Magnetic Resonance Imaging for cereal products

- Like

- Digg

- Del

- Tumblr

- VKontakte

- Buffer

- Love This

- Odnoklassniki

- Meneame

- Blogger

- Amazon

- Yahoo Mail

- Gmail

- AOL

- Newsvine

- HackerNews

- Evernote

- MySpace

- Mail.ru

- Viadeo

- Line

- Comments

- Yummly

- SMS

- Viber

- Telegram

- Subscribe

- Skype

- Facebook Messenger

- Kakao

- LiveJournal

- Yammer

- Edgar

- Fintel

- Mix

- Instapaper

- Copy Link

Posted: 3 May 2005 | John van Duynhoven and Gerard van Dalen, Foods Research Centre, Unilever R&D, Vlaardingen (NL), Ales Mohoric and Henk van As, Wageningen University and Research Center (NL), Pedro Ramos Cabrer, Utrecht University (NL) and Klaas Nicolay, Utrecht University (NL) and current affiliation Eindhoven University of Technology | No comments yet

How does the microstructure of a food product behave during processing? And what events take place during the shelf life of food products? New developments in Magnetic Resonance Imaging (MRI) enable cereal food technologists to address such questions within the context of product innovation.

In the food industry, pressure to bring new products faster to the market has increased and in the meantime the systems under investigation are becoming ever more complex. An important segment of food innovations comprises cereal products such as snacks and (pre-processed) staple foods. Food technologists well appreciate the importance of understanding structure-property relations in developing these novel food products. Assessment of food micro- and macrostructures by conventional techniques, however, mostly involves invasive and destructive procedures. This precludes the observation of dynamic events in relation to food structures during processing and storage. Hence, Magnetic Resonance Imaging (MRI) has gained considerable interest, since this tomographic technique can map structures in a non-invasive and dynamic manner. The potential of MRI is currently exploited to its full extent within medicine, where it has become one of the most powerful diagnostic tools – an accomplishment for which a Nobel Prize was recently awarded (Sir Peter Mansfield, Paul C. Lauterbur, 2003). In its most widely used form, MRI detects water in soft tissues and image contrast can be obtained by exploiting differences in water density and/or mobility. In the last decade, MRI has also found applications in food science. It has become clear, however, that ‘conventional’ MRI techniques are not always adequate for assessment of cereal products, especially those in the low-moisture regime. Under low moisture conditions, cereal products typically have extended shelf life stability and/or favourable sensory properties such as crispness. In order to address the measurement challenges for such systems, Unilever and the Universities of Wageningen, Utrecht and Delft embarked on a project to develop and implement novel MRI methodology. Here we will present several examples of the application of novel MRI methodology for visualisation of moisture migration in cereal systems. It will be demonstrated that MRI can be used to monitor ingress of water during cooking of processed rice kernels in real time mode. We will also show how MRI can be deployed to assess migration of moisture in multi-component snacks, where differences in water activities exist.

How does the microstructure of a food product behave during processing? And what events take place during the shelf life of food products? New developments in Magnetic Resonance Imaging (MRI) enable cereal food technologists to address such questions within the context of product innovation. In the food industry, pressure to bring new products faster to the market has increased and in the meantime the systems under investigation are becoming ever more complex. An important segment of food innovations comprises cereal products such as snacks and (pre-processed) staple foods. Food technologists well appreciate the importance of understanding structure-property relations in developing these novel food products. Assessment of food micro- and macrostructures by conventional techniques, however, mostly involves invasive and destructive procedures. This precludes the observation of dynamic events in relation to food structures during processing and storage. Hence, Magnetic Resonance Imaging (MRI) has gained considerable interest, since this tomographic technique can map structures in a non-invasive and dynamic manner. The potential of MRI is currently exploited to its full extent within medicine, where it has become one of the most powerful diagnostic tools – an accomplishment for which a Nobel Prize was recently awarded (Sir Peter Mansfield, Paul C. Lauterbur, 2003). In its most widely used form, MRI detects water in soft tissues and image contrast can be obtained by exploiting differences in water density and/or mobility. In the last decade, MRI has also found applications in food science. It has become clear, however, that ‘conventional’ MRI techniques are not always adequate for assessment of cereal products, especially those in the low-moisture regime. Under low moisture conditions, cereal products typically have extended shelf life stability and/or favourable sensory properties such as crispness. In order to address the measurement challenges for such systems, Unilever and the Universities of Wageningen, Utrecht and Delft embarked on a project to develop and implement novel MRI methodology. Here we will present several examples of the application of novel MRI methodology for visualisation of moisture migration in cereal systems. It will be demonstrated that MRI can be used to monitor ingress of water during cooking of processed rice kernels in real time mode. We will also show how MRI can be deployed to assess migration of moisture in multi-component snacks, where differences in water activities exist.

How does the microstructure of a food product behave during processing? And what events take place during the shelf life of food products? New developments in Magnetic Resonance Imaging (MRI) enable cereal food technologists to address such questions within the context of product innovation.

In the food industry, pressure to bring new products faster to the market has increased and in the meantime the systems under investigation are becoming ever more complex. An important segment of food innovations comprises cereal products such as snacks and (pre-processed) staple foods. Food technologists well appreciate the importance of understanding structure-property relations in developing these novel food products. Assessment of food micro- and macrostructures by conventional techniques, however, mostly involves invasive and destructive procedures. This precludes the observation of dynamic events in relation to food structures during processing and storage. Hence, Magnetic Resonance Imaging (MRI) has gained considerable interest, since this tomographic technique can map structures in a non-invasive and dynamic manner. The potential of MRI is currently exploited to its full extent within medicine, where it has become one of the most powerful diagnostic tools – an accomplishment for which a Nobel Prize was recently awarded (Sir Peter Mansfield, Paul C. Lauterbur, 2003). In its most widely used form, MRI detects water in soft tissues and image contrast can be obtained by exploiting differences in water density and/or mobility. In the last decade, MRI has also found applications in food science. It has become clear, however, that ‘conventional’ MRI techniques are not always adequate for assessment of cereal products, especially those in the low-moisture regime. Under low moisture conditions, cereal products typically have extended shelf life stability and/or favourable sensory properties such as crispness. In order to address the measurement challenges for such systems, Unilever and the Universities of Wageningen, Utrecht and Delft embarked on a project to develop and implement novel MRI methodology. Here we will present several examples of the application of novel MRI methodology for visualisation of moisture migration in cereal systems. It will be demonstrated that MRI can be used to monitor ingress of water during cooking of processed rice kernels in real time mode. We will also show how MRI can be deployed to assess migration of moisture in multi-component snacks, where differences in water activities exist.

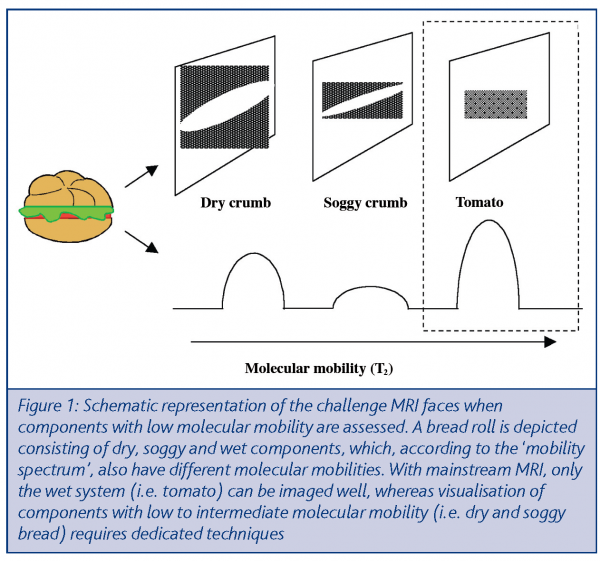

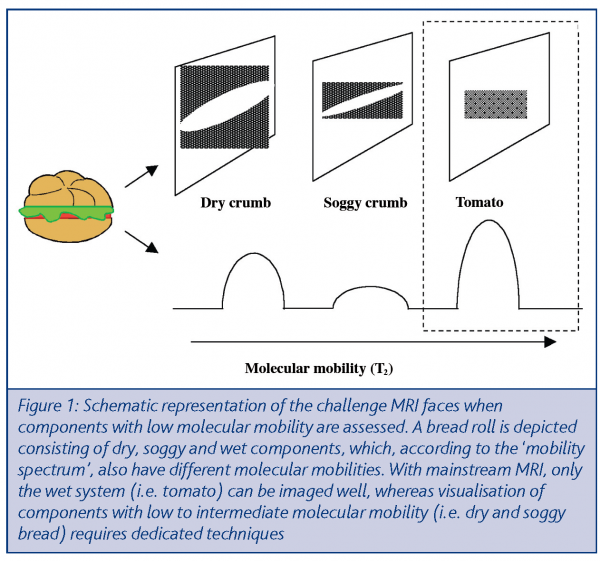

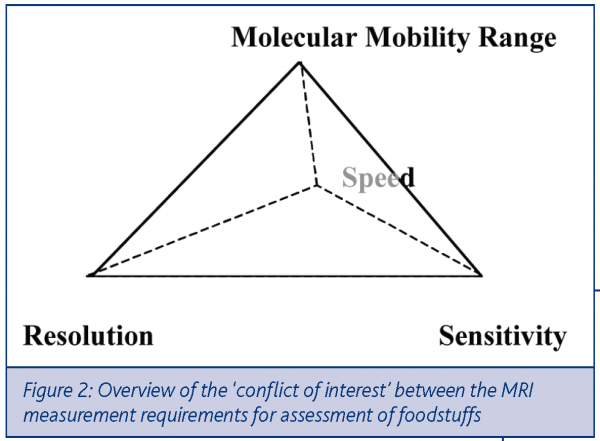

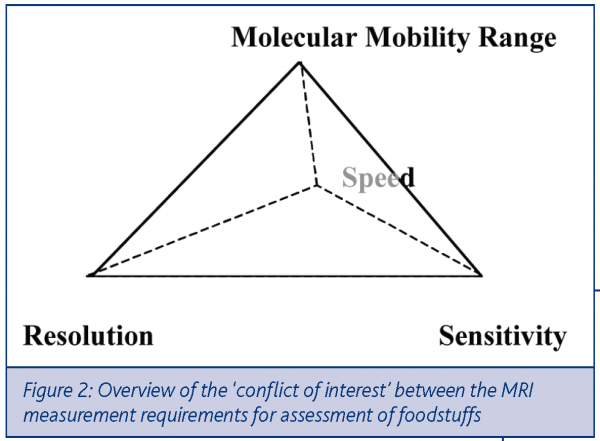

The conflict of interest in MRI

As with other tomographic techniques, the performance of MRI suffers from a trade-off between sensitivity, measurement speed and spatial resolution. It is not always acknowledged that MRI is also compromised with respect to the range of water mobilities that can be assessed. This is represented in Figure 1, where a model multi-component food system is represented. The system consists of components with different molecular mobility (tomato and dry and soggy bread), as is indicated on the ‘mobility spectrum’ below. With the established MRI techniques, components with high molecular mobility are typically observed, which is adequate for most medical diagnostic applications, but unfavourable for cereal components with low molecular mobilityi. This is depicted in Figure 1, where a ‘mobility spectrum’ is shown for a simple multi-component food system. The ‘mobility scale’ in such systems corresponds to the transverse relaxation time T2, which is a commonly used parameter in NMR and MRI. The so-called solid state MRI techniques can also assess the lower molecular mobility regime, (short T2 values) but also suffer from the trade-off between the three aforementioned measurement requirements. Hence, we arrive at a ‘conflict of interest’ between four MRI measurement requirements, as depicted in Figure 2. In this study, two examples are given of MRI methods that find acceptable compromises in this ‘requirement tetrahedron’. One method is suitable for imaging small objects with high speed and is used to monitor rice kernels during cooking in real time mode. The other method can resolve components with low to high molecular mobility, with a sensitivity and spatial and time resolution that is sufficient to monitor moisture transport in multi-component food systems during shelf life.

Cooking of processed rice

Cooking is one of the most important processing steps in the preparation of foods. It involves transport of heat and mass (water) and, commonly, several ingredients in the cooked food material undergo phase-transitions, such as gelatinisation of starch. To a large extent the initial phase-composition and microstructure of the material govern the rates of these processes. MRI is ideally suited for studies on the relation between structure and processing properties, since it can detect both molecular mobility and localisation in a dynamic and non-invasive manner. For many materials however, conventional MRI does not provide sufficient spatial and temporal resolution. Important examples where the conventional MRI approaches fall short in resolving power are cereals such as rice. Rice kernels typically have spatial dimensions of millimetres, cooking times in the tens of minutes, during which starch becomes gelatinised. In order to be able to make useful observations with MRI, investigators, until now, either emphasised spatial or time-resolution – sacrificing one requirement in favour of the other.

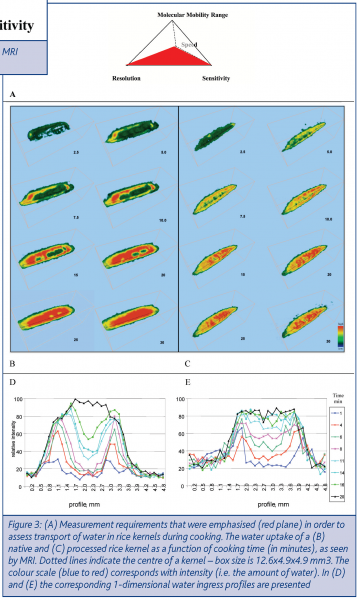

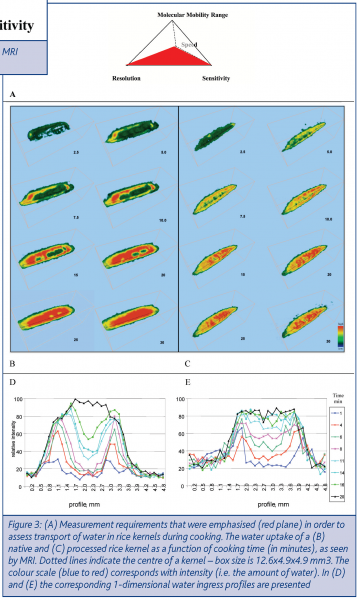

In our studies, we tailored MRI methods towards achieving sensitivity, temporal and spatial resolution that are adequate for establishing relations between moisture content profiles and rice kernel microstructures. This challenge is illustrated by means of the tetrahedron in Figure 3A, where the plane indicates which measurement requirements were emphasised. We proceeded to follow the cooking of rice kernels in real timeii, by acquiring 3D images during the entire cooking process. The water uptake during cooking is visualised by volume rendering showing the ingress of water. In Figure 3 the results are shown for a native and a processed rice kernel (note that only eight time steps are shown in Figure 3B,C). The ingress fronts do not move homogeneously from the edge to the centre of the kernel, which can be attributed to the presence of narrow cracks. The native kernel shows a relatively slow increase of water content with a relatively sharp ingress front, whereas the porous kernel shows a fast and uniform increase of the water contentiii. This is even more visible in the 1-dimensional water migration fronts shown in Figures 3D,E (these were derived from the 3-dimensional data in Figure 3B,C). The quality of the real-time structural information gathered by MRI has enabled us to develop and verify transport models that adequately describe the events taking place during the cooking of ricev.

Water transport in multi-component snacks

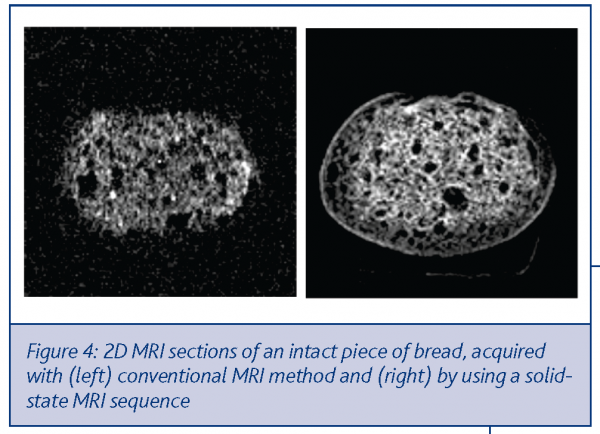

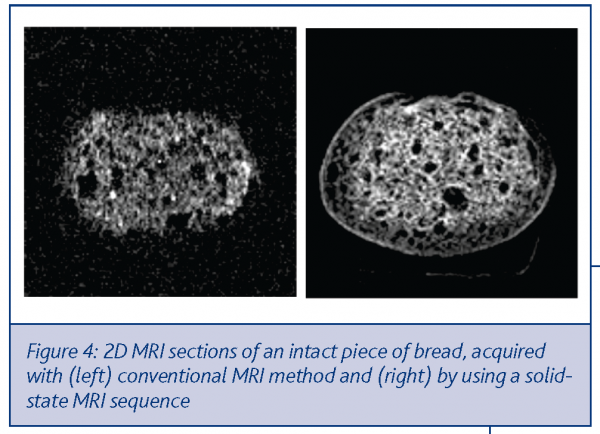

Shelf-life stability of multi-component foodstuffs is a major challenge for the modern food industry. Differences in water content (and activity) among different components of these products inevitably lead to water (re)distribution phenomena, causing product quality deterioration during shelf life. The use of non-invasive measurement methodologies would significantly increase the understanding of these transport processes. The detection of components with low molecular mobility, however, requires state of the art solid state MRI techniques. An example of the performance of these techniques is given in Figure 4. Whereas the conventional MRI technique only visualises the mobile component, the dedicated solid state MRI method reveals more structural detail .

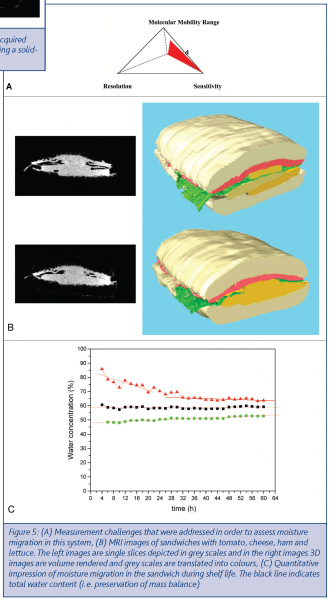

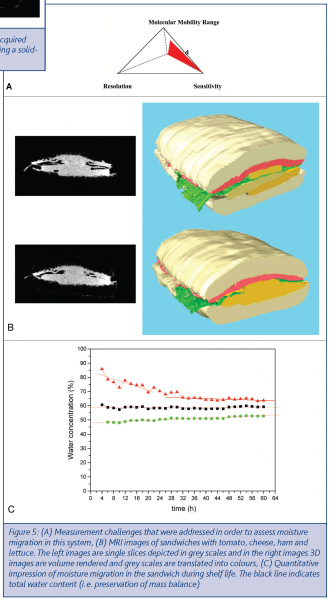

The visualisation of both mobile and less mobile components by solid state MRI is further illustrated in Figure 5B, which shows 2D and 3D images of a sandwich consisting of low- intermediate- and high-moisture components. These components can be well discerned by solid state MRI and this opens up the possibility to monitor moisture transport phenomena during shelf life. For this purpose two MRI methods were developed, which differ in emphasis on the different measurement requirements. A relatively fast protocol (0.5 hours per image) was used to measure moisture transport in the sandwich, which is shown in Figure 5B. This plot illustrates that water redistribution can be monitored in a quantitative manner, with high time resolution. In this example, however, only the total water content of the different components is estimated – populations with different molecular mobility cannot be resolved (illustrated in the requirement tetrahedron in Figure 5A).

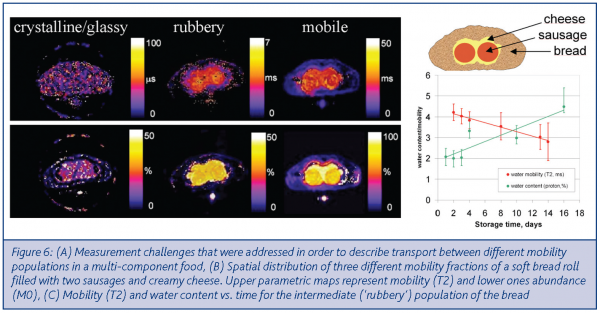

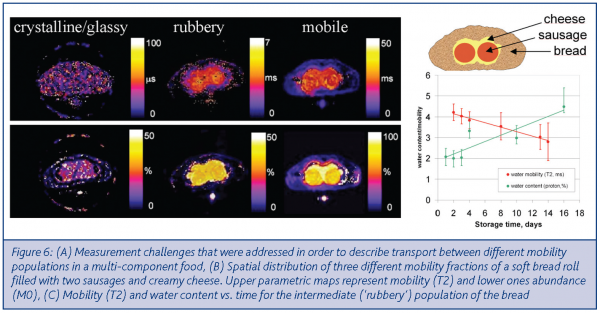

In a second MRI measurement protocol, different mobility regimes can be discerned, but this is at the expense of speed, as is illustrated in Figure 6A. Such a ‘mobility resolved’ measurement typically takes approximately eight hours and is not suitable for rapid transport events. The result of such a measurement is given in Figure 6B, which presents mobilities (so called T2 values) and concentrations of three different mobility populations, i.e. glassy/crystalline, rubbery and liquid (left to right). The redistribution of moisture between these populations is presented in a quantitative manner for the intermediate mobility regime (rubbery or soggy) of the bread component in Figure 6B. Within the bread component one can observe that the population with intermediate mobility increases in population. Interestingly, its relative mobility decreases, which may be attributed to the concomitant effect of staling. The high content of dynamic information that can be uniquely provided by MRI is crucial for the development and validation of physical models that describe transport and phase-compositional phenomena during shelf life.

Perspectives

The examples presented here pertain to realistic examples as they can occur in product development. The MRI experiments presented allowed for a quantitative description of transport phenomena in cereal products. Such information can be deployed to assess the efficacy of technologies to control moisture transport. In the case of rice, this involves processing routes to control kernel microstructures. Similarly, the development of food systems with contrast in water activity can benefit from the non-invasive assessment of the efficacy of moisture barriers.

The MRI measurements presented here also open up the possibility of validating models for moisture transport in foods. We expect that the ability to measure in a non-invasive and real-time manner will allow for the unambiguous rejection or confirmation of speculative transport models.

Acknowledgement

This work was carried out through a collaboration of Unilever R&D and the universities of Wageningen, Utrecht and Delft, with support of the Dutch Ministry of Economical affairs (BTS program, project no. BTS00103).

References

i. Non-biomedical applications of MRI: assessment of water transport in food (2004) P. Ramos Cabrer, J van Duynhoven, G. van Dalen, K. Nicolay, Cienca en la Frontiera, January 2005

ii. Magnetic resonance imaging of rice during cooking, A. Mohoriã, F. Vergeldt, E. Gerkema, A. de Jager, J.P.M. van Duynhoven, G. van Dalen, H. van As, J. Magn. Reson. 171 (2004) 157-162

iii. The effect of porous structure of rice on the hydration rate investigated by NMR, A. Mohoriã, J. van Duynhoven, G. van Dalen, F. Vergeldt, E. Gerkema, A. de Jager, H. van As, to be published in Magnetic Resonance in Food Science, RSC Books, London

iv. Single Point Imaging of Bread-Based Food Products, P. Ramos Cabrer, J.P.M. van Duynhoven, E.L.A. Blezer and K. Nicolay (2003) pp. 17-24 in Magnetic Resonance in Food Science, Latest Developments, P S Belton, A M Gil, G A Webb and D Rutledge, Eds. RSC Books, London

v. Mathematical Modelling of Water Uptake through Diffusion in 3D Swelling Substrates, L.R. van den Doel, A. Mohoric, F. Vergeldt, J. van Duynhoven, H. Blonk, H. van As, L.J. van Vliet, submitted for publication in Journal of Computational Physics