Effects of milk processing on odour and taste

- Like

- Digg

- Del

- Tumblr

- VKontakte

- Buffer

- Love This

- Odnoklassniki

- Meneame

- Blogger

- Amazon

- Yahoo Mail

- Gmail

- AOL

- Newsvine

- HackerNews

- Evernote

- MySpace

- Mail.ru

- Viadeo

- Line

- Comments

- Yummly

- SMS

- Viber

- Telegram

- Subscribe

- Skype

- Facebook Messenger

- Kakao

- LiveJournal

- Yammer

- Edgar

- Fintel

- Mix

- Instapaper

- Copy Link

Posted: 9 March 2006 | Wolfgang Hoffmann, Federal Research Centre for Nutrition and Food, Location Kiel, Katja Borcherding, G.C. Hahn & Co., Lübeck, Matthias Denker, Marijana Parat-Wilhelms, Andrea Luger and Hans Steinhart, Department of Food Chemistry, University of Hamburg, Germany | No comments yet

The popularity of milky coffee beverages is based on its energising effect and special flavour. This is particularly true with younger consumers, who reject traditional beverages with evaporated milk or coffee cream, and prefer products with relatively high amounts of milk as it softens the bitter coffee taste effectively.

Numerous studies have been carried out on roasted coffee powder3-9, but not on the influence of milk processing and milk ingredients on odour and taste of white coffee beverages1,2. In the frame of a research project, milk products processed under defined conditions and analysed under physico-chemical aspects were added to a standardised, fresh coffee beverage. Some of the methods and results are presented in this article.

The popularity of milky coffee beverages is based on its energising effect and special flavour. This is particularly true with younger consumers, who reject traditional beverages with evaporated milk or coffee cream, and prefer products with relatively high amounts of milk as it softens the bitter coffee taste effectively. Numerous studies have been carried out on roasted coffee powder3-9, but not on the influence of milk processing and milk ingredients on odour and taste of white coffee beverages1,2. In the frame of a research project, milk products processed under defined conditions and analysed under physico-chemical aspects were added to a standardised, fresh coffee beverage. Some of the methods and results are presented in this article.

The popularity of milky coffee beverages is based on its energising effect and special flavour. This is particularly true with younger consumers, who reject traditional beverages with evaporated milk or coffee cream, and prefer products with relatively high amounts of milk as it softens the bitter coffee taste effectively.

Numerous studies have been carried out on roasted coffee powder3-9, but not on the influence of milk processing and milk ingredients on odour and taste of white coffee beverages1,2. In the frame of a research project, milk products processed under defined conditions and analysed under physico-chemical aspects were added to a standardised, fresh coffee beverage. Some of the methods and results are presented in this article.

Materials and methods

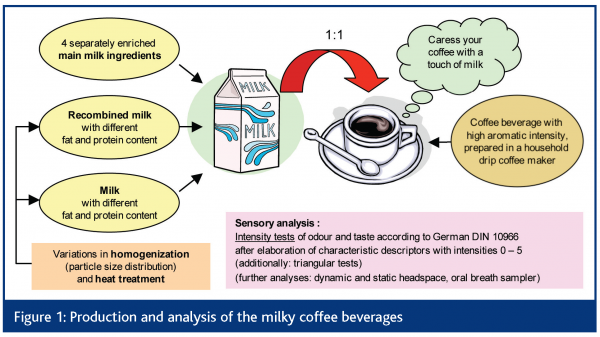

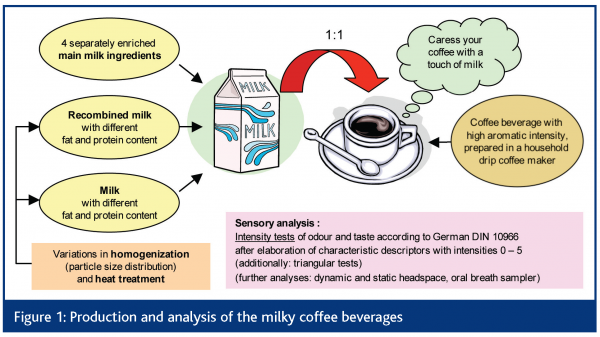

The coffee beverage was prepared with dark roasted Coffea Arabica beans from Kenya (supplied by Tchibo, Germany) and tap water in a household drip coffee maker. It was of high aromatic intensity and therefore well suited for high milk addition. Hereto, a sensory panel trained according to German DIN 10950 elaborated characteristic descriptors that featured an intensity scale from zero (no odour/taste) to five (dominant, very strong odour or taste). These descriptors were used in the following intensity tests according to German DIN 10966. For the tests, the freshly brewed coffee beverages were filled into paper cups with lids and mixed with the same amount of the milk products (Figure 1). The tasting temperature of the white coffee beverage was 30–35 °C and the pH value between 6.2 and 6.3.

In preliminary investigations the effects of the different main constituents of milk on the coffee beverage were analysed.

For this purpose, powders with high casein or whey protein content (min. 82 per cent) were manufactured from fresh raw milk by membrane filtration and subsequent freeze-drying10. The manufacture began by skimming raw milk by centrifugation. The subsequent microfiltration of the skimmed milk separates the whey proteins from the casein fraction and was carried out in a pilot plant (MFS-1, TetraPak, Germany) at 50 °C. A high wall shear stress along the membrane limited the undesirable fouling of the ceramic membrane with an average pore size of 0.1 µm (Membralox P19-40, SCT, France). An increase in the transmembrane pressure along the filter module was prevented by circulating the permeate co-current to the feed in such a way that it built a pressure profile parallel to it, thus creating a constant low transmembrane pressure. During the microfiltration the native globular whey proteins could pass through the membrane, whereas the casein fraction remained mostly in the retentate. Small casein micelles could pass into the permeate, but transferred only a small protein quantity. The retentate volume (quarter of the skim milk volume) was diluted with distilled water (triple volume) and microfiltered again. This washing step, termed diafiltration, was repeated three times in order to eliminate the remaining whey proteins, lactose and salts. The nearly-casein free first permeate, known as ‘ideal whey’, was ultrafiltered to concentrate the whey proteins. The membrane used (Koch Membrane Systems, UK) had a cut-off value of 10 kD (D = Dalton), which means that all molecules above a molecular weight of 10,000 are retained. Three further diafiltrations reduced lactose and milk salts. Subsequent freeze-drying transformed the two watery protein concentrates into preserved products (water ca. 1 %) without loss of dry matter and without denaturing of the heat-labile whey proteins.

Emulsified milk fat was obtained by repeated washing of cream (35 % fat) with protein-free ultrafiltration permeate in a centrifuge. The washing steps reduced the protein content from approximately 2.3 to 0.3 %. Lactose powder was supplied by a dairy.

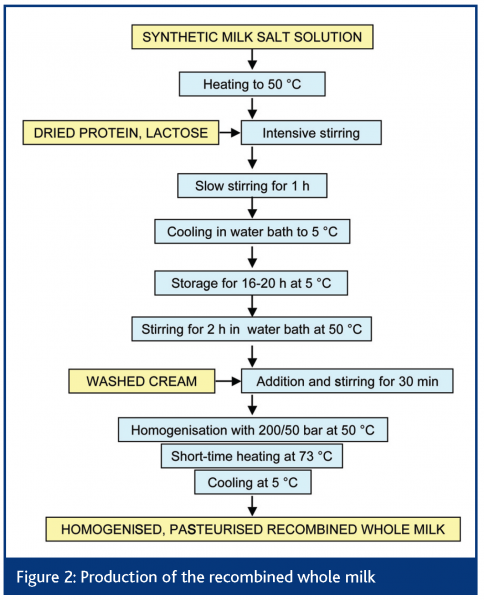

These four enriched milk constituents (casein, whey protein, emulsified milk fat and lactose) were added to a synthetic milk salt solution by Jenness and Koops11. The resulting ‘recombined milk’ (manufacture see figure 2) should correspond to an average pasteurised consumer whole milk (3.5% fat, 2.8% casein, 0.7% whey protein, 4.7% lactose). This should be valid not only for the composition but also for the thermal treatment, as well as for the distribution of the fat globules by appropriate homogenisation. Thermal treatment and homogenisation were performed in pilot plants (APV Invensys, Germany).

Results and discussion

Effects of recombined whole milk

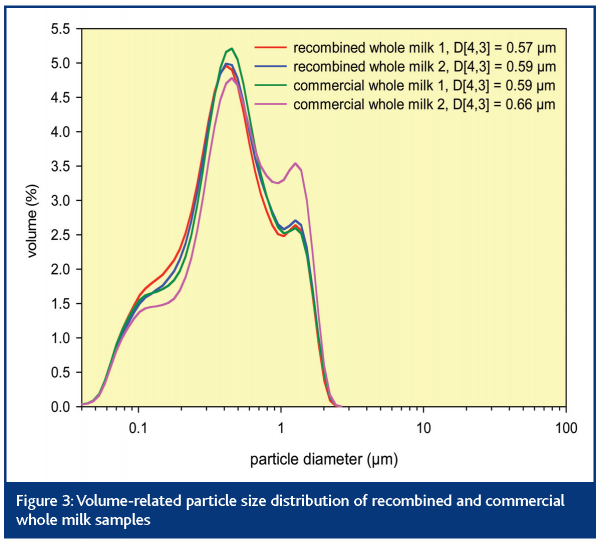

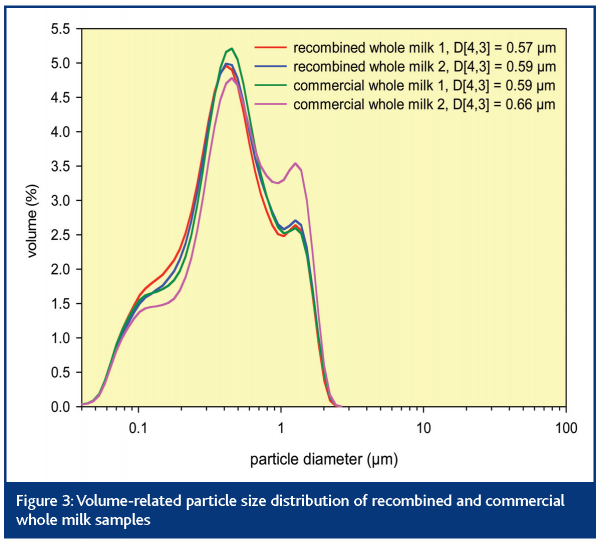

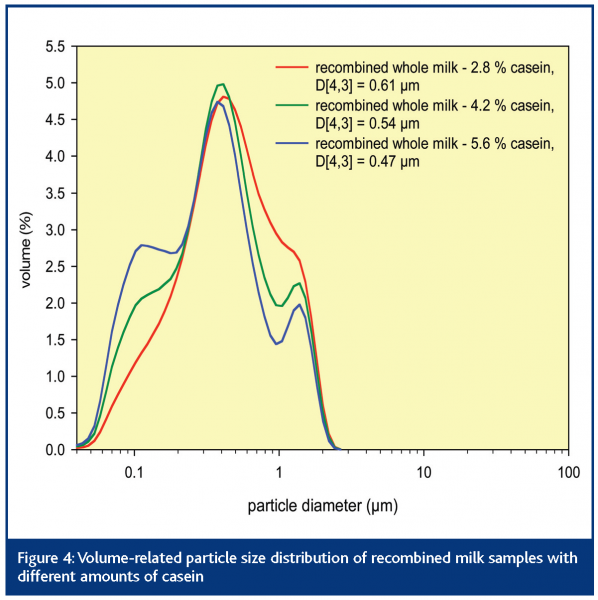

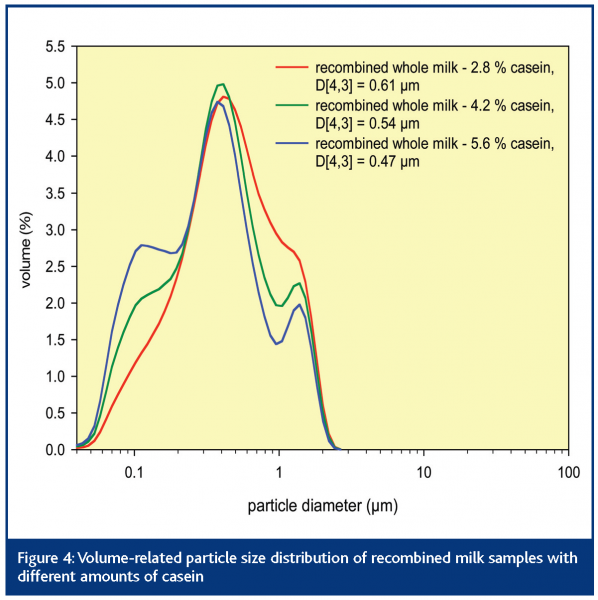

After the influence of the enriched milk constituents on odour and taste of the coffee beverage had been determined, the recombined milk was used to test the cumulative effect of the reunited ingredients. Compared with commercial pasteurised and homogenised whole milk samples, the recombined milk exhibited the typical colour (use of yellowish edible grade lactose) and showed a relatively flat, nearly neutral odour and taste. The particle size distribution, which was measured with a laser diffraction spectrophotometer, matched well (Figure 3). The volume-related mean diameter D4,3 was approx. 0.6 µm and represented largely the fat globule size. Increasing the casein amount to 4.2 or 5.6% resulted in bimodal distribution curves with a second maximum (above 0.1 µm) – probably near the mean diameter of the casein micelles. D4,3 was accordingly reduced to 0.54 and 0.47 µm (Figure 4).

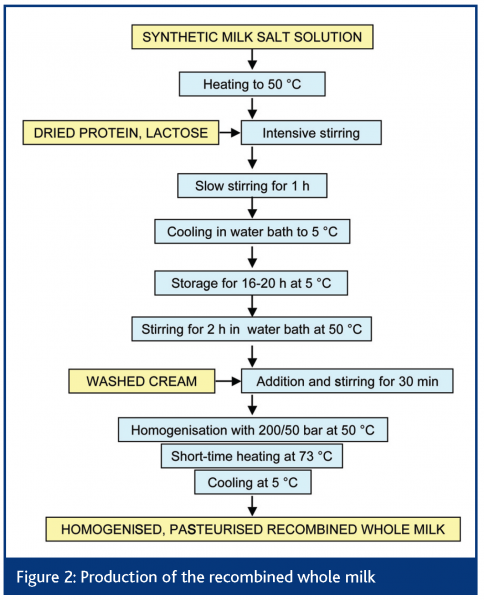

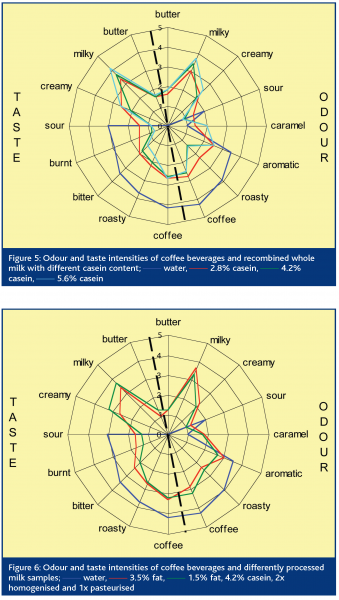

When the commercial whole milk samples or the recombined milk were added to the hot coffee beverage, the sensory intensity tests revealed only very small differences (milky odour). Obviously, the separation and recombination of the milk ingredients were not detrimental to the sensory acceptance. The results of the intensity tests for the recombined milk with 2.8% casein and for the modified recombined milks with 4.2 and 5.6% casein are shown in Figure 5. Compared to an addition of pure water, coffee descriptors reacted to the addition of the recombinate with a decreased intensity, whereas milk descriptors reacted according to the added quantity. With increasing amounts of casein, the intensity of the odour descriptors sour and roasty declined significantly. This is also valid for the taste descriptors burnt and sour, whereas the milky odour and taste increased. The sour-reducing effect of casein was already noticed in the odour and taste of the coffee beverage with casein concentrate. With the increase in the amount of casein from 4.2 to 5.6%, the intensity of some descriptors changed – although not significantly.

Effect of fat distribution and casein in low-fat milk on coffee beverages

The effects of a reduced fat content were analysed in products from fresh raw milk. The low-fat milk with 1.5% fat should always undergo a more intense homogenisation in order to achieve a whole fat globule surface and a creaminess comparable to those of whole milk. Pasteurised (73 °C, 20 s) whole milk, homogenised at 200/50 bar, served as control. This sample showed a volume-related mean fat globule diameter D4,3 of 0.47 µm. Relating the average value to the fat globule surface resulted in D3,2 values of 0.30 µm. The low-fat milk, which was pasteurised after the first and second homogenisation of each 250/50 bar, had a D4,3 value of 0.23 µm and a D3,2 value of 0.14 µm.

From the D3,2 values (in µm) the specific volume-related surface SV (in m2/ml fat) could be calculated12: SV = 6 / D[3,2]. Using this formula, the total fat globule surface of the whole milk (D[3,2] = 0.30 µm) was approximately 750 m2/kg milk. For the twice-homogenised and twice-pasteurised low-fat milk only a slightly smaller surface of 690 m2/kg milk was calculated. However, it had to be considered that with the low fat content and the very small fat globules the casein micelles played an increasingly important role in the calculation. The bimodal distribution curve showed that a demarcation of casein and fat particles could be set at 0.195 µm, which seemed realistic and resulted in an increased D[3,2] of 0.32 µm and a smaller calculated surface of approx. 300 m2/kg milk. According to a rough estimation of Walstra13, the fat globule surface is covered by approx. 10 mg protein/m2 fat. This means that the whole milk produced required approx. 0.7–0.8% protein and the special low-fat milk only approx. 0.3% for the emulsification of the fat globules.

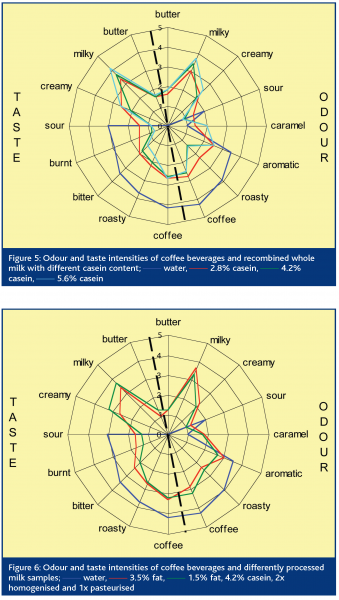

Triangular tests showed that it was possible to detect the effects of adding twice-homogenised low-fat milk samples and whole milk to the coffee beverage. Hence, an intensity test was performed in order to identify the responsible descriptors. The low-fat milk did not differ, or only negligibly, from the whole milk for the entire odour and the milk-typical taste descriptors. Nevertheless, the coffee-taste descriptors were generally better perceived after the addition of the low-fat milk.

An increased casein content of 4.2% in a low-fat milk, that was twice-homogenised and once pasteurised, resulted in a more creamy and milky taste compared to the whole milk, whereas the sour, burnt and bitter taste descriptors were now less noticed (Figure 6). The addition of casein increased the viscosity from 2.09 to 2.50 mPa s, thus explaining the perception of the creamy characteristic. However, the odour is not affected by alterations of viscosity. In previous investigations it had already been perceived that the addition of casein reduced the sour taste.

Conclusions

The results show that pasteurised consumer milk with a reduced fat content of 3.5 to 1.5% and more finely distributed fat globules mainly affects the coffee taste of a white coffee beverage. The descriptors for the odour and milky taste were almost invariably noticed. The creamy and milky taste perception of such low-fat milk in a coffee beverage could be enhanced by the addition of casein. Simultaneously, a decrease in the intensity of the coffee taste was achieved. The heat treatment of the consumer milk (pasteurisation, UHT treatment and sterilisation) was – under the assigned conditions – less important for the odour and taste than expected (results not presented). In summary, it may be said that defined milk processing may lead to a customer-oriented product development of white coffee beverages with adjusted sensory properties.

Acknowledgements

This research project was supported by the Federal Ministry of Economics and Labour, the AiF and the Research Association of the German Food Industry (FEI). AiF project no. 12970 N.

References

- Bücking, M., Steinhart, H. (2002). Headspace GC and sensory analysis characterization of the influence of different milk additives on the flavor release of coffee beverages. J. Agric. Food Chem. 50(6), 1529-1534.

- Grieß, M., Büttner, A. (2003). Untersuchungen zur retronasalen Wahrnehmung von Espresso-Aroma. In Deutsche Forschungsanstalt für Lebensmittelchemie, München, 83-98.

- Czerny, M., Mayer, F., Grosch, W. (1999). Sensory study on the character impact odorants of roasted arabica coffee. J. Agric. Food Chem., 47, 695-699.

- Grosch, W. (1995). Instrumental and sensory analysis of coffee volatiles. 16th Int. Colloquium on Coffee Science, Kyoto, ASIC, 147-156.

- Grosch, W. (1999). Key odorants of roasted coffee; evaluation, release, formation. 18th Int. Colloquium on Coffee Science, Helsinki, ASIC, 17-26.

- Maier, H. G. (1999). Fortschritte auf den Gebieten der Chemie, der Analytik und der Pharmakologie des Kaffees. Deutsche Lebensmittel-Rundschau, 95, 487-495.

- Schlich, P. (1998). What are the sensory differences among coffee? Food Quality and Preference, 9, 103-106.

- Semmelroch, P., Grosch, W. (1996). Studies on character impact odorants of coffee brews. J. Agric. Food Chem., 44, 537-543.

- Shibamoto, T. (1991). An overview of coffee aroma and flavor chemistry. 14th Int. Colloquium on Coffee Science, San Francisco, ASIC, 107-116.

- Sachdeva, S., Buchheim, W. (1997). Separation of native casein and whey proteins during crossflow microfiltration of skim milk. Austral. J. Dairy Technology, 52, 92-97.

- Jenness, R., Koops, J. (1962). Preparation and properties of a salt solution which simulates milk ultrafiltrate. Netherl. Milk Dairy J., 16 (3), 153-164.

- Buchheim, W., Falk, G., Hinz, A. (1986). Ultrastructural aspects and physico-chemical properties of UHT-treated coffee cream. Food Microstructure, 5, 181-192.

- Walstra, P., Geurts, T.J., Noomen, A., Jellema, A., Boekel, M.A.J.S. van (1999). Dairy Technology. Marcel Dekker, New York.