Spray drying of dairy products: a review

- Like

- Digg

- Del

- Tumblr

- VKontakte

- Buffer

- Love This

- Odnoklassniki

- Meneame

- Blogger

- Amazon

- Yahoo Mail

- Gmail

- AOL

- Newsvine

- HackerNews

- Evernote

- MySpace

- Mail.ru

- Viadeo

- Line

- Comments

- Yummly

- SMS

- Viber

- Telegram

- Subscribe

- Skype

- Facebook Messenger

- Kakao

- LiveJournal

- Yammer

- Edgar

- Fintel

- Mix

- Instapaper

- Copy Link

Posted: 9 March 2006 | Pierre Schuck, Science et Technologie du Lait et de l'CEuf, Inra-Agrocampus | No comments yet

Milk is extremely perishable and yet, for a number of reasons, it has to be preserved for later consumption. The removal of water prevents the growth of micro-organisms and facilitates preservation and storage of milk constituents. Spray drying is one of the most convenient techniques for producing milk powders and for stabilising milk constituents.

Milk is extremely perishable and yet, for a number of reasons, it has to be preserved for later consumption. The removal of water prevents the growth of micro-organisms and facilitates preservation and storage of milk constituents. Spray drying is one of the most convenient techniques for producing milk powders and for stabilising milk constituents.

Milk is extremely perishable and yet, for a number of reasons, it has to be preserved for later consumption. The removal of water prevents the growth of micro-organisms and facilitates preservation and storage of milk constituents. Spray drying is one of the most convenient techniques for producing milk powders and for stabilising milk constituents.

Before spray drying, the milk undergoes several processes (such as heat treatment, cream separation, membrane processes, vacuum evaporation and homogenisation). The chemical, physical, technological, nutritional, functional and microbiological properties of the final products are influenced by a number of factors such as operating conditions, properties of the dairy products and storage conditions. This article describes the process of spray drying of dairy products and reviews advances in knowledge of properties of spray-dried milk products; modelling and water transfer simulation (drying and rehydration), dairy powders, spray drying equipment and energy consumption.

Dehydration of milk and whey is intended to stabilise these products for their storage and later use. These powders are used mostly in animal feeding. With changes in agricultural policies (such as the implementation of the quota system and dissolution of the price support system), the dairy industry was forced to look for better use of the dairy surplus and the by-products of cheese (whey) produced from milk and butter milk manufactured from cream. Studies were undertaken into reuse of protein fractions whose nutritional qualities and functioning led us to believe they could have multiple applications. The results have been a change in the nature of dairy powders during the last 15 years1. The total quantity of powder did not vary (approximately 1,400,000 t in 1986 and in 2004) but the amount of milk powder decreased by 40% between 1986 and 2004. This decrease mainly involved skimmed and full fat milk powders. However, the production of whole milk powder and whey powder increased by 62% and 73%, respectively, between 1986 and 2004. This increase was reflected in types of whey and derived powders (protein concentrates) produced. This overall change may be explained by the quota system implemented that gives better control over dairy production. As cheese production from cow’s milk increased by 31% between 1986 and 2003, there was a corresponding increase in whey production and a decrease in milk powder production.

Since the 1980s, the dairy industry has developed new technological processes for extracting and purifying proteins (e.g. casein, caseinates, whey proteins etc.)2, such as dairy proteins and whey concentrates3, micellar casein concentrates4, native phosphocaseinate suspension (NPCS)5, selectively demineralised concentrates6 and super-clean skimmed milk concentrates4 – mainly due to advances in filtration technology (microfiltration, ultrafiltration, nanofiltration and reverse osmosis).

Most of these proteins are marketed in dehydrated form and used either as nutritional or functional ingredients. Milk ‘cracking’ in different dried and stable forms led to a sudden increase in the use of intermediate dairy products. Many new uses of these constituents then appeared with the manufacture of formula products, substitutes and adapted raw materials.

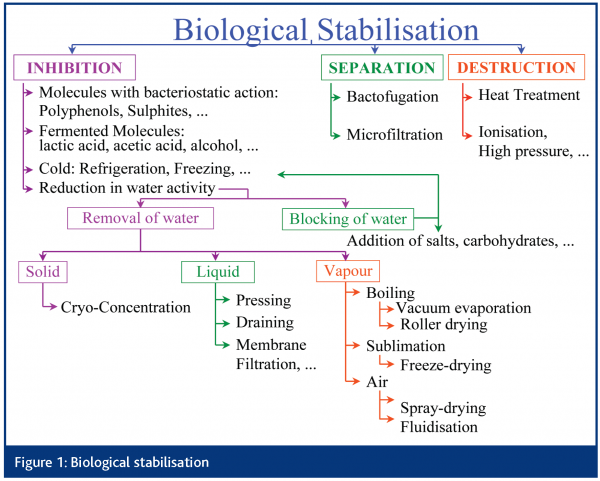

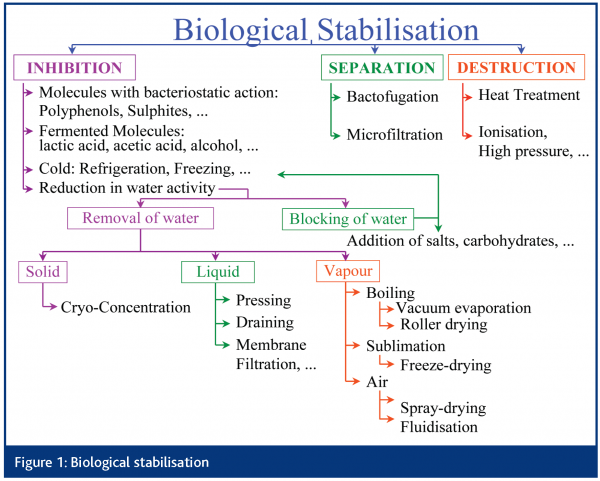

The most frequently used technique for dehydrating dairy products is spray drying. Figure 1 shows different methods of biological stabilisation in which spray drying is a stabilisation method based on biological inhibition and reduction of water activity. Spray drying became popular in the industrial world in the 1970s, but at that time there were few scientific or technical studies about the practice and, in particular, none on the effects of spray drying parameters, nor the physico-chemical composition or microbiology of the concentrates on powder quality. Manufacturers acquired expertise in milk drying and eventually in whey drying processes through trial and error. Due to the variety and complexity of the mixes to be dried, a more rigorous method, based on physico-chemical and thermodynamic properties, has become necessary. Greater understanding of the biochemical properties of milk products before drying, water transfer during spray drying, properties of powders and influencing factors has now become indispensable in the production of milk powder. The lack of technical and economic information and of scientific methods has prevented manufacturers from optimising equipment in terms of energy costs and powder quality.

The aim of this review is to give a brief summary of the process of spray drying dairy products and to review current knowledge of the properties of spray-dried milk products, the modelling and simulation of water transfer processes (drying and rehydration), dairy powders, spray drying equipment and energy consumption.

Properties of spray dried milk products

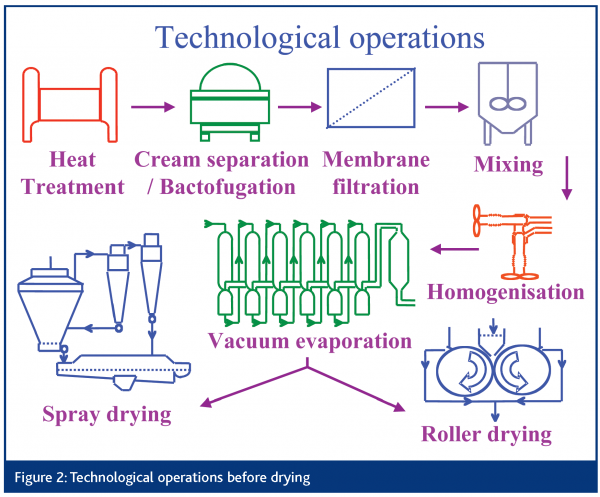

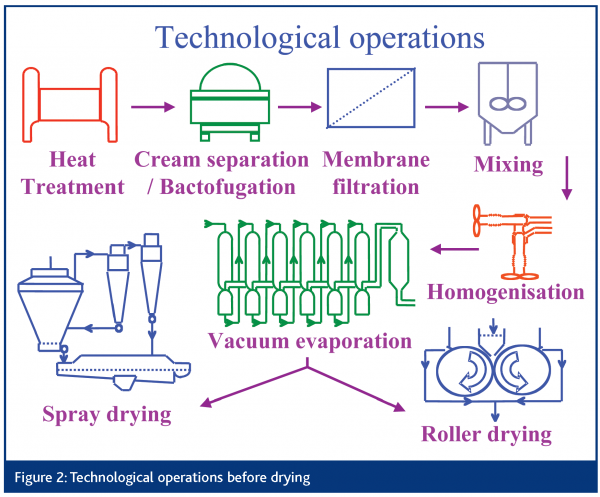

A dairy powder is not only characterised by its composition (proteins, carbohydrates, fats, minerals and water) but also by its microbiological and physical properties (bulk and particle density, instant characteristics, flowability, floodability, hygroscopicity, degree of caking, whey protein nitrogen index, thermostability, insolubility index, dispersibility index, wettability index, sinkability index, free fat, occluded air, interstitial air and particle size) which form the basic elements of quality specification. There are well-defined test methods for determining these characteristics, according to international standards7,8,9. These characteristics depend on technological operations before drying (Figure 2), drying parameters (type of tower spray dryer, nozzles/wheels, pressure, agglomeration, thermodynamic conditions of the air: temperature, relative humidity and velocity) and characteristics of the concentrate before spraying (composition/physico-chemical characteristics, viscosity, thermo-sensibility, availability of water). Several scientific papers have been published on the effects of technological parameters on these properties10,11. Water content, water dynamics and water availability are among the most important properties. The nutritional quality of dairy powders depends on the intensity of the thermal processing during the technological process. Thermal processing induces physicochemical changes which tend to decrease the availability of the nutrients (loss of vitamins, reduction of available lysin content, whey protein denaturation) or to produce nutritional compounds such as lactulose.

Modelling, simulation and water transfer

The physical and biochemical qualities of milk powder depend on the water distribution in the concentrate at the air/water droplet interface, which, in turn, depends on the composition of the concentrate12,13. Roos14 and Schuck et al.15 have described the physico-chemical properties of pure and bound water and the effects of water on physical state, transition temperatures, sticking temperature, reaction kinetics and stability of milk products. The emphasis is on the physical state of non-fatty solids and the effects of water and its physical state on physico-chemical changes, growth of micro-organisms and stability16,17. Spray-drying, storage and quality of milk powder are significantly dependent on both the physical state of the lactose (one of the main components in skimmed milk powder) and on the proteins and other carbohydrates, which themselves are dependent on the glass transition temperature (Tg). The spray-drying of skimmed milk concentrate is so rapid that the lactose cannot crystallise. Rapid removal of water in subsequent spray drying does not allow lactose crystallisation and, when water is removed, lactose is transformed to a solid-like, amorphous glass directly from the dissolved state. Many dehydrated foods contain amorphous components in the glass form. This is a non-equilibrium state with higher energy in relation to the corresponding equilibrium state. If the temperature of a material in this state rises above a certain critical value then it transforms into a rubber. This phenomenon is known as glass transition and the temperature at which it occurs is the glass transition range temperature. This transition results in an increase in mobility in the rubbery states which, in turn, can produce changes in physical and chemical properties of the material. Carbohydrates, including sugars, starch and hemi-celluloses, can exist in the amorphous glassy state in dried foods. Low molecular weight sugars in the glassy state are usually extremely hygroscopic and have low glass transition temperatures. This can lead to problems in spray drying and/or in storage. The addition of high molecular weight compounds to these low molecular weight sugars can improve spray drying and storage conditions. Proteins, including gelatin, elastin, gluten, glutenin, casein, whey proteins and lysozyme, are also found in the amorphous state in dried food. In the dry state, they have a relatively high glass transition temperature. The above articles and Vuataz’s recent reports18,19,20 demonstrate the role of water before concentration, during spray drying and after drying (stability, preservation). As a result, there are some studies on water and protein and water and lactose interactions and their effects on functional properties of powders21,22,23,24,25. Several authors have tried to model the mechanisms of water transfer and the kinetics of drying in droplets26,27. However, the complexity of the mathematical models presented makes it difficult for manufacturers to put them into practice.

Dairy powders

The different processes of spray drying, combined with membrane filtration, also affect the physico-chemical environment, the purity and the biochemical properties of milk powders and produce a range of powders with different physical and functional properties such as high milk protein powder, whey protein powder, whole milk powder or high fat powder28,29,30. Physico-chemical factors currently help the dairy industry to optimise drying parameters and characterise these new dairy concentrates (except for the dry matter and viscosity). The methods generally used to analyse solubility, dispersibility and wettability of milk powders8,9,10 provide unsatisfactory results because they do not fully take into account the new functions31.

Equipment and energy consumption

For more than 30 years, spray drying has been the most frequently used milk drying technique. It is also the most convenient technique for producing powders directly from pumpable feeds. Indeed, since the 1970s there has been an increase in the capacity of tower spray dryers (from 1 to 6 t of water drained per hour). Tower spray dryers treating from 10 to 15 t of water per hour have recently been installed in New Zealand and in Australia. The total capacity and number of tower spray dryers have more than doubled in a short time in certain countries32.

Spray drying involves atomising the feed into a spray of droplets which are put into contact with hot air in a drying chamber. There are three modes of contact: co-current, counter-current and mixed flow. Sprays are produced by a rotary (wheel) or nozzle atomiser11.

The tower is a one stage spray drying unit which means that the processing time in the spray drying chamber is very short (approximately 20 – 60 s). There is thus no real equilibrium between air humidity and product humidity. Therefore, if the outlet air temperature is raised, the energy efficiency of the unit decreases11,34,35. The two stage spray dryer consists of limiting spray drying for longer processes and is therefore closer to thermodynamic balance. Upon being discharged from the spray drying unit, the product should have a maximum moisture that is compatible with continuous evacuation. This significantly lowers the outlet air temperature and increases the inlet air temperature. In order to obtain the required residual moisture, the final drying takes place in an external vibrating fluid, or vibro-fluidiser, in which the air flow and the treatment temperatures are lower than in the chamber and thus better designed for qualitative preservation of the powder11. The two stage dryer has demonstrated how to reduce drying costs and improve the performance of units, by transferring most of the drying from atomisation to phase fluidisation until the wet product begins to stick to the walls of the chamber. This contact is inevitable in view of the internal agitation necessary for the thermal exchange. Removing this limit led to complete overhaul of the spray drying phase and resulted in the three-stage dryer – the biggest breakthrough in this field since the emergence of spray drying. As it is impossible to operate without the walls of the unit, the aim was to minimise any contact between the walls and the wet product using the three stage dryer. The latter was stabilised and dried in an internal fluid bed inside the spray drying chamber11,33,34.

There are other spray dryer designs such as the tall-form tower, flat-bottom chamber, restricted-height chamber, high or extra high-temperature chamber, box dryer, integrated belt chamber (Filtermat®) and integrated filter dryer (IFD®). The type of tower spray dryer depends on the specific properties of the product to be dried (high fat content, starches, maltodextrin, egg products, hygroscopic products, etc.)11 and the choice of the technology used depends on the thermal efficiency (calculated according to different methods35,36,37,38), the qualities and properties of the product to be dried and the powders to be obtained. A thermohygrometric sensor is used for some examples of such measurements (temperature, absolute and relative humidity, dry air flow rate, water activity), for calculation of mass and absolute humidity to prevent sticking in the dry chamber and to optimise powder moisture and water activity in relation to the relative humidity of the outlet air39.

Recommendations for fire prevention in spray drying of milk

Fire in spray dryers for milk or milk products can lead to dangerous situations for the operators and may cause serious damage to plant and buildings. Fire prevention in such areas is primarily achieved through efforts to avoid situations involving a fire hazard. Any situation that may involve a fire hazard must therefore be quickly detected, either through a system of recording and automatic alarms, or through visual inspection. In the event that a fire breaks out in spite of all precautions, provisions to avoid injury to personnel must be in place, to prevent and limit damage.

Conclusions

This article discusses the complexity of the spray drying process for dairy manufactures who want to optimise production. It is impossible to provide a simple mathematical model that takes into account simultaneously all the parameters for complex processes in the spray drying of dairy products.

Furthermore, existing studies, mainly centred on skimmed milk, cannot easily be extrapolated to other dairy products. More information is necessary on interaction processes, production and functions of dairy products in order to increase our knowledge of the mechanisms of water transfer, drying parameters, storage conditions and rehydration of dairy powders.

Acknowledgement

This article uses information from the author’s original paper entitled ‘The state of the art in spray drying of dairy products’ in Le Lait journal from 2002.

References

- Centre National Interprofessionnel de l’Economie Laitière, l’économie laitière en chiffres, CNIEL, Paris, France, 1987 & 2005.

- Maubois J.L., New applications of membrane technology in the dairy industry, Aust. J. Dairy Technol. 46 (1991) 91-95.

- Maubois J.L., Pierre A., Fauquant J., Piot M., Industrial fractionation of main whey proteins, Bull. Int. Dairy Fed. 212 (1987) 154-159.

- Schuck P., Piot M., Méjean S., Fauquant J., Brulé G., Maubois J.L., Déshydratation des laits enrichis en caséine micellaire par microfiltration; comparaison des propriétés des poudres obtenues avec celles d’une poudre de lait ultra-propre, Lait 74 (1994) 47-63.

- Schuck P., Piot M., Méjean S., Le Graët Y., Fauquant J., Brulé G., Maubois, J.L., Déshydratation par atomisation de phosphocaséinate natif obtenu par microfiltration sur membrane, Lait 74 (1994) 375-388.

- Jeantet R., Schuck P., Famelart M.H., Maubois J.L., Intérêt de la nanofiltration dans la production de poudres de lactosérum déminéralisées, Lait 76 (1996) 283-301.

- Pisecky J., Handbook of milk powder manufacture, Niro A/S, Copenhagen, Denmark, 1997.

- American Dairy Products Institute, Standard For Grades of Dry Milk Including Methods of Analysis, ADPI, Chicago, USA, 1990.

- Haugaard Sorensen I., Krag J., Pisecky J., Westergaard V., Méthodes d’analyses des produits laitiers déshydratés, Niro A/S, Copenhagen, Denmark, 1978.

- Pisecky J., Standards, specifications and test methods for dry milk products, in: Mac Carthy D. (Ed.), Concentration and drying of food, Elsevier, London, UK, 1986, pp. 203-220.

- Masters K., Spray Drying, SprayDryConsult Intl. ApS, Denmark, 2002.

- Schuck P., Briard V., Méjean S., Piot M., Famelart M. H., Maubois J.L., Dehydration by desorption and by spray drying of dairy proteins: Influence of the mineral environment, Drying Technol. 17 (1999) 1347-1357.

- Schuck P., Davenel A., Mariette F., Briard V., Méjean S., Piot M., Rehydration of casein powder: effects of added mineral salts and salt addition methods on water transfer, Int. Dairy J. (2001) In Press.

- Roos Y., Importance of glass transition and water activity to spray drying and stability of dairy powders, Lait 82 (2002) 475-484.

- Schuck P., Blanchard E., Dolivet A., Méjea, S., Onillon E., Jeantet R., Water activity and glass transition in dairy ingredients. Lait 85 (2005) 295-304.

- Genin N., René F., Analyse du rôle de la transition vitreuse dans les procédés de conservation agro-alimentaires, J. Food Eng. 26 (1995) 391-408.

- Labuza T.P., The effect of water activity on reaction kinetics of food deterioration, Food Technol. 34 (1980) 36-59.

- Vuataz G., Preservation of skim milk powders: role of water activity and temperature in lactose crystallization and lysine loss, in: Seow C.C., (Ed.), Food preservation by moisture control, Elsevier Applied Science, London, UK, 1988, pp. 73-101.

- Vuataz G., Prévention des transitions de phases dans les systèmes déshydratés pendant le traitement et le stockage, in: Les Rencontres Agoral (Ed.), Les Produits alimentaires et l’eau – L’eau dans l’Aliment – L’eau matière première, Tec et Doc, Lavoisier, Paris, France, 1999, pp. 75-86.

- The phase diagram of milk: a new tool for optimising the drying process, Lait 82 (2002) 485-500.

- Schuck P., Appréhension des mécanismes de transfert d’eau lors du séchage par atomisation de bases protéiques laitières et lors de leur réhydratation. Effet de l’environnement glucidique et minéral, Thèse ENSAR, Rennes, 1999

- Busin L., Buisson P., Bimbenet J.J., Notion de transition vitreuse appliquée au séchage par pulvérisation de solutions glucidiques, Sci. Aliments 16 (1996) 443-459.

- Jouppila K., Roos Y.H., Water sorption and time-dependent phenomena of milk powders, J. Dairy Sci. 77 (1994) 1798-1808.

- Roos Y.H., Water in milk products, in Fox P.F., (Ed.), Advanced Dairy Chemistry Volume 3, Lactose, water, salts and vitamins, Chapman & Hall, London, UK, 1997, pp. 303-346

- Davenel A., Schuck P., Marchal P., A NMR relaxometry method for determining the reconstitutability and the water-holding capacity of protein-rich milk powders, Milchwissenschaft 52 (1997) 35-39.

- Ferrari G., Meerdink G., Walstra P., Drying kinetics for a single droplet of skim-milk, J. Food Eng. 10 (1989) 215-230.

- Furuta T., Moisture transfer modelling of a liquid food droplet on drying, in: Thorne S. (Ed.), Mathematical modelling of food processing operations, Elsevier Applied Science, London, UK, 1992, pp. 99-136.

- Mistry V.V., Manufacture and application of high milk protein powder, Lait 82 (2002) 515-522.

- Hall G.M., Iglesias O., Functional properties of dried milk whey, Food Sci. Technol. Int. 3 (1997) 381-383.

- Keogh M.K., Okennedy B.T., Milk fat microencapsulation using whey proteins, Int. Dairy J. 9 (1999) 657-663.

- Ilari J.L., Loisel C., La maîtrise de la fonctionnalité des poudres, Process 1063 (1991) 39-43.

- Pisecky J., Technology advances in the production of spray dried milk, J. Soc. Dairy Technol. 38 (1985) 60-64.

- Sougnez M., L’évolution du séchage par atomisation, Chim. Mag. 1 (1983) 1-4.

- Knipschildt M.E., Drying of milk and milk products, in: Robinson R.K., (Ed.), Modern Dairy Technology. Advances in Milk Processing, Elsevier, London, UK, 1986, pp. 131-233.

- Bimbenet J.J., Le séchage dans les industries agricoles et alimentaires, SEPAIC, Paris, France, (1978) 1-31.

- Kessler H.G., Energy aspects of food preconcentration, in: Mac Carthy D. (Ed.), Concentration and drying of food, Elsevier, London, UK, 1986, pp. 147-163.

- Schuck P., Roignant M., Brulé G., Méjean S., Bimbenet J.J., Caractérisation énergétique d’une tour de séchage par atomisation multiple effet, Ind. Alim. Agric. 115 (1998) 9-14.

- Bimbenet J.J., Schuck P., Roignant M., Brûlé G., Méjean S. Heat balance of a multistage spray-dryer: principles and example of application. Le Lait 82 (4), 541-551 (2002)

- Schuck P., Méjean S., Dolivet A., Jeantet R. Thermohygrometric sensor: a tool for optimizing the spray drying process. Innov. Food Sci. and Emerg. Technol. 6, 45-50 (2005)