Examining crust problems of frozen bread

- Like

- Digg

- Del

- Tumblr

- VKontakte

- Buffer

- Love This

- Odnoklassniki

- Meneame

- Blogger

- Amazon

- Yahoo Mail

- Gmail

- AOL

- Newsvine

- HackerNews

- Evernote

- MySpace

- Mail.ru

- Viadeo

- Line

- Comments

- Yummly

- SMS

- Viber

- Telegram

- Subscribe

- Skype

- Facebook Messenger

- Kakao

- LiveJournal

- Yammer

- Edgar

- Fintel

- Mix

- Instapaper

- Copy Link

Posted: 11 August 2006 | Pr Alain Le BAIL, Nasser Hamdami, Vanessa Jury and Jean-Yves Monteau, ENITIAA – France, Armel Davenel and Tiphaine Lucas, CEMAGREF, France and Pablo. D. Ribotta, Facultad de Ciencias Agropecuarias, Universidad Nacional de Córdoba, Argentina | 1 comment

While overall bread consumption remains more or less constant, Bake Off Technology (BOT) is increasing its market share every year with an annual growth rate close to 10 per cent. BOT consists of producing bread from industrial refrigerated, frozen or non-frozen bakery goods and selling them in bakeries or making them available in supermarkets for domestic baking. Partially baked bread, being frozen or non-frozen, is the success story of BOT. However, it may be exposed to different quality problems such as crust colouration and crust flaking. The impact of selected process conditions on crust flaking are outlined; among them the chilling and freezing step following partial baking seems to have particular importance. Different hypotheses that may explain this step of the process and crust flaking are investigated and a problem-solving strategy is proposed.

While overall bread consumption remains more or less constant, Bake Off Technology (BOT) is increasing its market share every year with an annual growth rate close to 10 per cent. BOT consists of producing bread from industrial refrigerated, frozen or non-frozen bakery goods and selling them in bakeries or making them available in supermarkets for domestic baking. Partially baked bread, being frozen or non-frozen, is the success story of BOT. However, it may be exposed to different quality problems such as crust colouration and crust flaking. The impact of selected process conditions on crust flaking are outlined; among them the chilling and freezing step following partial baking seems to have particular importance. Different hypotheses that may explain this step of the process and crust flaking are investigated and a problem-solving strategy is proposed.

While overall bread consumption remains more or less constant, Bake Off Technology (BOT) is increasing its market share every year with an annual growth rate close to 10 per cent. BOT consists of producing bread from industrial refrigerated, frozen or non-frozen bakery goods and selling them in bakeries or making them available in supermarkets for domestic baking. Partially baked bread, being frozen or non-frozen, is the success story of BOT. However, it may be exposed to different quality problems such as crust colouration and crust flaking. The impact of selected process conditions on crust flaking are outlined; among them the chilling and freezing step following partial baking seems to have particular importance. Different hypotheses that may explain this step of the process and crust flaking are investigated and a problem-solving strategy is proposed.

Bread and baked cereal goods (termed BCG) such as bread, viennoiserie and many other specialties are at the base of the pyramid of nutrition (Figure 1). Today the European market is adapting to the demands of European consumers, providing a large variety of BCG including ethnic products, health-promoting products, non allergenic products (i.e. gluten free bread) with a high level of ‘freshness’ (‘freshly baked’-like) and organoleptic qualities.

Also, the labour cost and the demand from consumers for freshly baked BCG has resulted in the rapid growth of Bake Off Technology (BOT). BOT enables bread, viennoiserie and other bakery products to be produced from an industrial scale down to smaller bakeries, which could be mere baking shops with minimally trained staff preparing BCG on demand using a proving cabinet and oven. The market share of frozen bakery products seems relatively small but is growing at a very high rate (approximately 10 per cent a year). BOT needs to be adapted to the needs of the consumer for products with improved nutritional quality and health benefits.

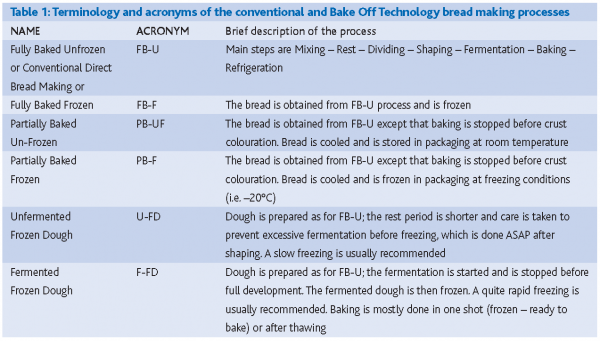

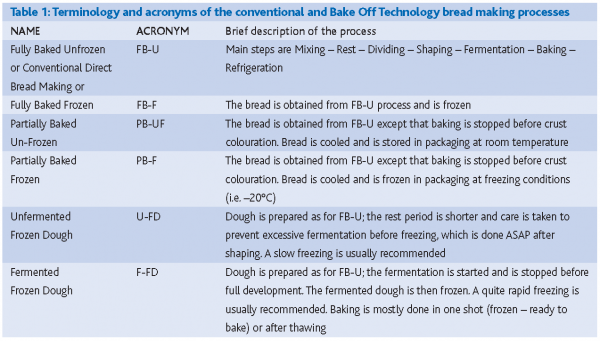

Several bread-making technologies that are on the market, are listed in Table 1. The three main technologies of BOT are: Un-fermented Frozen Dough (UFD), Partially Baked Frozen Bread (PBF) and Partially Baked Un-frozen (PBUF). Specific formulations and mixes of ingredients – and even yeast strains – have been developed by the baking ingredients industry for these technologies and there is abundant literature available on the subject. UFD is the leading product in terms of market share of BOT in France, whereas PBF is the leading product in most other European countries (especially in Germany). UFD requires skill to carry out the fermentation phase and the baking. Conversely, PBF and PBUF don’t require any specific expertise. Sophisticated packaging may be used with PBUF, such as MAP (Modified Atmosphere Packaging), to ensure an acceptable shelf life. Breads are usually thawed prior to baking in a convection oven. Partially baked (PBF and PBUF) products can be prepared quickly (in less than one hour); nevertheless, their production is energy demanding (requiring two bakes) and some quality problems might occur, especially with the crust (such as flaking, discolouration, etc.). The unfermented frozen dough technology (UFD) enables the production of bread with quality very close to that of the conventional bread making process. The Fermented Frozen Dough (F-FD) technology has not developed as much due to quality problems. However, this technology, also termed ‘ready to bake’, is still promising. The challenge is that in the case of temperature abuse in the cold chain, the surface of the dough pieces may reach melting point and sticking to other product, which creates an unacceptable crust after baking.

Impact of process parameters on crust flaking

Frozen part-baked bread is considered the success story of frozen bakery products. It is important to note that the concept applies not only to bread, but many other bakery products such as pizza dough, pies and quiches – to name a few. However, the literature available on crust flaking is not abundant. Consumers and industry consider crust in very different ways. Recently, crust-less sandwiches have been successfully marketed, showing that consumers may be interested in a ‘no-crust’ concept. However, most people visiting France appreciate the specific crispy crust of a French baguette and find it difficult to find a similar quality in their native country. The crust can be defined as the singular area of bread that is formed during the baking step. Nevertheless, all steps of the process may affect the final crust quality: the flour quality; the mixing conditions; the fermentation conditions; the condition of the batter at the end of fermentation; the partial baking conditions; the chilling condition; the freezing condition; the storage condition and the final baking condition. An extensive study has been carried out on this problem in the form of a national project in 2000-2002. A French baguette was used as a model system. The impact of fermentation conditions (50% and 90% air humidity at 27°C), chilling conditions after partial baking (50–55% and 90–95% air humidity at 20°C) and freezing conditions (blast air freezing began with centre bread temperature at the entrance of the freezer at 35°C, 45°C or 55°C) on crust flaking of part baked bread was studied. (All details related to this study are available in LeBail et al. 2005). An experimental design procedure allowed the simultaneous evaluation of each of these parameters. Crust flaking was evaluated from a mass ratio after crushing the bread between slabs. The chilling condition after partial baking appeared to be the most influential parameter on crust flaking. The proving condition was the second parameter most responsible for crust flaking. Generally, a higher air humidity during the process will minimise crust flaking. A higher temperature of partially baked bread at the entrance of the freezer (55°C vs. 35°C in the studied conditions) seems to increase crust flaking. This trend was not always significant. A final important point was that despite the occurrence of crust flaking during final baking, the phenomena may be predicted and was obviously visible at the end of the freezing process. These experimental facts address questions about crust flaking. Two major hypotheses can be proposed to explain the problem: (i) ice concentration below the crust and (ii) thermomechanical problems between crust and crumb.

Ice concentration below the crust

During post bake chilling, the bread surface temperature drops rapidly yet the centre of the bread remains hot for longer. The associated partial vapour gradient between centre and surface, combined with the open cellular structure of the crumb and the barrier-like structure of the crust causes moisture to diffuse toward the bread surface which risks condensation freezing below the crust, exposing the crust to a mechanical stress. This assumption has been investigated in our group (PhD N. Hamdami, 2000-2003). The assumption of possible moisture crystallisation under the crust was confirmed. Nevertheless, the amount of water was not extremely important and this assumption may not be sufficient to explain the crust flaking problem per se.

Thermomechanical problem between crust and crumb

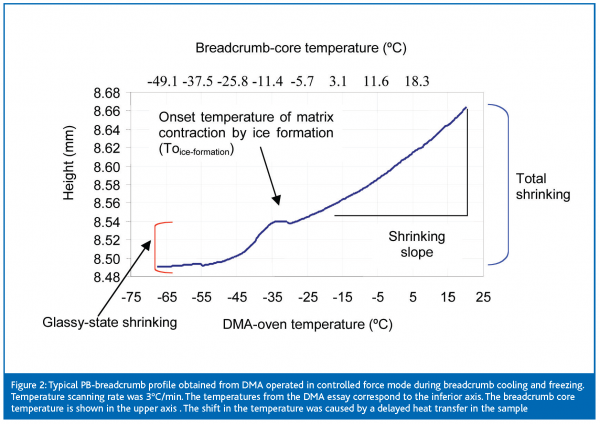

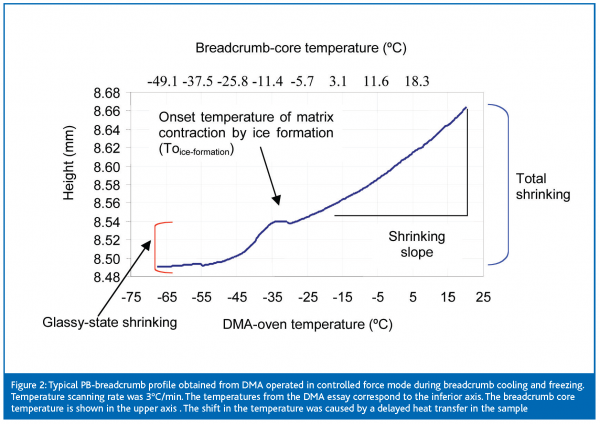

It can be seen that crumb contracts during post bake chilling. Some studies showed that it even contracts during baking after the initial oven rise. The contraction during post bake chilling is visible on the flanks of a baguette, which usually exhibits curling (Figure 3a). However, crust flaking mostly occurs at the tip and on the flanks of a baguette (Figure 3b). Crumb contraction exposed the surface of the bread to strain and stresses. The fragile crust structure, which becomes more rigid during freezing, might not bare this strain. Depending on the freezing conditions and flexibility of the crust at the moment of contraction, it will either take the strain or rupture. These assumptions were first investigated by Magnetic Resonance Imaging at CEMAGREF (Rennes-France) by Dr T. Lucas. MRI has been used to assess possible moisture or ice concentration below the crust during the study on crust flaking (National project quoted above). The images revealed that a densification of the structure below the crust occurred during chilling and freezing of partially baked bread. Even though possible moisture condensation and crystallisation may contribute to the increase of MRI signal that was observed below the crust, a densification (contraction) of the structure below the crust was the most likely and valid hypothesis (Lucas et al. 2005). A specific study has been carried out on crumb thermo mechanics in our group during the Post Doctoral stay of Dr Pablo RIBOTTA in 2004-2005 (funded by Région Pays de Loire). Crumb contraction has been studied in a Dynamic Mechanical Analyser that was used as a dilatometer. A piece of crumb (typically 8 mm thick) was exposed to a temperature scan from 20°C to –70°C, meanwhile crumb contraction was continuously measured. A typical experimental plot is shown in Figure 2, which illustrates the shrinkage of the crumb that occurs through the entire cooling and freezing process. This shrinkage exposes the tip of the baguette to a ‘clamp effect’ that can easily be understood. The freezing point in Figure 2 coincided with the beginning of the plateau in thermal contraction indicating that freezing produces the perceptible fall in the curve. This fall could be related to the matrix freezing: as breadcrumbs freeze, water is removed from the protein-starch-water matrix in the form of ice and the rate of volume matrix decreases. In order to study the thermo-mechanical properties of PB-breadcrumbs, their contraction profile during cooling and freezing was studied. The parameters evaluated (Figure 2) were the onset temperature of matrix contraction due to ice formation (intersection of the two straight lines that fit the two linear portion of the curve), the shrinking slope from matrix-cooling step and the total shrinking.

Results to be published soon (Ribotta et al. 2006; Ribotta et al. 2006) show that the contraction of the crumb is partially related to amylose recrystallisation occurring in the time frame of the post bake chilling process. The magnitude of the contraction may be changed by the use of specific enzymes and also by controlling the freezing conditions; ongoing studies in our group are focussing on this. Rapid freezing, for example, doesn’t seem well adapted. Mild baking seems to result in a larger contraction. Of course, the formulation remains an important factor, even though the process obviously interacts with it. In particular, the structure of the crumb with more or less pronounced connectivity between cells of the crumb might interact with crumb contraction (this might depend, for example, on the use of shortening and emulsifiers). The structure of the crust, which will be more or less hydrated depending on fermentation and baking process, will interact. Once its glass transition temperature is passed, the crust will become more fragile and might not support the strains imposed by the crumb.

Future strategy

The few results presented have enabled a partial reproach of the problem, which is indeed quite complicated. A strong interaction between the process and the formulation is obviously to be taken into consideration. The glass transition of the crust, which is related to its hydration and therefore to the fermentation and baking conditions (and even to the mixing condition that interacts with gluten hydration and aggregation), is also linked to the mechanical tolerance (plasticity) of the crust. The following steps are advisable:

- A simple toll should be developed, consisting of measuring the outer dimensions of a product at the end of partial baking, the end of freezing and end of final baking. The changes in dimensions may enable the prediction of crust problems

- A second step would be to focus on the impact of partial baking conditions. It seems that milder baking results in a higher crumb contraction, demonstrating that the partial baking process is ‘risky’. Specific time-temperature profiles may be needed depending on the geometry of the product and on the baking oven

- A third step may consist of studying the impact of the processing conditions of the refrigeration phase on crust flaking and on changes in dimensions. The freezing velocity will interact with the thermomechanical problem of crust – crumb differential contraction. Tests must be carried out to optimise the processing conditions

- Good control of the moisture during fermentation is obviously an important point. More humidity means more hydration of the crust and therefore more crust plasticity. Nevertheless, if a crispy crust is expected, a proper balance must be found

These guidelines are basic. A refined approach is needed for each case and each geometry. Formulation and fermentation conditions are obviously important phases that should not be neglected as well. Currently, we are also focusing on the conditions of final thawing – baking (PhD V. Jury 2004-2007) on moisture loss and on crust colouration kinetic. Another ongoing study focuses on the aroma of partially baked breads.

A further important aspect lies in the fact that BOT is energy demanding; investigation is also needed to assess the impact of processing conditions on energy consumption and on environmental impact of these growing technologies. Our group, in collaboration with CEMAGREF-Rennes-France has gained experience in this complex problem and more generally in BOT, even though much investigation is still needed.

Acknowledgements

Work presented in this summary has been funded by the French Ministry of Research; the French Ministry of Agriculture and Fishery, ENITIAA, CEMAGREF; the Région ‘Pays de La Loire’ and the France-Iran PhD programs.

References

Hamdami, N., J. Y. Monteau, et al. (2004-a). “Thermophysical properties evolution of French partly baked bread during freezing.” Food Research International 37(7): 703-713.

Hamdami, N., J. Y. Monteau, et al. (2004-b). “Heat and mass transfer in par-baked bread during freezing.” Food Research International 37: 477-488.

Hamdami, N., J. Y. Monteau, et al. (2006). “Moisture diffusivity and water activity of part-baked bread at above and sub-freezing temperatures.” International Journal of Food Science and Technology 41: 33-44.

Hamdami, N., N. Monteau, et al. (2004-c). Heat and moisture transfer simulation during freezing of bread. ICEF9 – 2004 International Conference Engineering and Food, Montpellier, FRANCE.

LeBail, A., J. Y. Monteau, et al. (2005). “Impact of selected process parameters on crust flaking of frozen part baked bread.” Journal of food engineering 69: 503-509.

LeBail, A. and P. Ribotta (2005). Thermomechanical behavior of a crumb during chilling and freezing. Potential impact on crust flaking and interaction with formulation using selected enzymes. Starch: Recent Achievements in Understanding of Structure and Functionality

XIII International Sctarch Convention. V. P. Yuryev, P. Tomasik and E. Bertoft. New York, Nova Science Publishers.

Lucas, T., S. Quellec, et al. (2005). “Chilling and freezing of part-baked breads. II. Experimental assessment of water phase changes and of structure collapse.” Journal of Food Engineering 70(2): 151-164.

Ribotta, P. and A. Le-Bail (2006). “Thermophysical and thermomechanical assessment of partially baked bread during chilling and freezing process.” Journal of Food Engineering Accepted.

Ribotta, P. and A. Le-Bail (2006). “Thermo-physical assessment of bread during staling.” LWT In Press (ref. YFSTL:1553).

Thank you so much for this article. I’m a food engineer starting in the frozen bread making industry here in Brazil. We hava a small company but we are hising fast. I’ve learn a lot from this page and hope to learn more. Will you be in IBA München this year?

Best regards