ISP: A breakthrough for better ice cream

- Like

- Digg

- Del

- Tumblr

- VKontakte

- Buffer

- Love This

- Odnoklassniki

- Meneame

- Blogger

- Amazon

- Yahoo Mail

- Gmail

- AOL

- Newsvine

- HackerNews

- Evernote

- MySpace

- Mail.ru

- Viadeo

- Line

- Comments

- Yummly

- SMS

- Viber

- Telegram

- Subscribe

- Skype

- Facebook Messenger

- Kakao

- LiveJournal

- Yammer

- Edgar

- Fintel

- Mix

- Instapaper

- Copy Link

Posted: 4 September 2007 | Jim Crilly, Vice President Research & Development, Unilever Ice Cream Category | No comments yet

Fat and sugar are key nutrients in ice cream and very important as structural building blocks. But with consumers less keen on saturated fat and sugar in their diets, there is a greater need to utilise additional structure from the ice phase to maintain excellent sensory delivery.

Fat and sugar are key nutrients in ice cream and very important as structural building blocks. But with consumers less keen on saturated fat and sugar in their diets, there is a greater need to utilise additional structure from the ice phase to maintain excellent sensory delivery.

Fat and sugar are key nutrients in ice cream and very important as structural building blocks. But with consumers less keen on saturated fat and sugar in their diets, there is a greater need to utilise additional structure from the ice phase to maintain excellent sensory delivery.

Ice content and ice crystal size play a critical role in determining the taste and texture in ice cream. Re-crystallisation and coarsening of ice lead to quality loss, resulting in cold eating products. This problem is exacerbated by elevated temperatures and temperature fluctuations experienced on storage. To counter these effects, conventional technology uses good process control and additives, such as gums or thickeners. However, both these challenges (better nutrition and good quality) taken together demand a new dimension in ice control.

The discovery of ice structuring proteins (ISP) signalled that nature might provide a solution to these challenges. Research showed that these special proteins could not only limit growth rate of ice and its re-crystallisation but could also influence the morphology of the ice structure. Unilever established a major R&D programme complemented by external collaborators to explore ISP functionality and its possible use in ice cream and water-ices. Later it focused on five key challenges: developing a sustainable source, compiling a comprehensive safety dossier, securing regulatory approval from authorities around the world, and conducting consumer research to determine product development and innovation. The introduction of ISP as a new ingredient in ice cream will enable new generations of vitality based innovation that have not been possible until now.

Ice Structuring Proteins: What are they and how do they work?

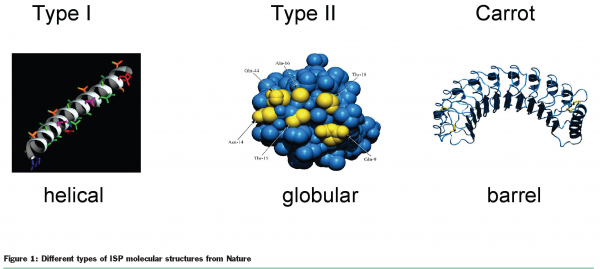

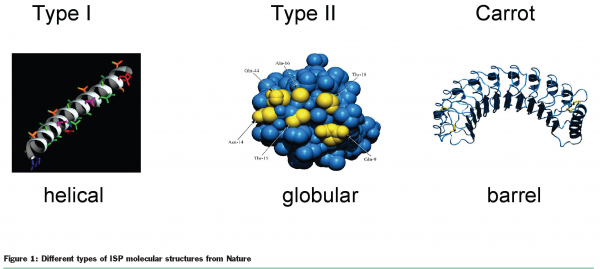

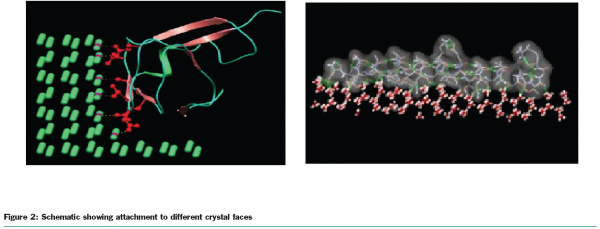

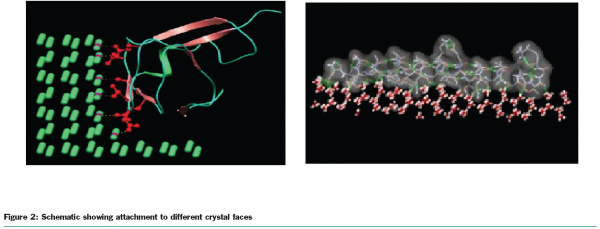

Cells of living organisms are usually irreversibly damaged when frozen. Ice formation depletes the cell of the essential aqueous fluid phase required for function, disturbs the ion and solute concentration, causes denaturation of bio molecules and can break cell membranes apart. However, in a diverse range of organisms, such as plants, fungi, fish, grass and even carrots, nature has provided a means to resist damage from freezing. All are found to contain particular proteins which assist survival by variously altering the temperature at which ice formation takes place, the structure of the crystals formed or their number and distribution. The proteins from different origins have different structures (See Figure 1) and have been given various names such as antifreeze proteins, ice growth modifiers or thermal hysteresis proteins according to their phenomenological effect. More recently the term, ‘ice structuring protein’ was proposed (Clarke et al., 2002) because, regardless of their source and structure, all the proteins have one common property; that is the ability to attach to and influence the growth of ice crystals.(See Figure 2) The particular protein which has been developed by Unilever was originally found in Ocean Pout, a species of fish living in the North Atlantic Ocean.

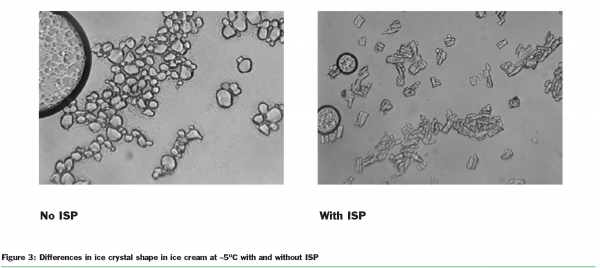

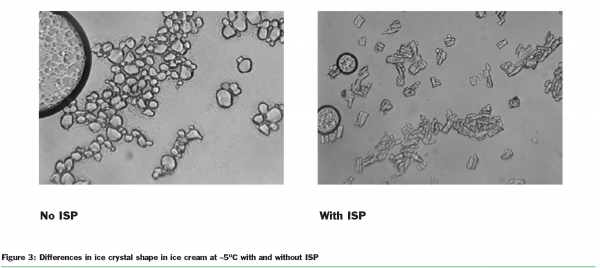

ISP operates differently to the traditional technology for altering the physical properties of ice cream products including texture, mouth-feel and melt resistance. Stabilisers increase the viscosity of the ice cream matrix and modify the gel network at the interface between the ice and the water matrix. This increased viscosity slows down the diffusion during melting, thus retarding melting effects. It is generally accepted that ISP ‘binds’ to the developing ice crystal on particular crystallographic faces and has an effect only during crystal growth. ISP adsorbs preferentially and so alters the growth patterns and rates of the evolving ice structure. ISP itself does not affect the quantity of ice present at any given temperature but impacts upon the size and shape of crystals formed. Ice-ISP interactions are highly specific and, as such, very small quantities of ISP can have dramatic effects. Shape changes are noticed even at bulk solution concentrations as low as 10ppm. Typical effects with ISP are that rod shaped crystals are formed rather than the usual round shape in shear-frozen systems such as ice cream. (See Figure 3)

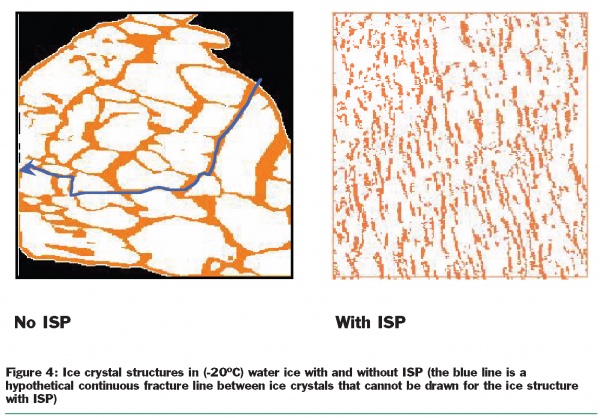

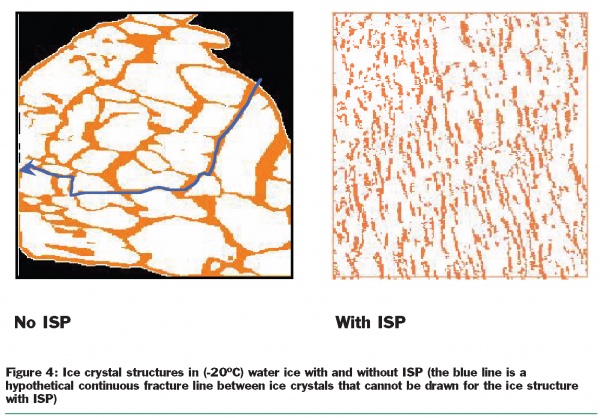

Microscopic habit modification of individual crystals leads to changes in the gross physical properties of the ice network. With a more angular shape of ice crystals there is a greater interaction between them, extending over a long range. After freezing, ice cream is hardened to storage temperatures (below -20oC) during which ice crystals grow and ice content increases, but no new crystals are formed. The final ice crystal structure of a product made without ISP is quite different to that produced with the addition of ISP. (See Figure 4)

Properties in ice cream and water ice

The combined changes of ice crystal shape and interaction conspire, through network formation, to alter the properties of ISP containing products. Changes derive not from the presence of ISP by itself, but its effect on the ice structure formation during processing. Typical gross effects in ice cream and water ice products are to increase firmness and structure. Such effects lead to better physical stability on temperature fluctuation and altered effects of sensory characteristics such as mouth feel, bite and creaminess through changes to rate of structure loss and flavour delivery. Enhanced ice network should retard dripping and hence provide a longer lasting product for consumers. The ice crystal networks, being highly tortuous, would not allow easy removal of flavouring or colour from the structure and be more difficult to be ‘sucked’ out on consumption. The changed sensory aspect would facilitate production of great tasting low fat products. Such possible new products could be higher quality low/zero fat products, products with higher fruit content and ones with much lower added sugar. Lastly there would be great opportunity to provide novel textures and more complicated and intricate shapes.

ISP production

Sourcing of ISP was identified as a major challenge, as hundreds of kilograms would be required for commercial production of ice products. Obtaining quantities of ISP from natural fish sources is currently neither economically feasible, nor sustainable as it would lead to the depletion of specific fish stocks.

To overcome these challenges and ensure a consistent, reproducible supply, the preferred option was to produce the ISP by fermentation using a genetically modified micro-organism. This method utilises established approaches commonly used for many other food ingredients (e.g. chymosin used in vegetarian cheese, enzymes and vitamins). Baker’s yeast is well accepted as a host organism for commercial production, with a long history of safe use in food production.

Fermentation is operated using yeast modified with a gene cassette encoding for the ISP to ensure it can be expressed in the cells. The process is run as a closed system ensuring that the biomass is contained and the conditions in the fermenter vessel are optimised for protein production. ISP is secreted from the yeast into the growth surrounding fermentation broth. Cells are completely removed from the preparation at the first stage of downstream processing by micro filtration, ensuring a yeast free product containing no modified material nor having any residue or characteristics associated with fish.

Safety

The introduction of ISP into foods required a major safety programme to assess any risk of toxicology or allergenicity in digestion. In particular ISP had to be shown to be safe for people with fish allergy as well as incapable of generating an allergic antibody response. Unilever designed and undertook studies with world experts in food allergy, which showed that people who reacted to ocean pout did not react to ISP and that people who consumed ISP every day for eight weeks neither produced antibodies to the protein, nor showed evidence of any other immune response. In separate bioinformatic studies, it was demonstrated that ISP lacked any sequence similarity to known allergens and was readily broken down by digestion, providing additional assurance of lack of allergenic potential.

Innovation

ISP provides innovation opportunities across a whole range of ice cream products– water ice, fruit sorbets, ice cream, in both take-home and impulse markets. It has the potential to really change the eating experience for consumers.

The first products containing ISP were launched into the US market in 2003 and further launches have followed in other countries where the ingredient has been approved for use. Key applications have been targeted towards consumers who want healthier choices or where poor cold chains affect the quality of delivered products. Traditionally, fat based coatings such as chocolate have been used to protect impulse products (in terms of preserving shape or architecture) but the increase in firmness in products by virtue of the more connected ice structure from ISP now enables uncoated products to hold shape and quality through distribution, reaching consumers in locations that were previously just not possible.

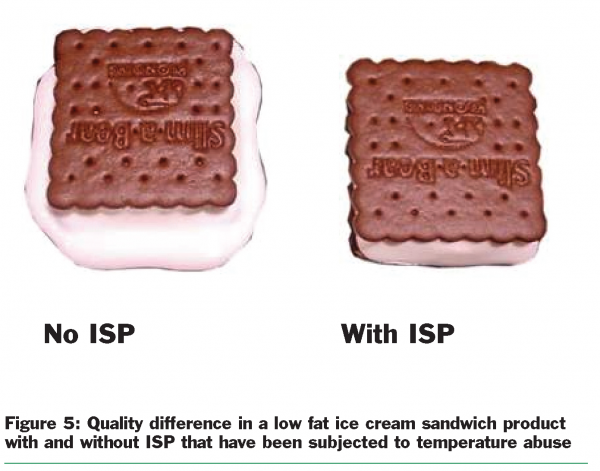

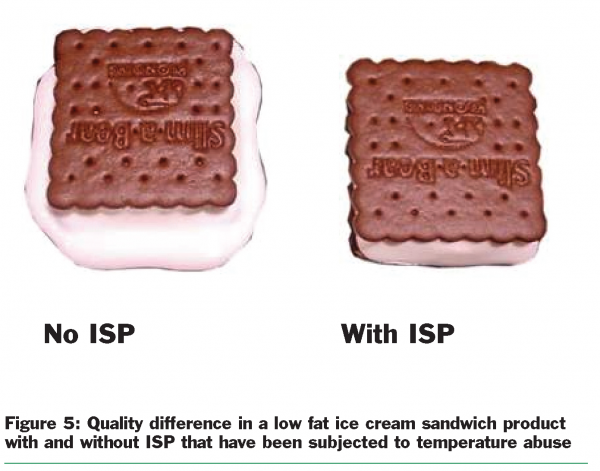

Improvement in texture (increased firmness, thickness and body) obtained with ISP has proved particularly beneficial in recipes with lower fat (<5 per cent) or even fat free. This has delivered superior tasting low fat ranges to the market. It has been relevant to tub products but even more so to product formats such as sticks, bars and sandwich products which are more susceptible to damage and deterioration through distribution. The product shape and definition are key quality parameters. The increase in firmness obtained with ISP can also be an advantage in, for example, sandwich products as they are less ‘messy’ since firmer ice cream is more resistant to compression by the fingers. (See Figure 5)

ISP has also been applied to water ices in a range of novelty products that are longer lasting with less drip and with a more consistent flavour delivery. This translates for the consumer to smaller products that last as long as regular size ones, or novelty products with texture contrast. Products have been extended to new formats from stick products to more interactive fun products such as free flowing particulates, beads or ‘shots’ of water ice or milk ice distributed safely through the traditional supply chain. The increased hardness of products with ISP means solids levels of these particulate products can be increased such that natural or fruit sugars can be used to give intense flavour rather than artificial sweeteners.

Importantly for the future, ISP will also enable opportunities of traditionally indulgent textures but with much healthier nutritional profiles where structured ice will enhance textures rather than the current reliance on fat or sugar.

Conclusions

The introduction of ISP by Unilever is arguably the most significant development in ice cream ingredient technology for thirty years. Highly specific ice control enables better ice cream and new possibilities for healthier products with low fat, less added sugar and more fruit and milk components. It will enable new generations of innovations with novel textures and formats with better nutrition too. The entire innovation programme was conducted with clear commitment to Unilever’s Vitality mission and track record in corporate social responsibility and environmental care as well as guidance by the principles of the New Foods Manifesto (Elkington and Hailes, 1999). In line with Unilever’s stringent safety policies, safety was given the highest priority with the development of a very comprehensive toxicology package which has been scrutinised by many scientists and health professionals worldwide. All have concurred with the opinion that the ingredient is safe. The sourcing development involving the precise genetic modification of baker’s yeast and large scale fermentation as a closed system is a great example of a clean, sustainable and highly responsible application of ‘white’ biotechnology. This single achievement allowed ISP to be sourced sustainably and commercially and enabled innovations to be brought to market. ISP has now achieved regulatory approval in 15 countries and is already enjoyed by consumers in several markets across the world. Approval for its use in Europe is still pending.

ISP is a technological breakthrough based on nature’s own solution for ice control. It has been the result of purposeful and productive scientific research conducted under the highest standards of responsibility by many people and creative product development exploiting the benefits of ISP to enable better ice cream for everyone.

Acknowledgements

The author wishes to acknowledge major contributions to this article from R&D colleagues: D.J.Cebula, S.J.Mayes, C.Sidebottom and R. Crevel of Unilever R&D, Colworth Science Park, Bedford, UK. Also, for the kind permission to reproduce images of the ISP molecular structures the author is indebted to Professor Frank Sonnichsen, Case Western Reserve University, Canada and Professor Rod Hubbard, University of York, UK

References

Clarke, C.J.; Buckley, S.L. and Lindner, N. (2002) Ice structuring proteins: a new name for anti-freeze proteins. CryoLetters, 23:89-92.

Elkington, J. and Hailes, J. (1999) The New Foods Guide, pp. 280-286 VICTOR GOLLANCZ London.