The Symbiosis-EU project: Converging technologies for improving meat quality

- Like

- Digg

- Del

- Tumblr

- VKontakte

- Buffer

- Love This

- Odnoklassniki

- Meneame

- Blogger

- Amazon

- Yahoo Mail

- Gmail

- AOL

- Newsvine

- HackerNews

- Evernote

- MySpace

- Mail.ru

- Viadeo

- Line

- Comments

- Yummly

- SMS

- Viber

- Telegram

- Subscribe

- Skype

- Facebook Messenger

- Kakao

- LiveJournal

- Yammer

- Edgar

- Fintel

- Mix

- Instapaper

- Copy Link

Posted: 15 December 2010 | Antonietta La Storia, Gianluigi Mauriello, Francesco Villani & Danilo Ercolini, Department of Food Science, University of Naples Federico II | No comments yet

The SYMBIOSIS-EU project is a small collaborative project granted by the EU within the 7th frame programme and brings together 14 beneficiaries from six EU countries (plus one each from NZ and US) to study meat quality and safety. The list of partners contributing to the project is reported in Table 1. It is a three year project that started in 2008 and will conclude in 2011. The Agricultural University of Athens leads the project with Professor George Nychas as coordinator.

The SYMBIOSIS-EU project is a small collaborative project granted by the EU within the 7th frame programme and brings together 14 beneficiaries from six EU countries (plus one each from NZ and US) to study meat quality and safety. The list of partners contributing to the project is reported in Table 1. It is a three year project that started in 2008 and will conclude in 2011. The Agricultural University of Athens leads the project with Professor George Nychas as coordinator.

The SYMBIOSIS-EU project is a small collaborative project granted by the EU within the 7th frame programme and brings together 14 beneficiaries from six EU countries (plus one each from NZ and US) to study meat quality and safety. The list of partners contributing to the project is reported in Table 1. It is a three year project that started in 2008 and will conclude in 2011. The Agricultural University of Athens leads the project with Professor George Nychas as coordinator.

Approaches that are able to give a reliable indication of meat quality and safety at retail and through consumption are of utmost importance. Therefore, it is crucial to have valid methods to monitor freshness and safety in order to be able to ensure quality, irrespective of perspective (i.e., that of the consumer, the industry, the inspection authority or the scientist). It is important to study and provide identification and quantification of the most commonly occurring metabolic compounds associated to meat spoilage. Most of the microbial metabolites developed in meat can have an impact on the sensory quality of meat or can be regarded as markers of development of undesired microorganisms. To this end, development and application of practical means such as analytical methods or devices and robust model systems are of great importance in assuring consumers on food product safety and quality. The methods of investigation must be reliable, simple and rapid and must be suitable for the analysis of a large number of samples at a relatively low cost to be actually useful for the meat processing industry.

Table 1

Symbiosis Partner |

Country |

| Agricultural University of Athens | GR |

| University of Naples Federico II | IT |

| Cranfield University | UK |

| National Institute for Public Health and the Environment (RIVM) | NL |

| Ecole Nationale d’Ingénieurs des Travaux Agricoles de Clermont- Ferrand | F |

| Videometer A/S (SME) | DK |

| Environmental Science & Research | NZ |

| Colorado State University | USA |

| Zenon S. A (SME) | GR |

| TechnoBioChip Scarl (SME) | IT |

| National Agricultural Research Foundation | GR |

| University of Manchester | UK |

| PAP (SME) | GR |

| Flex packaging AL Spa (SME) | IT |

In order to identify effective indicators for reliable monitoring of meat quality and safety, it is important to know the microorganisms responsible for the production of certain metabolites and their precursors in meat and what influence such metabolic activity can have on meat quality. This is essential knowledge, to be able to know when and how to exploit those molecules for the benefit of the industry, authorities and consumers.

The type and extent of microbial contamination on muscle foods immediately after harvest depends on handling procedures and various treatments that may be applied during the dressing process. It is well known that spoilage is caused by only a fraction of so-called Ephemeral Spoilage Organisms (ESO) that become dominant through selection depending on conditions prevailing during storage. A number of selective factors (e.g., pH, temperature, nutrients, etc) favour the growth of particular bacteria and, as a consequence, a characteristic and specific microbial association develops and is present at the time of spoilage, leading to its characteristic spoilage features.

The project is based on the application of a multidisciplinary system-wide approach relying on converging technologies (bioinformatics, nanotechnology, modelling) to obtain knowledge for meat safety that will be translated into simple devices and practical indicators of quality and safety.

The principal objectives of the project are:

» to develop and / or validate chemical (fluorescence based, biosensors etc.) and molecular methods (detection of microbial nucleic acids) for the evaluation of meat quality

» to develop a platform for data sharing and integration

» to apply multivariate statistical methods to identify quality indexes based on multiple compounds

» to integrate the information obtained by developing a system to immediately and automatically transform the acquired data in a ‘diagnosis’ of meat quality and safety

The project plan designed to meet these objectives comprises of three pillars of activities:

1. microbial status and major metabolomic and molecular profiling of spoilage bacteria

2. development of an easy to use integrated system to monitor meat safety and quality

3. development of protocols for simple, effective and cheap evaluation of meat quality and safety in industry, based on new indices of quality and safety relying on detection of metabolites by simple sensors, driven by user friendly software that facilitates practical use of the developed methods

The project will be of benefit to the EU meat industry, providing useful tools and fundamental knowledge of the spoilage and hazard. It will also impact on the research and informatics communities.

One of the activities within the first pillar is on the development of active antimicrobial packaging for the storage of meat. This activity is carried out at the Department of Food Science of the University of Naples Federico II, Italy. The scientist in charge at the University of Naples is Dr. Danilo Ercolini.

Numerous types of food packaging in combination with different storage techniques can be used in order to extend the shelf life of meat. One of the key technological measures needed during storage is the preservation of meat from microbial spoilage and contamination / proliferation of pathogenic microorganisms.

Active packaging is an innovative food packaging concept that has been introduced to satisfy consumer demand for high quality, safety and extended shelf life of food products. Among the active packaging applications, the incorporation of antimicrobials is receiving considerable attention as a means of inactivating bacteria, slowing the growth rate of microorganisms and maintaining food quality and safety. Particular attention is given to active packaging where the activation is performed using natural antimicrobial substances, among which bacteriocins play a fundamental role. The bacteriocins are small proteins synthesised by bacteria and have an antimicrobial power against microorganisms closely related to the producer and not against the producer itself. Such molecules can be food grade when produced by microorganisms commonly occurring in food such as lactic acid bacteria. In the Symbiosis-EU project, bacteriocins from lactic acid bacteria are used for the activation of plastic films for meat packaging.

The shelf life of meat depends on many factors including the number and type of microorganisms initially contaminating the muscles and their subsequent development. The storage temperatures play an important role in the handling of the raw meat products. Many groups of organisms contain members potentially contributing to meat spoilage under appropriate conditions. This makes the microbial ecology of spoiling raw meat very complex and spoilage very difficult to prevent. The main bacteria implicated in the spoilage of refrigerated meat include Brochothrix thermosphacta, Lactobacillus spp., Leuconostoc spp., Carnobacterium spp., Pseudomonas spp. and Enterobacteriaceae.

The aim of using active antimicrobial packaging is to inhibit the development of one or more of the above microorganisms and preserve the quality of meat during storage and distribution. The plastic polyethylene films are prepared by coating the bacteriocin solution on the surface of the plastic film in contact with the food and then the films are used to produce bags in which the meat is stored under vacuum.

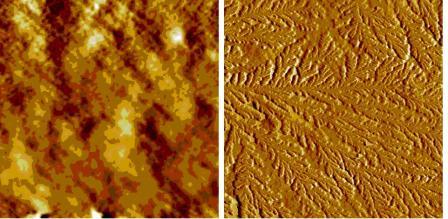

The antimicrobial activity of the treated plastic films is evaluated in vitro by using agar media plates inoculated with indicator microbial strains that are sensitive to the bacteriocin. The antimicrobial activity of plastic films activated with bacteriocins against Brochothrix thermosphacta is shown in Figure 1. The lack of growth of the bacteria in the area in contact with the activated film is shown by a clear zone surrounding the film. The non-activated film does not show clarification zones indicating that the indicator micro – organism can grow and give turbidity when in contact with the untreated plastic material. A further check of the antimicrobial activity is performed by putting a microbial cell suspension in direct contact with the activated surface of the plastic film and observing the health status of the cells by microscopy. In fact, viable fluorescent staining techniques are available that allow differential counting of live and damaged microbial cells with the help of epi-fluorescence microscopy.

igure 1 Antimicrobial activity of plastic film treated with bacteriocin solution against Brochothrix thermosphacta

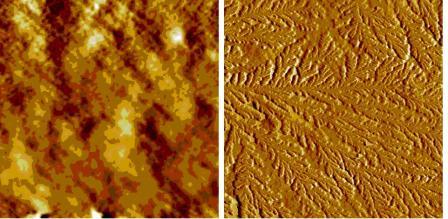

The plastic films before and after the antimicrobial coating are analysed in order to assess the possible changes of the chemical and physical properties following the treatment. In addition, the coating of the antimicrobial solution on the surface of the plastic films is also evaluated by Atomic Force Microscopy (AFM) in order to observe the roughness of different plastic surfaces after treatment at a non-scale level. Representative AFM images 20 x 20 μm2 of treated and untreated films are reported in Figure 2. In the illustrated case, the treated film presents an even distribution of the antimicrobial solution on the surface of the plastic film, which is essential to achieve a homogeneous rather than point specific antimicrobial activity.

Figure 2 Representative images from AFM analysis of polyethylene film (20x20 μm2) before (panel A) and after (panel B) a coating treatment with a bacteriocin solution

The developed antimicrobial packaging is then exploited in meat packaging, especially for the vacuum storage of large pieces of meat muscle. Vacuum packaging is an essential complement to the use of activated films because it will guarantee the close contact between the antimicrobial treated surface and the surface of meat. The microbial contamination of meat is, indeed, superficial.

The microbiological quality of meat stored in conventional or active packaging at low temperatures is also evaluated over time by quantifying the loads of the most commonly occurring spoilage related microbial groups long after common shelf life times. The microbial populations are not only quantified by plating on selective culture media but a species-level identification is also performed in order to have a clear picture of the microbial species contributing to the deterioration of meat quality during storage. The identifications are performed by using the most reliable molecular techniques, including fingerprinting methods and sequencing of portions of bacterial genomes that are useful for taxonomic purposes. During the first two years of activity within the Symbiosis-EU project, the principal microbial species occurring during meat storage in different packaging conditions have been identified and a first deliverable of the project contains a report listing bacteria most commonly developed during meat storage by differentiating the type of microbial species that develops if meat is stored in air, vacuum, active-vacuum or protective atmospheres. They are all psychrotrophic bacteria that can grow at chilled temperatures that are commonly employed in the storage of fresh meat.

The microbial species change in type and load during storage thus affecting meat quality. The diverse microorganisms can contribute differently to the spoilage of meat by releasing metabolites that are often odour-active molecules and that can contribute to the sensory unacceptability of the meat. To look at changes in the release of volatile molecules from meat during storage in the different packaging conditions, head space- solid phase micro extraction-gas chromatography/mass spectrometry (HS-SPME-GC/MS) analyses are performed on meat cuts at each sampling time. It has been observed that some molecules are specifically developed in some storage conditions and not in others, basically because they are produced by microorganisms that can grow in such conditions. Another aim of the project is to try and associate the release of some molecules to the development of specific microbial species. In order to prove this, experiments are carried out by intentionally inoculating meat with different biotypes of the same microbial species and monitoring the volatile organic compounds released during the storage of meat. Therefore, the presence of certain molecules or groups of molecules could be attributed to specific microorganisms at a certain level of contamination and the volatile compounds could be regarded as markers of specific bacteria.

A further aim of the project is indeed to work out some specific metabolic markers of meat spoilage that can be used for the development of biosensors to be employed for a rapid evaluation of meat quality. By the end of the project, a list of promising spoilage markers will be available. The molecules developed earlier during storage will be the most interesting to indicate a precocious start of the spoilage process.

About the Author

Danilo Ercolini

Within the Symbiosis-EU project, Danilo Ercolini is the scientific responsible of the activities of the research unit at the Department of Food Science, University of Naples Federico II. He received a PhD in Food Science and Technology and is currently assistant Professor in Microbiology at the University of Naples Federico II. He is member of the Editorial board of the journals Applied and Environmental Microbiology, Food Microbiology and International Journal of Food Microbiology.