Demonstration of novel technologies and advanced heating has been a key goal for NovelQ

- Like

- Digg

- Del

- Tumblr

- VKontakte

- Buffer

- Love This

- Odnoklassniki

- Meneame

- Blogger

- Amazon

- Yahoo Mail

- Gmail

- AOL

- Newsvine

- HackerNews

- Evernote

- MySpace

- Mail.ru

- Viadeo

- Line

- Comments

- Yummly

- SMS

- Viber

- Telegram

- Subscribe

- Skype

- Facebook Messenger

- Kakao

- LiveJournal

- Yammer

- Edgar

- Fintel

- Mix

- Instapaper

- Copy Link

Posted: 5 November 2010 | Lilia Ahrné, Director of Department Process and Technology Development, SIK and Ariette Matser, Senior Scientist Novel Processing, Wageningen UR, Food & Biobased Research | No comments yet

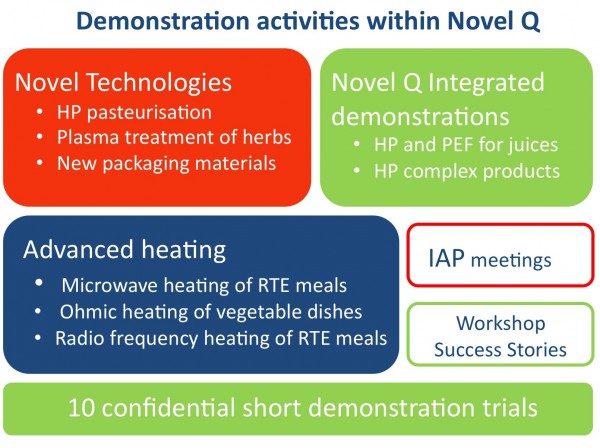

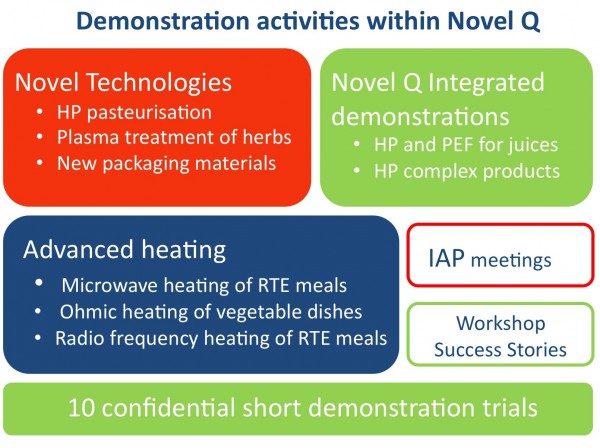

One of the goals of NovelQ is to facilitate and speed up industrial exploitation of novel technologies by carrying out extensive demonstration activities with real food products and industrial equipment in close collaboration with the food industry. A variety of activities have been undertaken during the lifetime of NovelQ demonstrating the advantages of novel processing and advanced heating with respect to product quality and shelf-life (Figure 1).

One of the goals of NovelQ is to facilitate and speed up industrial exploitation of novel technologies by carrying out extensive demonstration activities with real food products and industrial equipment in close collaboration with the food industry. A variety of activities have been undertaken during the lifetime of NovelQ demonstrating the advantages of novel processing and advanced heating with respect to product quality and shelf-life (Figure 1).

One of the goals of NovelQ is to facilitate and speed up industrial exploitation of novel technologies by carrying out extensive demonstration activities with real food products and industrial equipment in close collaboration with the food industry. A variety of activities have been undertaken during the lifetime of NovelQ demonstrating the advantages of novel processing and advanced heating with respect to product quality and shelf-life (Figure 1).

During the first 18 months, demonstration activities were focused on more mature advanced heating technologies such as microwaving, radio frequency and ohmic heating. Although these technologies have been studied for quite some time and they have clear advantages for some applications, the number of known applications in the food industry that are commercially successful is still low. Within NovelQ, three 18-month demonstration projects, partially financed by industry, were completed using new applications for advanced heating. To stimulate further the use of advanced heating by the food industry, a workshop – ‘Success stories in advanced heating technologies’ – was organised by SIK (Swedish Institute for Food and Biotechnology) at which equipment producers and food industry presented success stories and identified bottlenecks for implementation.

Figure 1 During the lifetime of the NovelQ project, various type of demonstration projects have been done in collaboration with industry. HP = High Pressure; PEF = Pulsed Electric Field; RTE = Ready-to-eat; IAP = Industrial Advisory Platform

During the midterm of NovelQ, a competitive call led to three new demonstration projects, coordinated by industrial partners, focusing on new technologies. These projects included high pressure processing for a variety of innovative and healthy foods, plasma treatment of herbs and new packaging material for high pressure processing. Furthermore, 10 short (one / two day) confidential demonstration trials were carried out with IAP members to test new ideas involving novel processing.

Finally, in the last 18 months, two integral demonstration projects which integrated all the scientific results obtained by NovelQ were performed. One of the demonstrations compared thermally processed orange juice with high pressure and pulsed electric fields, based on equivalent microbial inactivation, in terms of general quality attributes such as sensory characteristics, and shelf-life. The other demonstrations consisted of HP sterilisation processes (shelf stable foods) of complex products (meals). Results from these integral demonstrations will be presented at the final NovelQ IAP meeting to be held in Wageningen on 5 – 6 October 2010 (more information at www.novelq.org).

Advanced heating

» A minimal pasteurisation / sterilisation technology by application of water immersed radio-frequency heating for food products in consumer packages. (A&F, Struik Foods Group, The Netherlands)

» Design of ready-to-eat meals compositions for uniform microwave heating (SIK, Procordia Food, Sweden)

» Ohmic heating technology of highly viscous pumpable foods with particles (CTCPA, OPAL, PENY, France) Novel technologies

» Cold plasma treatment for inactivation of microorganisms on food surfaces (Koldsteril, Switzerland)

» Packaging materials for high pressure sterilisation (Icimendue, Italy)

» High Pressure processing of healthy, complex food products (TOP, The Netherland, NC Hyperbaric, Spain)

Integral demonstration

» Pasteurisation of orange juice (high pressure pasteurisation, PEF and thermally processed). For more details, see ‘How to compare novel and conventional processing methods in new product development: a case-study on orange juice’ in this issue

» Integral demonstration for complex sterilised ready-to-eat meals (thermal and high pressure pasteurisation)

Short-time demonstration projects

Ten companies together with a NovelQ partner have demonstrated new applications of advanced heating and novel processing. The applications tested include:

» Ohmic heating fruit preparations

» HP cereals products

» Robotic handling of delicate products

» HP dairy products

» Continuous microwave heating

» Microwave drying waste products

» Microwave drying cereals

» HP sterilisation vegetables

About the Author

Ariette Matser

Ariette Matser is currently Senior Scientist – Mild Preservation and Novel Technologies and Programme Coordinator – Mild Preservation within Food & Biobased Research of Wageningen UR. She studied Food Science at Wageningen UR. Her primary research activities include novel technologies and food safety and quality, preservation and processing of food products and effects on food quality, and food structure and the effects of processing on this. Management activities are involvement in (inter) national R&D projects, project acquisition and coordination of activities on novel technologies. She is Project Coordinator of the European project NovelQ.

Lilia Ahrné

Dr. Lilia Ahrné is Director of the Department for Process and Technology Development at SIK – The Swedish Institute for Food and Biotechnology and Associated Professor in Food Engineering at Chalmers Technical University. Before joining SIK, she worked for Tetra Pak Processing Systems. Her research interests are to understand the effect of processing on physical, chemical and structural characteristics of foods, and use this knowledge to develop new processes and products taking in account sustainability aspects as energy consumption and costs. Processes under study include both traditional and novel technologies. She has extensive experience in coordination of industrial and European research projects.