CCFRA: science and technology for better business

- Like

- Digg

- Del

- Tumblr

- VKontakte

- Buffer

- Love This

- Odnoklassniki

- Meneame

- Blogger

- Amazon

- Yahoo Mail

- Gmail

- AOL

- Newsvine

- HackerNews

- Evernote

- MySpace

- Mail.ru

- Viadeo

- Line

- Comments

- Yummly

- SMS

- Viber

- Telegram

- Subscribe

- Skype

- Facebook Messenger

- Kakao

- LiveJournal

- Yammer

- Edgar

- Fintel

- Mix

- Instapaper

- Copy Link

Posted: 7 March 2007 | Dr Leighton Jones, Head of Corporate Communications, CCFRA | No comments yet

The principal priorities for all food companies are safety, quality, efficiency and innovation. Everyday, CCFRA helps food and drinks companies to achieve these – and so succeed in business.

The principal priorities for all food companies are safety, quality, efficiency and innovation. Everyday, CCFRA helps food and drinks companies to achieve these – and so succeed in business.

The principal priorities for all food companies are safety, quality, efficiency and innovation. Everyday, CCFRA helps food and drinks companies to achieve these – and so succeed in business.

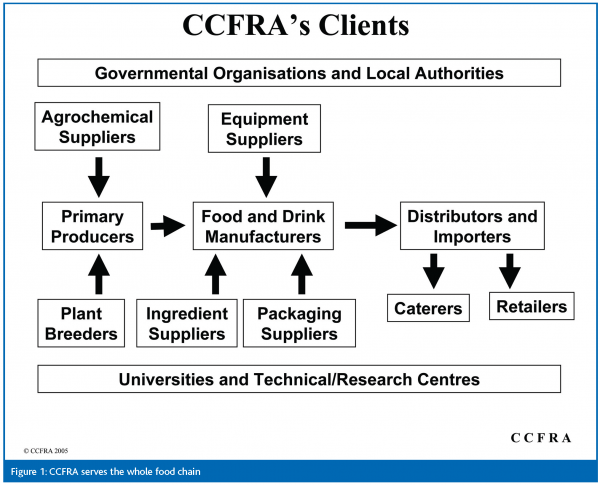

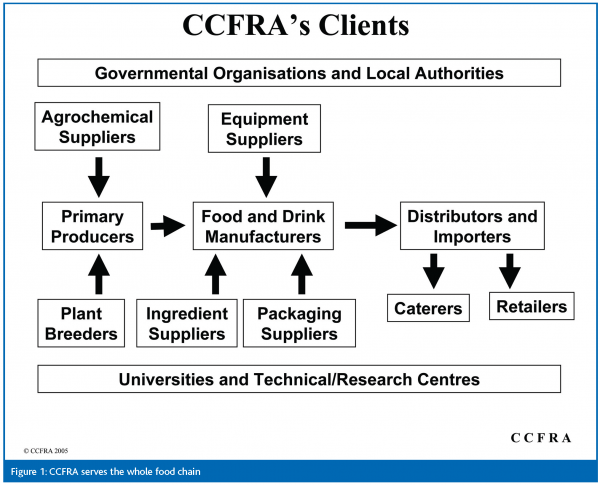

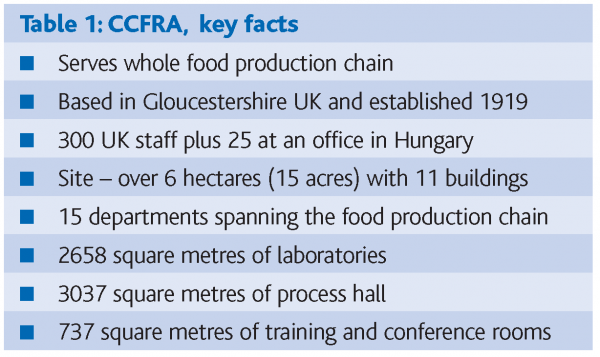

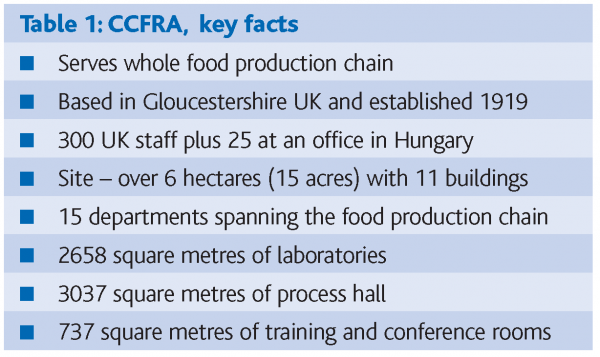

With members in over 60 different countries, CCFRA (Campden & Chorleywood Food Research Association) is the world’s largest member-based food research organisation. It supports companies all along the food production chain – from crop production through processing and manufacturing to retail and food service – as well as from allied industries such as agrochemicals, packaging, transport and equipment manufacturing (Figure 1). This article highlights just some of CCFRA’s work. Further information can be accessed from a special webpage that supplements this article (see below).

The product development chain

From creating ideas to benchmarking newly launched products, CCFRA supports all stages of product development. The market insight team monitors the latest developments and trends, whilst the consumer and sensory science team can identify what consumers want from a product. Both provide vital information for that extra competitive edge.

“Converting ideas to product, demands formulation expertise for a range of technologies that we offer,” explains Philip Richardson, Head of Food Manufacturing Technologies. “We have extensive experience of heat processing, UHT/aseptic, chilled and frozen foods, novel technologies, modified atmosphere packaging and microwaving. Our pilot facilities include a product development kitchen, controlled temperature preparation areas, clean filling and packaging areas and process halls. These allow companies to conduct development trials without disrupting their own manufacturing operations.”

These facilities are complemented by the expertise, pilot plant and services CCFRA offers the bakery sector, as Terry Sharp, Head of Baking and Cereals Processing explains: “As well as bakery trend prediction, development of prototypes for market research and growth areas such as part-baked, ready-to-bake and shelf-life extension, we have been involved in highly novel activities like bakery products as pharmaceutical delivery systems. And with ‘healthy eating’ as a major driver, we have brought our expertise to bear on a range of product reformulation projects.”

Consumers’ growing awareness of glycaemic index (GI) provides a good example of how CCFRA responds to industry needs through new services. GI is a measure of the body’s response, in terms of blood sugar levels, to carbohydrate-containing foods. Although companies want to consider GI in product development or reformulation, in order to make on-pack GI claims, its measurement is complex, requiring specialist skills and facilities. CCFRA has developed a much simpler hydrolysis index (HI) procedure, more suited to screening foods during product development for an indication of the food’s GI (high, medium or low).

Rapid and reliable prediction of microbiological shelf life is also important. By providing rapid predictions, computer models of the growth of spoilage organisms give a quick indication of likely product shelf-life and save considerable time and money by narrowing the focus of practical trials. Models cover the major groups such as Pseudomonas, Enterobacteriaceae, Bacillus and yeasts, as well as spoilage consortia, with recent data added to cover spoilage of packaged fresh produce.

For products that require reheating, accurate on-pack instructions are essential for consumers to produce a product that is microbiologically safe and of the highest sensory and nutritional quality. With extensive experience of how chilled and frozen products heat in microwave and conventional ovens, under grills and on hobs, CCFRA’s independent instruction development service uses equipment calibrated to UKAS standards to cover these options.

Companies can also obtain an independent view of how their new products compare with those of competitors, through CCFRA’s growing product benchmarking service. Provided by an experienced team of home economists, chefs and expert shoppers, the service identifies, sources, prepares and assesses new products, to express an independent view as a simple eating enjoyment score.

Nutrition claims and food composition

Early consideration of on-pack information can also help shape product development, as John Hammond, Head of Information and Legislation explains: “We can advise on product formulation so that product names, claims and descriptions are supportable. We can review either the full label or selected aspects and we can forewarn of potential difficulties and suggest practical alternatives. With product labelling affected by rules from well over 100 separate pieces of UK and EU legislation, as well as extensive formal and informal guidance, the advice offered can be used to avoid costly re-formulations, label or product write-offs and even difficulties with enforcement authorities.”

The new EU regulation on nutrition and health claims, which came into force early in 2007, provides a good example. This has major consequences for food manufacturers and retailers and the way they label their products. For example, any nutrition claim (on what the product contains) or health claim (on what the product or one of its constituents does) will have to come from a positive list of permitted claims and be based on generally accepted scientific evidence. CCFRA’s food legislation activities keep members informed of developments like these through the Food Law Alert bulletin; Food Law Notes manual; tailored briefing presentations and seminars; and the long-established food law enquiry service.

Food chemists at CCFRA also actively support companies in this area. Use of NMR for rapid fat determination complements established methods for saturated fats, trans fats and omega-3 and –6 fatty acids. A fact sheet on ‘Analytical Implications of the Current Salt Issue’ promotes better understanding of how sodium and chloride analysis relates to on-pack declarations.

Food packaging

Increasingly, the package is more than just a vessel to contain the food or drink, but is an integral part of the product: it protects; preserves and provides the first impression of the contents. Reflecting this, CCFRA’s packaging services have grown significantly in recent years to help companies identify appropriate packaging for their product; test the properties of alternative materials; troubleshoot problems that arise and monitor the latest developments in packaging technology.

Permeability testing of packaging materials is a good example, as Alan Campbell, CCFRA’s Packaging Technology Manager, explains: “Oxygen and water vapour can adversely affect the flavour, texture, colour and nutritional properties of food. Manufacturers and processors who use partially permeable packaging such as plastic films have to bear this in mind. We have the equipment for measuring oxygen and water vapour transmission rates through a variety of plastics films and packages, and the expertise to explain the significance of the measurements for product quality and shelf-life.”

With facilities to conduct pilot trials for everything from modified atmosphere and aseptic packaging to sterilisation and microwaving, CCFRA is involved with the full range of flexible and rigid packaging materials – from pouches, trays and bags to glass and metal. They are also often asked to troubleshoot packaging problems and carry out integrity testing to determine leaks and the strength of package seals.

Multi-laminate pouches, for example, are increasingly popular for many quality products, ranging from soup to pet food. Although proving very successful, the introduction of new materials can occasionally lead to problems. An understanding of the structure of the material around possible faults – such as channels across seals – combined with knowledge of the sealing technology, can help to provide a rapid solution to the problem. Sections of flexible laminates or rigid plastic containers can be examined microscopically and analysed by Fourier Transform Infrared Spectroscopy to confirm the composition of the material, check that the thickness of individual layers are as specified, or identify layers which are delaminating.

“Microscopy is a good example of how we are able to call upon the expertise of specialist colleagues to solve problems” adds Alan. “We also work with chemists for taint or migration problems; hygiene specialists for cleanability of packaging systems; product intelligence experts for novel products in the marketplace and food law experts for packaging legislation”

With an eye to the future, the packaging team has increasingly been monitoring developments with a range of active and intelligent packaging formats to advise companies who want to make use of them. Examples include oxygen and moisture scavengers, lactose and cholesterol removers and microwave susceptors to radio-frequency (RFID) tagging, anti-counterfeit devices and microwave ‘doneness’ indicators.

International support

CCFRA’s services are drawn on by companies and governments from across the world. Its work with Kuwaiti authorities provides a good example. Kuwait imports around 85 per cent of its food and assuring the safety of this and domestically produced food is paramount for the authorities. For several years CCFRA has been providing extensive technical advisory services to the Kuwait Institute for Scientific Research (KISR) in the development of a food control infrastructure for the Kuwait Municipality. This wide-ranging work has included:

- Reviewing, benchmarking and developing food control systems

- Developing ‘rating’ systems to identify which food premises to inspect

- Devising risk assessment procedures for identifying which foods to sample and how

- Design of laboratories and provision of analytical methods

- Development of analyst job descriptions and analyst training

- Creating a specification to help the authorities procure a computerised food sampling system that links to a laboratory information management system (LIMS) for efficient data gathering for samples along the import, distribution and testing chain

The work of C&C Hungary in supporting companies with suppliers in Central and Eastern Europe provides another good example. The Hungarian site offers support services in food and drink safety, quality management, product development, consumer preference studies and a range of training activities. Much of this work centres on product quality, for example through sensory analysis, sensory benchmarking and consumer studies. This is complemented by extensive work on quality management, traceability and safety assurance systems.

Other recent examples of international support include:

- HACCP and QM consultancy and training support in Kenya, Egypt, South Africa, Brazil, the Philippines, Mauritius and Europe – the latter including a series of twenty 5-day HACCP workshops as part of the European Commission initiative ‘Better Training for Safer Food’

- Bakery courses at overseas venues to meet the needs of non-UK companies, saving delegates time and companies money. Using the facilities at partner companies – Anchor Yeast in Johannesburg and Odlums in Dublin – facilitated courses covering biscuit, bread and cake technology, fibre in bakery products and ‘flour power’. These complemented confidential, tailored courses where delegates could openly discuss specific business-critical issues close to the production environment, provided for companies from Denmark, Mauritius, Egypt, Hungary, Saudi Arabia and China

- Training on advanced thermal processing to Thai trainers who will disseminate the expertise through the Thai heat preserved food sector – as part of the EU Thailand Economic Co-operation Small Project Facility. Also consultancy and support visits to companies in Europe, Mexico, Peru, Venezuela and South Africa

- Support of food laboratories, including their accreditation to CLAS – the Campden Laboratory Accreditation Scheme. Recently, Turkey and South Africa were added to the list of countries where laboratories have achieved CLAS accreditation, which now covers laboratories from Ireland, Britain and mainland Europe to as far afield as the Maldives

A look to the future

CCFRA works closely with its members to ensure that its activities meet their needs. These technical needs are defined in a strategy document ‘The needs of the agrifood chain’ – developed and revised on a triennial basis. At the last review, two areas emerged as particularly significant. The first, diet and health, will continue to be prominent as CCFRA supports members with, for example, product reformulation, nutritional analysis and labelling, as described above. The second, sustainability, is attracting considerable attention from food and drinks companies and will become a major driver in 2007. CCFRA is increasingly active in helping companies understand what ‘sustainability’ means for them including, for example, waste minimisation and reduced energy and water consumption.

Further information

A webpage supplementing this article can be found at http://www.campden.co.uk/ccfra/newfood.htm It provides contact details for the scientists and technologists listed, a copy of the ‘needs’ strategy and CCFRA’s research programme, as well as links to further information on related services, research, training and publications. You can also ask to be sent further information by e-mailing us at [email protected] and quoting ‘New Food magazine’.