Conveyor belt hygiene

- Like

- Digg

- Del

- Tumblr

- VKontakte

- Buffer

- Love This

- Odnoklassniki

- Meneame

- Blogger

- Amazon

- Yahoo Mail

- Gmail

- AOL

- Newsvine

- HackerNews

- Evernote

- MySpace

- Mail.ru

- Viadeo

- Line

- Comments

- Yummly

- SMS

- Viber

- Telegram

- Subscribe

- Skype

- Facebook Messenger

- Kakao

- LiveJournal

- Yammer

- Edgar

- Fintel

- Mix

- Instapaper

- Copy Link

Posted: 13 June 2008 | Albert Amgar, General Manager, ASEPT | No comments yet

Conveying is a unit operation of food process engineering that aims at carrying raw materials, intermediate products or end products. This operation is therefore largely used in the food processing industry.

Conveying is a unit operation of food process engineering that aims at carrying raw materials, intermediate products or end products. This operation is therefore largely used in the food processing industry.

Conveying is a unit operation of food process engineering that aims at carrying raw materials, intermediate products or end products. This operation is therefore largely used in the food processing industry.

When unprotected products are conveyed, food safety relies essentially on the control of contamination. Conveyors, therefore, are a central concern of the food industry, and they are frequently considered as a critical step in regards to food hygiene, as the belts and bands can transfer soil and micro-organisms and participate in the cross-contamination from one product to another, and from one room to another.

Unfortunately, the cleanability of this equipment is infrequently optimised. The equipment is subjected to a high rate of wear, and they rapidly become less cleanable. In addition, there are many types of conveyors with many possible uses, which makes the implementation of effective hygiene operations more difficult.

The issues of contamination control are summarised by a running step, followed by a cleaning step, mostly performed manually, and then a disinfection step when appropriate. The frequency of cleaning operations should be defined in relation with the belt soiling. This soiling, particularly if it builds up quickly, will contribute to a high microbiological contamination level so that the micro-organisms of interest (i) will be more difficult to remove and (ii) will be transferred to other conveyed products.

Scientific and technological bases

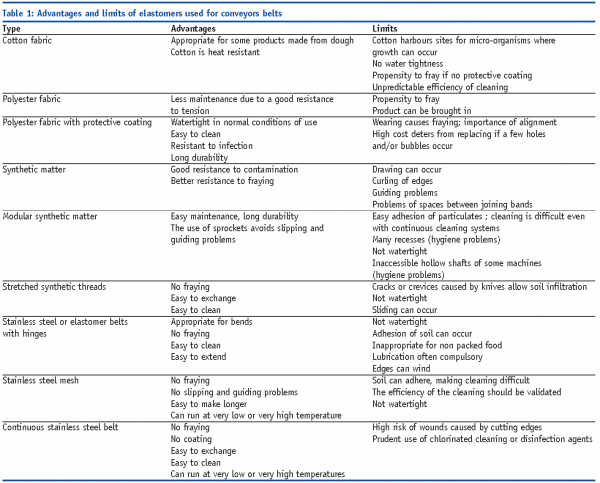

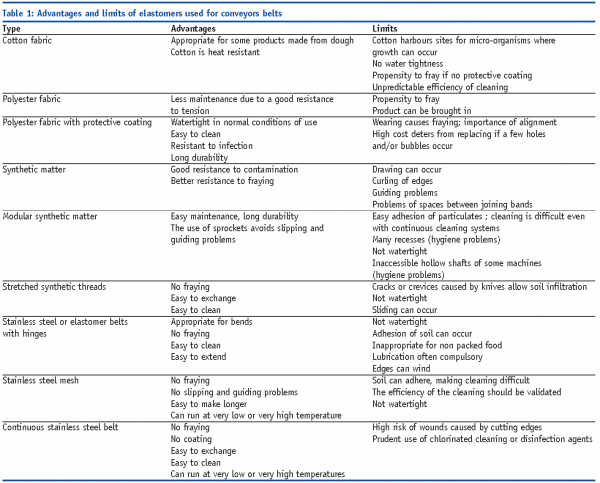

Rules for the hygienic design of conveyors have been published by EHEDG, the European Hygienic Engineering & Design Group. Yet what is known about conveyors’ materials is still limited. Apparently, no one is able to bring clear and definite answers in regards to the choice of materials and their frequency of renewal (see Table 1 on page 19). From a hygiene viewpoint, there is no available, fully suitable solution on the marketplace today.

One design of conveyors bands is the modular assembling of small clamped parts. This design is largely used for storage, packaging or deep freezing applications. It also tends to be used for the processing itself, because it is a flexible and strong system. However, its surface is not waterproof and permits the soiling of the floor underneath. In addition, there are soil retention spaces between the parts that are uneasy to clean and disinfect. Even if the wear resistance of these belts is higher than that of continuous belts, it has been shown that delamination can cause the deterioration of modular belts made of HDPE (high density polyethylene). The optimum frequency of renewal therefore should be clearly defined.

Materials with biocidal activity have been proposed recently to limit uncontrolled growth of micro-organisms. An advantage of these materials is their ability to control the survival or growth of micro-organisms in cracks, resulting from the equipment’s use. The problems with these materials are that the biocidal substances should diffuse slowly in order for the material to keep the biocidal activity for its entire life, and that cleaning and disinfection should not lixiviate the biocidal substance. The real impact of these materials remains insufficiently established for the industry to be convinced.

Currently, the profusion of available products makes any objective choice difficult for the users.

A few selection criteria for conveyors belts or bands

The belt is an open surface that should be easy to clean.

Material

Most bands (90%) are made of elastomers. They must comply with the European legislation in force, notably the Directives 89/109/EC, 90/128/EC and 2002/72/EC. The choice of the belt or band material is subject to several constraints, such as the cleanability (resistance to chemicals) and the mechanical resistance. These two types of resistance must be validated as regards to cleaning and disinfection chemicals. It is recommended to request the report of in-use aging tests. The available types of belts and bands are presented in Table 1 on page 19. Most materials are coated with thermoplastic polyurethane or TPU. TPU is preferable to PVC as far as hygiene is concerned, as PVC can have surface crevices, yet several authors criticise the sensitivity of TPU to deterioration by hydrolysis and micro-organisms.

Roughness and surface condition

Low roughness is preferred for the belt or the band in order to prevent soil accumulation. The importance granted to roughness should be linked to the zone in which the conveyor is located. The surface condition (topographic elements) is prominent: smoothness, absence of bumps and micro-bubbles. Specifications should be established and a report of validated trials of the belt or band should be requested.

Junctions

Mechanical joints have little or no compatibility with hygienic requirements (soil build-up). This is why ‘endless’ belts or bands should be preferred. The repair of the junctions should be made according to the manufacturer’s instructions: beware of in-house recipes that would not respect hygienic practices! The edges of the belts must not rub against the conveyor’s frame. The coating of the edges, which should be rounded and watertight, is therefore recommended.

Modular belts can be more difficult to clean and allow soil to fall on the floor. Wedges or spikes can become a source of foreign material in food. The material of conveyors belts or bands in contact with food should not be toxic, yet the absence of toxicity is not always synonymous with optimum cleanability.

A caveat has to be performed regarding the use of antimicrobial materials for belts. It should not prevent cleaning and disinfecting where appropriate. Several compounds such as triclosan have been in use for years, but are not permitted in Europe for food contact materials. In regards to silver-containing materials, their efficacy in conditions prevailing in the food industry has not been demonstrated. Their manufacturers claim there is no migration and that silver ions are located in the under layer of the coating, and therefore not in contact with the food.

Frame, mounting and structure of the conveyor belt

They should be easy to clean if they are easily dismantled or accessible. Belt edges should be positioned by removable hoods or protections that can be cleaned easily. This solution is the preferred one, since the grooves that position the belts can also harbour contaminated soil.

To make the cleaning easy, it is necessary that the belt can be slackened quickly with the help of a flexible system or a pivoting roller. In other words, a belt you cannot slacken is one you cannot clean.

Legs bolted to the floor should be replaced by easily cleanable ones. There is no reason not to choose the most easily cleanable. The number of legs can also create cleaning problems. This number should be minimised, to allow easier cleaning operations.