Bacterial transfer during slicing of delicatessen meats

Posted: 4 September 2007 | Elliot T. Ryser and Ewen C.D. Todd, Michigan State University; and Keith L. Vorst, California Polytechnic Institute | No comments yet

Delicatessen slicers have long been recognised as a source for the spread of both spoilage and pathogenic microorganisms in the retail food environment. However, based on the higher prevalence of Listeria monocytogenes – a serious bacterial foodborne pathogen of major public health significance, in delicatessen meats sliced at retail and several major outbreaks of listeriosis traced to deli meats, delicatessen slicers are now well recognised as an important vehicle for cross-contamination. This article describes a series of factors that affect the numbers of Listeria cells transferred during retail slicing of deli meats and some means of minimising the risk of transfer.

Delicatessen slicers have long been recognised as a source for the spread of both spoilage and pathogenic microorganisms in the retail food environment. However, based on the higher prevalence of Listeria monocytogenes – a serious bacterial foodborne pathogen of major public health significance, in delicatessen meats sliced at retail and several major outbreaks of listeriosis traced to deli meats, delicatessen slicers are now well recognised as an important vehicle for cross-contamination. This article describes a series of factors that affect the numbers of Listeria cells transferred during retail slicing of deli meats and some means of minimising the risk of transfer.

Delicatessen slicers have long been recognised as a source for the spread of both spoilage and pathogenic microorganisms in the retail food environment. However, based on the higher prevalence of Listeria monocytogenes – a serious bacterial foodborne pathogen of major public health significance, in delicatessen meats sliced at retail and several major outbreaks of listeriosis traced to deli meats, delicatessen slicers are now well recognised as an important vehicle for cross-contamination. This article describes a series of factors that affect the numbers of Listeria cells transferred during retail slicing of deli meats and some means of minimising the risk of transfer.

Listeria monocytogenes is the leading microbiological cause of Class I recalls of cooked or ready-to-eat meat products in the United States with contamination of these products usually occurring after processing but before packaging. In one large survey by Gombas et al., (2003), 82 of 9,199 (0.89 per cent) luncheon meat samples yielded L. monocytogenes with 75.6 per cent of these positive samples containing less than 1 CFU/g. Most importantly, luncheon meats that were sliced at retail were 6.8 times more likely to contain L. monocytogenes than those sliced before being packaged by the manufacturer. This higher prevalence of L. monocytogenes in delicatessen meat sliced at retail clearly points to the delicatessen slicer as an important vehicle for cross-contamination.

Transfer of pathogens through slicing machines was recognised over 40 years ago. However, until recently, delicatessen slicers and other food processing/handling equipment (e.g., sausage peelers, dicers, conveyor belts) were not always designed in a way that facilitated effective cleaning and sanitising. Before coming in contact with the slicer surface, L. monocytogenes may be exposed to refrigeration temperatures, low pH (fermented meats and cheeses), limited available water, and various chemical sanitisers. In order for cross-contamination to occur, L. monocytogenes must first come in contact with the slicer and survive for a period of time between slicing of various products. While on the slicer surface, L. monocytogenes exposure to desiccation and sanitisers is also likely. These stresses have been shown to alter the sensitivity of L. monocytogenes to other subsequent stresses, sometimes making this organism more difficult to eradicate from the environment. Not surprisingly, these environmentally persistent strains also possess greater capability to adhere to food contact surfaces (Lunden et al., 2003) and form biofilms, with attachment of L. monocytogenes to stainless steel occurring in as little as 20 minutes (Mafu et al., 1991).

Adherence and subsequent release of any microorganisms from a blade during slicing is impacted by a multitude of factors that relate to the particular bacterial strain as well as slicer design, type/condition of the blade (e.g., stainless steel grade, blade sharpness, extent of wear and corrosion), cutting force and type/composition of the product being sliced (e.g., moisture and fat content), a few of which will now be described in greater detail.

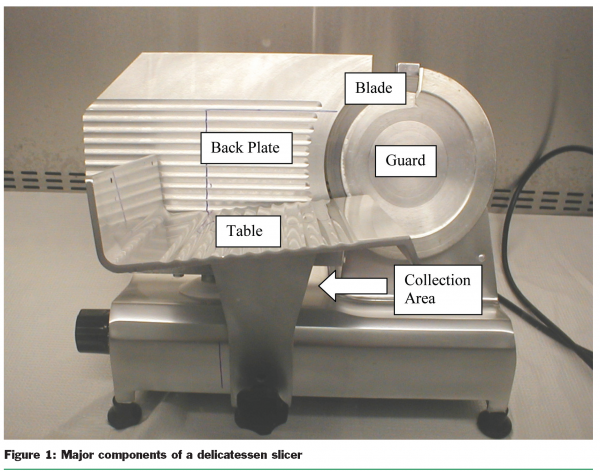

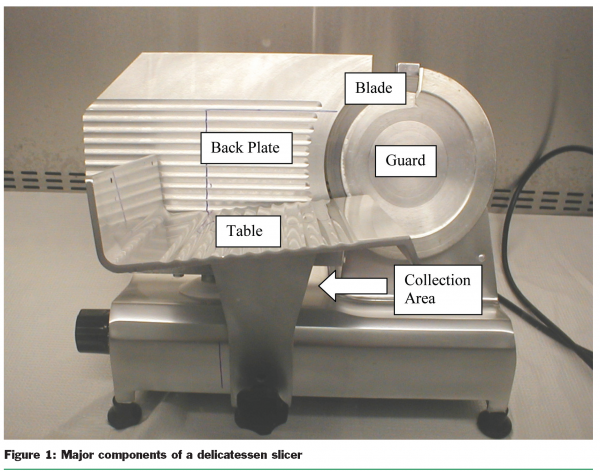

Product contact areas on delicatessen slicers

The current design of most delicatessen slicers includes five primary food contact surfaces – (1) table (surface on which the product rests during slicing), (2) backplate (surface to which the cut surface of the product is directly exposed during slicing), (3) blade guard, (4) blade and (5) collection area for the sliced product (Figure 1). However, adequate cleaning and sanitising of delicatessen slicers remains a formidable challenge due to the presence of many difficult-to-clean areas where meat residues can collect to form biofilms. Areas of particular concern include the blade and guard as well as the countertop that can potentially become contaminated from the generation of aerosolised meat particulates during slicing.

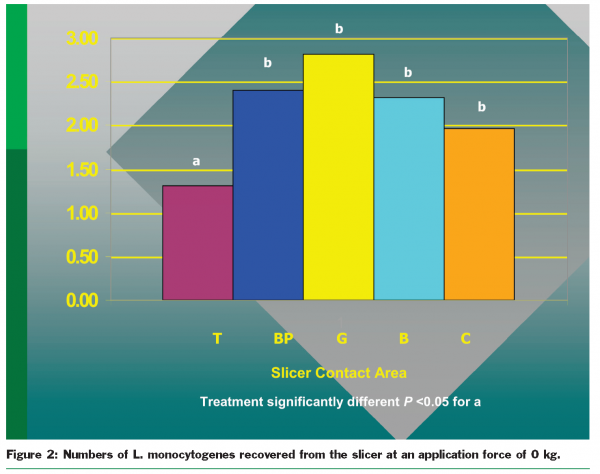

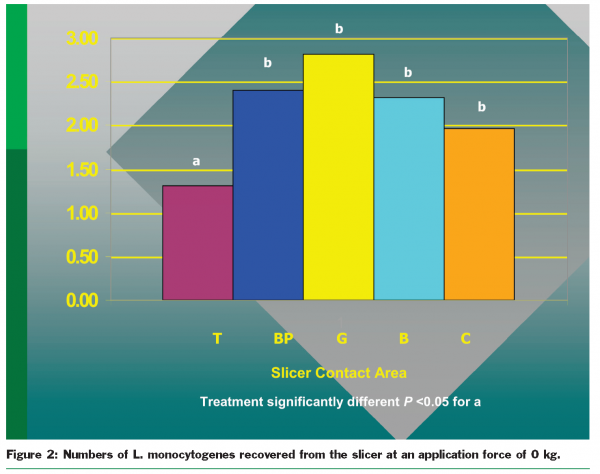

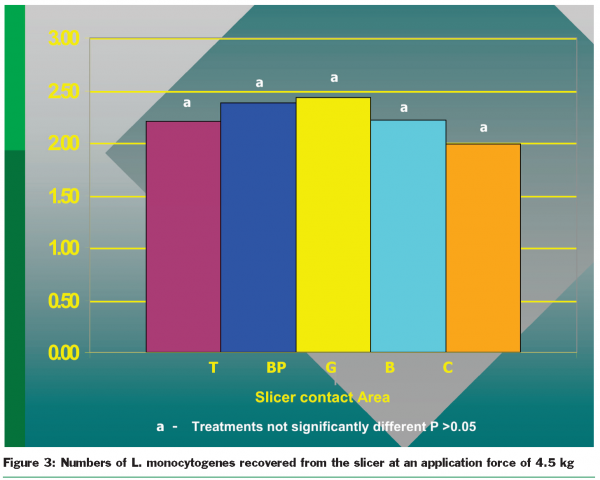

Application force

When slicing any given product, a force is applied and transmitted from the product to the backplate during slicing. This application force is one of several factors that have been shown to impact bacterial transfer. When Vorst et al. (2006a) sliced L. monocytogenes-inoculated roast turkey breast without applying any additional force to the product during slicing, significantly fewer Listeria cells were transferred to the table compared to the four other food contact surfaces of the slicer (Figure 2). However, all five areas of the slicer became uniformly contaminated when the application force was increased to 4.5kg, indicating greater and more even spread of Listeria during slicing (Figure 3).

Product characteristics

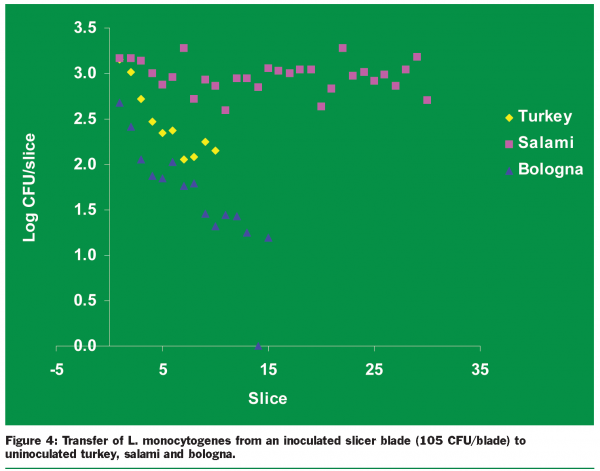

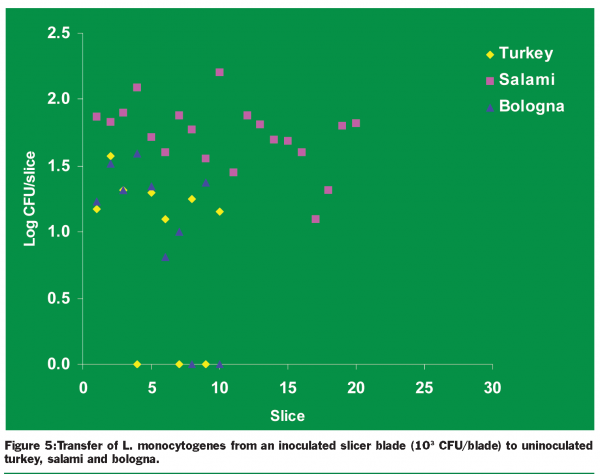

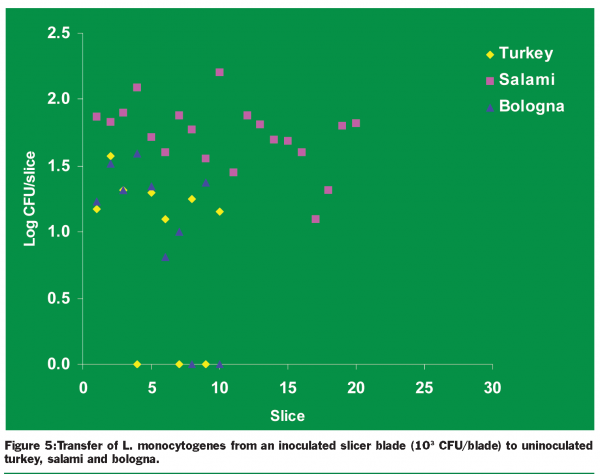

Another major factor influencing bacterial transfer during slicing of deli meats presumably relates to product composition, most importantly fat and moisture content, and is also likely influenced by product temperature. In a recent report by Vorst et al. (2006a), three different deli meats were chosen for slicing based on differences in fat and moisture content – roast turkey breast (<1 per cent fat, 78 per cent moisture), bologna (27 per cent fat, 60 per cent moisture) and salami (36 per cent fat, 43 per cent moisture). After repeated slicing, visual differences in the amount of product residue could be seen on the blade with slicing of salami producing a pronounced layer of fat on the blade compared to turkey and bologna, both of which produced far less obvious residues. Based on these observations, one can logically predict that slicing of low moisture/high fat products will result in greater bacterial transfer compared to high moisture/low products where the “washing/cleaning” effect would be expected to be greater during slicing as also reported by Lin et al. (2006).

Listeria transfer during slicing of deli meats

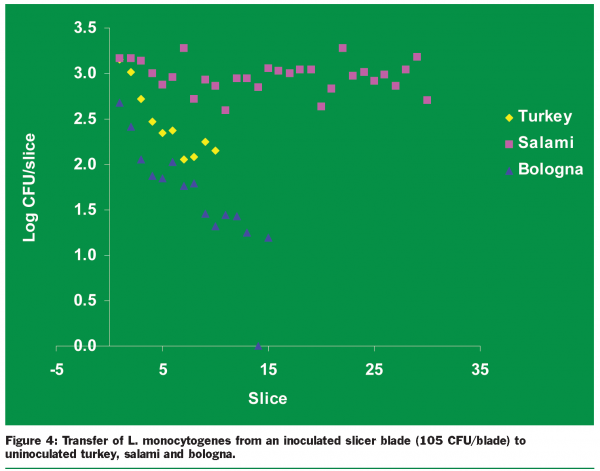

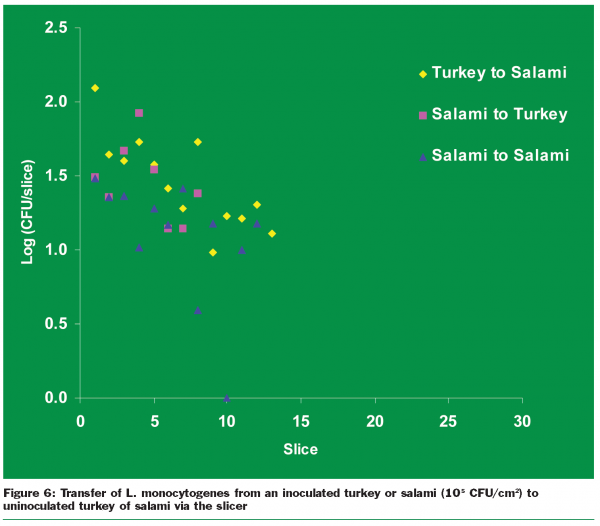

In one of only a few published studies addressing bacterial transfer during slicing of deli meats, Vorst et al. (2006a) used a commercial delicatessen slicer to quantify the numbers of Listeria cells transferred for two different slicing scenarios: (a) an inoculated slicer blade (~108, 105, 103 CFU/blade) to 30 slices of uninoculated delicatessen turkey, bologna, and salami, and (b) a surface-inoculated product (108, 105, 103 CFU/cm2) to 30 slices of uninoculated product with this artificially contaminated slicer serving as the vector for subsequent transfer.

Blade to product transfer

After slicing roast turkey, bologna and salami with a slicer blade that was preciously inoculated 105 L. monocytogenes CFU/blade, the initial slice (~20 g) from each of the three products contained 102 – 103 CFU/slice, indicating that no more than one per cent of the original inoculum on the blade was transferred to the first slice. However, beyond the first slice, major differences in transfer were seen based on product type (Figure 4). In the case of salami, L. monocytogenes was quantifiable out to at least 30 slices, whereas the pathogen was no longer detectable by direct plating after 15 slices of bologna and 10 slices of turkey. At the lowest inoculation level of 103 CFU/blade (Figure 4 – Keith), a similar trend in transfer was seen with Listeria quantifiable in the first 20 slices of salami by direct plating compared to 10 slices of turkey and 9 slices of bologna. However, in both cases occasional positive enrichments beyond the last slice in which Listeria could be quantified by direct plating indicates that even these later slices may pose a risk to susceptible individuals if the pathogen can grow in such a product during extended storage.

Product to blade to product transfer

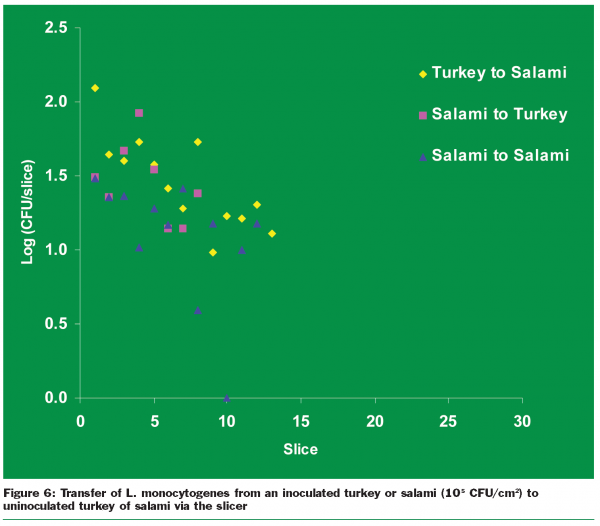

In the second of these two scenarios, the same deli meats were surface inoculated and then used to contaminate the slicer after which uninoculated deli meats of the same or different type were sliced. At the highest inoculum level of 108 CFU/cm2, L. monocytogenes populations decreased from ~107 to 103 CFU/slice when slicing of inoculated turkey was followed by uninoculated turkey. However, the pathogen was no longer quantifiable when uninoculated turkey followed slicing of surface-inoculated turkey containing 105 CFU/cm2. Using product that was surface-inoculated at 105 CFU/cm2, Listeria was detectable by direct plating for the following slicing scenarios: inoculated turkey followed by uninoculated salami (13 slices), inoculated salami followed by uninoculated turkey (10 slices), and inoculated salami followed by uninoculated salami (12 slices) (Figure 6). Whereas slicing inoculated salami followed by uninoculated salami consistently yielded positive enrichments out to 30 slices, the same was not true for inoculated turkey followed by uninoculated salami or inoculated salami followed by uninoculated turkey with enrichments positive out to only 17 and 10 slices, respectively. Consequently, the order in which products are sliced will partially determine the extent of Listeria transfer.

Condition of the slicer blade

Stainless steel blades are prone to considerable wear over time as well as scratching, pitting and corrosion from continued exposure to chlorine- and acid-based sanitisers. Consequently, such scratches and pits that inevitably develop on slicer blades after several years of use as described by Vorst et al (2006a) become preferential harborage sites for bacterial attachment and subsequent biofilm formation that can also impact the rate of bacterial transfer. The extent of blade wear over time as measured by surface roughness is also related to the grade of stainless steel (e.g., grade 304, 316) and surface finish (e.g., electropolished, 2B, sandblasted). Therefore, since grade 316 stainless is less prone to surface abrasions than grade 304, the former would be expected to be less conducive to bacterial transfer (Vorst et al. 2006b).

Conclusions

Based on recommended guidelines detailed in the United States 2005 Food Code, equipment used in food preparation, including delicatessen slicers, must be cleaned every 24 hours if held at less than 50C or every 10 hours when held at 10-12.80C with cleanliness being defined as “clean to sight and touch”. However, these recommendations clearly allow ample time for bacterial attachment, growth, and subsequent transfer to previously uncontaminated deli meats between cleanings. Earlier delicatessen slicers contained numerous difficult-to-clean growth niches where soiling was not always visually apparent. However, now that delicatessen slicers have been recognised as the major vehicle for cross-contamination of deli meats, considerable progress has been made in re-designing slicers for ease of cleaning and sanitising. Similar attention is now being given to the impact of biofilm formation on Listeria transfer from delicatessen slicers and the rate of Listeria transfer from different types of conveyor belts during the manufacture of various deli meats with these results to be reported elsewhere. However, careful attention to cleaning and sanitising – particularly after slicing high-fat deli meats and cheeses, as well as continued routine maintenance should go a long way in minimising the risks associated with Listeria-contamination of these products at retail.

References

Food and Drug Administration Center for Food Safety and Applied Nutrition. 2005 Food Code. Available at: www.cfsan.fda.gov/~dms/fc05-toc.html, Accessed May 1, 2007.

Gombas D.E., Chen Y., Clavero R.S., and Scott V.N. (2003). Survey of Listeria monocytogenes in ready-to-eat foods. Journal of Food Protection, 66, 559-569

Lin C., Takeuchi K., Zhang L., Dohm C.B., Meyer J.D., Hall P.A., and Doyle M.P. (2006).

Cross-contamination between processing equipment and deli meats by Listeria monocytogenes. Journal of Food Protection, 69, 71 – 79

Lunden J.M., Autio T.J., and Korkeala H.J. (2003). Transfer of persistent Listeria monocytogenes contamination between food-processing plants associated with a dicing machine. Journal of Food Protection, 65, 1129-1133

Mafu A.A., Roy D., Goulet J., and Savoie L. (1991). Characterization of physiochemical forces involved in adhesion of Listeria monocytogenes to surfaces. Applied and Environmental Microbiology, 57, 1969-1973

Vorst K.L., Todd E.C.D., and Ryser E.T. (2006a). Transfer of Listeria monocytogenes during mechanical slicing of turkey breast, bologna, and salami. Journal of Food Protection, 69, 619-626.

Vorst K.L., Todd E.C.D., and Ryser E.T. (2006b). Transfer of Listeria monocytogenes during slicing of turkey breast, bologna, and salami using kitchen knives. Journal of Food Protection, 69, 2939-2946.