Optimal drying is no easy task

- Like

- Digg

- Del

- Tumblr

- VKontakte

- Buffer

- Love This

- Odnoklassniki

- Meneame

- Blogger

- Amazon

- Yahoo Mail

- Gmail

- AOL

- Newsvine

- HackerNews

- Evernote

- MySpace

- Mail.ru

- Viadeo

- Line

- Comments

- Yummly

- SMS

- Viber

- Telegram

- Subscribe

- Skype

- Facebook Messenger

- Kakao

- LiveJournal

- Yammer

- Edgar

- Fintel

- Mix

- Instapaper

- Copy Link

Posted: 18 August 2008 | Maarten Schutyser, Maykel Verschueren, Han Straatsma, Hadiyanto, Coen Akkerman, Peter de Jong, NIZO food research | No comments yet

Drying processes in the food industry often operate at a suboptimal level. The most important reason for this is that to obtain optimal drying, a complex balance must be found among variables such as energy costs, product quality, dryer design and safety. Therefore, there is a need for a systematic approach and concrete solutions. NIZO food research has developed a step-by-step optimisation approach that not only makes use of process and product scans, but simulation techniques such as CFD (Computational Fluid Dynamics).

Drying processes in the food industry often operate at a suboptimal level. The most important reason for this is that to obtain optimal drying, a complex balance must be found among variables such as energy costs, product quality, dryer design and safety. Therefore, there is a need for a systematic approach and concrete solutions. NIZO food research has developed a step-by-step optimisation approach that not only makes use of process and product scans, but simulation techniques such as CFD (Computational Fluid Dynamics).

Drying processes in the food industry often operate at a suboptimal level. The most important reason for this is that to obtain optimal drying, a complex balance must be found among variables such as energy costs, product quality, dryer design and safety. Therefore, there is a need for a systematic approach and concrete solutions. NIZO food research has developed a step-by-step optimisation approach that not only makes use of process and product scans, but simulation techniques such as CFD (Computational Fluid Dynamics).

Results show that quick wins of 10-20 per cent of the operational costs can be achieved. Another trend is towards increasingly complex ingredients with unique characteristics. In addition to spray drying, the range of applications for other drying technologies such as drum drying and freeze drying continues to expand. For instance, Zeodration, a promising alternative to freeze drying, offers possibilities for the drying of probiotics, neutraceuticals, fruit and aromatic sauces.

Drying in the food industry

Acute contamination problems, the desire for increased production capacity or an unusual product quality often form the inducement for a revision of the drying conditions and sometimes even the design of a drying process. NIZO assists the food industry with a structured optimisation approach. Advanced analysis techniques and simulation techniques are used to optimise both process efficiency and production quality. Furthermore, the higher and more diverse demands on production quality and the increasing energy prices make it increasingly beneficial to consider alternatives to spray drying such as drum drying, Zeodration and fluidised bed drying.

Spray drying

In spray drying, the product to be dried, which is usually pre-concentrated with an evaporator or membrane system, is atomised and brought into contact with hot air. Due to the high rate of water evaporation, the temperature of the drops as they dry remains low, and therefore this trying technique is extremely suitable for heat-sensitive products such as food products and pharmaceuticals.

In practice, the objective is to achieve the highest possible capacity, the lowest possible energy consumption and the longest possible running time without contamination of the installation. For capacity and energy consumption, it is beneficial to choose an inlet air temperature that is as high as possible and an outlet air temperature that is as low as possible. The capacity gains, in particular, are spectacular: an increase of the inlet air temperature by 10°C (from 180°C to 190°C for instance) results in a capacity gain of approximately 10 per cent. However, higher temperatures have the following consequences:

- Higher thermal load on the product → poorer product characteristics

- Other outlet conditions

- Higher powder moisture content for the same outlet air temperature: → product more sticky → more contamination; or

- Higher outlet air temperature for the same powder moisture content: → higher thermal load

- Higher risk of fire

It is therefore important to consider all the factors to arrive at a good compromise between product characteristics on one hand and capacity, energy consumption and safety on the other. NIZO has developed a structured approach for this.

In practice, the spray dryers are often followed by a (vibro) fluidised bed dryer to dry the powder to the desired final moisture content and to cool it to a suitable temperature for storage.

Increasing use is being made of MSDs (Multi-Stage Dryers) with an integrated fluidised bed in the cone of the dryer, in which an intensive vortex is maintained by an extra air stream. These dryers can often operate with higher inlet air temperatures because this bed can receive powders with higher moisture contents without the occurrence of lump formation and wall contamination. Furthermore, these dryers are suitable for the production of powders with a high level of agglomeration. For instant powders especially, this is a beneficial characteristic.

Other drying techniques

In addition to spray drying, drum drying, Zeodration and fluidised bed drying offer possibilities for making powers with unique characteristics at limited operational costs:

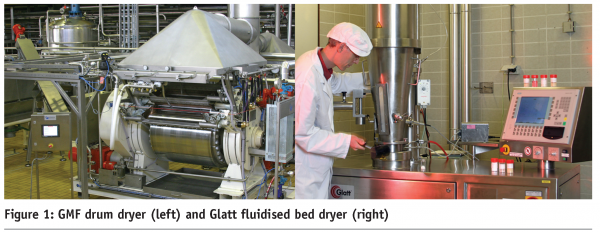

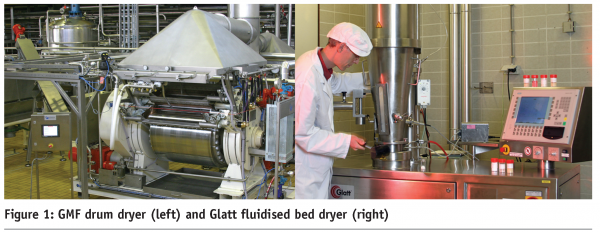

- Drum drying is a continuous process in which the product to be dried is applied as a thin film layer to the outside of a rotating drum heated from the inside. After each rotation, a knife scrapes the dried product from the drum as a film or as flakes. The drum dryer is well suited for sticky and highly viscous products, which are difficult or impossible to spray dry. Heat-sensitive products can be dried at lower temperatures by operating the dryer at sub-atmospheric pressure. The thermal efficiency of a drum dryer is favourable, because no energy is lost in the hot outlet air, in contrast to systems such as spray dryers. Refer to the website http://www.gmfgouda.com/drum-dryer/drum-dryer-nl.html for additional information

- Zeodration drying technology is a very interesting alternative to freeze drying. The combination of vacuum conditions and the use of zeolite make it possible to dry under relatively mild conditions. The zeolite (molecular sieve) can selectively adsorb water molecules, while the aromatic components remain in the product. In contrast to conventional freeze drying, the energy consumption (50 per cent lower) is a big advantage. Recently, the new Bucher Zeodration system was successfully tested for drying probiotics, neutraceuticals, fruit and aromatic sauces. Among other things, it has been determined that in comparison to normal freeze drying, the taste of kiwi and yoghurt are better retained

- In fluidised bed systems, complex, heat-sensitive products can be dried, agglomerated and coated. In a new system from Glatt (Procell), specific small quantities of products can be easily fluidised by making use of a small air gap for the air distribution. With a special addition in which fine particles are returned via a zig-zag sieve, this system can be converted to a spouted bed system that can be operated continuously. This system is particularly well suited for building up particles in various layers. To illustrate, tests were recently performed with the encapsulation of fat in sugar. By encapsulating fat in sugar, it is possible to obtain a homogenous distribution of both materials in the intended product

Optimal drying

Step-by-step optimisation

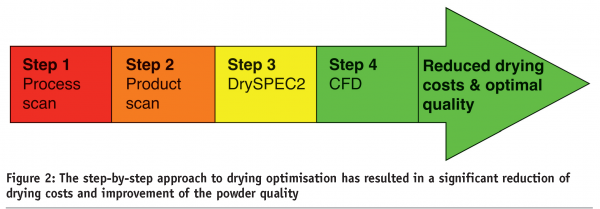

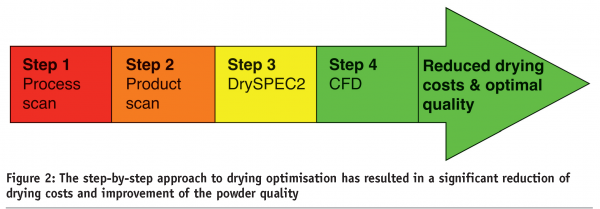

A step-by-step approach is recommended for the optimisation of both existing installations and installations that are being newly developed (Figure 2). Over the course of the past 15 years, NIZO has gained experience with this approach in collaboration with the food industry. It often appears that not all steps are necessary and that, for instance, contamination occurs during the evaporation process, and it ultimately enters the product. Results show that quick wins of 10-20 per cent of the operational costs can be achieved.

- The process includes a critical inspection of the drying process and process environment by a drying expert. Problems may be found not only in the drying process itself but also in the prior processes (heating, evaporating, cycloning, et cetera). Accurate data on drying conditions can be obtained through measurements made during one or more production runs

- The product scan is focused on analysing the most relevant characteristics of the powder. The impact of temperature and air humidity can also be included in this scan, so it is known under which drying conditions an optimal product can be made

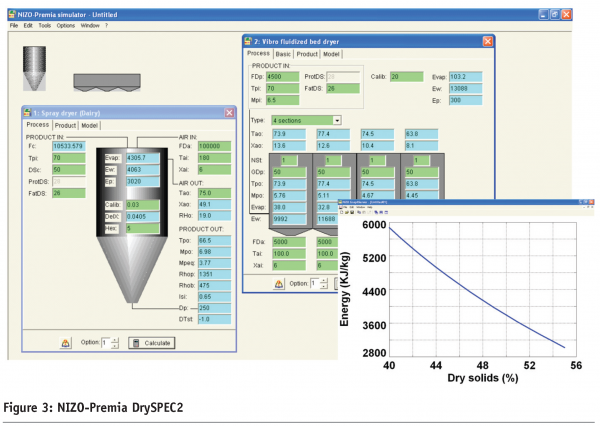

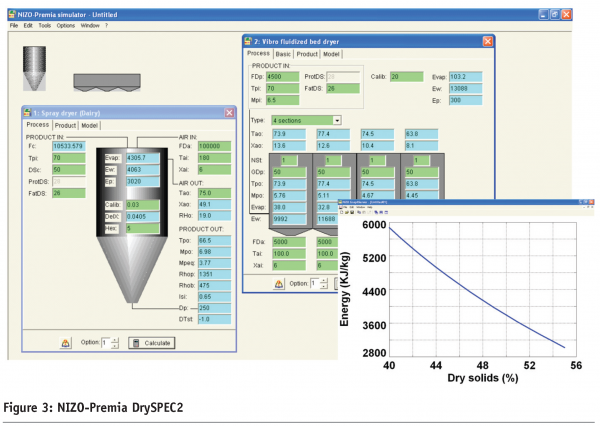

- Through use of a ‘near-equilibrium model’ (DrySPEC2), correlations can be established between raw material characteristics, drying conditions, product characteristics and energy consumption. With these correlations, an optimal operating range can be determined for the specific dryer and the product

- Enhanced CFD drying models are available for the evaluation and optimisation of the impact of a dryer design and local drying conditions on the product characteristics. Results can be used for such purposes as developing an improved dryer design or the reduction of contamination problems

Advanced powder analysis techniques

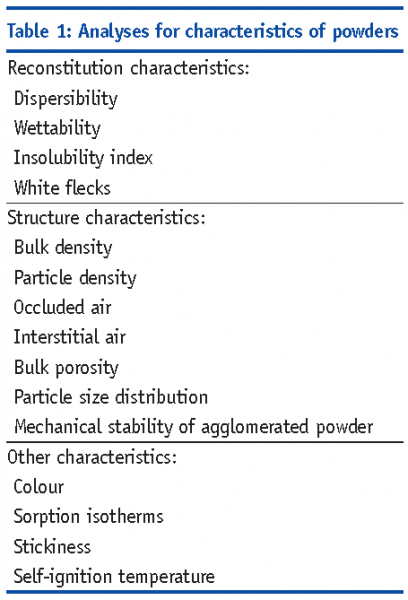

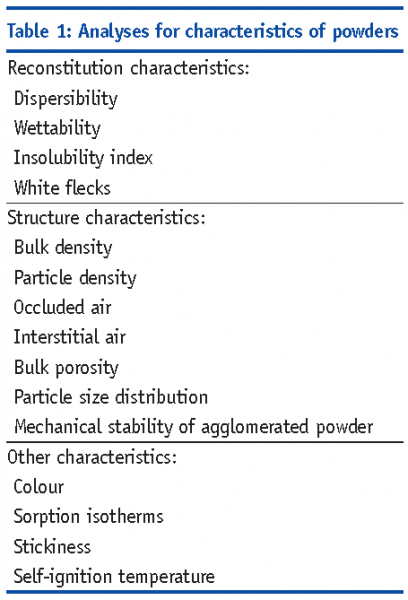

For optimisation of the drying process, the following powder characteristics are of great importance:

- Sorption isotherm

The sorption isotherms describe the water activity of the product as a function of the moisture content at a certain temperature. The water activity of hygroscopic products is much lower than less hygroscopic products with the same moisture content. To carry out predictive calculations, it is essential to know the sorption isotherms of the products in question. A problem that often occurs during determination of the sorption characteristics is crystallisation of certain components, such as sugars. Drying in spray dryers occurs so quickly that there is usually no time for crystallisation, and therefore sugars remain in the amorphous state. During determination of the sorption isotherms, a longer period of time is often required to arrive at sorption equilibrium. Particularly at high moisture contents and temperatures, crystallisation may occur. In the crystallised state, however, a product has different sorption characteristics than in the amorphous state. Analyses in which crystallisation occurs are therefore unusable. With advanced equipment (VTI SGA-CX vapour sorption analyser), sorption isotherms can be quickly and accurately determined.

- Stickiness

For many drying applications, such as hydrolysed or sour whey and other products with high sugar content, stickiness of the powder is a critical parameter that is dependent on product composition and, particularly during the drying, on the temperature and moisture content. Stickiness can promote the desired agglomeration, but it can also lead to contamination or lump formation. Up to now, the best results have been obtained with a visual method. The powder is placed in a dish and brought to the desired conditions in a climate cabinet at a controlled temperature and air humidity. By moving the dish, it is possible to visually assess whether the product is or is not sticky. In collaboration with the TUDelft and IPCOS, NIZO has taken the initiative to apply DyMonT (Dynamic MoniToring) to determine stickiness under dynamic conditions (such as in a fluidised bed of powder)4,7,8. The measurement of the high pressure fluctuations in the fluidised bed and the analysis of the fluctuations with the so-called attractor comparison method appear to be the key to success. Through use of this method, it is possible to detect extremely small changes in the hydrodynamic bed behaviour as a result of an increase of the stickiness. This technique allows us to determine the stickiness of powder under relevant drying conditions.

- Self-ignition characteristics

Just like a fire in a hay-stack as the result of overheating, oxidation reactions in the innermost part of a lump or layer of powder can produce more heat than is removed through conduction. The temperature then quickly rises, resulting in self-ignition of the powder. The ambient temperature required to initiate self-ignition of a lump is called the self-ignition temperature and is dependent on the lump size. In the case of spray drying, depositions near the hot air inlet pose the greatest potential danger of fire. Self-ignition characteristics can be determined in an oven made suitable for the purpose.

Other powder analyses are usually relevant to the application of the powder. The reconstitution characteristics, for example, provide information about the behaviour of the powder when it is brought into contact with a liquid. Table 1 provides an overview of the analyses that are employed to characterise powders.

The use of models for drying optimisation

NIZO food research has worked on the development of predictive models for various production processes, including the spray drying process, since 1985. The models are implemented in modules and are part of a user-friendly computer program (NIZO-Premia). The same modules can also be used in NIZO-Premic to monitor and regulate in-line processes. These programs are used as tools for carrying out projects for clients. A number of models are now also available for third parties.

One of the first programs NIZO food research developed is DrySPEC22. This handles calculations for two-stage dryers (spray dryer and vibro fluidised bed) (Figure 3). The program establishes the relationship between the characteristics of the raw material and the process conditions on one hand and the characteristics of the final product and the energy consumption on the other. A ‘near-equilibrium model’ is used as the basis for the calculation of the powder moisture content of the spray dryer. For the calculation of the other powder characteristics, empirical relationships are employed. For this approach, a kinetic model of the drying process is not required, which means the calculation time is extremely short (< 1 second). Experiments have shown that the difference from equilibrium for a particular spray dryer remains virtually unchanged as the temperatures and flow rates are changed. The best practice for use of this model is to use actual data from a practical situation to determine the difference from equilibrium and the heat loss to the environment. This allows accurate prediction of the effect of variation of the process conditions and raw material characteristics.

For the drying of hygroscopic products, the moisture content of the drawn in outside air, which is dependent on the weather conditions and the season, is of great importance. DrySPEC2 is extremely well suited for calculating how the process conditions must be adapted to compensate for these variations.

The use of Computational Fluid Dynamics (CFD) for drying optimisation

To address all the industrial problems, there was a need to model every detail of the spray drying process3. Throughout the years, in collaboration with software company CD-Adapco, the expansion module es-spraydry has been developed, which can be used in the commercial CFD package STAR-CD (see also websites www.cd-adapco.com/products/STAR-CD and www.cd-adapco.com/products/es-solutions/es-spraydry.html). This makes it possible for the entire air flow pattern in the spray dryer and the paths of the atomised drops to be simulated in three dimensions, combined with the diffusion limited drying process of the drops and the mass and heat exchange between dry air and particles. Recently, within the framework of a European project called EdeCad, the model was expanded to include a model to describe collisions between the drying particles and the agglomeration5,6. The possibilities of the CFD package are legion, including:

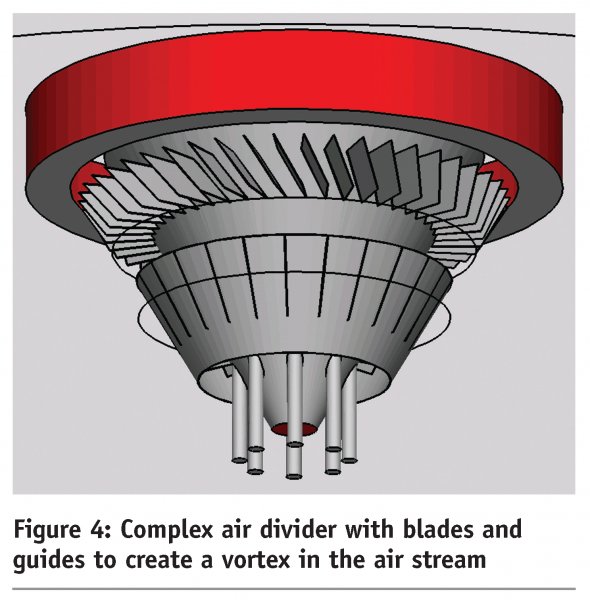

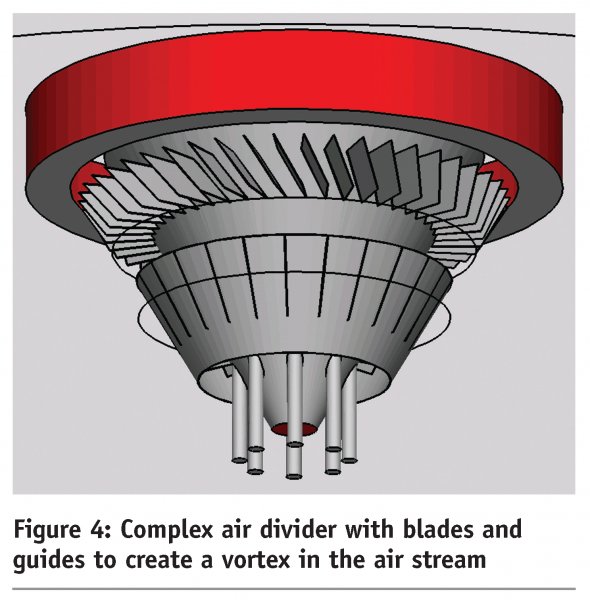

- Improvement of the development of spray dryers. The design and location of air inlets and outlets are largely determinant for the flow pattern in the dryer and thus for the drying efficiency. This package makes it simple to simulate components such as complex air spreaders (Figure 4)

- Reduction of contamination problems. The simulation provides information such as the location at which particles contact the walls and the conditions under which this occurs (speed and collision angle, temperature and moisture content of the outside of the particle). Dependent on the stickiness characteristics of the product, an assessment can be made of whether or not the particle will adhere to the wall and how the process conditions must be adapted to reduce contamination

- Improvement of product characteristics. A simulation provides complete data over time of the moisture content gradient and temperature of the drops as they are drying. With additional models, this data can be linked to the product characteristics, such as the insolubility index1

- Improvement of agglomeration. With the collision and agglomeration model, predictions can be made of the degree to which agglomeration occurs under the established process conditions and how the agglomeration can be promoted. The positions and the spray direction of the atomisers and the return location of fine particles (from the cyclone separator) play an important role

Conclusions

NIZO offers a range of analysis and simulation techniques that it successfully implements for the optimisation and design of dryer installations. An essential aspect is the integral approach, which addresses both process efficiency and production quality. Furthermore, a new measurement technique (DyMonT) is being developed with which powder characteristics can be monitored under relevant process conditions (such as stickiness and particle size). This measurement technique can strongly contribute to the regulation of powder agglomeration and the reduction of contamination during drying processes. Alternative drying technologies such as Zeodration are used to create unique product characteristics (such as drying kiwi and yoghurt with retention of aromas) as well as to reduce energy costs. One last development is the miniaturisation of the spray drying process. NIZO aims to use this technology to develop a high-throughput screening system with which a wide range of product formulations (such as probiotics) can be tested under various drying conditions.

References

- Straatsma, J., van Houwelingen, G., Steenbergen, A.E., and De Jong, P. (1999) Spray drying of food products: 2. Prediction of insolubility index. J. Food Eng. 42, 73–7.

- Straatsma, J., van Houwelingen, G., Meulman, A.P., and Steenbergen, A.E. (1991) DrySPEC2: A computer model of a two-stage dryer. J. Soc. Dairy Technol. 44, 107–11.

- Straatsma, J., Verschueren, M., Gunsing, M., de Jong, P., and Verdurmen, R.E.M. (2007) CFD simulation of spray drying of food products. Computational Fluid Dynamics for food processing. Ed. Da-Wen Sun, CRC Press.

- Van Ommen, J. R., Coppens, M.O., Van den Bleek, C.M., and Schouten, J.C. (2000) Early warning of agglomeration in fluidized beds by attractor comparison. AIChE J. 46, 2183-97.

- Verdurmen, R.E.M., Menn, P., Ritzert, J., Blei, S., Nhumaio, G.C.S., et. al. (2004) Simulation of agglomeration in spray drying installations: The EDECAD project. Drying Technology Vol. 22, 1403-61.

- Verschueren, M. (2006) Simulation of agglomeration in spray drying installations: The EDECAD project. 15th International Drying Symposium, Budapest, Hungary, 20-23 August 2006 (Lecture).

- Verschueren, M., Verdurmen, R.E.M.,van Houwelingen, G., Backx, A.C.P.M., van der Knaap, J.E.A., et. al. (2007) Dynamic stickiness measurements by attractor comparison: A feasibility study. Proc. Int. Conf. Liquid Atomization and Spray Systems (ICLASS). Aug. 27 – Sep. 1, 2007, Kyoto, Japan.

- Verschueren, M., Straatsma, J., Schutyser, M., Akkerman, C., de Jong, P. (2007) New tools to optimize spray dryers. New Food Issue 2, 20-4.

Issue

Related organisations

Related people

Coen Akkerman, Han Straatsma, Maarten Schutyser, Peter de Jong