The decision support tool to select appropriate technologies for specific industries

- Like

- Digg

- Del

- Tumblr

- VKontakte

- Buffer

- Love This

- Odnoklassniki

- Meneame

- Blogger

- Amazon

- Yahoo Mail

- Gmail

- AOL

- Newsvine

- HackerNews

- Evernote

- MySpace

- Mail.ru

- Viadeo

- Line

- Comments

- Yummly

- SMS

- Viber

- Telegram

- Subscribe

- Skype

- Facebook Messenger

- Kakao

- LiveJournal

- Yammer

- Edgar

- Fintel

- Mix

- Instapaper

- Copy Link

Posted: 4 November 2010 | Ariette Matser, Miriam Quataert, Remco Hamoen and Huug de Vries, Wageningen UR, Food & Biobased Research | No comments yet

In past years, it has become clear that the variety and complexity of novel processing methods is a major bottleneck for companies in deciding where to invest. Even though the pros and cons of technologies have been highlighted in various books (HPP, PEF-books, EME etc.), the most appropriate technologies for specific applications often have not been compared directly. Thus, NovelQ has created a decision support tool for companies.

By answering a short list of specific questions, a potential user (e.g. a food manufacturer) can easily evaluate whether a technology is relevant for their products and if implementation is economically feasible.

In past years, it has become clear that the variety and complexity of novel processing methods is a major bottleneck for companies in deciding where to invest. Even though the pros and cons of technologies have been highlighted in various books (HPP, PEF-books, EME etc.), the most appropriate technologies for specific applications often have not been compared directly. Thus, NovelQ has created a decision support tool for companies. By answering a short list of specific questions, a potential user (e.g. a food manufacturer) can easily evaluate whether a technology is relevant for their products and if implementation is economically feasible.

In past years, it has become clear that the variety and complexity of novel processing methods is a major bottleneck for companies in deciding where to invest. Even though the pros and cons of technologies have been highlighted in various books (HPP, PEF-books, EME etc.), the most appropriate technologies for specific applications often have not been compared directly. Thus, NovelQ has created a decision support tool for companies.

By answering a short list of specific questions, a potential user (e.g. a food manufacturer) can easily evaluate whether a technology is relevant for their products and if implementation is economically feasible. The tool includes a menu with extensive information about processingrelated areas such as packaging, product quality assessment, pre- and post-processing steps and environmental considerations.

State-of-the-art in novel processing – such as high pressure, pulsed electric fields, cold plasma, ohmic heating, microwave, radio frequency and pulsed lights – has been described in a variety of review journals and books. NovelQ has written business cases for these technologies including new scientific insights specifically for industry and made them available to members of the Industry Advisory Platform (IAP). However, it is still difficult for the industry to evaluate novel processes (NP) and this can be a limiting factor for further development and implementation.

To promote implementation, it is necessary to provide an approach for selecting an appropriate novel scheme on the basis of desired quality and shelf life for a specific food product. NovelQ has developed a decision support system based on a chain-oriented approach to investigate the optimal technology and conditions, including cost aspects. The purpose of the decision support system is to assist food manufacturers and their equipment suppliers in the assessment and screening of novel preservation technologies. This (decision support system) tool can be used to evaluate whether novel technologies are relevant and offer significant benefit, which can be translated into an economical relevance.

The tool can be used in two ways: applications for which no conventional alternative is available (e.g. due to the effects of heat on specific properties of the product) and those applications for which industry is seeking new applications (e.g. premium soups and sauces).

The NovelQ business cases formed the basis of the decision support system. This version was discussed with industry, both those with novel technology experts and potential users. Based on feedback, an upgraded and user-friendly version has been launched with the layout, technical specification and visual information restructured for users.

Presentation of the design of the DSS software tool

The aim of the decision support system tool is to help potential users of novel processing technologies to make decisions about the likely benefits for their business. The tool needed to be widely accessible and intuitive to use. It was decided, therefore, to create an internet-based system rather than distributed stand-alone software. Access is via the NovelQ IAP home page (see Figure 1).

Figure 1 Homepage of decision support system providing information on novel processing (left) and entrance to the questions to select potentially interesting technologies

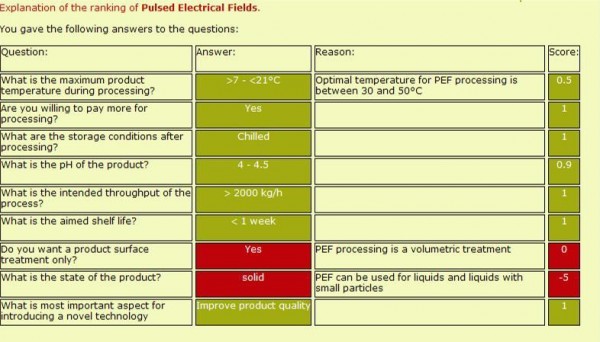

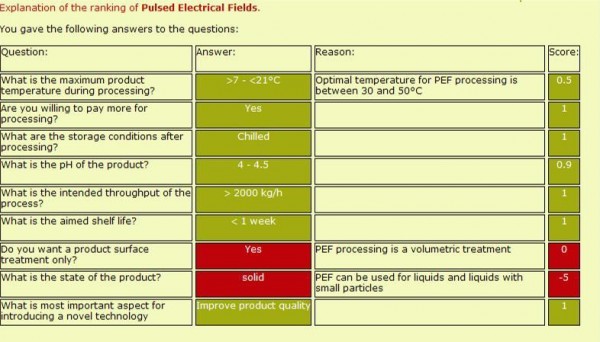

At the core of the tool is a list of questions about the novel processing technologies. Users responses about treatment and products generate the most relevant follow-on questions automatically. The technologies available are ranked based on the user’s answers, which are summarised on the results page (see Figure 2). Answers can be easily changed and the updated ranking shown without changing the question and the order in which they are presented. Users can also find more detailed information giving a general description of the technology, potential applications, placement in the production process, status of the tech nology and commercial availability and existing applications as well as an explanation as to why a technology is less relevant for a given application or product (see Figure 3).

Figure 2 Example of questions and ranking of technologies for a specific application

Figure 3 Explanation of ranking of pulsed electric field for solid product

The outcomes of using the DSS tool

In addition to the advice on potential interesting novel processing technologies for a specific application, users suggested a menu for information about products in the market, packaging options and research facilities (see Figure 1). Newly-marketed product examples have been included in the tool describing the product, its packaging and relevant information such as brand, producer, technology, ingredients, storage conditions, shelf life and market.

Possible packaging schemes include information about different kinds of packaging materials that can be used for novel processes including photographs and descriptions of the materials. Information about the properties of materials in relation to processing conditions is also provided. Examples of appropriate materials that cannot withstand specific conditions (e.g. in case of high pressure, high temperature profiles) are demonstrated with pictures of treated packaging samples.

Product quality is the most important deciding factor in the application of new technologies. However, providing convincing and reliable quality samples is not straight – forward. For example, a colour scale index programme had to be developed to distinguish between processed products; the tool shows several images of treated products (see Figure 4) for comparison. Direct comparison is facilitated by images of products (orange juice) processed using conventional heat pasteurisation, pulsed electrical fields (pasteurisation) and high pressure (pasteurisation). The final outcomes are presented in the product quality case menu-option.

Figure 4 Example of product quality information in the decision support system

Product samples are of major importance to industry. Thus, a feature for research facilities has been added accessing an extensive list of potential research pilot facilities including technical specifications and contact details of the providers (see Figure 5).

The tool also includes a comparison of estimated costs of the technologies. Real costs of a technology are subject to the specific application (e.g. throughput, number of working hours, depreciation period and interest) but estimated costs allow users to consider costs associated with the tech – nologies and processing costs a company will also incur such as pre-processing, packaging and logistics. Estimated costs include processing, without pre-treatment and packaging costs, but include equipment, energy and maintenance.

Implementation of novel technologies in existing processing facilities may cause severe problems. Assistance to adapt pre- and post-processing systems is imperative. The tool provides information about different processing lines, and required adjustments, by means of pictograms.

Finally, environmental impact of new technologies is becoming increasingly vital for decision makers. Life-cycle-assessment data is embedded in the tool where available.

Conclusion

A second version of the NovelQ decision support system tool is available for NovelQ IAP members. New Food readers are invited to join the NovelQ IAP and test the tool. Feedback is welcomed and will be used to develop the tool further.

About the Authors

Ariette Matser

Ariette Matser is currently Senior Scientist – Mild Preservation and Novel Technologies and Programme Coordinator – Mild Preservation within Food & Biobased Research of Wageningen UR. She studied Food Science at Wageningen UR. Her primary research activities include novel technologies and food safety and quality, preservation and processing of food products and effects on food quality, and food structure and the effects of processing on this. Management activities are involvement in (inter) national R&D projects, project acquisition and coordination of activities on novel technologies. She is Project Coordinator of the European project NovelQ.

Miriam Quataert

Miriam Quataert is Senior Scientist, Product Development and Application and Programme Coordinator Food Design and Structuring within Food & Biobased Research of Wageningen UR. She studied Food Science at Wageningen UR. Miriam has a background in product development within research and industry. Her primary research and project activities are in the area of new product development, food reformulation, effect of novel processing on food quality and texture. Management activities are involvement in (inter) national R&D projects, project acquisition and coordination of activities on food design and structuring.

Huug de Vries

Within Wageningen UR, Huug de Vries has been responsible for the Food Technology Centre (FTC) since April, 2006. FTC focuses on initiation, research and development of novel processing technologies in the food and life science sectors. Huug de Vries is also the Project Coordinator of the European Integrated Project ‘Novel Processing Methods for the Production and Distribution of High-Quality and Safe Foods (NovelQ)’. Previously, Huug de Vries was the Director of Strategy and Commercial Affairs at A&F B.V. and project manager for the development of a sustainable maritime reefer container for transport of perishables. He has participated in projects covering the entire chain from sustainable food production, processing and distribution up to consumption. His PhD research – at the edge of physics and biology – was carried out at the department of Molecule and Laser Physics at the Radboud University of Nijmegen, The Netherlands.