Chocolate cooling and demoulding

- Like

- Digg

- Del

- Tumblr

- VKontakte

- Buffer

- Love This

- Odnoklassniki

- Meneame

- Blogger

- Amazon

- Yahoo Mail

- Gmail

- AOL

- Newsvine

- HackerNews

- Evernote

- MySpace

- Mail.ru

- Viadeo

- Line

- Comments

- Yummly

- SMS

- Viber

- Telegram

- Subscribe

- Skype

- Facebook Messenger

- Kakao

- LiveJournal

- Yammer

- Edgar

- Fintel

- Mix

- Instapaper

- Copy Link

Posted: 23 May 2006 | Dave Cruickshank, Chocolate Development Manager, Cadbury Trebor Bassett | 2 comments

Tempering and cooling are best regarded as two parts of the same process: the solidification of chocolate.There are interactions between the two processes and they both need to be carried out correctly in order to ensure an efficient process and create a high quality product.This article examines these processes and outlines the technologies employed at each stage.

Tempering and cooling are best regarded as two parts of the same process: the solidification of chocolate.There are interactions between the two processes and they both need to be carried out correctly in order to ensure an efficient process and create a high quality product.This article examines these processes and outlines the technologies employed at each stage.

Tempering and cooling are best regarded as two parts of the same process: the solidification of chocolate.There are interactions between the two processes and they both need to be carried out correctly in order to ensure an efficient process and create a high quality product.This article examines these processes and outlines the technologies employed at each stage.

The functions of cooling are:

- To remove specific and latent heat

- To contract the chocolate such that it releases cleanly from the mould

- To produce a stable and attractive product

Product factors

The product recipe has a major effect on the cooling requirements and cooler performance. For cocoa butter based systems the aim is to crystallise the fat into the stable Form 5 (Wille and Lutton 1966) polymorph. This gives a stable, attractive product and also creates the necessary contraction required to allow clean demoulding.

However, the requirement to crystallise fat into small crystals of Form 5 limits the rate of cooling that can be applied. If this is exceeded by either low cooler temperatures or short cooling times, then less stable, lower polymorphs such as Form 4 will result that do not give the stability or contraction needed.

Other recipe factors will affect the maximum acceptable cooling rate, such as the proportion of butterfat present and the presence and type of vegetable fat (where legally permissible). These ingredients both have the potential to reduce the crystallisation rate of Form 5 and, thus, longer cooling times will be required.

The other factor that must be considered is the rate of heat conduction through chocolate. This is low and thus requires cooling times on large chocolate bars to be longer to allow heat from the centre to be conducted to the surface where it can be removed.

The level of temper present in the chocolate will also have an effect on contraction. Both very low and very high levels will reduce contraction, which may lead to incomplete demoulding.

For non cocoa butter based systems, the polymorphism is less complex. Faster cooling rates are possible because, at chocolate cooling temperatures, only one polymorphic form is possible. Here, the only constraint is to avoid cooling into a glassy amorphous state. The constraints of heat conduction though are the same as for cocoa butter based systems.

Cooler conditions

Heat load

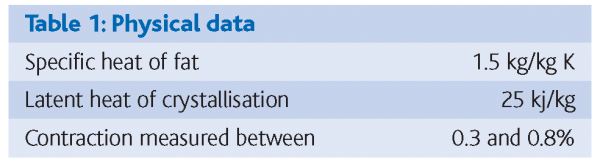

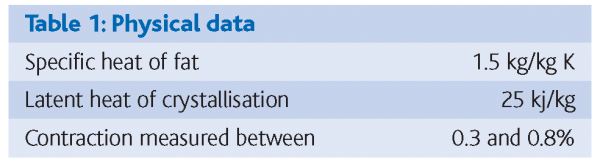

It is possible to calculate the heat load from the crystallising fat in a typical moulding plant cooler. By way of illustration, assume that the chocolate contains 30% fat, and that the temperer crystallises 1% of that fat. The final stabilised solid fat content of the chocolate is measurable by NMR (Nuclear Magnetic Resonance) but in the UK 55% solid fat at 20 °C (68 °F) is typical. The cooler must then firstly remove the latent heat from a net 54% of the fat as it crystallises.

In a moulding plant running at 6t per hour this requires 46kw to be removed. In addition there are many other factors that will add to this theoretical heat load. These include the following:

- Specific heat from other ingredients e.g. milk, sugar etc

- Centres or inclusions if any

- Moulds, chains, mould frames

- Air leakage

- Conduction through the fabric of the cooler

Temperature

Cooler conditions should be set on the basis of the temperature that the product needs to achieve.Apart from temperature settings, which are usually controlled and measured close to the heat exchange coils of the chiller plant, there are other factors such as track speed and air flow that need to be taken into account. It is usual to consider coolers as having three distinct temperature zones:

- Zone 1, which is mainly for specific heat removal, has temperature settings of 12-15 °C (54-59 °F). Product is in this zone, typically, for 5 min

- Zone 2, which is where the majority of the latent heat is removed. Table 1 shows that latent heat is much larger than specific heat and tends to be released suddenly as crystallisation sets in. This will have lower temperatures than zone 1 and, potentially, a much longer time. Large units or bars will require 30-40 mins of cooling in zone 2. Typical temperatures are 7-10 °C (45-50 °F)

- Zone 3, where product is warmed prior to the exit of the cooler. The main purpose is to heat product to a temperature above the dew point of the packing room. Temperatures and times are typically the same as in zone 1

Dark chocolate or milk chocolates with low butterfat contents will not require such low temperatures and 2-3 °C can be added to the temperatures quoted above for this type of recipe.

Air speed

The main requirement is to have turbulent flow across the product and moulds and this is generally agreed to occur once the air speed has reached 5m/sec (990ft/min). There is little advantage in exceeding this rate unless the air is heated significantly on its return to the cooler coils.

Residence time

This is controlled by varying the track speed, usually measured in moulds per minute. Large solid units require a longer cooling time than small thin units.

Humidity control

It is vital to avoid any condensation forming on the product while in the cooling tunnel. Condensation will lead to sugar bloom, a surface defect due to sugar firstly dissolving in the condensation and then recrystallising. It can, in extreme circumstances, cause moulds or yeasts to begin growing on the chocolate surface. For these reasons, air in the cooling tunnels is dehumidified.Air simply cooled to, for example 13 °C (55 °F), will be saturated with water vapour (100% RH) at that temperature. In order to dehumidify the air, it is ‘overcooled’ to, for example 1.5 °C (35 °F), and then reheated to 13 Deg. This air then has a relative humidity of 45%. Dehumidification requires additional energy use and it is thus important that the process is optimised.

Intense coolers

It is sometimes necessary to deposit a hot centre e.g. a caramel at 55 °C (140 °F) into a chocolate shell. In this case the purpose of intense coolers is to prevent the centre from melting or detempering the chocolate. Typically, the shell is cooled to 10 °C (50 °F) prior to depositing the centre, and cooling continues immediately after depositing to ensure that the chocolate is undamaged.

Cooler design

Single level cooler

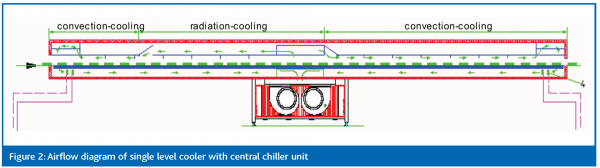

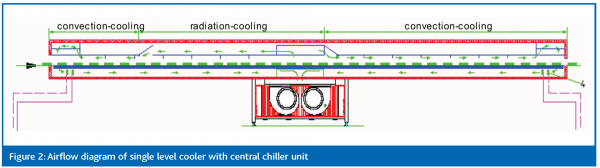

Although outside the scope of this article, the single level cooler, (Figure 1) seen after most enrobers, has an elegant simplicity of design that makes it easy to understand the way it operates.

The chillers introduce conditioned air at the centre of the cooler that passes towards each end of the tunnel (Figure 2). Air passing back towards the enrober runs counter current to the units, which in itself introduces the basis of the required temperature profile. Essentially, the air that the units first experience has been warmed partly by units further into the tunnel, with adjustments from strategically placed heaters. Air passing forwards in the same direction as the unit flow is also heated close to the exit to warm the units prior to leaving the tunnel.

The basic layout of the tunnel makes it easy to arrive at the correct temperature profile.While it is relatively simple to accommodate a single level cooler with a residence time of 15-20 mins, which is adequate for most enrober products, larger moulded products require much longer times, for which a single level design would be impracticably long. This has led to multi-level designs which are used on most moulding and shell plants.

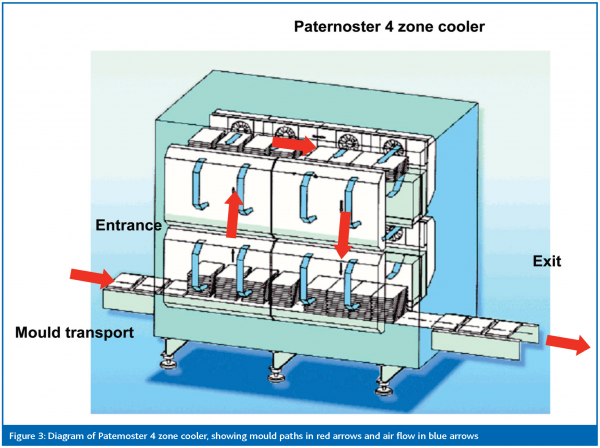

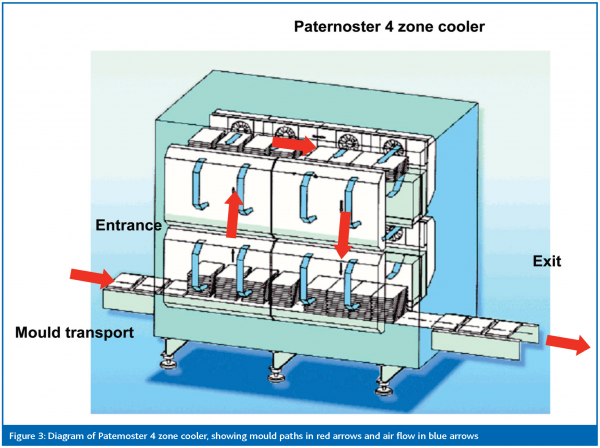

Paternoster 4 zone cooler

This design (Figure 3) enables moulds to enter from one side and be raised to the top of the tower in groups of three or four, and then lowered to the bottom on the other side. There are four separately controllable chillers: two on the ‘up’ side and two on the ‘down’ side. These blow air from side to side across and between the moulds. Figure 4 shows the chiller fans and coils on the left, with the racks that carry the moulds on the right. Such coolers can be used singly or in series and the same basic design can also be used as a mould heater. In a shell plant there would be three cooling stages: after the shell forming stage; after the centre deposit and after the units have been backed off.

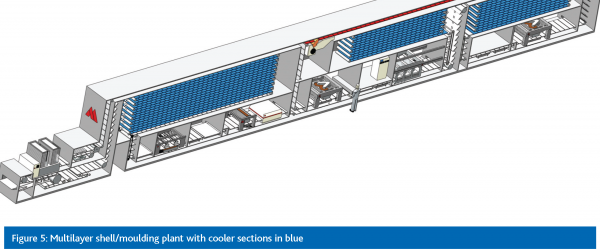

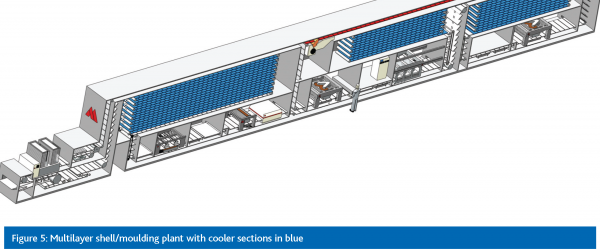

Multilayer shell/moulding plant

This is the most complex layout with coolers stacked above the depositers and shell forming sections (Figures 5/6). It is also the most space efficient of the options. The compact nature of the design means that the control of airflow is achieved by a variety of guides, baffles etc. which, over time, are at risk of being moved or damaged during cleaning and maintenance – sometimes to the detriment of their performance. In all designs, the aim is to produce the ideal temperature profile for the product.

Innovations in cooling

Radiant cooling

Radiant cooling is not a recent development and, in fact, features in some commercially available coolers, particularly single level designs. It comprises matt black cooled panels that act as an additional cooling source that supplements the cold air flow and cold tables, where fitted. They provide a small proportion of the total cooling capacity of the tunnel.

Mars Inc US patent 6419970

This patent covers the use of extreme cooling conditions at low or ultra low temper levels. It claims improvements in gloss and detail retention from cooling, using air temperatures below 0 °C (32 °F) in a rapid cooling process. It also necessarily provides for re-warming in a humidity controlled environment to maintain good appearance.

Jet turbulence coolers

Here the use of air at 20m/sec (3960ft/min) claims to offer advantages over ‘conventional’ processes at lower air speeds. They are most effective at the point in the process where crystallisation occurs. The emission of latent heat is sudden and, as illustrated in Table 1, latent heat is much larger than specific heat.

Demoulding

If the tempering and cooling processes have been optimised, then demoulding is a minor part of the process with good quality product cleanly leaving moulds that are returned to the start of the process.

A small amount of force is usually required to remove the product from the mould and this either takes the form of a hammer or a mechanism that twists the moulds. Units tend to hold in place by electrostatic charges, which is more of a problem with light or small units than moulded bars.

Units are demoulded onto either plaques or a belt, depending on subsequent packing arrangements. Both options are illustrated in Figures 7 and 8.

Conclusion

The processes of tempering and cooling are related and are best considered as a single two stage process. The parameters must be matched both to the plant and the recipe in order to give high quality work and efficient operation.

References

- Wille, R.L & Lutton, E.S., “Polymorphism of cocoa butter” J.Amer.Oil Chem. Society vol 43 (1966) pp 491-496

- Willcocks et al US Patent No 6419970, July 16 2002

- Nelson R.B., “Enrobers,Moulding Equipments and Coolers” in “Industrial Chocolate Manufacture and Use” ed Beckett, S.T. 3rd Edition, Blackwell Science, 1999

Acknowledgements

The author acknowledges the following for plant photographs and diagrams: Piotr Czarnecki – Aasted Microverk Clinton Hudgell – Buhler James Bainbridge – Sollich

Thanks are also due to colleagues at Bournville for suggestions, comments and corrections.Any errors or mistakes are the author’s alone.

Original work prepared for the PMCA 2005 Annual Production Conference.

Cooling tunnels are a vital component in the world of chocolate production. In an industry that is dependant on uniformity, quality and precision in high quantities- ensuring that cooling tunnels are operating as well as possible while producing the best product is paramount. So how do you improve the efficiency of the cooling tunnels for the confectionery industry?

Cooling tunnels are a vital component in the world of chocolate production. In an industry that is dependent on uniformity, quality and precision in high quantities- ensuring that cooling tunnels are operating as well as possible while producing the best product is paramount. So how do you improve the efficiency of the cooling tunnels for the confectionery industry?