Quick and simple sensory evaluation of your products

- Like

- Digg

- Del

- Tumblr

- VKontakte

- Buffer

- Love This

- Odnoklassniki

- Meneame

- Blogger

- Amazon

- Yahoo Mail

- Gmail

- AOL

- Newsvine

- HackerNews

- Evernote

- MySpace

- Mail.ru

- Viadeo

- Line

- Comments

- Yummly

- SMS

- Viber

- Telegram

- Subscribe

- Skype

- Facebook Messenger

- Kakao

- LiveJournal

- Yammer

- Edgar

- Fintel

- Mix

- Instapaper

- Copy Link

Posted: 6 March 2012 | Dr. Lene Meinert, Consultant, Department of Raw Meat Quality, Danish Meat Research Institute | No comments yet

Imagine that you have found a new and cheaper supplier of spice mixes for one of your popular products. Imagine too that you want to change the raw material composition of the product. Indeed, there are many parameters that could be modified. But how do you get an easy and quick overview of the flavours of the different products? Ideally, you want the consumers to enjoy a pleasant eating experience, the kind of experience they appreciate and that makes them want to buy the product again and again.

The French wine industry needed to find a method of assessing the quality of a large number of barrels of wine in their wine cellars. They needed to know which wines were ready to be bottled. It was important that the method was very simple and that it could be performed down in the wine cellar. They developed the Napping® method, which quite simply involved placing the wines on a single sheet of paper according to how similar or different the wines tasted. The wines that were similar in taste were placed close to each other on the sheet of paper. The wine producer could then evaluate whether that particular group of wines was ready for bottling or whether they should be left to mature for a while longer. At DMRI, we have taken the Napping® method and adapted it to the needs of the Danish meat industry. Our method is known as Mapping by DMRI, though the principle is more or less the same.

Imagine that you have found a new and cheaper supplier of spice mixes for one of your popular products. Imagine too that you want to change the raw material composition of the product. Indeed, there are many parameters that could be modified. But how do you get an easy and quick overview of the flavours of the different products? Ideally, you want the consumers to enjoy a pleasant eating experience, the kind of experience they appreciate and that makes them want to buy the product again and again. The French wine industry needed to find a method of assessing the quality of a large number of barrels of wine in their wine cellars. They needed to know which wines were ready to be bottled. It was important that the method was very simple and that it could be performed down in the wine cellar. They developed the Napping® method, which quite simply involved placing the wines on a single sheet of paper according to how similar or different the wines tasted. The wines that were similar in taste were placed close to each other on the sheet of paper. The wine producer could then evaluate whether that particular group of wines was ready for bottling or whether they should be left to mature for a while longer. At DMRI, we have taken the Napping® method and adapted it to the needs of the Danish meat industry. Our method is known as Mapping by DMRI, though the principle is more or less the same.

Imagine that you have found a new and cheaper supplier of spice mixes for one of your popular products. Imagine too that you want to change the raw material composition of the product. Indeed, there are many parameters that could be modified. But how do you get an easy and quick overview of the flavours of the different products? Ideally, you want the consumers to enjoy a pleasant eating experience, the kind of experience they appreciate and that makes them want to buy the product again and again.

The French wine industry needed to find a method of assessing the quality of a large number of barrels of wine in their wine cellars. They needed to know which wines were ready to be bottled. It was important that the method was very simple and that it could be performed down in the wine cellar. They developed the Napping® method, which quite simply involved placing the wines on a single sheet of paper according to how similar or different the wines tasted. The wines that were similar in taste were placed close to each other on the sheet of paper. The wine producer could then evaluate whether that particular group of wines was ready for bottling or whether they should be left to mature for a while longer. At DMRI, we have taken the Napping® method and adapted it to the needs of the Danish meat industry. Our method is known as Mapping by DMRI, though the principle is more or less the same.

What determines the texture of pork sausage?

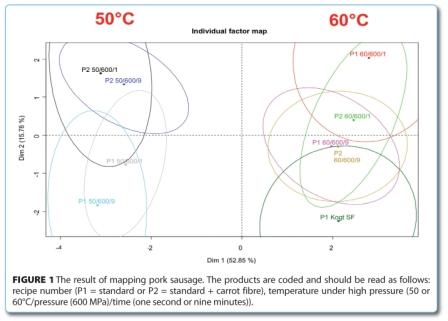

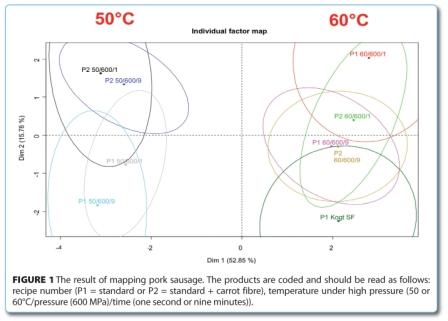

In a specific example of Mapping by DMRI, DMRI produced nine different types of high pressure processed pork sausages. During the high pressure treatment, both the recipe and the time / temperature were changed. The texture and ease of cutting of the sausages were very important attributes, and we therefore set up a panel of 10 assessors, though we could just as well have chosen colleagues. Each assessor was given a sheet of A3 paper and a slice of each of the nine sausages in a small beaker, and then the ’mapping’ could begin. The 10 assessors were asked to taste the sausages, evaluate the texture and place the sausages on the sheet of paper. When each assessor had decided where to place all nine sausage samples, he/she then lifted the beakers one at a time, drew a cross on the paper to indicate where each sausage sample had been and wrote down the sample number of the sausage (one to nine).

When the mapping method has been performed, you can see where each assessor has decided to place the products. However, it is more interesting to obtain an overall result of all the assessors’ evaluations. To do this, the positions of all the products (in this case, pork sausage) are measured with a ruler, and the results are entered into a spreadsheet and are calculated using a user-friendly statistical program ‘PanelCheck’.

The result is a simple diagram that is read in much the same way as one would read a map, in other words it does not have the familiar x and y axes. Figure 1 shows the result of a mapping of high pressure treated sausages. You need to look at how the products are distributed. Most importantly, you can see that all the products that were treated at 50°C are placed on the left side, while all the 60°C products are grouped on the right, which indicates that temperature has a significant effect on texture. That was the distribution on the horizontal axis (Dimension 1).

The vertical axis (Dimension 2) shows that products from two different recipes are placed at 50°C, with the P1s lowest (standard recipe) and the P2s highest (standard recipe containing carrot fibre). This indicates that there are differences in the texture, depending on the recipe. This relationship is not seen at 60°C, where the P1s and the P2s are distributed more randomly. If, as a product developer, you want to use the recipe containing carrot fibre, for example because of its health value, then it would be best to continue using high pressure treatment at 50°C.

What do the consumers think of the new product?

The holistic method, which is based on overall perceptions, is an easy way of getting an overview of what the consumers think of a new product. When generic words such as traditional, exotic, summery, youthful etc. are used, the method creates a link between sensory evaluation and marketing. The method is divided into two parts: 1) selecting the words using CATA (check all that apply) and 2) quantifying the selected words.

Table 1: The 10 words which the consumers felt best described the seven marinades

| Word |

Number of times selected |

| Summery |

36 |

| Boring |

34 |

| Exciting |

26 |

| Strange |

23 |

| Delicious |

21 |

| Simple |

19 |

| Traditional |

16 |

| Familiar |

17 |

| Appetising |

17 |

| Surprising |

13 |

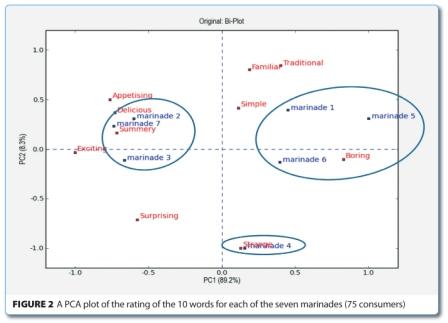

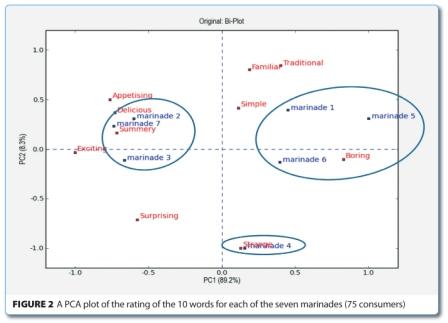

Friland A/S recently used the holistic method in an assessment of consumer attitudes towards the appearance of seven different marinades, and a very clear response was seen. The consumers were given marinades in the form of retail-packed marinated pork chops, and no information on the marinades was provided.

For the selection of the words, a small group of consumers (approximately 20 persons) were asked to select all the words (from a list of 32 words) which they could associate with the appearance of each of the seven marinades. The consumers were also encouraged to add their own words. It was decided to continue the assessment using the words that had been selected most often (Top 10). At this stage in the assessment, the producers could also choose to insert their own words if, for example, they wanted to test words for a campaign.

A new group of 75 consumers then rated the 10 selected words for each marinade – again, it was the appearance that was being evaluated. All 10 words were evaluated on a 15 centimetre line scale for each marinade, giving a total of 70 words, which might sound like a lot, but it all took less than 10 minutes.

The consumers divided the seven marinades into three groups (see Figure 2), associating the three marinades with clear colours and visible seasoning with the words appetising, exciting, delicious and summery and describing the three most common marinades as boring, traditional and familiar. One of the marinades stood out from the rest in that the consumers described its appearance as strange. The holistic method provided Friland A/S with a good and quick overview of the consumers’ evaluation of the marinades.

The methods are very straightforward and easy to use and are expected to become important tools in many different food companies. DMRI holds one-day courses in the use of these methods and is also happy to provide advice. The work on developing the methods was financed by the Pig Levy Fund and the Ministry of Food, Agriculture and Fisheries.

About the author

Dr. Lene Meinert has been a consultant at the Danish Meat Research Institute, Department of Raw Meat Quality since 2008. Lene has a master and PhD from the University of Copenhagen within the field of food science with focus on sensory science, chemistry and microbiology. Today, she is involved in several R&D projects including development of rapid sensory methods for industrial application, mathematical model for shelf-life prediction of fresh pork, bioactive components in pork and bi-products and finally boar taint detection by human nose method. Lene has wide experience in the coordination of research projects involving both universities and industry.