Developments in food refrigeration

Posted: 23 May 2007 | Judith Evans, Senior Research Project Manager, FRPERC (Food Refrigeration and Process Engineering Research Centre), University of Bristol | No comments yet

Refrigeration is a vital part of modern food production. Without a means to cool and keep food cold, the quality and safety of food would be compromised and the sophisticated cold chain we are used to would not be possible. The whole food chain is underpinned by refrigeration from primary food processing through storage, transport, retail and domestic refrigeration in consumers’ homes.

Refrigeration is a vital part of modern food production. Without a means to cool and keep food cold, the quality and safety of food would be compromised and the sophisticated cold chain we are used to would not be possible. The whole food chain is underpinned by refrigeration from primary food processing through storage, transport, retail and domestic refrigeration in consumers’ homes.

Refrigeration is a vital part of modern food production. Without a means to cool and keep food cold, the quality and safety of food would be compromised and the sophisticated cold chain we are used to would not be possible. The whole food chain is underpinned by refrigeration from primary food processing through storage, transport, retail and domestic refrigeration in consumers’ homes.

Refrigerants

Refrigeration systems using a working fluid or ‘refrigerant’ were invented in the early 1800’s. These early systems used air, carbon-dioxide, sulphur dioxide or ammonia as the refrigerating fluid. Such systems were superseded in the 1930’s by CFCs (Chlorofluorocarbons) that quickly became the dominant refrigerants as they were then considered to be efficient, cheap, non-flammable and non-toxic.

In the 1970s it was realised that CFCs were responsible for damaging the ozone layer and in 1989 the Montreal Protocol agreed a phase out of CFCs. This lead to the development of HCFCs (Hydrochlorofluorocarbons) and HFCs (Hydrofluorocarbons) as alternative refrigerants. Although these chemicals had low ozone depletion potential they still had high greenhouse warming potential. Their emissions are now being monitored through legislation such as the F-gas (fluorinated gasses) regulations.

This has resulted in interest in new refrigerants and new refrigeration technologies. Many of these refrigerants are actually ‘old’ refrigerants that are now more able to compete due to improvements in equipment. Ammonia, one of the earliest refrigerants has been more widely used. Although thermodynamically a very efficient refrigerant, it was often not selected due to concerns over safety. Recent work at TNO (MINIREF, 2005) has been concentrating on overcoming this issue by developing systems where the charge of refrigerant is minimised by using compact equipment such as microbore heat exchangers. By the use of such components a reduction of up to 95 per cent of the charge is hoped to be achieved.

Carbon-dioxide, can now be operated efficiently using modern equipment capable of withstanding its high operating pressures.

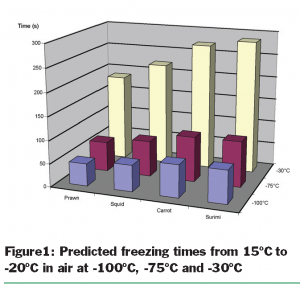

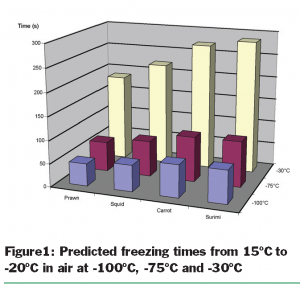

Air, one of the earliest refrigerants, has potential to operate at extremely low temperatures that are comparable to cryogens and to also deliver efficient heating for food. Using modern high speed, high efficiency turbo machinery that is compact and extremely reliable air cycle has the potential to rapidly freeze food and has many advantages in terms of food quality and reduced freezer ‘footprint’. For small food items such as carrots, prawns, or squid it is predicted that freezing time to –20°C in an air cycle fluidised bed freezer operating at –100°C would be four times faster than conventional freezing in air at –30°C (Evans, Gigiel and Brown, 2005) (Figure 1).

Other refrigerants such as hydrocarbons have also been successful.

Energy and efficiency

Refrigeration makes up a large proportion of the energy used in food manufacturing (Swain, 2006) and there is huge potential to optimise refrigeration systems.

Experts estimate that a reduction in energy of 20 per cent could be achieved on most refrigeration systems. Energy consumption can be reduced by optimising the heat loads on the plant and/or by operating refrigeration equipment more efficiently.

The majority of cooling systems for larger solid products are limited by conduction within the product and this can only be overcome by using alternative technologies such as heat pipes or by vascular chilling where a cold fluid is passed through the vascular system of a carcass after slaughter. Heat can also be extracted more efficiently from solid products by two stage cooling, localised environmental control (Burfoot et al, 2004), spray, immersion or vacuum cooling (Brown, 1997). High humidity storage and/or cooling are also advantageous for unwrapped products where weight loss is an issue. The use of ice banks for chilling, storage or fogging systems in retail display cabinets have been used to considerably reduce weight loss from foods (Brown, Corry and James, 2004).

Recently, interest has developed in deep chilling or superchilling. Deep chilling offers several potential advantages, principally the ability to extend food storage life from days to weeks. The presence of ice crystals in deep chilled products could help to maintain acceptable temperatures throughout the chill chain.

Recent developments in EC (Electronically Commutated) fans, electronic expansion valves and controls have also provided energy savings. Considerable energy savings are possible by optimising defrosts. The use of passive or ‘off-cycle’ defrosts have become the preferred method to defrost chilled retail display cabinets and chill rooms. In frozen cabinets and rooms, off cycle defrosts are not possible as the evaporator temperature never rises above 0°C. However, large amounts of energy are wasted during the electrical defrost process. This has been estimated as being as high as 85 per cent of the defrost energy in frozen retail cabinets. Defrosting the evaporator only when necessary can therefore save considerable amounts of energy. Recently, work has shown that thin, electrically-conductive films applied to surfaces and heated with milliseconds-long pulses of electricity can make ice melt from surfaces (http://engineering.dartmouth.edu/thayer/research/ice-engg.html). If this technology can be economically applied to evaporators it has potential for low energy and efficient defrosting.

Using modern insulating materials and protection can also reduce heat loads across insulation and through doors. With thermal conductivities up to five times lower than typical polyurethane panels, vacuum insulation panels (VIPs) offer enhanced thermal resistance for the same or even reduced thickness. Once production costs are reduced they have potential in many sectors of the food industry. Decreasing the area available for air exchange will reduce heat gain through doors. This is commonly achieved by use of strip or air curtains that can have varying effectiveness to air movement of up to 0.85-0.9. However, air curtains must be correctly fitted to achieve high effectiveness and strip curtains well maintained (Foster et al, 2003). The use of automatic doors, rapid roll doors and doors with air locks all reduce door opening times and therefore heat loads. If air locks are dehumidified this will reduce the latent load on the room further reducing the heat load and also the energy required to defrost any of the moisture frozen onto the evaporator.

Future refrigeration technologies

Other long-term options have also emerged over the last 10-15 years. Several novel technologies have potential as chilling or freezing technologies of the future. Of these, acoustic/stirling and magnetic refrigeration have undergone developments in the USA, Europe and the UK. Work is just beginning to commercialise small (domestic/small commercial) acoustic/stirling systems at Pennsylvania State University and small (domestic) magnetic refrigerators at Ames Laboratory in the United States and Camfridge in Cambridge (UK) (Wilson et al, 2007). Other technologies such as thermionic and magnetic resonance freezing are still only small scale and are only likely to be suitable for commercial chilling or freezing in the long-term perspective.

The downside of many of these new technologies is initial cost and availability. Currently many technologies are not fully developed. A common dilemma is the assessment of initial cost versus lifetime costs. With the recent increases in energy costs this has placed a greater emphasis on lifetime running costs of equipment and this has begun to make alternative technologies with higher initial costs more attractive.

References

Brown, T. Processes for primary chilling of pork. Meat Refrigeration – Why and How? EU Concerted Action Programme: CT94 1881, University of Bristol 1997.

Brown, T, Corry, J E L and James, S J. Humidification of chilled fruit and vegetables on retail display using ultrasonic fogging system pith water/air ozonation. International Journal of Refrigeration, 27, 862-868, 2004.

Burfoot, D, Reavell, S, Wilkinson, D and Duke, N. Localised air delivery to reduce energy use in the food industry. Journal of Food Engineering 62 (2004) 23–28.

Christensen, K G and Chun, S. (2004). The world’s first McDonald’s restaurant using natural refrigerants. 6th IIR Gustav Lorentzen Natural Working Fluids Conference. Current applications and opportunities, 29th August to 1st September 2004, Glasgow, UK

Evans, J A, Gigiel, A J and Brown, T (2005). Fast freezing using air cycle technologies EuroFreeze 2005, Individual Quick Freezing of Foods, Sofia, Bulgaria, January 2005.

Foster, A.M., Swain, M.J., Barrett, R. and James, S.J. Experimental verification of analytical and CFD predictions of infiltration through cold store entrances. International Journal of Refrigeration: 26: 8: 918-925, 2003. http://engineering.dartmouth.edu/thayer/research/ice-engg.html

Ketteringham, L and James, S. The use of high thermal conductivity inserts to improve the cooling of cooked foods. J Fd Eng, 45 (2000), 49-53.

Magnussen, O M, Johansen, S, Nordtvedt, T S, Hardarson, V, Haugland, A and Hemmingsten, A K T. Advances in superchilling. New Food, Issue 1, 2007, 38-41.

MINIREF. TNO Refrigeration and Heating Technology, 2005.

Night Wind. TNO. EU – FP6 – ENERGY Contract Number 20045

Pearson, S. Refrigerating systems using low pressure receivers. Proc. Inst. R. 1982-83, 62-73.

Swain, M J. Improving the energy efficiency of food refrigeration operations. IChemE Food and Drink Newsletter, 4 Sept. 2006.

The commercialisation of solar powered transport refrigeration. ETSU S/P200317/REP, DTI/Pub URN 01/1017, 2001.

Wang, F, Maidment, G G, Ford, A, Barker, N and Missenden, J F. Ground source heating and cooling in the UK. Proc. Inst R. 2006-07, 6-1.

Wilson, N, Ozcan, S, Sandeman, K and Burdett, P. Overview of magnetic refrigeration. Proc. Inst R. 2006-07, 4-1.