Product-oriented intensive heating process design

- Like

- Digg

- Del

- Tumblr

- VKontakte

- Buffer

- Love This

- Odnoklassniki

- Meneame

- Blogger

- Amazon

- Yahoo Mail

- Gmail

- AOL

- Newsvine

- HackerNews

- Evernote

- MySpace

- Mail.ru

- Viadeo

- Line

- Comments

- Yummly

- SMS

- Viber

- Telegram

- Subscribe

- Skype

- Facebook Messenger

- Kakao

- LiveJournal

- Yammer

- Edgar

- Fintel

- Mix

- Instapaper

- Copy Link

Posted: 7 March 2007 | J. Broeze, R.G.M. van der Sman, H.M. Vollebregt and R.W. van den Berg, Agrotechnology and Food Sciences Group, Wageningen UR | No comments yet

Control of product quality and process yields in innovative food production processes can be largely improved through better understanding of the relations between process design and product quality. The effects of intensive heating processes such as frying, baking, roasting and microwave on product quality are still poorly understood. Currently, when designing new food processing lines, […]

Control of product quality and process yields in innovative food production processes can be largely improved through better understanding of the relations between process design and product quality. The effects of intensive heating processes such as frying, baking, roasting and microwave on product quality are still poorly understood. Currently, when designing new food processing lines, empirical knowledge of the effects of various process types on product quality is leading. With upcoming ‘new’ heating methods, more fundamental insight is essential.

A model-based design will help food equipment industries and early adopters of new technology to minimise costs for pilots.

Drivers for process innovations

Food process innovation and optimisation have high priority for various reasons:

- International competition leads to consolidations and scaling up of business and production processes

- Process automation is widely adopted to reduce personnel costs

- To maintain uniform high quality standards in the industrialised processes, there is a growing concern for quality control

- There is a need for awareness of food safety issues

- An increasing priority for product innovations

Rodd6 identifies three key areas within the current requirements of the global food manufacturing industry:

- Process performance; “modern manufacturing technologies need to account for this, higher or lower temperatures, for example.”

- Communication protocols and networks; “including communications integrated in both the local control loop and the overall process system.”

- Optimisation production lines to meet ongoing changes in the product being manufactured

Insight in product quality-oriented process control is directly connected with these issues.

Intensive heating processes such as frying, baking and roasting are often used to create a texture contrast to food, i.e. a moist core encased with a crispy crust. Owing to a lack of understanding of heat and moisture migration within the product, the crust formation is largely unpredictable for food manufacturers. Modifying or innovating heating process equipment without violating the product quality is even more difficult.

Numerical simulation models can predict the effects of modifying process settings and possible measures. Furthermore, models can be used for ‘intelligent sensors’ that relate product quality with measurable product and process data.

In co-operation with several (industrial) parties the Agrotechnology and Food Sciences Group from Wageningen University and Research Center has made important progress in understanding moisture migration and crust formation in heating processes. Numerical simulation models are used to predict temperature distribution within the food products and effects such as denaturation, moisture transport and crust formation. With this approach, in close co-operation with several (industrial) parties the suitability of various novel heating processes to replace existing processes are being explored.

Strategies for product-oriented process design

We distinguish different strategies for utilisation of the modelling knowledge/expertise:

Exploring the (dis)advantages of innovative intensive heating processes

With the availability of submodels for various heating principles, the effects of various combinations of heating principles can be predicted. The results can be used for preliminary selection of candidate process settings.

Early evaluation of innovative process designs

Uncertainty about the effectiveness and efficiency of processes may hinder the adaptation of alternative intensive heating processes (e.g. use of microwave or radio frequency). This uncertainty can be reduced and removed through illustrating the expected effects and risks through numerical modelling of the products’ quality development in the intended process setting.

For various applications we have, amongst others, evaluated the temperature gradients within the product, cooking value, moisture distribution and loss, chances of run-away temperatures, etc.

Scaling up: from lab-scale to pilot or industrial process lines

Scaling up processes brings about changes of physical dimensions and time scales. Modelling can be of assistance in determining the feasibility of the intended scaling on the intended effects of the processes on the products’ quality.

As a spin-off from this type of applied-scientific work, the knowledge can also be applied for designing new food products (for instance the design of geometry of ready meals with more homogeneous heating characteristics in household microwaves, new snacks, etc).

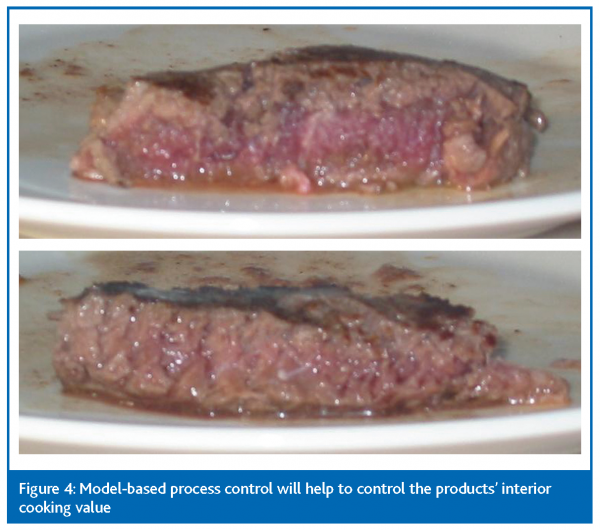

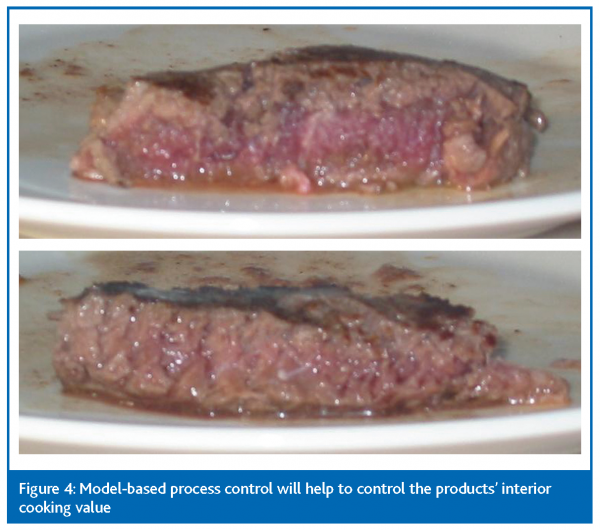

Optimal control through intelligent measuring methods

Owing to the variations of process inputs and varying preferences with respect to output, applying constant process settings generally does not result in optimal product quality. Optimisation of product quality is furthermore hindered by the fact that ‘product quality’ cannot be measured with one individual sensor.

A ‘model-predictive process control’ (MPC) method will facilitate a product-oriented process control. In such an approach, process insight obtained with the detailed process models described above is utilised to relate product quality attributes with measurable values (such as oven temperature, pressure, RH, product surface temperature, weight loss, etc.).

Understanding food quality development

The following food quality attributes are more or less understood with the current physical-chemical knowledge of food products:

- Product temperature, including temperature profiles (relevant for microbial safety and for consumer acceptance during final preparation)

- Moisture content and distribution within the product and crust formation (relevant for sensory experience during consumption)

- Cooking values (physical-chemical modifications within the product, driven by temperature and moisture contents)

To predict these quality attributes, we have integrated the following phenomena in our model:

- Heat transfer (convective) from surrounding medium (such as hot air, water or oil) to the product surface

- Heat transfer to the product through electromagnetic radiation (microwave, RF)

- Heat conduction inside the product

- Evaporation or condensation of water vapour on the product surface

- Conversion of bound moisture to free moisture due to protein denaturation

- Type-of-product-specific pressure driven moisture transport

- Convective heat transport by the migration of moisture

Understanding food physics

Crust formation

Crust formation in moist foods occurs through the removal of moisture from the outer part of the food, while keeping the core moist. The removed moisture is replaced by air, such that the original structure of the food’s solid matrix phase is maintained and becomes crispy, and results in a crunchy sensation during consumption.

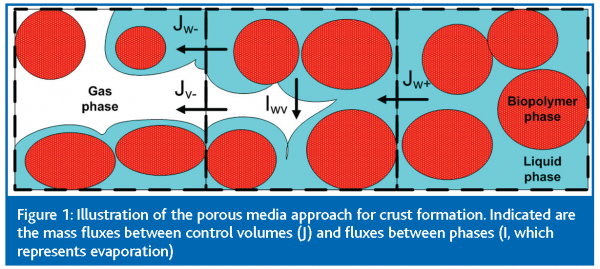

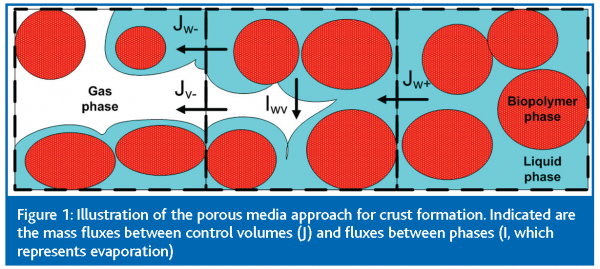

Crust formation can be described in numerical models by describing it as a composite material, consisting of a solid matrix of biopolymers (proteins, carbohydrates, lipids) and a dispersed phase, which can be a mixture of fluids such as water, air and oil. Inspired by soil science we view our material as a porous medium: the structure is formed by the solid part and the fluid is the air and moisture present in the product.

In contrast to soil science the porous medium approach is quite underdeveloped in food science. Perhaps this is explained by the more complex nature of food materials. Noticing the pioneering work of Stephen Whitaker1, the more recent work of Ashim Datta2 and the recent progress in soft condensed matter field in physics3 we have dared to tackle the complexity of food materials. Results have proven that the porous media approach4 holds for a broad range of food materials used in intensive heating, but must be supplemented with material-specific relations for forces driving moisture migration.

Electromagnetic heating

With electromagnetic heating (microwave, radio frequency), different processes are induced: local heating, perhaps even boiling, heat conduction and moisture transport to other parts of the food product. In packages of food products additional functions can be applied e.g. to prevent (shielding) or to enhance (for instance with the shape of the package) the effects of the microwaves. Simulating microwave heating for household microwave ovens has taught us that the particular geometry of the oven has a large impact on the results, as do the shape and the dielectric properties of the food products. The household microwave oven model can be used to analyse the effects of these factors for the development of new microwave products.

Protein denaturation

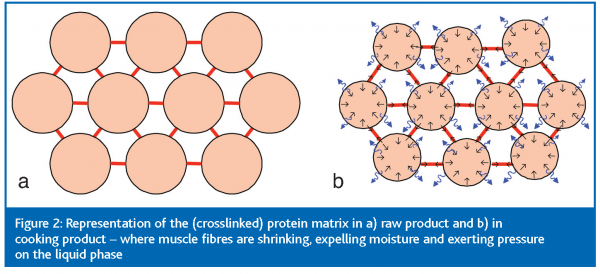

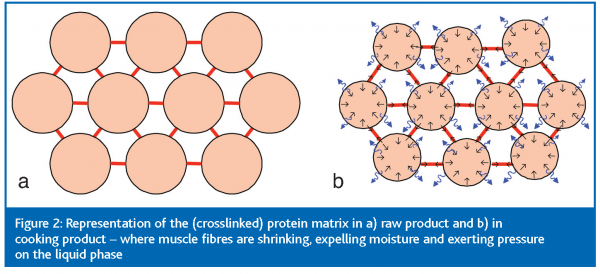

From literature surveys we have concluded that the cooking of meat is quite comparable with polymer syneresis, cheese ripening and sponge squeezing. These materials can be described by poroelastic theory, describing moisture transport due to a swelling pressure. In polymer physics the swelling pressure is related to hydrophobic interactions between polymer and solvent (osmotic pressure) and elasticity of the polymer network (network pressure). This readily applies to cooking product; as proteins denaturate they expose their hydrophobic part to the water, by which the water is expelled from the product. Product proteins form a crosslinked network and, due to denaturation, the protein chains shrink and exert extra (network) pressure on the network (Figure 2).

Example applications

Roasting beef

We have learned that for an accurate description of cooking and roasting meat, understanding and correct description of crust formation, protein denaturation and moisture transport within the product, as described above, are highly important.

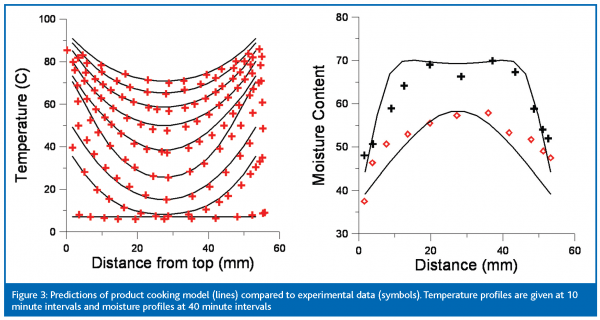

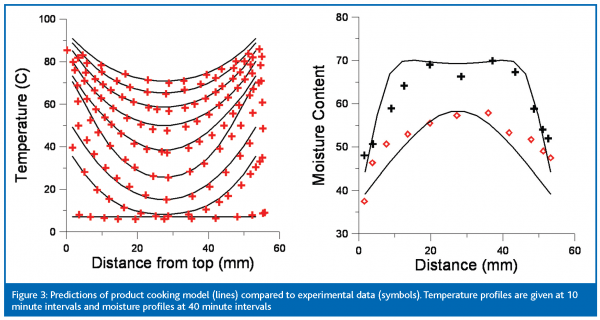

Validation of the model with data from literature7 shows good agreement (Figure 3).

Through simulations with varying oven conditions, insight in relationships between process design, process set points and product quality is developed.

Food packages for microwaves

The shape of a package influences the heating pattern in a microwave oven because it determines the shape of the food product. Besides typical electromagnetic product properties, geometric aspects such as corners and thickness of the product influence the resulting heating pattern. Another important aspect is the package material. Use of metal inside the package material results in shielding; this functionality can be utilised to protect components of the food from the microwaves and to focus the energy on other components.

Through application of the model, a selection of suitable packages for microwave meals was made.5

Other applications

Since the beginning of this decade we have extended the model to a broader variety of applications, including frying, baking and radio frequency applications.

We have experienced that especially in processes with large heat fluxes and fast crust formation (e.g. with frying) rapid changes in physical properties have large influences on the process behaviour. Adapting physical product parameters in the model is essential for a reliable outcome and correct understanding of model results.

Outlook

Intensive heating of food products results in complicated processes within the products. The development of models for these processes makes it possible to enhance insight in the complex process dynamics and product quality development. This forms a basis for new food production lines with more effective control of product quality and safety.

This article shows that modelling is a powerful tool to support the design of heating processes. Understanding the physical processes within the product enhances insight in the relation between product quality and process design and control.

Precise understanding of the physical processes (and change of process parameters due to changing product properties) and choosing suitable modelling methods are crucial for successful modelling. Use of the porous medium approach has proven to be very useful for modelling intensive heating of moist food products.

We foresee that the approach can also be applied to totally different processes, such as drying or fluidised beds.

References

- Whitaker, S. (1975): Simultaneous heat, mass and momentum transfer in porous media: a theory of drying. Adv. Heat Transfer 18(1A): 1-13.

- Ni, H., A.K. Datta, and K.E. Torrance (1999): Moisture transport in intensive microwave heating of biomaterials: a multiphase porous media model. Int. J. Heat Mass Transfer 42: 1501-1512.

- Mezzenga, R, P. Schurtenberger et al. (2005): Understanding foods as soft materials. Nature Materials 4(10): 729-740.

- Van der Sman, R.G.M. (2003): Simple model for estimating heat and mass transfer in regular-shaped foods, J. Food Eng. 60(4): 383-390.

- Luitjes, H., H.M. Vollebregt and R. Canters (2004): Virtual oven takes chill out of microwave cooking. New Food 1, 75.

- Rodd, M. (2006): Challenges and solutions. New Food 3, 20.

- Bengtson, N.E., B. Jakobsson, and M. Dagerskog. (1976): Cooking of beef by oven roasting: a study of heat and mass transfer. J. Food Sci. 41: 1047-1053.