Sugars and sugar substitutes testing

12 December 2022

Shares

Waters Corporation presents an overview of its liquid chromatography solutions for the routine testing of sugars and sugar substitutes in beverages.

Changing consumer preference, the introduction of sugar taxes and competitive pressures are some of the drivers of innovation in the beverage industry. Innovation can include reformulation of existing products as well as the development of new ones. Alternative products to carbonated soft drinks continue to reach our supermarket shelves, including product categories such as energy drinks, sports drinks, enhanced waters and functional dairy products.

Consumer preference and sugar taxes have also led to a focus on reducing sugar in beverages through reformulation of existing products or the introduction of new low or no sugar products. To enable the reduction or replacement of sugar in beverages, sugar substitutes are used to sweeten the products. These sugar substitutes, where approved for use, can include:

- High intensity sweeteners (aspartame, sucralose and acesulfame potassium)

- Sugar alcohols (erythritol, xylitol and sorbitol)

- Natural sweeteners (allulose, steviol glycosides and monk fruit).

Testing sugars and sugar substitutes

Laboratories play an important role in product reformulation and development, supporting product optimisation by confirming the concentration and ratios of sugar and sugar substitutes. Laboratory testing also supports product quality and label claims, ensuring product consistency, the correct values on labelling, and protecting brand reputation.

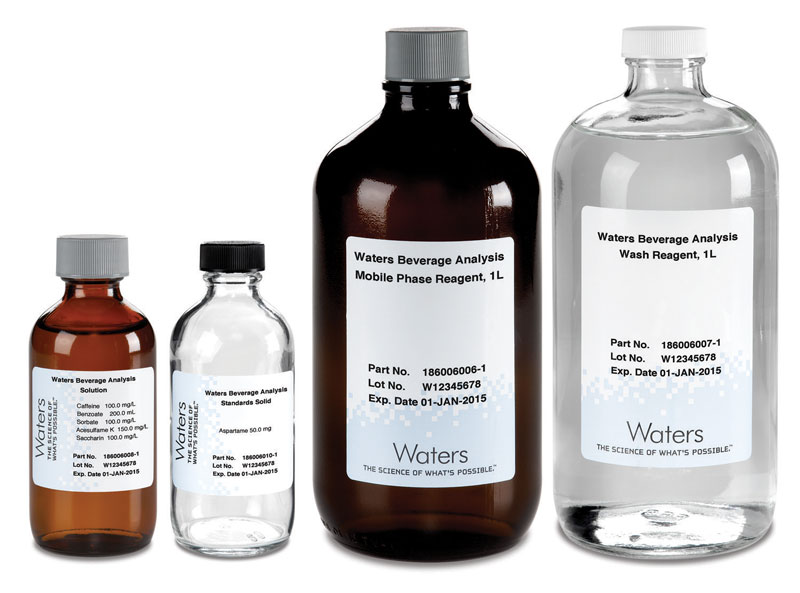

Figure 1: Waters ArcTM HPLC

Liquid chromatography (LC) is a widely used and flexible technique for the profiling and quantitation of sugars and sugar substitutes in beverages. High performance liquid chromatography (HPLC) coupled with an ultraviolet-visible light (UV-Vis) detector (Figure 1), is a common system configuration in many food and beverage testing laboratories.

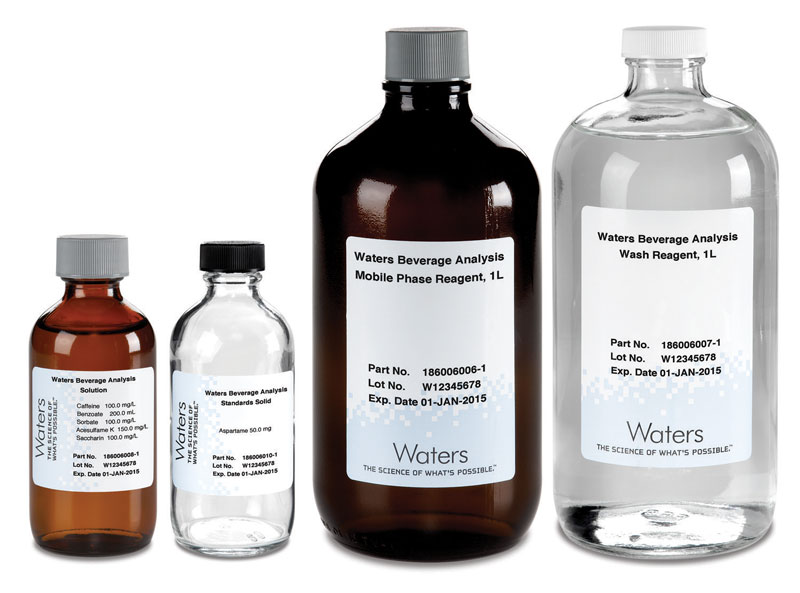

Figure 2: Waters Beverage Analysis Kit

High intensity sweeteners such as aspartame, saccharin and acesulfame potassium, along with the preservatives potassium sorbate and sodium benzoate and the flavouring caffeine, are routinely tested using HPLC with UV-Vis detection. Workflow solutions including the WatersTM Beverage Analysis Kit (Figure 2), allow for the easy implementation of a testing method for these six common additives in a standardised way.

LC testing methods

Detection of sugars and sugar substitutes

The wide adoption of UV-Vis detectors for routine LC analysis is mainly due to ease of use and reliability. However, a key requirement for UV-Vis detection is that the compound(s) of interest contain a strong chromophore (groups in the molecule which absorb light). For compounds which have a weak chromophore or do not contain one, derivatisation either pre or post column is required. The use of derivatisation might not be suitable for all laboratory workflows as the off-line (pre-column) approach can involve several time consuming steps and the on-line (post-column) approach requires a more complicated LC system setup.