Traditional and modern biotechnology

- Like

- Digg

- Del

- Tumblr

- VKontakte

- Buffer

- Love This

- Odnoklassniki

- Meneame

- Blogger

- Amazon

- Yahoo Mail

- Gmail

- AOL

- Newsvine

- HackerNews

- Evernote

- MySpace

- Mail.ru

- Viadeo

- Line

- Comments

- Yummly

- SMS

- Viber

- Telegram

- Subscribe

- Skype

- Facebook Messenger

- Kakao

- LiveJournal

- Yammer

- Edgar

- Fintel

- Mix

- Instapaper

- Copy Link

Posted: 3 May 2005 | Annika Wilhelmson, Anu Kaukovirta-Norja and Silja Home, VTT Biotechnology | No comments yet

The brewing industry has changed from local, small breweries to global companies and fully automated plants. Our knowledge on biological processes of the barley-to-beer chain and tools to control the process and product quality, benefit from the development of basic sciences and engineering.

Beer has been brewed for thousands of years. For a long time beer production was, however, pure cookery. The development of the brewing industry began in the 19th century – largely as a consequence of the development of technology in general. The scientific basis of beer brewing was also laid at that time. Sciences such as biochemistry and microbiology benefited greatly from the early malting and brewing research that was driven by the need to understand biological processes such as germination, mashing and fermentation. Later the term biotechnology was invented meaning industrial application of living cells and combining basic sciences with engineering. Nowadays the definition of biotechnology is even wider and covers the research and development of biological processes on a genetic and molecular level.

The brewing industry has changed from local, small breweries to global companies and fully automated plants. Our knowledge on biological processes of the barley-to-beer chain and tools to control the process and product quality, benefit from the development of basic sciences and engineering. Beer has been brewed for thousands of years. For a long time beer production was, however, pure cookery. The development of the brewing industry began in the 19th century – largely as a consequence of the development of technology in general. The scientific basis of beer brewing was also laid at that time. Sciences such as biochemistry and microbiology benefited greatly from the early malting and brewing research that was driven by the need to understand biological processes such as germination, mashing and fermentation. Later the term biotechnology was invented meaning industrial application of living cells and combining basic sciences with engineering. Nowadays the definition of biotechnology is even wider and covers the research and development of biological processes on a genetic and molecular level.

The brewing industry has changed from local, small breweries to global companies and fully automated plants. Our knowledge on biological processes of the barley-to-beer chain and tools to control the process and product quality, benefit from the development of basic sciences and engineering.

Beer has been brewed for thousands of years. For a long time beer production was, however, pure cookery. The development of the brewing industry began in the 19th century – largely as a consequence of the development of technology in general. The scientific basis of beer brewing was also laid at that time. Sciences such as biochemistry and microbiology benefited greatly from the early malting and brewing research that was driven by the need to understand biological processes such as germination, mashing and fermentation. Later the term biotechnology was invented meaning industrial application of living cells and combining basic sciences with engineering. Nowadays the definition of biotechnology is even wider and covers the research and development of biological processes on a genetic and molecular level.

From barley to beer

Germinated barley is the basic raw material of beer. Barley germination, termed malting, is the first of the two main biological processes of beer production. Germination begins with the steeping step, during which the barley embryo is awakened and begins to synthesise hormones and enzymes. Steeping is followed by the germination phase where these enzymes hydrolyse the cell walls and protein matrix in the grain, releasing starch granules susceptible to enzyme attack. Compounds causing malty, sweet, caramel or burnt aroma notes of beer originate from kilning or roasting of malt after germination. The hydrolytic reactions initiated during malting continue in the first phase of the brewing process (wort production) in which starch from malt, or other cereals, is broken down to fermentable sugars by malt enzymes. The insoluble grain components, mainly proteins and unhydrolysed cell wall compounds, are separated. The resulting liquid, termed wort, forms a good nutrient source for yeast growth and alcohol fermentation containing sugars, amino acids, minerals and vitamins. Another essential raw material of beer is hops, which is added to the wort during wort boiling. Hops give the typical bitter taste and ‘hoppy’ aroma.

Yeast fermentation – the second main process of beer production – is called the ‘soul of beer’. Different types of yeast strains have various technological properties and flavour formation patterns. The yeast strain used by a brewery is usually a secret.

Following fermentation there are several down-stream processing steps such as yeast removal, stabilisation and filtration that guarantee the beer quality and shelf life. The physical stability of beer is guaranteed by cooling the beer below zero, using stabilising agents and by filtration. The aim of stabilisation is to remove potential haze forming proteins and polyphenols. After filtration, beer is ready for packaging and delivery to the consumers.

Improvements in process efficiency

In principle the process steps have not been changed over the years. Malting still requires barley to be steeped, germinated and kilned. In brewing, malt flour is mixed with water, hydrolysed enzymatically and the wort is fermented by yeast. However, both scientific research and technical improvements have brought new information to malting and brewing, which has led to process development. New barley varieties have been bred aimed at higher enzyme production potential, increased extract content and homogenous modification of malt. Malting can be controlled by adjusting the process conditions: moisture, temperature, oxygen availability and carbon dioxide. Further process improvements require a deeper knowledge of barley physiology and the interaction between barley and its microbial community. It has been proved in recent years that microbes have a significant role in malting and may affect both germination behaviour and final malt quality. Barley grains are naturally colonised by a complex microbial community that grows and becomes more diverse during malting. Various types of microbial starter cultures have been developed to control microbial growth during malting. This technology is ready for industrial application.

Several attempts have been made to intensify fermentation. The use of high gravity brewing, which employs a higher concentration of wort than normal, has increased the production capacity of fermentation tanks. Also, the use of higher temperatures accelerates yeast fermentation. Traditionally beer production is a batch process. The idea of continuous beer fermentation was previously tested in the early 20th century and the first continuous fermentation plant was built in New Zealand. This system consisted of three fermentation tanks in series. Development of immobilisation technology enabled the next step for the development of continuous fermentation. In the immobilised yeast reactor, yeast cells are bound on, or entrapped in, an inert carrier material and wort is pumped through the system. The acceleration of fermentation is based on higher yeast concentration than traditional batch fermentation. Immobilised yeast technology has been successfully applied in Finnish breweries for secondary fermentation for more than ten years. The main reaction in secondary fermentation is the reduction of diacetyl to a level under the taste threshold. Diacetyl is produced by yeast during primary fermentation and it causes the buttery off-flavour in beer. Under traditional brewing conditions the reduction of diacetyl takes 1 – 2 weeks but using the immobilised yeast system, the process time can be reduced to a few hours.

The process modifications that intensify fermentation expose the yeast to harsh conditions such as high temperature, high osmotic pressure and high alcohol content. These conditions create stress reactions in the yeast cells that affect yeast performance and fermentation characteristics. Whichever process developments are used, the quality of a specific beer brand must remain unchanged. Therefore fermentation process intensification has increased the need for research in the field of yeast physiology. The brewer needs to know and understand his yeast better in order to control the process and reach the quality specifications.

Beer quality and safety

Our personal experience with beer quality goes back only a few decades and we don’t actually know what beer quality was like prior to this. Traditionally, beer has been produced in local breweries and served fresh. The globalisation of the brewing industry means that international beer brands are available in all parts of the world. Beer sold by a specific label must taste the same wherever and whenever it is produced (see ‘A Carlsberg like every other’, New Food Issue 2, 2003). Nowadays the requirement of a ‘best before date’ can be more than a year. Physical and microbiological stability can easily be reached by using present knowledge and technology. Flavour stability, however, requires further research and understanding of oxidation reactions and the behaviour of flavour intensive compounds – especially carbonyl compounds – through the entire production chain from barley to beer. Beer flavour stability is indeed an area where research is intensive today. Several research groups in the world are constantly looking for ways of measuring, predicting and improving beer flavour stability.

Historically, beer has been an important part of daily nutrition and regarded essential for health. In the 20th century beer lost its reputation and was classified as an alcoholic drink. In the last few years, much research has been carried out on the health effects of moderate alcohol consumption. Several research reports have shown that alcohol can reduce the risk of diseases such as cardiovascular disease and different types of cancer. Beer also contains many cereal- and hop-derived components that may make a positive contribution to our well-being.

Food safety issues are a hot topic that is here to stay. A large amount of research has been carried out evaluating the possible safety risks in the beer production chain. Moreover, quality assurance schemes have been defined to enable the traceability of a beer batch as far back as the particular production fields of its raw materials – barley and hops. However, more knowledge is still needed to understand how food safety problems might occur, for example which conditions lead to production of mycotoxins by field and storage fungi throughout the barely-to-beer chain.

Brewing and modern biotechnology

Can beer production benefit from so-called ‘modern biotechnology’ that works on a genetic and molecular level? The answer is, ‘yes’. Much of the behaviour of barley kernels, yeast strains and microbes in the malting and brewing processes is still unknown and unpredictable. Better understanding of the biological reactions and their control mechanisms will enable the precise control of our process steps. Publication of the yeast genome and development of genetic engineering techniques have introduced new possibilities to modify the metabolism of brewer’s yeast strains aiming, for example, to improve flavour formation or stress tolerance in intensified fermentations. Genetic engineering of plants is more complicated, but molecular marker assisted plant breeding has successfully been applied for malting barley. Recognition of genes in yeast or barley genomes alone does not provide sufficient information for the prediction of their relation to processing behaviour. Analytical tools, such as transcriptional analysis and proteomics, are already used for research purposes to study the effect of certain conditions on gene expression and protein synthesis. When these methods become robust and fast enough they offer new possibilities for process monitoring and control. Moreover, the research on enzyme reactions and flavour, haze or foam active compounds benefit greatly from the novel analytical tools that enable better understanding of reactions and interactions between different compounds at molecular level.

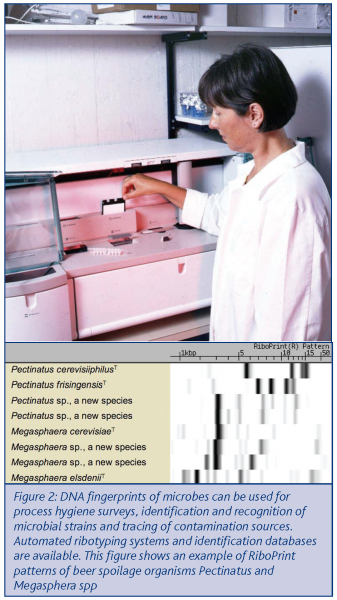

Process microbiology and hygiene control are essential aspects of quality assurance in malting and brewing. Traditional cultivation-based methods are still widely used. These methods reveal possible contamination only after several days or weeks of delay. Moreover, they do not discriminate between spoilage and beneficial bacteria. Several molecular biology methods, e.g. PCR-technology, have been described for the detection, characterisation and identification of brewery contaminants. DNA fingerprints of microbes make it possible to trace contamination routes and evaluate the efficiency of cleaning procedures of pipes and tanks. These specific methods are now becoming available for routine use.

Conclusions

Beer is a traditional product that has been produced from the same raw materials for centuries. Brewing technology combines the basic sciences: biochemistry, microbiology, physics and genetics with engineering, automation and information technologies. Although the biological processes of beer production have not changed, progress in science and engineering offers new tools that make it possible to monitor and control the processes more efficiently and reach the ever tighter requirements in production efficiency and product quality. Ideally, this enables the traditional beer character to be maintained in addition to guaranteed product uniformity, stability and safety.