Protecting quality of sliced meats

- Like

- Digg

- Del

- Tumblr

- VKontakte

- Buffer

- Love This

- Odnoklassniki

- Meneame

- Blogger

- Amazon

- Yahoo Mail

- Gmail

- AOL

- Newsvine

- HackerNews

- Evernote

- MySpace

- Mail.ru

- Viadeo

- Line

- Comments

- Yummly

- SMS

- Viber

- Telegram

- Subscribe

- Skype

- Facebook Messenger

- Kakao

- LiveJournal

- Yammer

- Edgar

- Fintel

- Mix

- Instapaper

- Copy Link

Posted: 29 July 2005 | Jens Stoumann Jensen, Project Manager, M.Sc. Food Science and Technology, Danish Meat Research Institute | No comments yet

Manufacturers of cured and cooked sliced meats are met with increasing demands on shelf life and safety. Improved knowledge and understanding of the interactions between the packaging parameters and their influence on colour stability, sensory perception, microbial safety and shelf life will be indispensable if they want to stay in the market.

Residual oxygen (O2), carbon dioxide content (CO2) and relative amount of headspace as well as gas and light transmission rates through packaging materials are crucial parameters. Important, too, are composition, temperature and initial aerobic count. Individual optimisation of parameters detached from their context is unlikely to be successful.

Manufacturers of cured and cooked sliced meats are met with increasing demands on shelf life and safety. Improved knowledge and understanding of the interactions between the packaging parameters and their influence on colour stability, sensory perception, microbial safety and shelf life will be indispensable if they want to stay in the market. Residual oxygen (O2), carbon dioxide content (CO2) and relative amount of headspace as well as gas and light transmission rates through packaging materials are crucial parameters. Important, too, are composition, temperature and initial aerobic count. Individual optimisation of parameters detached from their context is unlikely to be successful.

Manufacturers of cured and cooked sliced meats are met with increasing demands on shelf life and safety. Improved knowledge and understanding of the interactions between the packaging parameters and their influence on colour stability, sensory perception, microbial safety and shelf life will be indispensable if they want to stay in the market.

Residual oxygen (O2), carbon dioxide content (CO2) and relative amount of headspace as well as gas and light transmission rates through packaging materials are crucial parameters. Important, too, are composition, temperature and initial aerobic count. Individual optimisation of parameters detached from their context is unlikely to be successful.

Sliced meat is packed to facilitate distribution and protect it against physical, chemical and microbial changes. Initially, vacuum packaging was the preferred method to satisfy and develop this new and increasing market. But during the past 15-20 years vacuum has been gradually replaced by modified atmosphere packaging (MAP) that today accounts for more than 80 per cent of the prepacked sliced meat in Europe. From a marketing point of view MAP is superior to vacuum packaging in terms of presentation and convenience, but what about the maintenance of product quality and safety?

This article summarises some of the results obtained in MAP studies carried out at the DMRI in collaboration with the Danish meat industry and the Royal Veterinary & Agricultural University (KVL).

MAP, residual O2 and colour stability

Residual O2 plays a key role

When food products are exposed to light, undesirable quality changes that affect the presentation and other sensory values of the product can easily occur. The detrimental effects are often caused by oxidative reactions within lipids, proteins or other macromolecules in the food matrix.

Fresh and processed meat products are very sensitive to light and undesirable colour changes can be a great problem. In nitrite-cured meat products, NO complexes with myoglobine to form nitrosylmyoglobine, MbFe(II)NO, or the denatured pink complex nitrosylmyochrome, dMbFe(II)NO, found in, for example, cooked ham. Both are very unstable pigments that oxidise easily in the presence of light and small amounts of oxygen found in retail MA-packages4. Upon oxidation, the undesirable greyish-brown pigment, metmyochrome, dMbFe(III) will be formed.

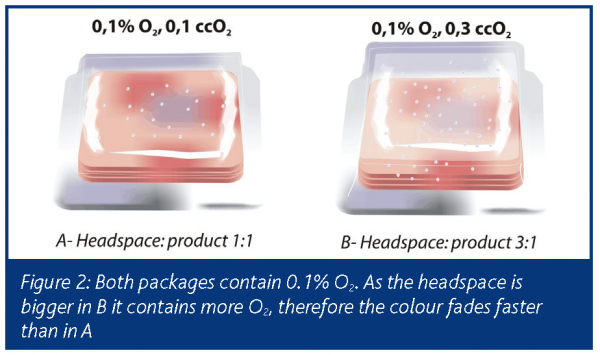

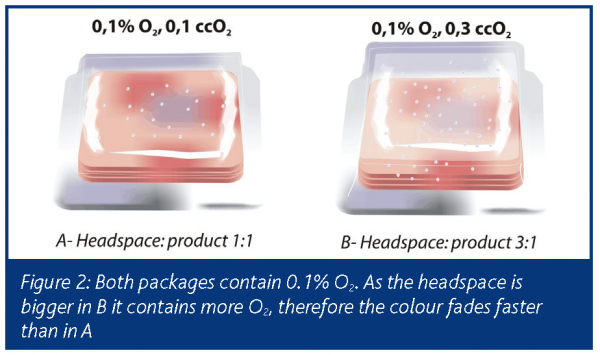

Many factors influence the colour stability of cured heat-treated meat. It has been proven that the residual O2-content and the volume ratio between the atmosphere (headspace) and the product in the package is particularly important.

To study the influence of packaging and storage parameters on colour stability, cured cooked ham in MAP was used for developing a multiplicative analysis of the variance model (GEMANOVA)6. The critical parameters investigated were the percentage of residual O2, product to headspace volume ratio (P:H), temperature, light intensity (Lux) and oxygen transmission rate (OTR). It was found that each investigated parameter interacted. However, the degree of discolouration was particularly influenced by residual O2 and P:H showing that the absolute content of residual O2 (percentage of residual O2 x headspace volume) is the decisive discolouration parameter. The complex interactions between the parameters investigated also emphasised the necessity of evaluating the parameters simultaneously instead of just considering them individually.

The model is capable of predicting whether a modification of critical parameters will cause a change in the a-value (redness) – an indicator of alterations in colour stability. The model has been validated in industrial scale experiments with different meat products that confirmed the importance of considering the relative amount of residual O2, as well as the absolute content.

The model is easy to use and available as a PC-based tool for people involved in product and packaging development.

Low OTR is indispensable

OTR is the transmission rate of O2 through the package measured at 23°C as cc/m2/24 hours/atmosphere. It was measured for different packaging materials under different conditions2. OTR is known to vary significantly depending on the type of material; its thickness upon thermoforming; relative humidity (RH) and temperature.

When a material is deep drawn or thermoformed, the oxygen permeability is increased because the virgin laminate is stretched to make a pocket to contain the sliced product. When a typical semi-rigid APET/PE bottom film is deep drawn to a tray of 100 x 100 mm and 23 mm in depth, the OTR is doubled.

A temperature decrease of 8°C in the 23-7°C range reduces the OTR by 26-48%, depending on the type of material used, thermoforming depth and RH. And while RH does not influence the OTR of APET and PETP films, a 2-3-fold increase is observed in the case of PA films.

The O2-content is clearly an important quality parameter. In MA packaged cooked ham an O2-content of 0.1% can be critical for the colour stability. An examination of commercial cold cuts revealed the residual O2-content in 65% of the products to be above 0.5% and in 92% above 0.1%.

It is therefore important for the sake of colour stability to use a film with as low an OTR as practically feasible.

Light is an important parameter

Although the absolute O2-content is the most critical parameter for colour stability, the modelling investigations also confirmed light intensity to be of relevance.

Meanwhile, temperatures in the range of 5-10°C are of minor importance regarding colour stability.

Sliced meat in refrigerated display cabinets are exposed to a powerful light influence. If the O2-content in the pack is high, too, the risk of colour fading exists. Low O2-content is decisive for colour retention. It is therefore important to use a packaging material with low OTR.

The intensity and amount of light exposure is important too. The colour of cured meat does not deteriorate as fast at 600 Lux as it does at 1200 Lux. The light transmission through clear laminates is approximately 90%. It can be reduced 70-90% by sticking a label on top of the package or by using a dyed or full panel printed lid film. This is a simple way of reducing the damaging effect of light during display2.

CO2 and colour stability

The level of CO2 commonly used in MAP of sliced meat (20-30 %) is insufficient for the CO2 to function as the main hurdle inhibiting growth of pathogenic and spoilage bacteria. As shown below partial pressures corresponding to at least 80% are required.

Until recently very little was known about the effect of the CO2 level on chemical reactions such as the auto- and photooxidation of MbFe(II)NO leading to discolouration and other degradation reactions in cooked cured meat products. Studies performed during our work on MAP optimisation5 revealed that the rate of autooxidation at increased partial pressures of CO2 (> 30%) was lowered very moderately and particularly at low temperatures. Light-induced photooxidation, being the most important parameter in colour deterioration, was not influenced at all.

MAP and safety

MAP is used for control of a range of food borne spoilage, as well as pathogenic, bacteria. The inhibitory effect is obtained by the combination of a low residual O2 and the use of an antibacterial gas such as CO2.

For pre-packed meat products, the bacterium in focus is Listeria monocytogenes – of which many strains are relatively CO2-tolerant.

CO2 prolongs the lag phase of Listeria and reduces its growth rate. The mechanism is not fully understood, but the dissolved CO2 probably causes the growth inhibition by interfering in activities within the cell’s metabolism. When the temperature is lowered, the solubility of CO2 increases, as does the inhibitory effect CO2, proving that the amount of dissolved CO2 is crucial for the rate of inhibitory action.

Combining conventional hurdles with low temperature and a high concentration of CO2 in the package can inhibit Listeria. Storage at 5°C provides better safety than storage at 10°C.

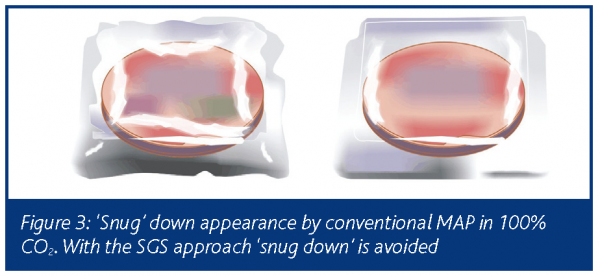

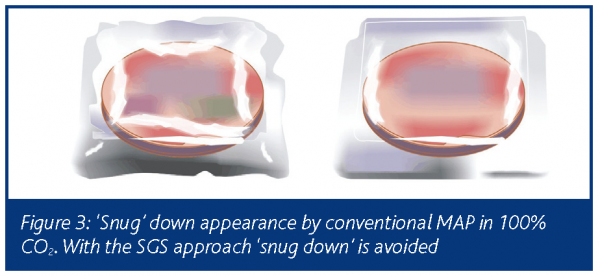

As the sole hurdle, more than 80% CO2 in the package and an H:P ratio of 2:1 or more is needed to inhibit Listeria growth completely at 5°C. Unfortunately, it reduces the product appearance due to CO2-absorption and package collapse. This occurence is termed ‘snug down’ and is followed by liquid purging from the product1.

It has also been observed that CO2 may affect the morphology of the individual Listeria strains in terms of cell elongation or extensive filamentation. This increases the risk of underestimating the number of cells in the packages. No residual inhibition is left after opening the packages and downshifting the CO2 to conventional atmospheric conditions3.

MAP and sensory quality

Apart from oxidation, unpleasant flavours and odours in MA packaged meat products are often caused by growth of the bacterium Brochothrix thermosphacta. Important factors contributing to conserving quality and increasing shelf life are low initial counts; good slicing hygiene; low residual O2 and packaging materials with low OTR.

Storage at maximum 5°C combined with packaging in 80% CO2 or more inhibits the growth of Brochothrix and other tainting microorganisms. This combination reduces the risk of developing off-odour or off-flavour7.

The temperature is crucial for quality maintenance. Storage at, for example, 10°C will deteriorate the quality to such an extent that products will be unacceptable after only two weeks’ storage, regardless of the MAP conditions.

High CO2, snug down and soluble gas stabilisation

100% CO2 inhibits growth of L. monocytogenes completely in unbroken packages, but causes ‘snug down’ leading to collapse and liquid purge in. Packages with ‘snug down’ no longer appeal to consumers and cannot be sold.

A new approach to MAP at high CO2 partial pressures, called soluble gas stabilisation (SGS), was investigated as a way to counteract the ‘snug down’ effect. The SGS approach has been used to extend the shelf life of fish (Sivertsvik et al, 2003). The preservative effect of CO2 on bacterial growth is caused by the absorption of CO2 from the headspace atmosphere into the contained product.

The meat products were treated with CO2 at low temperatures (0-2°C) and elevated pressures (2-3 bars) prior to packaging. Modelling studies of CO2 dynamics in cooked ham and meat sausage revealed that the initial partial pressure of CO2 influenced solubility the most9.

Test of the SGS method under small-scale conditions has proved it works in practice. Sliced cold cuts were packed in 100% CO2 without any ‘snug down’ and posterior purge. The treatment did not influence the sensory qualities and resulted in a lower residual O2 levels in the package as well.

Recommendations

As illustrated, several quality aspects must be considered simultaneously if conditions for maximum protection of quality and safety during storage and distribution of sliced meat products in MAP are to be optimised.

In summary, the following recommendations should be followed:

- Limiting the residual O2; <0.1% safeguards the colour and protects sensory quality

- Minimise the headspace to product volume ratio, preferably 1:1 or less

- Limit the light transmission as much as possible using labels or printed lid film

- Choose packaging materials with as low an OTR as you can afford!

- A maximum temperature of 5°C in distribution protects sensory quality and provides safety

- If you choose >80% CO2 to prevent growth of L. monocytogenes and spoilage bacteria, ensure headspace is increased or employ SGS to prevent ‘snug-down’ and purge

- Beware that the inhibitory effect of CO2 disappears upon opening!

References

- Gunvig, A. (2002): ”Kvali-MAP. MAP and product safety”. DMRI. Poster presented at Nordic Foodpack, September 4-6, 2002; Helsinki.

- Jakobsen, M.; Jespersen, L.; Juncher, D.; Becker, E. M.; Risbo, J. (2005): “Oxygen- and light-barrier properties of thermoformed packaging materials used for modified atmosphere packaging. Evaluation of performance under realistic storage conditions”. Accepted for publication in Packaging Technology and Sci.; vol 18.

- Jydegaard-Axelsen, A.-M.; Aaes-Jørgensen, A.; Koch, A. G.; Stoumann Jensen, J.; Knøchel, S. (2005): Changes in growth, rRNA content, and cell morphology of Listeria monocytogenes induced by CO2 up- and downshift”. Int. Journal of Food Microbiology, 98, 145-155.

- Möller; J. K. S.; Jakobsen, M.; Weber, C. J.; Martinussen, T.; Skibsted, L. H.; Bertelsen, G. (2003): “Optimisation of colour stability of cured ham during packaging and retail display by a multifactorial design”. Meat Science, 63, 169-175.

- Möller; J. K. S.; Nannerup, L.; Skibsted, L. H. (2005): ”Effect of carbon dioxide on autooxidation and photooxidation of nitrosylmyoglobine”. Meat Science, 69, 71-78.

- Nannerup, L.D.; Jakobsen, M.; van den Berg, F.; Stoumann Jensen, J.; Møller, J. K. S.; Bertelsen, G. (2004). ”Optimising colour quality of modified atmosphere packed sliced meat products by control of critical packaging parameters”, Meat Science, 68, 577-585.

- Rasmussen, V.H. (2002): ”Kvali-MAP. MAP and sensory shelf Life”. DMRI. Poster presented at Nordic Foodpack, September 4-6., 2002; Helsinki.

- Sivertsvik, M. (2003): “Solubility and diffusion of CO2 into fish; and the effect of CO2 and temperature on the storage quality of fresh Atlantic salmon”. PhD thesis; Dept. of Agricultural Engineering, Agricultural University of Norway. ISBN 82-575-0558-7

- Sivertsvik, M.; Stoumann Jensen, J. (2005): “Solubility and absorption rate of carbon dioxide into non-respiring foods. Part 3: Cooked meat products”. J. of Food Eng., 70(4), 499-505.