Microbiological standards in cocoa bean processing

- Like

- Digg

- Del

- Tumblr

- VKontakte

- Buffer

- Love This

- Odnoklassniki

- Meneame

- Blogger

- Amazon

- Yahoo Mail

- Gmail

- AOL

- Newsvine

- HackerNews

- Evernote

- MySpace

- Mail.ru

- Viadeo

- Line

- Comments

- Yummly

- SMS

- Viber

- Telegram

- Subscribe

- Skype

- Facebook Messenger

- Kakao

- LiveJournal

- Yammer

- Edgar

- Fintel

- Mix

- Instapaper

- Copy Link

Posted: 31 January 2005 | Andrew Snelson, Site Microbiologist, Cadbury Trebor Bassett | No comments yet

In a food processing environment, microbiology is an essential focus to ensure the safety of the end food product. In this article Andrew Snelson explains the processes that ensure microbiological safety during cocoa bean processing.

Cocoa butter and cocoa liquor are extracted from the seed of the Theobroma cocoa tree. Cocoa trees begin to bear fruit when they are 3-4 years old when, unusually, pink and white flowers (and then pods) grow straight out of the trunk and main branches of the tree. Flowers are present throughout the year but appear in abundance before the rain begins. Only a small proportion of all the flowers develop into fruit during a period of about five months and each tree will yield between 20 and 30 pods. In West Africa the peak time for harvesting is between September and December – and in this period, the crop from one tree will produce 450 grams of chocolate. Owing to the fact that cocoa trees grow well in humid tropical climates with regular rains, in a short dry season most of the world’s cocoa is grown in a narrow belt ten degrees either side of the equator. The main producers of cocoa are West Africa (Ghana, Nigeria and the Ivory Coast), South America (Brazil and Equador) and Asia (Malaysia and Indonesia).

In a food processing environment, microbiology is an essential focus to ensure the safety of the end food product. In this article Andrew Snelson explains the processes that ensure microbiological safety during cocoa bean processing. Cocoa butter and cocoa liquor are extracted from the seed of the Theobroma cocoa tree. Cocoa trees begin to bear fruit when they are 3-4 years old when, unusually, pink and white flowers (and then pods) grow straight out of the trunk and main branches of the tree. Flowers are present throughout the year but appear in abundance before the rain begins. Only a small proportion of all the flowers develop into fruit during a period of about five months and each tree will yield between 20 and 30 pods. In West Africa the peak time for harvesting is between September and December – and in this period, the crop from one tree will produce 450 grams of chocolate. Owing to the fact that cocoa trees grow well in humid tropical climates with regular rains, in a short dry season most of the world’s cocoa is grown in a narrow belt ten degrees either side of the equator. The main producers of cocoa are West Africa (Ghana, Nigeria and the Ivory Coast), South America (Brazil and Equador) and Asia (Malaysia and Indonesia).

In a food processing environment, microbiology is an essential focus to ensure the safety of the end food product. In this article Andrew Snelson explains the processes that ensure microbiological safety during cocoa bean processing.

Cocoa butter and cocoa liquor are extracted from the seed of the Theobroma cocoa tree. Cocoa trees begin to bear fruit when they are 3-4 years old when, unusually, pink and white flowers (and then pods) grow straight out of the trunk and main branches of the tree. Flowers are present throughout the year but appear in abundance before the rain begins. Only a small proportion of all the flowers develop into fruit during a period of about five months and each tree will yield between 20 and 30 pods. In West Africa the peak time for harvesting is between September and December – and in this period, the crop from one tree will produce 450 grams of chocolate. Owing to the fact that cocoa trees grow well in humid tropical climates with regular rains, in a short dry season most of the world’s cocoa is grown in a narrow belt ten degrees either side of the equator. The main producers of cocoa are West Africa (Ghana, Nigeria and the Ivory Coast), South America (Brazil and Equador) and Asia (Malaysia and Indonesia).

Harvesting of the pods is proceeded by a two stage curing process of fermentation followed by drying. This prepares the beans for market and is the first stage in the development of the chocolate flavour. Cadbury buys its high quality beans from Ghana and processes them at its highly technical Cadbury cocoa factory in Chirk, North Wales. The Chirk site operates twenty four hours a day, seven days a week, to produce the basic ingredients from which all Cadbury chocolate products are made. Fifty thousand tonnes of cocoa beans are processed each year using the latest technological control systems to ensure that the end product is of the highest quality.

Quality of raw cocoa beans

The International Cocoa Standards require cocoa beans of merchantable quality to be fermented, thoroughly dry, free from smoky beans, free from abnormal or foreign odours and free from evidence of adulteration. It must be reasonably free from living insects, broken beans, fragments and pieces of shell and foreign matter and be reasonably uniform in size. Cocoa cargo is graded on the basis of the count of defective beans in the cut test. Defective beans should not exceed the following limits:

- Grade 1 cocoa beans: mouldy beans max 3% by count; slaty beans (i.e. underfermented) max 3% by count; insect damaged, germinated or flat beans – total max 3% by count

- Grade 2 cocoa beans: mouldy beans max 4% by count; slaty beans max 8% by count; insect damaged, germinated or flat beans – total max 6% by count

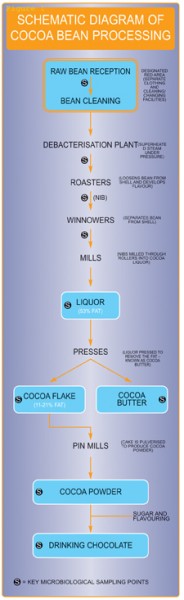

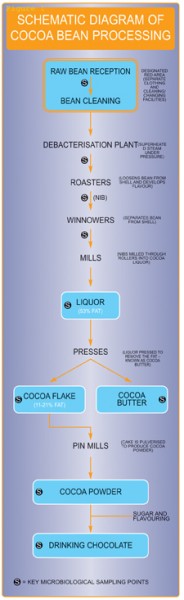

Processing of cocoa beans

Raw bean cleaning

The first stage in the processing of cocoa beans is when the beans arrive at the processing site in a bulk container and a representative sample is taken. The raw beans are then unloaded to the raw bean cleaning area, which is separate from the main body of the factory due to the potential contamination risk from the raw beans and also the dust. Here stones, string and other foreign matter are removed using sieves, cyclones and magnets.

Debacterisation

Next the beans are transferred by conveyor to the debacterisation plant where they are subjected to super heated steam under pressure and are then transferred to the roaster (typical aerobic plate count post debacterisation is less than 200 cfu/g with coliforms and Salmonella absent).

Roasting

Roasting loosens the beans from the shell while the time/temperature combination of 1-2 hrs at 100-150°C also helps to inactivate any remaining organisms. The flavour and aroma are also developed by the roasting process.

Winnowing

Here the outer shell is cracked and separated from the bean, which is now called a cocoa nib.

Grinding

Roasted nibs are milled through rollers and then transformed into a thick paste known as liquor or cocoa mass. At this point the liquor fat content is approximately 53 per cent and must be sampled prior to dispatch to Cadbury manufacturing sites. Typical liquor would have an aerobic plate count between 1-2000 cfu/g as well as an absence of coliforms, mould and pathogens.

Liquor press

Liquor is then pressed to remove the fat (cocoa butter) and, following hydraulic pressing, a cocoa cake is produced which has a fat content of approximately 21 per cent (other fat percentages can be produced, dependent on the press time). Sampled cake should have a similar microbial level to that of liquor.

Powder production

The cocoa cake is then pulverised through mills to produce Cadbury cocoa powder or can be blended with other ingredients to produce Cadbury drinking chocolate. The powders are then packed into bags or composites, having passed all the necessary analytical, organoleptic and microbiological tests (Figure 1).

Environmental monitoring

Cocoa beans are regarded as a potentially contaminated raw material and cocoa dust from un-debacterised beans is also a possible source of Salmonella. Therefore, along with segregation of the raw bean, cleaning and handling operations and environmental sampling is carried out in order to monitor the various distinct areas. Air sampling is performed at 30 separate areas of the factory from the bean deck/bean cleaning area to the finished goods warehouse and all significant points in between. A ‘Biotest’ air sampler is used to conduct the air sampling tests and specifically designed strips of agar wells are inserted into the chamber. Total viable count (TVC) and coliforms are both tested for. Upon loading the strip into the sampler it is allowed to run for 30 seconds, which is equivalent to 30 litres of air exposure. Once complete, the strip is removed from the sampler and aseptically stored until incubation. The strips are incubated at 30°C for 64-72 hrs for TVC and 36°C for 18-24 hrs for coliforms. After the incubation phase, the number of colony forming units (CFUs) on the whole strip are recorded and then multiplied by a factor of 33.3 to give the number of CFUs per metre cubed of air exposed. In conjunction with the air sampling, swabs are used to monitor production areas for the absence of Salmonella. A 50cm2 sponge swab is used that is pre soaked with neutralising buffer. This is supplied in a sterile 100ml container with a sterile plastic glove (the sponge is non toxic to Salmonella). An area of approximately 225cm2 is swabbed after which the sponge is returned to its container and 80ml of Brilliant Green Milk Broth (BGMB) is added. BGMB neutralises the inhibitory compounds that might be present and emulsifies the sample. Brilliant green dye is then added to the UHT milk for the isolation of Salmonella. The containers are incubated at 36°C for 18-20 hrs followed by the standard Salmonella method using MSRV agar and LICNR broth.

Water sampling is also carried out to evaluate the general microbial flora present in water samples, including process waters and potable water sources. The method covers the enumeration of aerobic organisms in water capable of growth at temperatures of between 22-30°C. Water samples are tested for coliforms, faecal streptococci, Salmonella and total bacterial count. Plant swabbing is routinely performed to ascertain the level of cleanliness of machinery and equipment and also the effectiveness of factory cleans and CIP systems. Where possible an area of 100cm2 is swabbed and then the swab is immersed in maximum recovery diluent prior to plating out. Plant swabs are tested for coliforms, yeast, mould and total bacterial count.

Summary

By controlling and monitoring the processing of cocoa beans from their raw state through to their processed form, the microbiological quality of the flavoured cocoa butter, deodorised cocoa butter, cocoa liquor and cocoa powder can be assured. The special flavours produced when fresh milk, cocoa mass and sugar are cooked together in the first stages of the chocolate making process give Cadbury Dairy Milk its very special taste.