High-pressure – meat processing and milk gels

- Like

- Digg

- Del

- Tumblr

- VKontakte

- Buffer

- Love This

- Odnoklassniki

- Meneame

- Blogger

- Amazon

- Yahoo Mail

- Gmail

- AOL

- Newsvine

- HackerNews

- Evernote

- MySpace

- Mail.ru

- Viadeo

- Line

- Comments

- Yummly

- SMS

- Viber

- Telegram

- Subscribe

- Skype

- Facebook Messenger

- Kakao

- LiveJournal

- Yammer

- Edgar

- Fintel

- Mix

- Instapaper

- Copy Link

Posted: 20 February 2009 | Professor Vibeke Orlien, Associate Professor Food Chemistry, University of Copenhagen | No comments yet

Consumers prefer food products, convenience products and ready-to-eat meals to have the taste of being freshly made. Moreover, it must be nutritious, safe, of high quality and originate from sustainable production. High-pressure (HP) technology can be utilised to its full potential as a minimal processing method to address consumers preferences and reflect the human ethics of natural, tasty, clean-label and eco-friendly products. For example, it is possible to produce chicken meat with improved oxidative stability and high water holding capacity and neutral milk gels with less sugar. The future new type of HP-food products may be just around the corner.

Consumers prefer food products, convenience products and ready-to-eat meals to have the taste of being freshly made. Moreover, it must be nutritious, safe, of high quality and originate from sustainable production. High-pressure (HP) technology can be utilised to its full potential as a minimal processing method to address consumers preferences and reflect the human ethics of natural, tasty, clean-label and eco-friendly products. For example, it is possible to produce chicken meat with improved oxidative stability and high water holding capacity and neutral milk gels with less sugar. The future new type of HP-food products may be just around the corner.

Consumers prefer food products, convenience products and ready-to-eat meals to have the taste of being freshly made. Moreover, it must be nutritious, safe, of high quality and originate from sustainable production. High-pressure (HP) technology can be utilised to its full potential as a minimal processing method to address consumers preferences and reflect the human ethics of natural, tasty, clean-label and eco-friendly products. For example, it is possible to produce chicken meat with improved oxidative stability and high water holding capacity and neutral milk gels with less sugar. The future new type of HP-food products may be just around the corner.

The perspective of producing high quality foods with an extended shelf-life by use of HP technology is based on the ability to inactivate bacteria and enzymes concomitantly with a minimum loss of nutritional and sensory quality. Investigations on the effects of pressure on microbial inactivation are reported in literature and HP-treatment is being used worldwide in the food industry as a preservation step in the production of cured meat products and fresh juices and other fruit-based products without destroying flavour and vitamins. The prospective of new types of food products by use of HP is due to the specific actions of pressure on food constituents. As a minimal process technology, HP does not break covalent bonds and thereby protects the small chemical constituents like flavour compounds and vitamins. Hence, HP affects only non-covalent bonds and can be used to modify macromolecules, like proteins, and thereby to change the functionality of food proteins.

HP-processing relies on the application of hydraulic pressures between 100 to 800 MPa (1000 to 8000 atm), and due to the isostatic principle, the material will experience the same pressure instantaneously throughout and no gradients rise. Therefore, irrespective of the size, shape and composition of the food, the results are a uniform treatment.

High pressure offers new opportunities for the modification of biomolecule structure and functional properties.

High pressure offers new opportunities for product development aiming at high quality food products with unique physical and sensory properties.

However, food products where HP has been used in an active processing step are rare, unfortunately because many new types of high quality HP-food products can be brought into the consumers’ life.

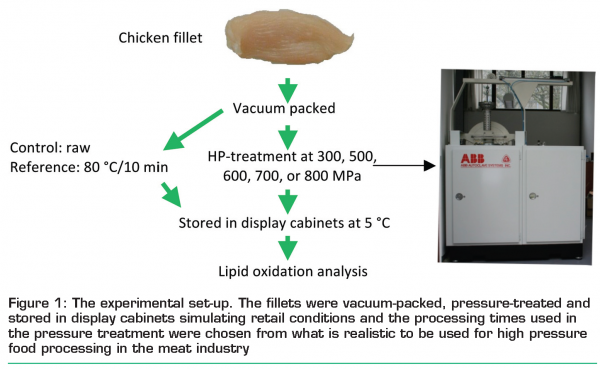

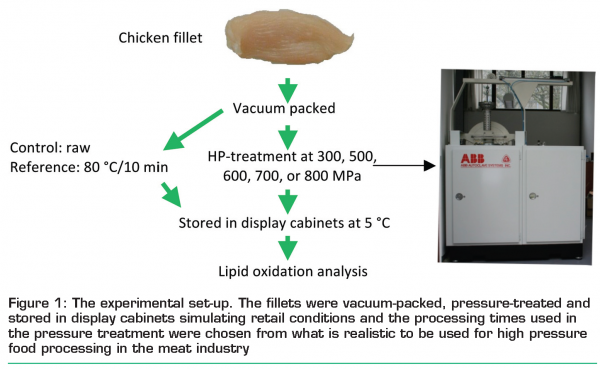

HP-processed chicken meat

Consumers request ‘natural’ meat products with fewer additives and the industry request the technology to produce those products. HP technology has the possibility in relation to meat product manufacturing. When conventional thermal treatment is applied to meat, lipid oxidation is the major cause of deterioration during the following storage of the meat products, in particularly for meat containing a significant amount of unsaturated fatty acids like chicken meat. Lipid oxidation leads to rancidity and off-flavours (secondary lipid oxidation products), and therefore a quantitative description of the lipid oxidation in pressurised meat and meat products is needed for a successful implementation of HP technology in the meat industry. An important tool is the knowledge of the effects of varying experimental factors such as working pressure, processing time and storage time. Thus, lipid oxidation in HP-treated chicken meat exposed to varying working pressure and pressurising time during subsequent chill storage was investigated and compared to heat-treated and raw meat (Figure 1).

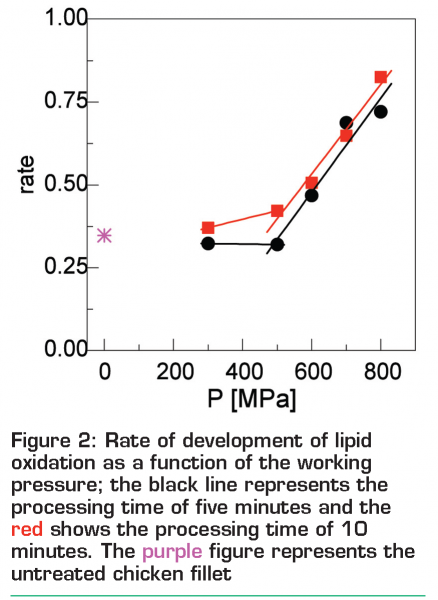

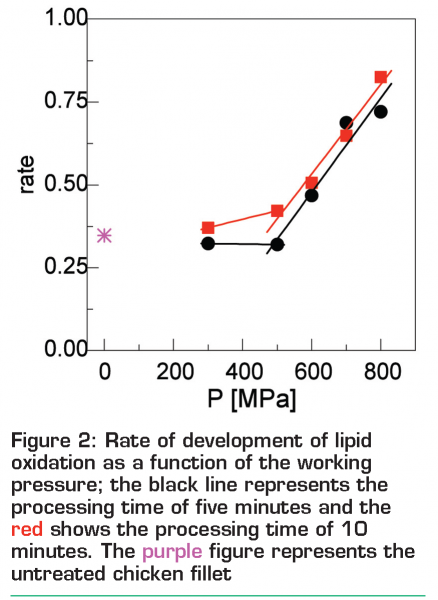

In the study1, measurements of secondary lipid oxidation products TBARS gave no indication of rancidity in untreated chicken fillets during chill storage, whereas it was found that oxidation as expected developed rapidly in the heat treated fillets. The degree of oxidation caused by HP varied primarily with the level of the working pressure and less with the processing time, as observed by the different extent of lipid oxidation. It was found that HP-treatment at 300 and 500 MPa for five or 10 minutes had no effect on the lipid oxidation, as the level of TBARS values were comparable to the TBARS values for the untreated meat, whereas HP-treatment at 600, 700, and 800 MPa resulted in an increase in the lipid oxidation products. The most effective HP-treatment, with respect to acceleration of lipid oxidation, was the most intense treatment at 800 MPa for 10 minutes, giving the same level of lipid oxidation as the heat treatment. The linear dependence of the working pressure on the progression on lipid oxidation during subsequent chill storage as seen in Figure 2 provides a description for oxidative changes at working pressures realistic to HP-food processing, and shows that 500 MPa is a critical pressure connected with acceleration of lipid oxidation.

It is well-known that herbs and spices can be used as natural antioxidants, and the use of herbs and spices, especially rosemary, has been shown to minimise lipid oxidation in various meat products. However, other spices used for chicken dishes in traditional cooking also deserve to be explored for a potential use as antioxidants in HP-processed chicken meat. Sage and garlic are such spices and in order to evaluate sage and garlic as natural antioxidants in combination with HP-treatment of chicken meat, the effect of working pressure on lipid oxidation in chicken meat with or without sage and garlic and with the spices in combination was investigated.

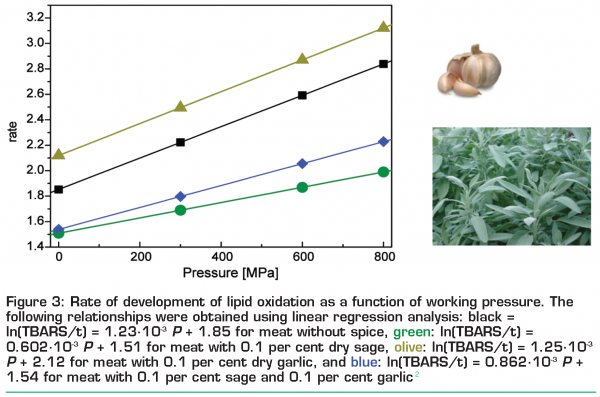

In this study2, the chicken meat was minced and the spice added prior to vacuum packing and HP-treatment. The effect of sage, garlic and sage plus garlic on lipid oxidation induced by HP-treatment (300, 600, and 800 MPa) during chill storage at 5°C for up to 15 days was investigated using TBARS as a measure of the extent of lipid oxidation. Lipid oxidation induced by pressure was again found to vary with the pressure and oxidative damage was found to be initiated for pressure treatment between 300 and 600 MPa. From the rates of lipid oxidation development, it was found that sage is very effective in protecting chicken meat. Pressure treatment did not induce significant lipid oxidation during the entire storage period for chicken meat with sage added, as the level of TBARS was comparable to the TBARS-values for the control meat without spice addition and not subjected to pressure treatment (Figure 3). In clear contrast, garlic had a pro-oxidative effect in the pressurised meat, as lipid oxidation was most significant for chicken meat with garlic added and subjected to pressure even at 300 MPa, and increasingly for 600 and 800 MPa. Interestingly, sage counteracted, to some extent, the pro-oxidative effect of garlic in the chicken meat as seen from the meat with addition of both sage and garlic compared to the meat with only garlic.

From the viewpoint of the consumer, the physical appearance is important, especially for meat, added coloured spices or vegetables used as natural antioxidants. HP-treatment of chicken fillets resulted in an altered appearance and all pressurised samples had higher L* values compared to the raw meat, representing a more white colour; an appearance similar to heat-treated chicken meat. As may be seen, the HP-treated chicken fillets looks more tender and juicy compared to the dry and stringy appearance of the heat-treated chicken meat.

HP-induced milk gels

The production of various types of milk products like yoghurts involves a souring processing step to form the gel network and typically requires bacterial fermentation of a starter culture and an incubation step that can be relatively time consuming. In some cases, sugar is added to the acid milk gels in order to counterbalance the sour taste. In a sour milk gel, the gelation is based on the strong network between the casein proteins and the whey protein β-lactoglobulin (β-Lg) due to the acid-induced dissociation of caseins and the thermal-induced denaturation of β-Lg. It has been discovered that solutions of β-Lg and of whey protein in water subjected to HP-treatment also form gels due to a pressure-induced denaturation of β-Lg. By taking advantage of the good gelation properties of β-Lg under pressure, perspectives of designing new types of dairy products blaze up.

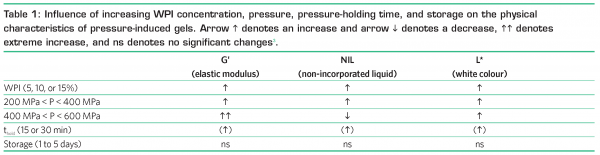

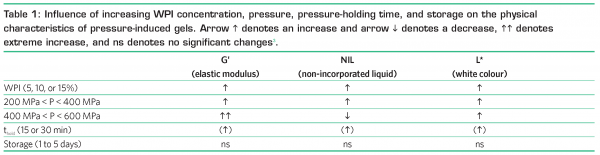

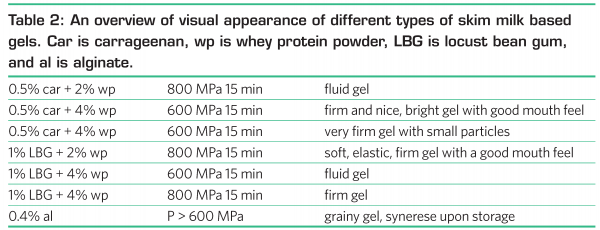

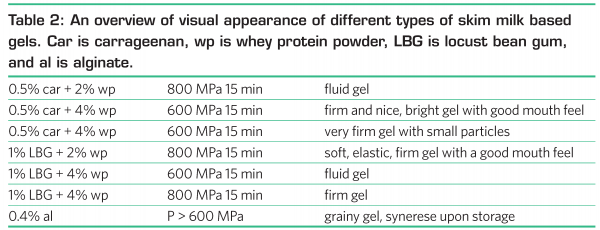

In the first study3, the influence of intensity and duration of the HP-treatment, concentration of whey protein, and the liquid base on the gel characteristics were investigated and compared with thermal gelation. Skimmed milk based whey protein isolate (WPI) solutions or water based WPI solutions containing 5, 10, or 15 per cent w/w WPI were made from reconstituted skimmed milk or purified water respectively and subjected to HP-treatment at 200, 300, 400, 500, or 600 MPa for 15 or 30 minutes and subsequently stored for one or five days at 5°C. Table 1 (page 57) summarises the results of the investigation on how the milk gel characteristics; gel elasticity (G’), non-incorporated water (NIL), and whiteness (L*), are affected by pressure, holding time, WPI concentration and gel storage.

Some remarkable effects on the gelation of milk-based whey protein solutions were observed in the elasticity and water holding capacity due to the concentration and pressure variations. The soft gels based on milk added 10 per cent WPI with a low amount of NIL suggest a rather rough structured gel network capable of retaining water during pressurisation and/or on pressure release. Upon increasing the WPI concentration to 15 per cent, the gel elasticity increases due to the additional protein-protein interactions resulting in a stronger network formation. The increase in NIL (up to 400 MPa) expresses a lower water holding capacity caused by a denser network structure formation which expels water during the HP-treatment. Above 400 MPa, the large improvements in the elastic strength suggest an even greater structural enlargement. At this pressure level β-Lg is partly unfolded and casein micelles dissociate into smaller units, effects which together enhance gel formation. Mechanistically, pressure denaturation of β-Lg facilitates intermolecular exchange reactions between the free thiol group and disulfide groups of other β-Lg and casein molecules, resulting in oligomer formation. In addition, non-covalent physical interactions such as hydrophobic, electrostatic and hydrogen bonding may be important for further aggregation and gel formation of pressure induced protein oligomers.

The research into the mechanism, structure, texture and perception of milk based gels formed during HP-treatment is of huge interest from a scientific, industrial and consumer perspective. Hydrocolloids are often used in the dairy and dessert industry and their functions are stabilisation, thickening, emulsifying, gelation and water retention. Typically, a small amount of hydrocolloids has a large effect on the respective function. Therefore, it is of interest to investigate the role of hydrocolloids in the production of HP milk gels. Various case studies where the texture, visual appearance and taste of gels made of HP-treated skimmed milk with different hydrocolloids were conducted with some of the results presented in Table 2. These results, together with the uncomplicated production of HP-gels show that there is a basis for producing soft or firm milk gels using HP. The pressure-induced gelation of milk, protein and hydrocolloids solutions is a complex phenomenon and the resulting gels are influenced by numerous parameters. Thus, further studies are in progress to elucidate the mechanism of gelation under pressure.

Conclusion

These case studies show that HP technology offers an attractive technique to produce new high quality food products due to the specific actions of pressure on food constituents.

References

- V. Orlien, E. Hansen, L.H. Skibsted. Lipid oxidation in high-pressure processed chicken breast muscle during chill storage: critical working pressure in relation to oxidation mechanism. Eur. Food Res. Technol. 2000, 211: 99-104

- L.R.B. Mariutti, V. Orlien, N. Bragagnolo, L.H. Skibsted. Effect of sage and garlic on lipid oxidation in high-pressure processed chicken meat. Eur. Food Res. Techn. 2008, 227: 337-344

- V. Orlien, H.B. Pedersen, J.C. Knudsen, L. H. Skibsted. Whey protein isolate as functional ingredient in high-pressure induced milk gels. Milchwissenschaft 2006, 61(1): 3-6