What changes occur in chocolate during conching?

- Like

- Digg

- Del

- Tumblr

- VKontakte

- Buffer

- Love This

- Odnoklassniki

- Meneame

- Blogger

- Amazon

- Yahoo Mail

- Gmail

- AOL

- Newsvine

- HackerNews

- Evernote

- MySpace

- Mail.ru

- Viadeo

- Line

- Comments

- Yummly

- SMS

- Viber

- Telegram

- Subscribe

- Skype

- Facebook Messenger

- Kakao

- LiveJournal

- Yammer

- Edgar

- Fintel

- Mix

- Instapaper

- Copy Link

Posted: 9 March 2006 | Mike Gray, Manufacturing Support Advisor, Nestle Product Technology Centre | 2 comments

Chocolate conching is not a precisely defined process and there are still elements of skill in producing a good flavoursome chocolate with the right viscosity for making sweets.

This article is an introduction to what goes on in the conche and demonstrates how complex a process conching is. A conche, so named because early versions were similar in shape to the seashell, is a mixer specifically designed for making chocolate.

Chocolate conching is not a precisely defined process and there are still elements of skill in producing a good flavoursome chocolate with the right viscosity for making sweets. This article is an introduction to what goes on in the conche and demonstrates how complex a process conching is. A conche, so named because early versions were similar in shape to the seashell, is a mixer specifically designed for making chocolate.

Chocolate conching is not a precisely defined process and there are still elements of skill in producing a good flavoursome chocolate with the right viscosity for making sweets.

This article is an introduction to what goes on in the conche and demonstrates how complex a process conching is. A conche, so named because early versions were similar in shape to the seashell, is a mixer specifically designed for making chocolate.

What is conching?

Chocolate making conventionally begins with mixing and size reduction of the ingredients: sugar, cocoa solids and, for milk or white chocolates, milk powder. The product of this size reduction, often called flake, is then conched in order to achieve the following:

- Create the desired final flavour in the chocolate

- Change it from a powdery state to a fluid that can be poured or pumped

During the conching process flavours are created, removed and changed, and all the solid particles are coated with fat. This fat forms a continuous phase and it is the completeness of this layer that determines the handling properties or viscosity of the finished chocolate. (Aguilar, Ziegler 1994)

Conching phases

There are three phases of chocolate conching:

- Dry conching: The mass is still crumbly and more like a powder

- Pasty/plastic phase: Much of the fat has been released and the mass gradually changes to a paste

- Liquefying: The last of the fat plus minor additions, such as emulsifiers and flavours, are added and the chocolate becomes liquid

The most important are the dry and pasty phases, during which the majority of the changes happen. There has been much emphasis placed on this stage of the process and this has created the most significant change in conching during the last two decades.

The boundaries between the phases are not obvious and some experience is needed to define them.

Changes in viscosity during conching

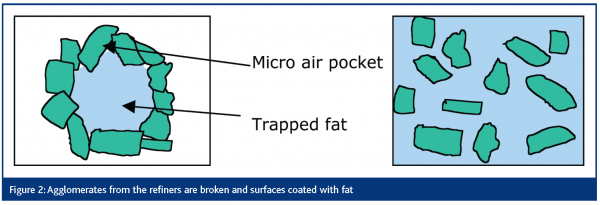

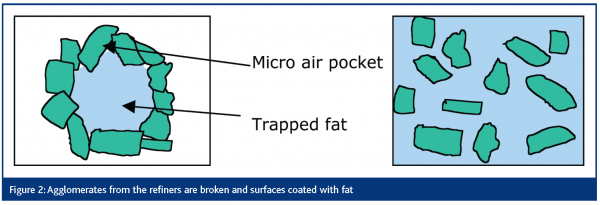

Size reduction is usually achieved with a roll refiner, each roll of which turns slightly faster than the previous one, creating a shearing action. This process results in new surfaces that attract each other and form agglomerates, which enclose most of the fat. For this reason, the output from the refiners is a cohesive powder that can be picked up almost without dirtying your hands. (For further information about refining see note below).

Little or no fat is added to this powder at the start of conching, but after a few hours, the mass becomes more fluid due to the application of a high degree of shear that breaks up the agglomerates and spreads fat across each particle.

No size reduction of the primary particles takes place during conching. It therefore follows that the final particle size of the chocolate must be created during the refining stage, which in turn means using the right fat content at the mixing and initial refining stages.

If there is too much fat or emulsifier (normally lecithin), the mass will be too liquid and the mixer arms cannot take hold and work the product. The agglomerates will slide over each other and not be broken up.

If there is too little fat, and the mass is too dry, it will act as a powder and just move out of the way of the mixer arms.

Work input and viscosity

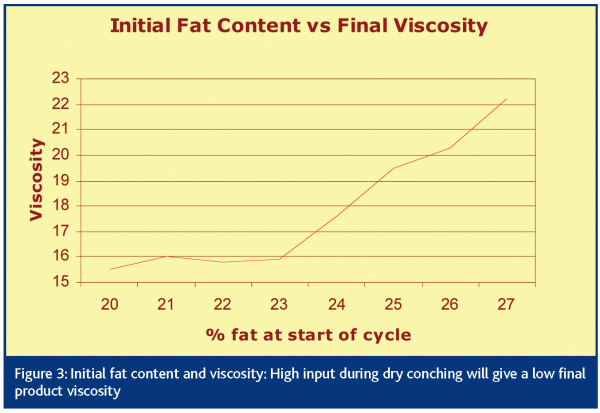

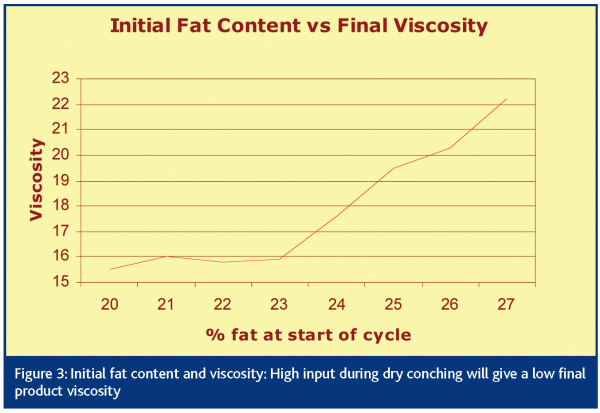

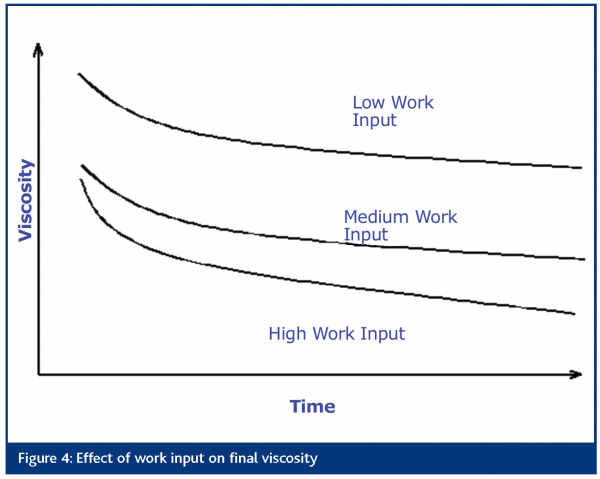

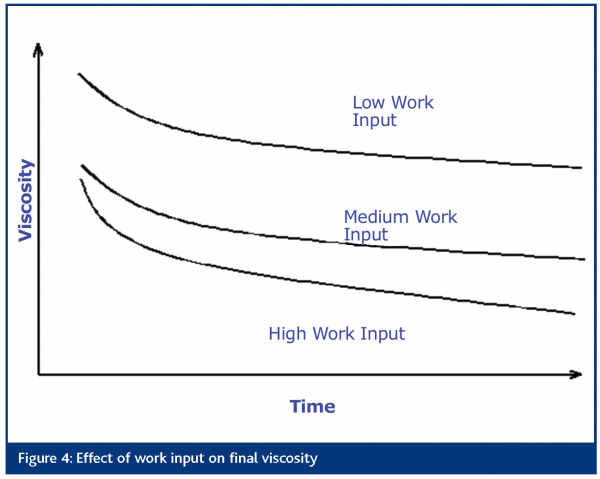

The work input or power capability of the conche has a direct impact on the final viscosity.

Longer conching times or post-conche intensive mixing cannot compensate for low initial work input. This is particularly true when comparing old and new conches. The only solution is the expensive one of adding extra cocoa butter.

Work input and temperature

The majority of the heat imparted to the mass is mechanical and comes from the mixing elements, with the remainder coming from the conche jacket. Many of the flavour changes during conching happen due to microenvironments within the conche. These exist very locally, as the name suggests – often only for a short time – and are due to the moisture that is released during dry conching making its way to the surface of the mass to escape. As it does so, it forms localised regions of higher moisture content, allowing various processes such as crystallisation of amorphous sugars, agglomeration of particles or flavour changing chemical reactions to take place that cannot take place in the mass as a whole, due to insufficient moisture.

The conche

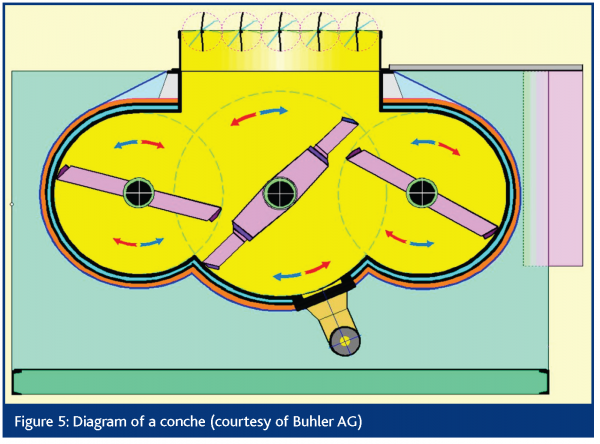

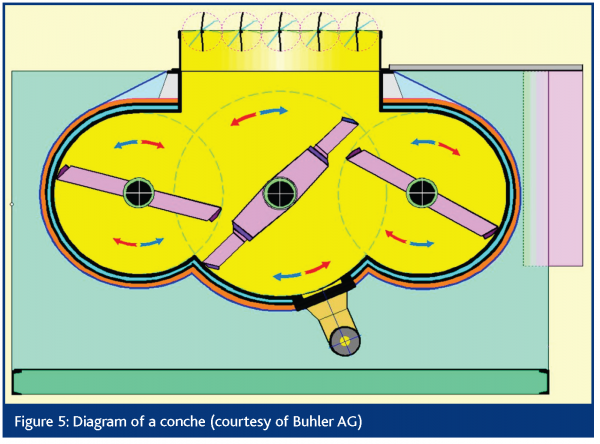

There is such a variety of conche types available – and even more that have been in use for many years and have now been superseded – that it is not feasible to present even a representative sample (Taylor 2005). For illustration purposes, one example is shown in Figure 5.

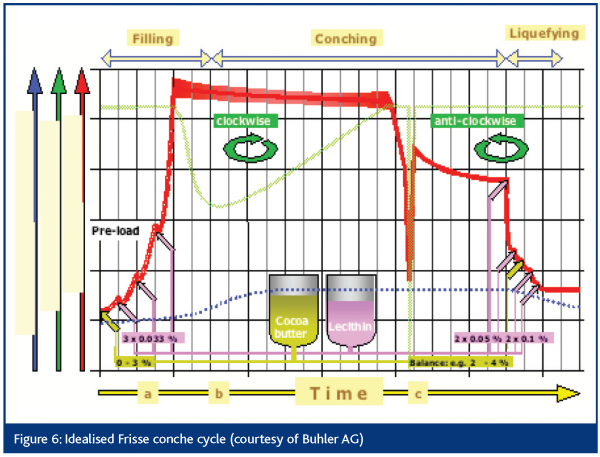

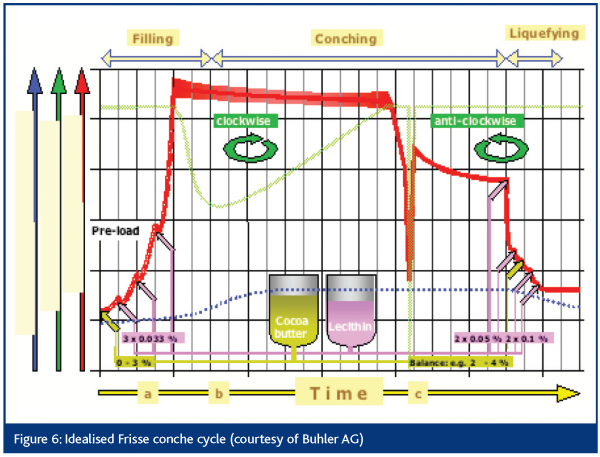

The conche operating cycle

This slide depicts the gradual addition of very small quantities of fat followed by lecithin – though fat can be used alone. This process aims to ‘wet’ the mass and so ensure that the conche does not call for more power than is available during the dry conching phase, which can make it stall.

The motor speed varies (as illustrated by the green line) to keep the power input steady at its maximum continuous rating. There is a dip just after filling due to the mass becoming more cohesive as fat is released and spread. At this point the mixing elements ‘grab’ the mass and begin to work it.

A similar cycle is used for most conches to make sure that they make the most efficient use of the cocoa butter. More often, the motor has two fixed speeds and the task of the specialist is to maximise the area under the power curve by optimising particle size, fat content and recipe.

Changes in flavour

There are three principal mechanisms that affect flavour, the first two of which take place only during dry conching, whilst the third starts on the refiner rolls and continues even when many of the particles are fat coated.

Removal of unwanted volatiles

The combination of mechanical energy from the mixing elements and external heating leads to evaporation of moisture. In addition, some acids – particularly acetic acid – and small quantities of aldehydes are also distilled off with the water.

The most significant changes happen during the first two hours of the conching process. The important factors are ventilation and the action and geometry of the conche. Frequent exposure of new surfaces to the atmosphere is necessary in order for the moisture and the associated volatiles to escape.

Creation of new flavours

Maillard reactions will create new flavours especially if the temperature is over 75°C.

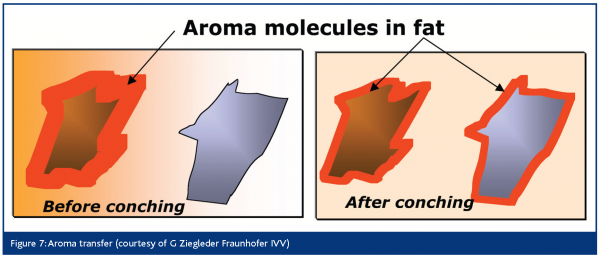

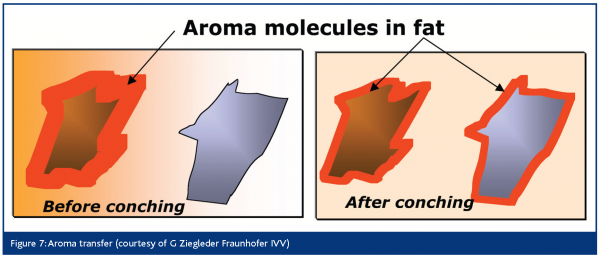

Transferring aroma molecules from cocoa to sugar

Recent evidence (Zeigleder et al 2000-2004) suggests that there is little flavour development during conching, unless using high temperatures (>75°C).

Instead, aroma molecules associated with the cocoa are transferred to sugar particles, where they have a different perceived flavour in the mouth. This transfer is a diffusion process and requires a certain amount of time, which is one of the significant differences between conching and simple mixing.

The conche cycle

What are the most important parameters?

Extensive evaluation of conche geometry and processing conditions led Ziegleder’s group (ref 3-6) to propose the following list of parameters in order of effect:

- Dry conching time

- The most important part of conching for flavour development/transfer

- Power input affects final flavour

- Mixer geometry affects conching time

- Initial fat content

- Moisture

- Ventilation of the conche

- Temperature

There are some interactions between three of the first four parameters. For example, the initial fat content affects dry conching time and power input: if the fat content is not correct at the dry conching stage, then conching will not occur. There is a possible query, however, over temperature being so low down the list.

Quantifying conching

How can conching be improved if it can’t be measured?

Sensory panels can be time consuming and are not always as reliable as preferred. However, when they are well trained they are probably the only practical way.

Zeigleder and his group have proposed an objective method for measuring the degree of conching that may be worth considering if resources are available: (Zeigleder et al 2005)

- Extraction of fat by centrifugation

- Measurement of tetramethyl pyrazine and benzaldehyde

- Derivation of equation using multi headspace extraction principle

- Conching – how long? Conche times have been reduced during the last two decades from 72 hours and more to probably no more than 24 hours for the best industrial masses. The average is closer to eight hours for milk masses, and a little longer for dark ones

White masses generally require shorter cycles, but conching is still necessary to get both flavour and viscosity right – particularly when using roller dried or caramelised milk powders.

- Conching – how hot?

Below 40°C the viscosity will be high, though for masses using monohydrate sugar alcohols such temperatures are essential. Above 60°C white chocolate will darken and its flavour will be affected. Above 75°C milk chocolate may caramelise depending upon its recipe – this is often desirable. Above 85°C milk chocolates can start to burn and introduce bitter notes. Again this may be desirable. 50°C to 100°C is suitable for dark chocolates. The choice of temperature will, again, be recipe and conche dependent. Older conches usually have both smaller jacket areas and produce less mechanical heating, so temperatures tend to rise more slowly and final cooling takes longer.

At the end of the cycle the mass must be cooled to 40°C – 45°C for storage or immediate use. White chocolate should be stored at the lower end of this range.

- Scaling up

Scaling up can be difficult, as pilot scale conches require proportionately larger hatches to fill, empty and clean than industrial ones. Surface-to-volume ratios and power-input per kilo of contents also change significantly with size. As a result, a 60kg pilot conche will not give the same flavour profile as a six tonne equivalent, though the viscosity characteristics should be similar.

What can go wrong?

As with any process, problems can, and do, occur.

Physical defects after conching

Grittiness is usually caused by over-rapid local release of moisture that cannot escape to atmosphere. It can be minimised by heating more slowly, venting the conche more efficiently or by adding a small amount (<0.1 per cent) of lecithin at the start of the cycle. Overloading the conche can be a factor too, as it can reduce the effective ventilation area.

‘Balling up’ can occur due to the initial fat content being too low. Typically, it consists of hard spheres, 1-2 mm in diameter, formed of compressed flake coated in fat that persist even after the addition of emulsifiers. Extra fat or some lecithin at the start of the cycle usually solves the problem.

Thickening of the mixture can also occur during storage. The following causes can be attributed:

- Unstable surfaces such as amorphous sugars, which interact particularly in white chocolates: this interaction increases with time due to water absorption and crystallisation, and is temperature dependent (Niediek 1991: Ziegleder, Amantis & Hornik 2004)

- Uncoated surfaces due to poor spreading of fat or emulsifier: these can also interact, although the effect is less strong than that of amorphous sugars. It helps to ensure that the residual moisture content is as low as possible, that storage temperatures are correct and that tanks are covered to minimise moisture uptake

Sensory defects

Off flavours generally come from the liquor. Other sources are undeodorised (or poorly deodorised) cocoa butter, milk powder or whey. Each should be tasted in turn to determine the cause. If the conching room is not well ventilated, transfer of volatiles from one conche to another can occur. Smokey or similar defects from the beans or liquor cannot be removed by conching.

Lack of flavour

Again, the liquor is the most common cause. Others are low conching temperature; too short a cycle which does not allow flavour to emerge; or too long a cycle which strips away the flavour. Bland milk powder can also result in a lack of cooked milk notes in white masses.

References

- Chocolate Manufacturing, Controlling the Process, Aguilar, Ziegler Proceedings of 48th PMCA Production Conference 1994, 144-150.

- The mysteries of conching, Taylor, Candy Business (2005 Mar/Apr) 18-22

- Conching – New findings, Ziegleder, Balimann, Mikle, Zaki, Susswaren Technik und Wirtschaft (2003) (February), 48 (3), 14-16

- Conching – new findings. Part II – flavour investigation. Ziegleder,, Balimann, Mikle, Zaki, Susswaren Technik und Wirtschaft (2003) (April), 48 (4), 16-18

- Conching – new findings – Part III – sensory properties and final conclusions, Ziegleder, Balimann, Mikle, Zaki, Susswaren Technik und Wirtschaft (2003) May, 48 (5), 14-16

- New knowledge about conching. Part 4. Conching degree and energy use. Zeigeleder, Balimann, Mikle, Zaki, Susswaren Technik und Wirtschaft (2005) (February), 50 (1-2), 10-12

- Problems of Exchange Reactions during Conching, Review for Chocolate, Confectionery and Bakery Niediek, Barbernics, (1981) 6 (1), 25-6

- Amorphous sugar, its formation and effect on chocolate quality, Niediek, The Manufacturing Confectioner (June 1991) 91-95.

- Thickening of molten white chocolates during storage, Ziegleder, Amantis, Hornik Lebensm.-Wiss u-technol.37 (2004) 649-656.

Appreciate all the valuable information I received from you today, thank you.

i had learned so much