphere to fall through a fluid under gravity. These are just a few of the methods that can be used with food systems and there are many more that can used to perform quality control checks or to characterise more complex viscous behaviour.

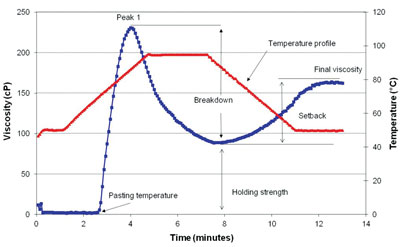

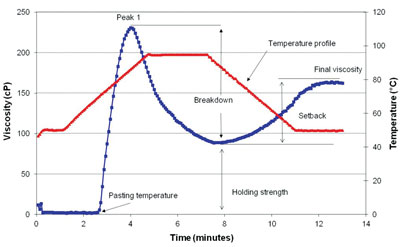

Figure 2

By far the most researched food in terms of viscosity is chocolate. The flow behaviour of chocolates is important both during processing as well as for organoleptic reasons. Chocolates have different flow properties depending on application and products are made for enrobing and for making blocks. However, the flow behaviour is complex due to the fact that a number of ingredients, namely sugar, cocoa butter, cocoa particles and milk products, need to be finely dispersed. The viscosity plays a crucial role as it affects texture, that is, how it flows in the mouth. The measurement of chocolate viscosity is highly specialised and requires a specific type of viscometer for the measurement to be performed accurately. The flow properties are usually described by the Casson flow curve and for this it is necessary to make measurements at different rotational speeds so that shear stresses at different shear rates can be determined. The Casson method gives information about the yield stress and the plastic viscosity. Yield stress is defined as the shear stress required to initiate flow of the chocolate and hence gives information about potential enrobing properties, whereas the plastic viscosity relates to the shear stress required to maintain constant flow. The latter thus relates to the way chocolate will flow in a mould or perhaps in the mouth. The viscosity test is typically carried out at 40°C and temperature control within a narrow range is important in order to perform the test accurately.

Figure 3

The quality of foods such as soups, sauces, gravies, custards, flans, desserts, and baked products, to name a few, depend heavily on structure forming properties of materials such as starch. After starch material is cooked, the granules swell and become fragile and can break down under shear and lose viscosity. This can have disastrous consequences on the viscosity and hence on the characteristic eating quality of the food. The effect of temperature on viscosity of starch based foods can be investigated by techniques such as the Brabender Amylograph and its derivative the Rapid Visco Analyser (RVA) (Figure 3). Both techniques are based on a rotational viscometer that continually records the viscosity of a sample while the temperature is changed in a controlled way. The resistance to flow of the test sample is measured by a rotating paddle at a known speed. A typical trace from an RVA test is given in Figure 2 and shows how the viscosity increases rapidly to a peak after starch gelatinisation. The continued heating and shearing of the flour batter damages the starch granules, resulting in release of water initially absorbed by the granules when the viscosity first increased, lowering the viscosity. A minimum in hot viscosity is then achieved, which then begins to increase as the temperature is gradually reduced. The starch is subjected to constant shear throughout the test and this provides useful information about stability during processing of food materials that rely on starch for their physical characteristics and quality.

In summary, viscosity of foods is an important property which plays a vital role during processing of batter and dough systems and for textural properties of foods such as soups and sauces. A range of techniques are available to measure viscosity from simple, quick-to-perform tests to more comprehensive characterisation in the form of flow curves. Materials such as chocolate which show complex viscous behaviour require specially designed tests to obtain flow properties relevant to end use.

About the author