Pulsed Electric Field pasteurisation of foods

- Like

- Digg

- Del

- Tumblr

- VKontakte

- Buffer

- Love This

- Odnoklassniki

- Meneame

- Blogger

- Amazon

- Yahoo Mail

- Gmail

- AOL

- Newsvine

- HackerNews

- Evernote

- MySpace

- Mail.ru

- Viadeo

- Line

- Comments

- Yummly

- SMS

- Viber

- Telegram

- Subscribe

- Skype

- Facebook Messenger

- Kakao

- LiveJournal

- Yammer

- Edgar

- Fintel

- Mix

- Instapaper

- Copy Link

Posted: 9 March 2006 | Huub L.M. Lelieveld | No comments yet

To have food available all year round, preservation is essential. However, traditional preservation methods such as drying, salting, acidifying, fermenting and heat treatments, whilst providing specific advantages, also have drawbacks. These include negative effects on colour, flavour and concentration of nutrients such as vitamins. New methods are emerging and one that is likely to find its way into the industry is pulsed electric field (PEF) treatment.

To have food available all year round, preservation is essential. However, traditional preservation methods such as drying, salting, acidifying, fermenting and heat treatments, whilst providing specific advantages, also have drawbacks. These include negative effects on colour, flavour and concentration of nutrients such as vitamins. New methods are emerging and one that is likely to find its way into the industry is pulsed electric field (PEF) treatment.

To have food available all year round, preservation is essential. However, traditional preservation methods such as drying, salting, acidifying, fermenting and heat treatments, whilst providing specific advantages, also have drawbacks. These include negative effects on colour, flavour and concentration of nutrients such as vitamins. New methods are emerging and one that is likely to find its way into the industry is pulsed electric field (PEF) treatment.

PEF is able to destroy vegetative micro-organisms without influencing colour, flavour and nutrients but, as PEF is not capable of inactivating most bacterial spores, it is not suitable for sterilisation. It may, however, be suitable for many products that traditionally are thermally pasteurised; such products that are acidic or have a low water activity and refrigerated low-acid products with a limited shelf life.

Pulsed electric fields (PEF) may destroy micro-organisms to the same effect as thermal pasteurisation. This article will discuss the inactivation of micro-organisms by PEF and the influence of PEF on enzymes, colour, flavour, nutrients and structure. It will also discuss product safety aspects and a PEF process line.

Inactivation of micro organisms and enzymes

When vegetative microbial cells are exposed to electric fields with a strength of approximately two volts per micrometer for a few microseconds, their membranes are perforated and the cells start to leak, causing death1-3. Conditions for inactivation vary widely4. The higher the initial temperature, the more efficient the inactivation5 – probably due to the increase in fluidity of the membrane. The product to be treated with PEF should therefore be heated to the optimum for PEF inactivation.

Bacterial spores are extremely resistant to PEF, making PEF unsuitable for sterilisation. Ascospores of moulds and yeasts also show extreme resistance. Although ascospores are not a common source of microbial spoilage, it is important to note that ascospores of Byssochlamys and Neosartorya might be the only survivors relevant to high-acid products.

PEF to destroy micro-organisms has no significant effect on proteins and thus on enzymes. Even under an extreme field there is no complete inactivation6. If the objective of PEF treatment is ambient stability, the process is unsuitable for products where enzymes would adversely affect product quality during storage. On the other hand, where enzymes must be preserved or freed from vegetative micro-organisms, PEF may be the ideal process.

Influence on product quality

The change in colour due to PEF treatment has been investigated for many products, including liquid whole egg, fruit and vegetable juices (orange, apple, carrot) and yoghurt. Initially, there is no change in colour and where the colour changes with storage time, the changes are less than with thermally pasteurised products7.

Generally, PEF does not influence flavour and taste. If any change after PEF treatment is observed it can be attributed to the storage conditions (affecting products independent of the processing received) or to the growth of micro-organism (not all micro-organisms may have been inactivated ). Apple and orange juice retain their fresh taste for a long time if kept refrigerated (~4°C). Also, the flavour and taste of milk products, egg products and green pea soup are not adversely affected by PEF7.

Structure

PEF affects cell membranes and thus may influence texture. Heating, however, also affects cell membranes. The degree of damage to the membrane depends on process parameters such as field strength, number of pulses, length of pulses and temperature.

Most eukaryotic cells are very sensitive to PEF even under conditions that do not affect prokaryotes. The structure of meat and fish may be affected to the extent that PEF becomes unsuitable for these products8. PEF induced cell damage may be desirable for vegetables that need boiling for some time to become digestible, destroying nutrients in the process.

Owing to the fact that heat causes coagulation of proteins, preservation by PEF may be particularly interesting for eggs and liquid egg products and for meat and fish based products in which the cell structure is not important.

Nutrients

Although little research has been carried out in this area, available data confirms that PEF, under the conditions applied for microbial inactivation does not adversely affect nutrients such as vitamin C, riboflavin, thiamine, cholecalciferol and tocopherol7.

Thermal processing of fruit juices reduces the bioavailability of flavonoids. Because PEF permeates cell membranes, the availability of intracellular nutrients such as lycopenes and flavonoids to the human body might be improved by replacing thermal pasteurisation by PEF treatment. Also, while heat destroys desirable enzymes such as myrosinase, it is reasonable to assume that PEF leaves these enzymes intact7.

Product safety

Microbiology

PEF is capable of inactivating vegetative micro-organisms, including pathogens. PEF may not inactivate all relevant micro-organisms completely, but it should at least reduce the viable counts of pathogens sufficiently to render the product safe during the shelf life of the product under suitable storage conditions. Confirming data have been produced for species of Listeria, Salmonella, Escherichia (incl. E. coli O157:H7), Klebsiella, Pseudomonas, Staphylococcus and Candida.

Toxicology

Contrary to heat, PEF does not (or only slightly) denature proteins. Proteins present in PEF processed food products will therefore differ from heat treated products. They will not differ from the proteins in the raw materials. In consideration of replacing heat treatments with PEF, all (potential) effects of heat on product safety aspects must be taken into account. Proton NMR fingerprinting showed differences between the concentrations of a range of compounds in tomato purees, treated with either heat or PEF9. However, more products must be investigated and the results compared with those of untreated products. Such a comparison will make it possible to conclude whether or not the changes are substantial, which is important to ascertain whether there are reasons for concern. Based mainly on theoretical considerations and calculations, taking into account field strength, current, time, polarity and chemical composition of food products, the FDA decided that there is no objection to PEF treatment of food for preservation purposes10.

Processing aspects

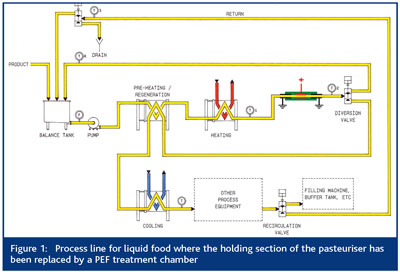

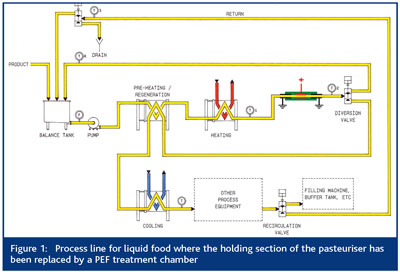

A process line for PEF treatment may be as shown in Figure 1. In this example the product to be treated is preheated to the optimum temperature for the product, e.g. 40°C; it then passes through the PEF chamber after which the product is cooled to the desired end temperature for further processing or packaging. The holding section of the heat exchanger has been replaced by the PEF chamber. In reality, more changes are needed: in the case of a thermal treatment, the process line downstream from the holding section of the heat exchanger is ‘pasteurised’ by the start-up liquid, usually water. In this way it can be assured that micro-organisms that may have contaminated the process line from that point will not re-contaminate the pasteurised product. To prevent contamination of the line downstream from the PEF chamber, start up must be carried out with a vegetative-microbe-free solution with the same conductivity as the product to be treated. Preferably an aqueous solution is used, so that it can be sterilised by filtration.

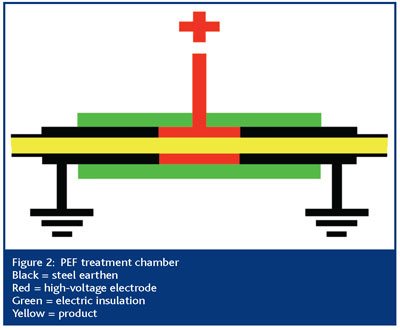

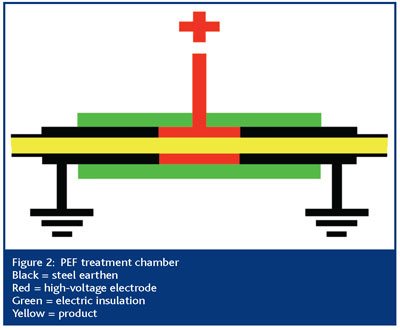

Figure 2 shows the cofield PEF chamber of Figure 1 in detail. The chamber is based on the design of the Ohio State University11. The chamber consists of two separate parts so that the piping system can be connected to earth on both sides of the assembly, eliminating electrical shock hazards. For liquids with a relatively high conductivity it may be advisable to use two of such assemblies in series, so that there are four chambers. The chambers can be connected electrically in such a way that the effect of Ohmic heating during the PEF treatment and its influence on the product conductivity is used to improve the efficiency of the process.

In a horizontal chamber warm liquid product moves up and cool product moves downwards. Warm product is more conductive and thus heats faster; the cooler product has a lower conductivity and thus heats more slowly. The temperature difference increases as does the movement of the product. The result is inhomogeneous treatment that may result in insufficient treatment of part of the product and thus adversely affect product shelf life and safety. This effect is avoided by placing the chamber in a vertical position7.

Although possible, cooling between chambers should be avoided: it is clumsy and increases costs. Cooling becomes necessary if the energy dissipation is too high, due to too high conductivity. Such a product may not be suitable for PEF.

Energy requirements

An effective PEF treatment would require 150 J/ml of product. With correct design, ensuring that all product receives the intended treatment, the energy requirement may even be lower.

Conclusion

For many products PEF may provide a serious alternative to pasteurisation by heat. Compared to heat treatment, PEF treated products taste more fresh and retain their colour and nutrients. Damage to the cells of animal products may make PEF unsuitable for meat or fish. In the case of vegetables, cell damage increases bioavailability of nutrients and therefore PEF may be desirable.

References

- Sale, A. J. H. & Hamilton,W. A. Effect of high electric fields on microorganisms I. Killing of bacteria and yeast. Biochimica et Biophysica Acta, 1967, 148, 781–788.

- Hamilton, W. A. & Sale,A. J. H. Effects of high electric fields on microorganisms: II. Killing of bacteria and yeasts. Biochimica et Biophysica Acta, 1967, 148,789–800.

- Sale, A. J. H. & Hamilton,W. A. Effect of high electric fields on microorganisms. III. Lysis of erythrocytes and protoplasts. Biochimica et Biophysica Acta, 1968, 163, 37–43.

- Martín-Belloso, O., Bendicho, S. & Elez-Martínez, P. Does high-intensity pulsed electric fields induce changes in enzymatic activity, protein confirmation, and vitamin and flavor stability? In Novel food processing technologies, Barbosa-Cánovas, G.V., Tapia, M.S. & Cano, M.P., eds.; Marcel Dekker/CRC Press, 2005, pp. 87-105.

- Wouters, P.C., Dutreux, N., Smelt, J.P.P.M. and Lelieveld, H.L.M., Effects of pulsed electric fields on inactivation kinetics of Listeria innocua. Appl. Environm. Microbiol. 1999, 65, 5364-5371.

- Van Loey, A., Verachtert, B. & Hendrickx, M., (2002). Effects of high electric field pulses on enzymes. Trends Food Sci Technol., 2002,12, 94-102.

- Lelieveld, H.L.M. PEF – A food industry’s view. In Novel food processing technologies, Barbosa-Cánovas, G.V., Tapia, M.S. & Cano, M.P., eds.; Marcel Dekker/CRC Press, 2005, pp. 145-156.

- Gudmundsson, M. and Hafsteinsson, H., Effect of electric field pulses on microstructure of muscle foods and roes. Trends Food Sci Technol. 2001, 12, 122-128.

- Lelieveld, H.L.M., Wouters, P.C. & Léon, A.L., Pulsed electric field treatment of food and product safety assurance. In Pulsed Electric Fields in Food Processing, G.V. Barbosa-Cánovas and Q.H. Zhang, eds.; Technomic Publ. Co., Lancaster, 2001, pp.259-264.

- Dunn, J. Pulsed electric field (CoolPure) cool pasteurization for milk, juices, and pumpable food. In Tecnologías avanzadas en esterilización y seguridad de alimentos y otros productos, M. Rodrigo, A. Martínez, S.M. Fiszman, C. Rodrigo and A. Mateu, eds.; CSIC, Burjasot, Valencia, 1995, pp. 293-296.

- Yin, Y., Zhang, Q.H. and Sastry, S.K. 1997. High voltage pulsed electric field treatment chambers for the preservation of liquid food products. United States Patent 5,690,978