Brazilian team develops cork-based sensor to detect sodium nitrite in drinks

Posted: 21 October 2025 | Ben Cornwell | No comments yet

A team in Brazil has created a low-cost cork-based sensor that detects sodium nitrite in drinks, strengthening contaminant monitoring and food safety.

Researchers in Brazil have developed a novel sensor capable of detecting sodium nitrite in drinks such as mineral water, orange juice and wine.

A team at the Federal University of São Carlos (UFSCar), Brazil, has developed a novel sensor capable of detecting sodium nitrite (NaNO2) in various drinks such as mineral water, orange juice and wine.

This risk motivated us to develop a simple, fast, and accessible way to detect the compound and ensure the quality and safety of liquid consumption.”

The breakthrough, published in Microchimica Acta, offers a fast, low-cost method to identify the preservative, which can form carcinogenic compounds and is banned in drinks in most countries.

Bruno Campos Janegitz, head of the Laboratory of Sensors, Nanomedicine, and Nanostructured Materials (LSNano) at UFSCar, who coordinated the study, said: “This risk motivated us to develop a simple, fast, and accessible way to detect the compound and ensure the quality and safety of liquid consumption.”

Food producers widely use sodium nitrite to preserve and colour processed meats such as bacon and ham. But in high amounts, it can trigger the formation of nitrosamines, compounds linked to cancer risk.

“Detection [of NaNO2] in beverages, especially wines, is important for quality control, since its use is not legally permitted in Brazil and most countries,” the authors wrote.

Building and testing the sensor

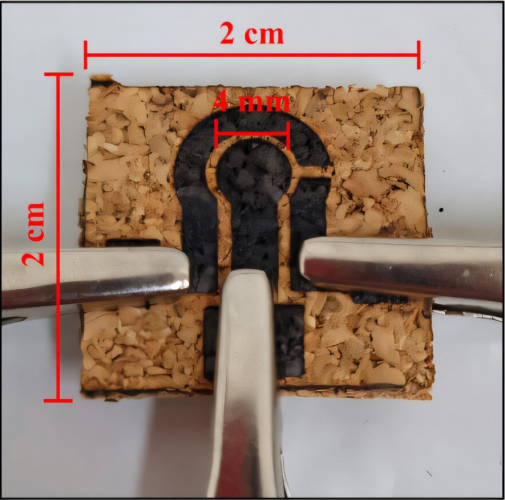

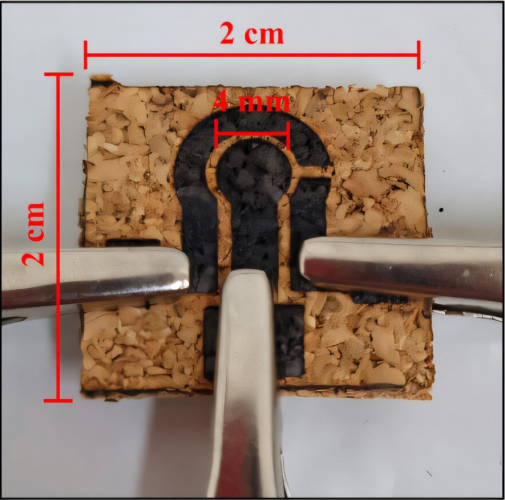

The project is currently undergoing laboratory validation and design refinement. Credit: Beatriz Germinare et al/ Microchimica Acta

To build the sensor, the UFSCar team turned to cork, chosen for its availability, sustainability and low cost. They then used a laser to transform its surface into graphene, a highly conductive form of carbon, as if light had traced pathways across the material.

After this step, the team applied a waterproof spray to prevent liquid absorption and coated the cork with nail polish to define the active area. Finally, they oven-dried the pieces at 40°C to optimise the laser parameters.

Janegitz explained: “This process is sustainable, doesn’t require toxic reagents, and results in a highly conductive material, which is essential because nitrite undergoes well-known electrochemical oxidation.”

When tested with diluted solutions of water, juice and wine containing nitrite, the device showed strong sensitivity and stability, successfully detecting concentrations relevant to food and environmental safety.

Although the project is still in the laboratory validation stage, the researchers believe the technology shows promise as a practical tool to help producers and regulators monitor contaminants in the food and beverage sector.

The next step will be refining the sensor’s design for real-world use.

Related topics

Beverages, Contaminants, Flavours & colours, Food Safety, Health & Nutrition, Ingredients, Research & development