Propraline project delivers a number of solutions for chocolate industry to improve praline quality

- Like

- Digg

- Del

- Tumblr

- VKontakte

- Buffer

- Love This

- Odnoklassniki

- Meneame

- Blogger

- Amazon

- Yahoo Mail

- Gmail

- AOL

- Newsvine

- HackerNews

- Evernote

- MySpace

- Mail.ru

- Viadeo

- Line

- Comments

- Yummly

- SMS

- Viber

- Telegram

- Subscribe

- Skype

- Facebook Messenger

- Kakao

- LiveJournal

- Yammer

- Edgar

- Fintel

- Mix

- Instapaper

- Copy Link

Posted: 6 March 2012 | Lilia Ahrné, Coordinator, ProPraline and Director Process and Technology Development at SIK – Swedish Institute for Food and Biotechnology | No comments yet

The ProPraline project is now finalised and after three years of intensive research, the project has delivered a number of solutions. Four booklets containing scientific information to help SMEs to produce pralines of high quality and extended shelf-life have been developed during the project and are now available to download on ProPraline external website: www.sik.se/propraline.

The objective of the ProPraline project has been to improve the competitiveness of the European SMEs producing exclusive, complicated and niche-oriented filled products like chocolate pralines by developing knowledge and technical solutions to improve quality and to extend the shelf-life of their products. Moreover, the project, through SMEs associations, has provided demonstration and training to a large number of European SMEs in how to manufacture new innovative chocolate pralines with high quality. The main S&T results obtained are well aligned with the objectives of the project as shown here:

The ProPraline project is now finalised and after three years of intensive research, the project has delivered a number of solutions. Four booklets containing scientific information to help SMEs to produce pralines of high quality and extended shelf-life have been developed during the project and are now available to download on ProPraline external website: www.sik.se/propraline. The objective of the ProPraline project has been to improve the competitiveness of the European SMEs producing exclusive, complicated and niche-oriented filled products like chocolate pralines by developing knowledge and technical solutions to improve quality and to extend the shelf-life of their products. Moreover, the project, through SMEs associations, has provided demonstration and training to a large number of European SMEs in how to manufacture new innovative chocolate pralines with high quality. The main S&T results obtained are well aligned with the objectives of the project as shown here:

The ProPraline project is now finalised and after three years of intensive research, the project has delivered a number of solutions. Four booklets containing scientific information to help SMEs to produce pralines of high quality and extended shelf-life have been developed during the project and are now available to download on ProPraline external website: www.sik.se/propraline.

The objective of the ProPraline project has been to improve the competitiveness of the European SMEs producing exclusive, complicated and niche-oriented filled products like chocolate pralines by developing knowledge and technical solutions to improve quality and to extend the shelf-life of their products. Moreover, the project, through SMEs associations, has provided demonstration and training to a large number of European SMEs in how to manufacture new innovative chocolate pralines with high quality. The main S&T results obtained are well aligned with the objectives of the project as shown here:

|

New Knowledge available for SMEs on Propraline website |

Technical solutions to increase shelf-life |

Book of methods for quality assessment

|

To control fat bloom:

To control of crack formation:

|

Table 1: Major results of ProPraline project with relevance to SMEs chocolate producers

Scientific approach and methodology

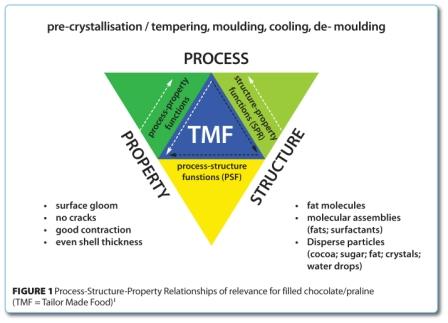

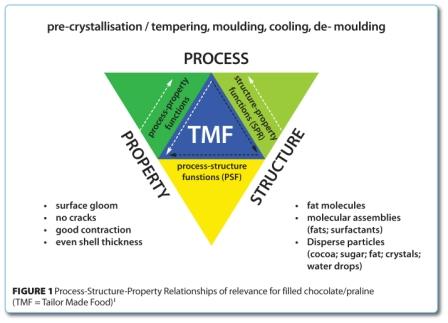

The project focused on understanding the mechanisms behind fat bloom and crack formation in filled confectionary products, which are two major quality problems, and finding routes to avoid them. Crack formation and fat bloom in filled chocolate / pralines are associated with deficiencies in chocolate structure affecting the mechanical strength, diffusivity / permeability-characteristics and micro-/macro homogeneity. In order to tackle these problems from a joint scientific and industrial point of view respective Property – Structure Functions (PSF) and Structure – Process Functions (SPF) have to be identified and quantified as shown in Figure 1.

Little work has been performed on the development of structure in chocolate. This is particularly true with respect to understanding process induced structuring mechanisms which are of crucial importance besides formulation aspects. It is known that the structure is created by the complex interplay of different formulation and processing related factors. Formulation optimisation without processing modification or vice versa may not lead to satisfying results. The joint consideration of formulation and processing aspects completes the innovative scheme that has been applied in this project.

The property-structure functions have allowed for identifying the structure aspects of relevance triggering crack formation and surface bloom from a molecular to a macrodisperse structure scale. It is expected that, besides formulation related molecular aspects, the structural aspects of major importance within the project are structure density, the disperse component’s size distributions, the fat polymorph distribution and the fat crystal network morphology. The structure-process functions provided quantitative rules for processing of the tailor-made structures of preference identified by the property-structure functions. With respect to processing, the major processing steps determining bulk and surface / interface structure characteristics of filled chocolate / praline products are pre-crystallisation/tempering, moulding, cooling and de-moulding. These parameters determine the property-structure functions related properties.

Several advanced techniques like confocal laser scanning microscopy, environmental scanning electron microscopy and profilometry have been used to quantify the structure of chocolate at different length scales. Mechanical properties have been determined by small and large deformation, and fat crystal and chemical characterisation has been performed using DSC and HPLC. A variety of new methods have also been developed, such as a new method to assess the mechanical properties of chocolate during storage, a new method to evaluate fat bloom (using Digieye), method – ology to quantify chocolate contraction and expansion, methodology to evaluate structure density in chocolate and follow up the kinetics of crystallisation.

New knowledge available for SMEs on ProPraline website

Book of methods

The ProPraline Book of Methods describes methods that are useful to study fat bloom and cracking and is directed towards praline producing companies, and more specifically towards SMEs. Several simple methods, for instance colour, micrometric and temper degree measurements, are described in this book. The devices for these methods are usually relatively affordable for SMEs and easy-to-handle. In addition, the book includes more complex (and usually more expensive) methods such as atomic force microscopy and confocal laser scanning microscopy. Even though SMEs usually cannot afford this type of equipment, they can learn about the existing possibilities and how to understand the results. For every method, the aim, some background information and a description of the method is given. Furthermore, an example is given which helps to understand how to evaluate and interpret the results.

ProPraline handbook – a practical guide for prevention of fat bloom and cracks

The handbook provides concise and practical information about the processing of high quality pralines in a format easily comprehended by SMEs. The handbook is divided into four main parts. The first part is the introduction that gives an overview of the production process, of prod – uct defects such as cracking and blooming and the general aspects of the raw materials and handling of pralines. The second part collects the advice and solutions for processing (e.g. tempering, cooling, moulding/demoulding, post-treatment and storage) to prevent the formation of fat bloom and cracking. The third part gives an overview of the product aspects (particle size, product geometry, composition of the filling, sensory analysis) that must be considered for the prevention of fat bloom and cracking. The fourth chapter includes the conclusion and take home messages.

Routes to prevent fat bloom and cracking

In this document, the research in the project that has led to practical procedures and applicable knowledge that can be used to prevent chocolate bloom and cracking are presented and explained with detail. The routes selected are relatively easy to implement in a SME chocolate producer and they bring significant impact on product quality. Some of the routes are more suitable for industrial producers, while others are well suited for artisan producers. Some findings of practical relevance for the SME praline producers include:

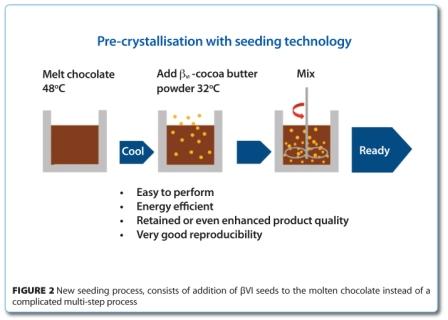

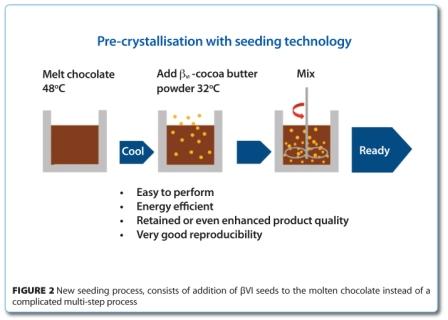

- Control of tempering or alternatively a new seeding tempering, that has been further developed in this project for SMEs, are important to reduce fat bloom

- Thermal post-treatments of shell and pralines can be used to control the development of chocolate bloom

- Control of cooling can reduce fat bloom

- Particle size in chocolate has relevance for the kinetics of fat bloom development

- Water activity in fillings has strong influence on the tendency of pralines to crack

ProPraline course material

All the PowerPoint presentations presented in the course ‘Possible routes for prevention of fat bloom and cracks in pralines’ are compiled in this document. This gives a pedagogic presentation of the scientific results obtained in the project, providing possibilities for a better understanding of the principles and their practical use.

New seeding technology

Better understanding of the effect of chocolate structure on fat bloom gave origin to the development of a new seeding process suitable for SMEs to replace the traditional tempering process. Seeding of both the chocolate and the filling retards fat bloom in pralines compared to conventional tempering. A business idea to start a spinoff company, ChocoWinS, has been awarded in a Venture Cup competition in Sweden and it is being further explored in Switzerland.

A schematic representation of the new seeding technology for SMEs is shown in Figure 2.

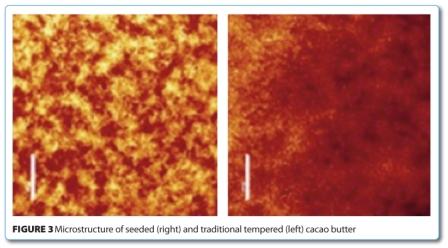

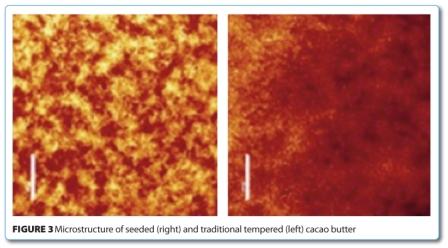

The new seeding process allows the fast development of a chocolate structure that gives a more compact and homogeneous structure after cooling. Figure 3 shows the differences in microstructure between the traditional tempering process and the new seeding technology.

The reduction of fat bloom caused by this technology, evaluated as oil migration, showed that an extension of two to three weeks shelf-life can be achieved.

Thermal post-treatments of pralines after production

One conclusion of the project is that the process of making a chocolate praline is not finalised directly after the cooling process – but that the handling, especially the temperature, during the first hours / day after production has a significant impact on the quality and shelf life of the final product.

Comparison of different thermal posttreatments in their ability to make chocolate more resistant towards oil migration showed that not only low-temperature but also short hightemperature treatments prior to storage are effective in retarding oil migration and fat bloom development in filled chocolate products.

New equipment and methodology to monitor crystallisation in process during cooling

A newly developed ultrasonic device at ETH called DetachLog made it possible to perform in real time in-line detection of the solidification during cooling, temper degree and product detachment from the mould wall. The measurements allow process optimisation, in particular for the tempering and cooling processes, leading to pralines with better quality.

Filling composition – control of water activity and geometry

Water activity in the filling and the geometry of the praline proved to have significant impact on the cracking behaviour. The water activity in the filling highly influenced the occurrence of cracks and it was found that aw <0.7 is required in order to avoid the problem. With the experimental set-up used in this work, squareshaped pralines cracked to a lesser extent than cone-shaped, and it can therefore be concluded that praline geometry has an effect on cracking. However, a more fundamental study is required before any general conclusion regarding cone versus square can be determined.

Cooling of pralines

Decreasing the cooling temperature to maximise the output and speed up demoulding can have a negative impact on product quality. It could be demonstrated that cooling rates are not only dependent on temperature but also air velocity. An increase of air velocity from one to six metres per second could compensate a temperature difference of 22°C in heat flux. Optimisation of cooling velocity gave good possibilities to decrease the cooling time and achieve good praline quality. A two-step cooling has been suggested as an energy effective alternative to perform the cooling step.

The results showed a clear difference between the different samples and the samples with highest resistance against fat bloom was those cooled at 7°C with an air velocity of one metre per second. In general, slower air velocity (one metre per second) together with lower cooling temperature (7°C or -10°C) generated less fat bloom compared to higher cooling temperature (12°C) and air velocity (six metres per second).

Milling of particles

The results obtained indicated that model pralines, stored at 23°C, with a particle size of 15 μm undergo a faster fat migration from filling to shell and thus a higher development of fat bloom, than model pralines with a particle size of 20 or 30 μm.

The ProPraline project was financed by the FP7 – Research for the benefit of specific groups / Research for SME associations / groupings (Grant Agreement number: 218423). The work presented in this manuscript includes contributions of the teams led by:

- Professor Erich Windhab ([email protected]) ETH, Eidgenössische Technische Hochschule Zürich, Switzerland

- Professor Koen Dewettinck ([email protected]), Universiteit Gent, Belgium

- Anna Fureby ([email protected])YKI, Ytkemiska Institutet, Sweden

- Anne Lechevretel ([email protected]) Pera Innovation Limited, UK

- Tunde Kuti ([email protected]) Campden & Chorleywood Elelmiszeripari Fejlesztesi Intezet Magyarorszag Kozhasznu Tarsasag, Hungary

- Guy Galet ([email protected]) Association Royale Belge des Industries du Chocolat, de la Praline, du Bisquit et de la Confiserie ASBL, Belgium

- Håkan Björklund ([email protected]) Svenska Choklad-, Konfektyr- och Kexfabrikantföreningen u.p.a EK, Sweden

- Miroslav Koberna ([email protected]) Portavinarska Komora Ceske Republiky, Czech Republic

- Emanuel Andren ([email protected]) Ganache AB, Sweden

- Jeroen Vereecken ([email protected])Chocolateri e Guylian N.V., Belgium

- Kelenyi Gyula ([email protected]) Szamos Marcipán Édesipari Termel és Kereskedelmi Kft., Hungary

- Karsten Nielesen ([email protected]) AarhusKarlshamn Denmark AS, Denmark

- Dr Yuantong Zeng ([email protected]) Buhler AG, Switzerland

About the author

Dr. Lilia Ahrné is Director of the Department for Process and Technology Development at SIK – The Swedish Institute for Food and Biotechnology and Associated Professor in Food Engineering at Chalmers Technical University. Before joining SIK, she worked for Tetra Pak Processing Systems. Her research interests are to understand the effect of processing on physical, chemical and structural characteristics of foods, and use this knowledge to develop new processes and products taking in account sustainability aspects as energy consumption and costs. Processes under study include both traditional and novel technologies. She has extensive experience in coordination of industrial and European research projects.