How to determine the spray drying parameters of dairy and food concentrates?

- Like

- Digg

- Del

- Tumblr

- VKontakte

- Buffer

- Love This

- Odnoklassniki

- Meneame

- Blogger

- Amazon

- Yahoo Mail

- Gmail

- AOL

- Newsvine

- HackerNews

- Evernote

- MySpace

- Mail.ru

- Viadeo

- Line

- Comments

- Yummly

- SMS

- Viber

- Telegram

- Subscribe

- Skype

- Facebook Messenger

- Kakao

- LiveJournal

- Yammer

- Edgar

- Fintel

- Mix

- Instapaper

- Copy Link

Posted: 10 September 2009 | Pierre Schuck & Romain Jeantet, INRA and Agrocampus Ouest and Eric Blanchard, Laiterie de Montaigu | No comments yet

Pierre Shuck and associates discuss spray drying parameters of dairy products. In part one, featured in this issue of New Food, the authors discuss the rationale behind their studies and introduce a new method of spray drying. Part two will feature in our next issue of New Food and reveal the results and conclusions drawn by the authors.

Pierre Shuck and associates discuss spray drying parameters of dairy products. In part one, featured in this issue of New Food, the authors discuss the rationale behind their studies and introduce a new method of spray drying. Part two will feature in our next issue of New Food and reveal the results and conclusions drawn by the authors.

Pierre Shuck and associates discuss spray drying parameters of dairy products. In part one, featured in this issue of New Food, the authors discuss the rationale behind their studies and introduce a new method of spray drying. Part two will feature in our next issue of New Food and reveal the results and conclusions drawn by the authors.

In this study, a new method was developed to evaluate the ratio of bound to unbound water by using drying by desorption. The results, combined with thermodynamic and physico-chemical parameters (such as absolute and relative humidity of air, total solids and temperature of concentrate, air flow rate, etc.), provide more precise determination of certain spray-drying parameters such as inlet air temperature and mass flow rate. More than 50 experiments were performed to correlate calculated and measured parameters in a pilot plant (Bionov) using water, skimmed milk, infant formula milk, caseinate maltodextrin and other food concentrates. The results showed that the difference between the calculated and measured inlet air temperature was less than five per cent, the determination coefficient being close to 0.96.

The economic value of this system is obvious, because it is easy to anticipate the spray-drying parameters by using a controller integrating the water availability of the concentrate and certain thermodynamic parameters. Software based on this step was developed (SD2P®, Spray Drying Parameter Simulation and Determination) and registered at the APP (Association pour la Protection des Programmes).

Drying (consisting of lowering water activity by water elimination) is an effective method for preserving biological products, since it does not involve severe heat treatment and it allows storage at an ambient temperature. Large amounts of liquid dairy products (skimmed and whole milk, whey, various fractions resulting from membrane filtration and chromatographic separation) and food are dried in order to produce feeds, food and ingredients. Most of these powders are spray-dried. This process consists in spraying the concentrated liquid in droplets of approximately 50 mm into a large drying chamber containing air heated at approximately 200°C. The temperature of the product itself lies between the wet bulb temperature and the temperature of the outlet air, i.e. it remains below 100°C. Since drying occurs within a few seconds, thermal damage is limited. Classical spray-dryers are combined with a fluid bed in the wet zone, which usually agglomerates the fine powder coming from the drying chamber, completes the drying process and cools the powder. In recent three stage installations, another fluid bed with agglomeration and additional drying functions is included at the bottom of the drying chamber1,2.

There have been few scientific or technical studies on the powder quality obtained from spray drying related to the process parameters, physico-chemical composition or microbiology of the concentrates. Manufacturers have acquired expertise in milk and whey drying processes through an empirical approach. However, due to the variety and complexity of the mixes to be dried, more rigorous methods based on physico-chemical and thermodynamic properties have now become necessary.

Droplet size distribution, droplet trajectories, air flow patterns, and internal and external mass and heat transfer during drying show complex dependence on flow-rates (air and concentrate), and physical characteristics depend on the product, the properties of the material to be dried and the design of the atomising device and the drying chamber2,3. Pisecky4 studied the parameters controlling powder moisture content and the influence of various factors on bulk density in a spray drying operation. He showed the different properties of dairy powders which are influenced by processing. Because of this complexity, it is difficult to devise a reliable mathematical model to determine the parameters and performance of a spray dryer as a function of the design variables, operating conditions and feed properties3. Several authors have studied the moisture transfer mechanisms for a liquid food droplet during drying5, the drying kinetics for a single droplet of skim milk3,6 and a comprehensive model based on control of milk drying processes7. These studies have demonstrated major unreliability for various reasons in these models of drying processes3,5,7 including the prediction of the mean droplet size and the dimensions of the atomiser used, hydrodynamic interaction of air and sprayed liquid, agglomeration of droplets after atomisation, history of shrinkage, desorption isotherms, internal air flow profiles, and drying conditions (air and concentrate flow rate, absolute and relative humidity).

Improvement in the quality of new dairy and food powders can be obtained only with the integration of new parameters such as glass transition temperature, water activity8, residence time distribution9, surface composition and surface temperature (versus drying time). The latter consists of drying modelling based on heat and mass transfer and balance equations. Two approaches can be considered: an overall approach, developed by Schuck et al.10, in which the model results in a mass and energy balance over the entire dryer, which can be a black box between both ends which efficiently predicts the settings and overall performance of the spray dryer before production starts for varying weather / product conditions, and a micro approach developed by Chen and Lin11, Patel et al.12,13 and Lin et al.14-16 which considers the drying kinetics and balance at the droplet level to determine information regarding the condition of the droplet (temperature / water content) as it dries. This reaction engineering approach makes it possible to model the drying droplet of various dairy products and is a new and interesting approach for improved control of the surface temperature of the droplet and subsequently the powder. This model can be used to predict certain aspects of powder quality / functionality. Whatever the approach used, one difficulty remains: i.e. how to take into account the water availability in the product, except for pure water.

The aim of this study was to propose a new method of drying by desorption in order to determine major drying parameters according to food components in relation to their interactions with water (bound and free water) and linked to water transfer kinetics.

Materials and methods

Drying by desorption

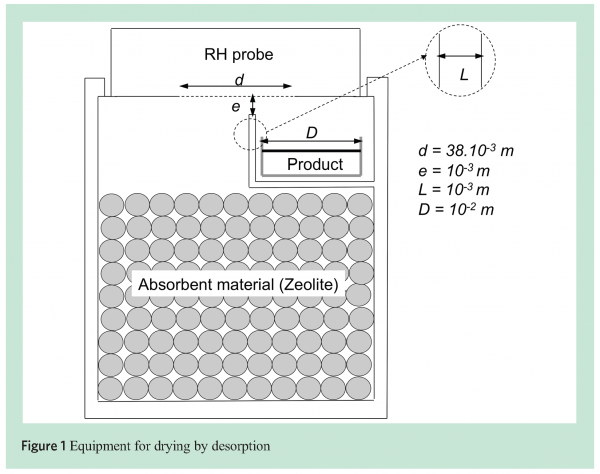

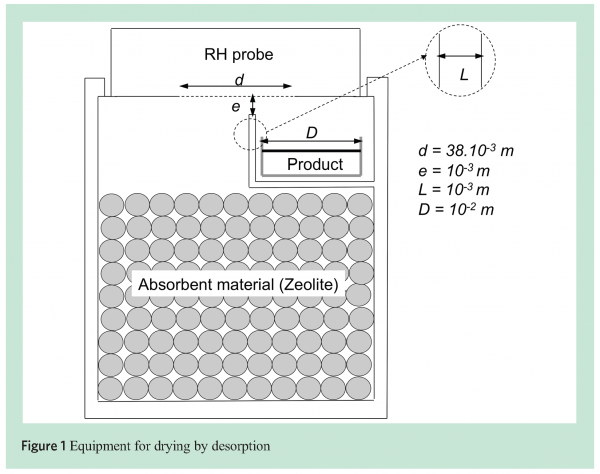

Concentrates were dried at 45°C (constant temperature) in a device (Rotronic, Bassersdorf, Switzerland) which consists of a two compartment cell, one (the smallest) containing the product (approximately 160 milligrams) and the other containing an excess of a strong absorbent, in this case zeolite. The mass ratio is approximately 100 grams zeolite to one gram product. At 45°C, the vapour pressure of zeolite is 30 Pa, whereas it is equal to the saturation vapour pressure (close to 3000 Pa) at the surface of the layer product. Water transfer takes place because of this vapour pressure gradient, in a similar way to the water transfer that occurs during drying. The main difference is in the kinetics of the transfer, which here takes two hours compared to a few seconds during spray drying. This device was described by Schuck et al17 (Figure 1, page 53). One relative humidity (RH) sensor (Rotronic, Bassersdorf, Switzerland) over the two compartments makes it possible to plot RH in the cell as a function of time.

Chemical analysis

Total solids (TS) were determined on a 1.5 gram sample mixed with sand after seven hours in a dry oven (105°C).

Preparation of concentrate

Raw skimmed milk and sweet whey were provided by Triballat (Noyal sur Vilaine, France) and Euroserum (Montauban, France), respectively. Concentration of milk and whey was performed in a two stage falling film vacuum evaporation pilot plant (GEA-Process Engineering, St Quentin en Yvelines, France) at Bionov (Rennes, France) to obtain three skimmed milk concentrates (N°s1, 2 and 3 at 30, 40 and 50 per cent of TS, respectively) and a concentrated sweet whey at 50 per cent of TS. The first evaporation stage was carried out at 60°C and led to a concentrate temperature of 40°C. The lactose of the concentrated sweet whey was crystallised up to 80 per cent. The infant milk concentrate was reconstituted from infant formula milk powder (Laiterie de Montaigu, Montaigu, France) at 40 per cent of TS. The glucose syrup was reconstituted from dried glucose syrup (dextrose equivalent 33) (Roquette Frères, Lestrem, France) at 40 per cent of TS. Micellar casein isolate (MCI) at 19 per cent of TS was separated from skim milk by tangential membrane microfiltration followed by purification through water diafiltration according to Fauquant et al,18 Pierre et al.19 and Schuck et al.20. Whey protein isolate (WPI) at 20 per cent of TS was obtained by membrane tangential ultrafiltration and diafiltration (four volumes) of microfiltrate, collected during MCI production with a spiral-wound organic membrane of 9.7 m2 and a cutoff close to 20 kg.mol-1 at a volume reduction of 20. Finally, 38 dairy and food concentrates were obtained before drying by desorption (including variations in the concentrate temperature). All the analyses and experiments were performed in duplicate.

Acknowledgements

This articles uses information from the author’s original paper entitled ‘Drying by desorption: a tool to determine spray drying parameters’ in Journal of Food Engineering 94, 199-204 (2009).

References

- Sougnez, M., 1983. L’évolution du séchage par atomisation, Chimie Magazine 1, 1-4.

- Masters, K., 2002. Spray Drying in Pratactice. SprayDryConsult International ApS (Eds.), Charlottenlund.

- Ferrari, G., Meerdink, G., Walstra, P., 1989. Drying kinetics for a single droplet of skim milk. Journal of Food Engineering 10, 215-230.

- Pisecky, J., 1981. Technology of skimmed milk. Journal of the Society of Dairy Technology 34, 57-67.

- Furuta, T., 1992. Moisture transfert modelling of a liquid food droplet on drying. In: Thorne, S., (Ed), Mathematical Modelling of Food Processing Operations. Elsevier Applied Science, London, pp 99-136.

- Kerkhof, P., Schoeber, W., 1974. Theoretical modeling of the drying behaviour of droplets in spray-dryers. In: Spicer, A., (Ed), Advanced in Preconcentration and Dehydration of Foods, Applied Science Publishers, London pp 349-397.

- Chen, X.D., 1994. Towards a comprehensive model based control of milk drying processes. Drying Technology 12, 1105-1130.

- Schuck, P., Méjean, S., Dolivet, A., Jeantet, R., Bhandari, B., 2007. Keeping quality of dairy ingredients. Le Lait 87, 481-488.

- Jeantet, R., Ducept, F., Dolivet, A., Méjean, S., Schuck P., 2008. Residence time distribution: a tool to improve spray-drying control. Dairy Science and Technology 88, 31-43.

- Schuck, P., Méjean, S., Dolivet, A., Jeantet R., 2005. Thermohygrometric sensor: a tool for optimizing the spray drying process. Innovative Food Science and Emerging Technology 6, 45-50.

- Chen, X.D., Lin, S.X.Q., 2005. Air Drying of Milk Droplet under Constant and Time-Dependent Conditions. American Institute of Chemical Engineers Journal 51 (6), 1790-1799.

- Patel, K., Chen, X.D., Kar, S., 2005a. Prediction of spray dried product quality using two simple drying kinetics models. Journal of Food Process Engineering 28, 567-594.

- Patel, K., Chen, X.D., Kar, S., Lin, S.X.Q., 2005b. The temperature uniformity during air drying of a colloidal liquid droplet. Drying Technology 23, 2337-2367.

- Lin, S.X.Q., Chen, X.D., 2005. Prediction of air drying of milk droplet under relatively high humidity using the reaction engineering approach. Drying Technology 23, 1395-1406

- Lin, S.X.Q., Chen, X.D., 2006. A model for drying of an aqueous lactose droplet using the reaction engineering approach. Drying Technology 24, 1329-1334.

- Lin, S.X.Q., Chen, X.D., 2007. The reaction engineering approach to modelling the cream and whey protein concentrate droplet drying. Chemical Engineering and Processing 46, 437-443.

- Schuck, P., Roignant, M., Brulé, G., Davenel, A., Famelart, M.H., Maubois, J.L., 1998. Simulation of water transfer in spray drying. Drying Technology 16, 1371-1393.

- Fauquant, J., Maubois, J.L., Pierre, A., 1988. Microfiltration du lait sur membrane minérale. Techniques Laitières 1028, 21-23.

- Pierre, A., Fauquant, J., Le Graët, Y., Piot, M., Maubois, J.L., 1992. Préparation de phosphocaséinate natif par microfiltration sur membrane. Le Lait 72, 461-474.

- Schuck, P., Piot, M., Méjean, S., Le Graët, Y., Fauquant, J., Brulé, G., Maubois, J.L., 1994. Déshydratation par atomisation de phosphocaséinate natif obtenu par microfiltration sur membrane. Le Lait 74, 375-388.

Issue

Related organisations

Related people

Eric Blanchard, Laiterie de Montaigu, Pierre Schuck, Romain Jeantet