Static and rotary spraying for perfect tank cleaning

- Like

- Digg

- Del

- Tumblr

- VKontakte

- Buffer

- Love This

- Odnoklassniki

- Meneame

- Blogger

- Amazon

- Yahoo Mail

- Gmail

- AOL

- Newsvine

- HackerNews

- Evernote

- MySpace

- Mail.ru

- Viadeo

- Line

- Comments

- Yummly

- SMS

- Viber

- Telegram

- Subscribe

- Skype

- Facebook Messenger

- Kakao

- LiveJournal

- Yammer

- Edgar

- Fintel

- Mix

- Instapaper

- Copy Link

Posted: 29 July 2005 | Frank Moerman, Chairman, EHEDG Belgium | No comments yet

In the beverage processing industry (spirits, brewing, juice bottling, dairy, etc.), cleaning-in-place is a well established technique. On a daily basis, huge numbers of small and large vessels must be cleaned in an economical, efficient and reproducible manner. To achieve these objectives, tank cleaning machines are used. In part 1 of his article, Frank Moerman compares the various static and rotary spraying heads offered for sale on the world market.

Cleaning-in-place is a method where cleaning of complete items of plant equipment or pipeline circuits is automatically performed without dismantling or opening the equipment. Little or no manual work on the part of the operator is involved. The process involves the circulation of cleaning solutions (detergent and cleaning solutions) through tanks and piping within the processing plant and the jetting or spraying of surfaces under conditions of increased turbulence and flow velocity. Cleaning-in-place is based on the application of a certain amount of energy – enough to ensure that the equipment surface is clean. This energy is provided by the solution temperature (thermal energy); the use of detergent or solvent (chemical energy) and the application of suitable pipeline velocities or pressures (kinetic energy).

In the beverage processing industry (spirits, brewing, juice bottling, dairy, etc.), cleaning-in-place is a well established technique. On a daily basis, huge numbers of small and large vessels must be cleaned in an economical, efficient and reproducible manner. To achieve these objectives, tank cleaning machines are used. In part 1 of his article, Frank Moerman compares the various static and rotary spraying heads offered for sale on the world market. Cleaning-in-place is a method where cleaning of complete items of plant equipment or pipeline circuits is automatically performed without dismantling or opening the equipment. Little or no manual work on the part of the operator is involved. The process involves the circulation of cleaning solutions (detergent and cleaning solutions) through tanks and piping within the processing plant and the jetting or spraying of surfaces under conditions of increased turbulence and flow velocity. Cleaning-in-place is based on the application of a certain amount of energy – enough to ensure that the equipment surface is clean. This energy is provided by the solution temperature (thermal energy); the use of detergent or solvent (chemical energy) and the application of suitable pipeline velocities or pressures (kinetic energy).

In the beverage processing industry (spirits, brewing, juice bottling, dairy, etc.), cleaning-in-place is a well established technique. On a daily basis, huge numbers of small and large vessels must be cleaned in an economical, efficient and reproducible manner. To achieve these objectives, tank cleaning machines are used. In part 1 of his article, Frank Moerman compares the various static and rotary spraying heads offered for sale on the world market.

Cleaning-in-place is a method where cleaning of complete items of plant equipment or pipeline circuits is automatically performed without dismantling or opening the equipment. Little or no manual work on the part of the operator is involved. The process involves the circulation of cleaning solutions (detergent and cleaning solutions) through tanks and piping within the processing plant and the jetting or spraying of surfaces under conditions of increased turbulence and flow velocity. Cleaning-in-place is based on the application of a certain amount of energy – enough to ensure that the equipment surface is clean. This energy is provided by the solution temperature (thermal energy); the use of detergent or solvent (chemical energy) and the application of suitable pipeline velocities or pressures (kinetic energy).

For large-sized tanks (processing vessels) spraying offers the best results: reduced downtime; increased productivity; less contamination and high quality cleaning whilst ensuring operator safety. Worldwide there are a large selection of tank washers and washing nozzles. A wealth of information can help you to identify the best tank washing nozzle for your application, but a universal solution is not available and each tank washer has its advantages and disadvantages. There are several factors/criteria that a food producer must consider.

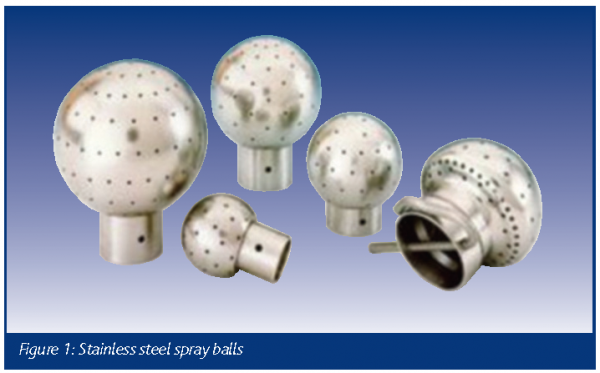

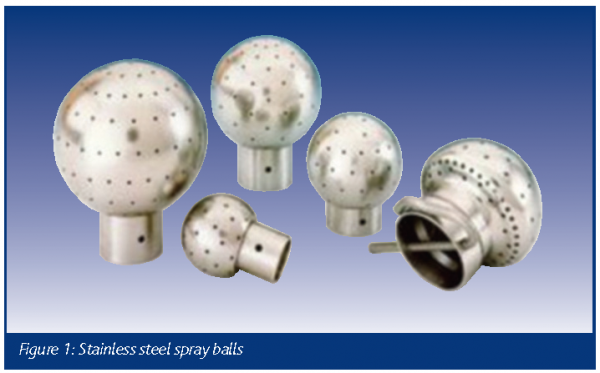

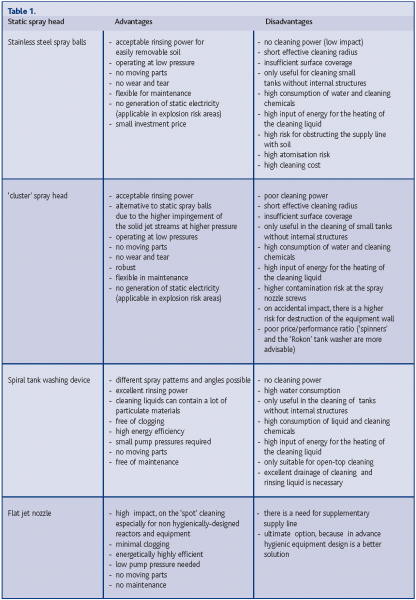

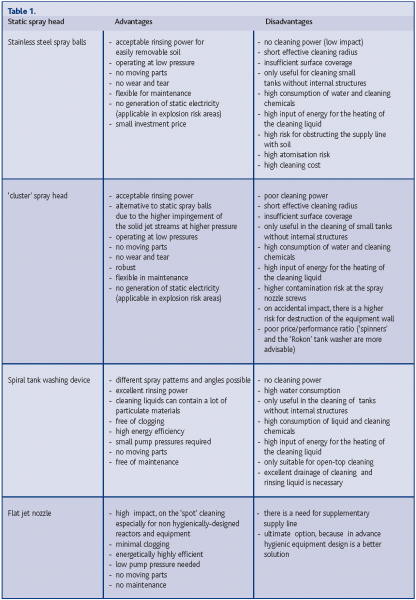

Stainless steel spray balls

Stainless steel spray balls (2.5-15 cm diameter) are fully or partially covered with holes (Figure 1). Made of PTFE, Hastelloy or sanitary polished stainless steel 316/316L, spray balls are thin-walled (1 mm) or thick-walled (2-6 mm). Thin-walled spray balls are more fragile and as a consequence the risk of destroying the fluid traject is higher. Moreover, atomisation is a major risk. Thick-wall spray balls have superior robustness making them more resistant to mechanical impact. Furthermore, each hole drilled through the thick-wall is virtually a nozzle tube, resulting in the jet streams travelling further than normal before breaking up. These stable and precisely orientated jet streams are characterised by a higher impact and cleaning efficiency. On the other hand, thin-walled spray balls create jet streams that have a somewhat whirling effect, removing the soil from the equipment surface in a turbulent way. With spray balls, there is always partial fluid coverage of the surfaces to be cleaned, due to direct wetting of the tank dome and indirect cascading flow on the tank walls.

As it often occurs that spray balls are mounted in a reactor/tank within the product liquid, the self cleaning power of the spray ball is of utmost importance. Therefore, the surface roughness of the stainless steel spray balls must be low and holes in the spray ball surface must be drilled in such a way that soil can be removed in the ‘dead legs’ between spray ball and supply-pipe. A drain hole is necessary in the lower part of the spray ball to guarantee the complete drainage of the cleaning/rinsing solution from the spray ball.

The purchaser of spraying devices must keep an eye on the number of holes in the spray ball surface. A small number of spray holes implies a larger counter pressure, demanding a larger pump pressure. Concomitantly, however, the impact of the water jets released by these spray balls also increases and the water consumption remains rather low. However, too small a number of holes decreases the moistening capacity of the spray ball, especially when the holes are blocked by soil or scale particles.

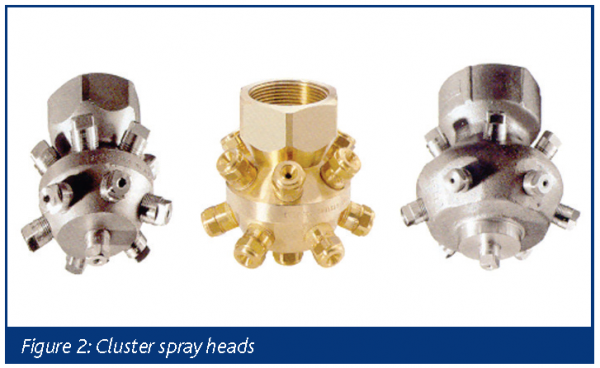

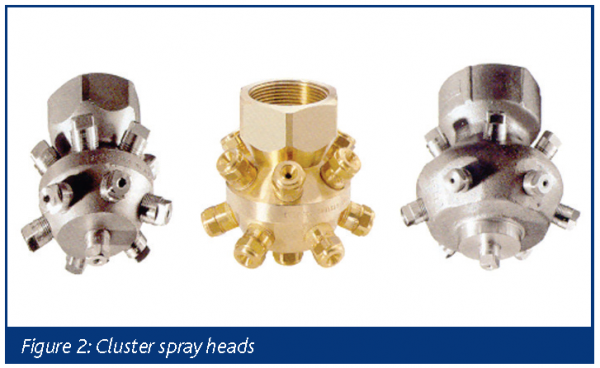

‘Cluster’ spray heads

This stationary spraying device consists of a multiple orifice body made of PTFE, PVC, PVDF, brass, Hastelloy or sanitary polished 316/316L. The body is fitted with several easily removable solid cone spray or solid stream nozzles. ‘Cluster’ spray heads have a diameter of 5-15 cm and a height of 4-20 cm. The pressures applied are 0.7-35 bar at flow rates of 20-600 l/min. For complete liquid drainage, these multiple orifice spraying devices have to be equipped with a lower drain hole .

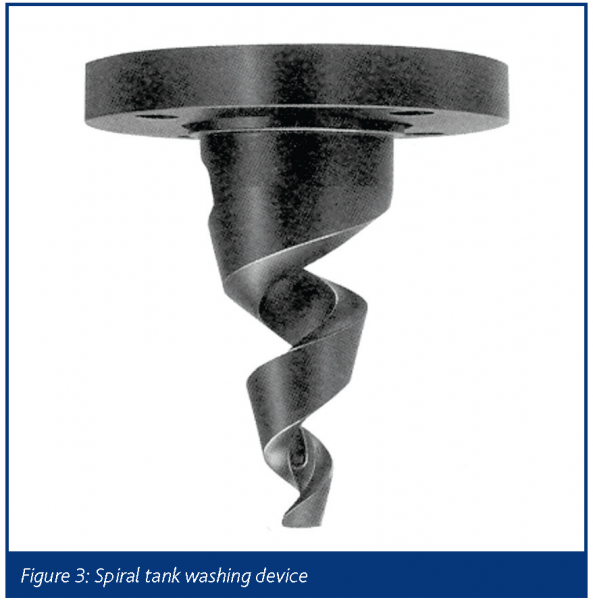

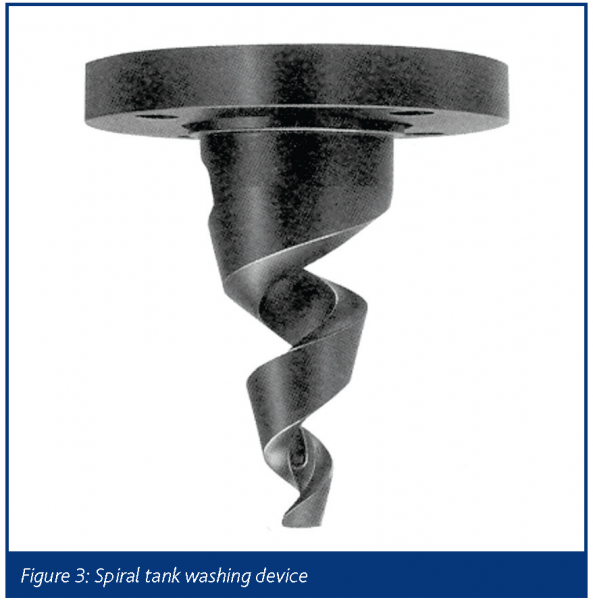

Spiral tank washing devices

A spiral tank washing device (on the commercial scene also named ‘pigtail’) consists of a continuously descending spiral made from cobalt, nickel-based alloys, stainless steel, brass, zirconium, tantalium, carbide material or PTFE and PVDF (see Figure 3). The construction material choice depends on the risk of oxidation; the risk of corrosion; the risk of chemical attack; work area temperature, etc. Spiral tank cleaning devices have a length of 5-30 cm and diameters of 2-12 cm. They can be mounted in the head of a tank on a (retractable) lance, or on a holder, in the latter case forming a ‘cluster’ type spraying device with several spiral nozzles.

Flat jet nozzles

This type of nozzle with round orifice gives a flat high impact spray pattern deflected over a certain angle. This type of nozzle is constructed from one piece of material, made from stainless steel, brass, PVC, PTFE, etc. The flow rates are 2-750 l/min at pressures of 0.7-15 bar.

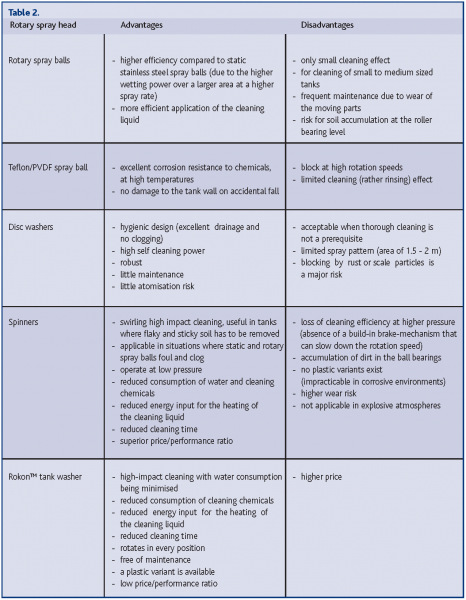

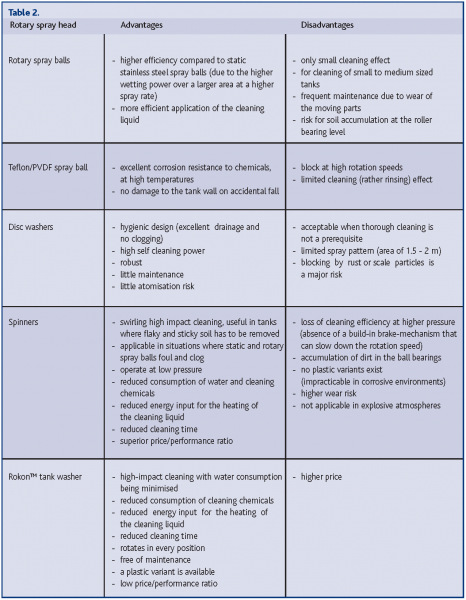

Rotary spray ball

This stainless steel tank washer consists of a compact spray ball that rotates at 3-15 rpm. The rotary cleaning head is driven by the flow of the cleaning fluid due to reactionary forces at the nozzle orifices. A drive system with gears controlling the rotation must avoid ineffectual high speed spinning (a differential speed reduction unit). Spray balls rotating at too high a speed create compact fluid jets that break open very quickly. The impingement effect of solid streams is much higher than full cone sprays. The rotary spray balls are made of Hastelloy or sanitary polished stainless steel 316/316L. Drilled holes or extended nozzles are present over the whole or a fraction of the rotary ball surface. The supply-line must be equipped with a filter to avoid the accumulation of soil within the rotary ball (this is a prerequisite in those cases where this body cannot be separated from the supply-body that contains the differential speed reduction unit). For maximum self-cleaning of the rotary washer, one nozzle must always be directed on the surface of that supply-body and the supply-line. Roller balls can be fixed within the tank in several positions, with the spinning of the tank washer being required in any mounted position. With time, wear to the roller bearings can be the cause of rotary heads starting to block under their own weight. Rotary cleaning heads operating at pressures of 3-14 bar and flow rates of 90-250 l/min have an effective cleaning radius of 1.8-2.5 m and an effective wetting radius up to 4 metres. They are applicable at temperatures of 120°C.

Rotary tank washing nozzles in Teflon and PVDF

The spray ball is constructed of a Teflon/PVDF fluoropolymer resin spray ring that rotates around a solid Teflon/PVDF connection body. The rotating spray ring is kept in place on the connection body by an easily removable external Teflon/PVDF retainer and Viton® O-ring. The connection body is attached to the liquid supply tube by a removable electro-polished type 316 stainless steel retaining clip. Multiple holes are drilled slopewise into the spray ring, in a way that produces a physical reaction force from the cleaning solution and drives the spray ring around the connection body. To remove the soil between the spray ring and the connection body, the spray ball must be dismantled from time to time.

The Teflon/PVDF spray balls operate at low pressures of 0.7-3.5 bar in a high temperature range of 150-160°C.

Disc washers

The cleaning fluid is directed through a guide vane onto the disc which instantly rotates, simultaneously dispensing a sphere of heavy, fast moving droplets to the entire surface of the tank. The disc washers are made of Teflon, Hastelloy, electro-polished stainless steel 316/316L or a combination of stainless steel/Teflon/PVDF. Some types are constructed in carbon filled PTFE, dissipating static electricity in potentially explosive atmospheres. Working pressures are 2-4 bar at flow rates of 50-270 l/min. The effective cleaning area is 0.5-2.3 m and the effective rinsing radius is 2-3.5 m. They can operate at a maximum temperature of 140°C.

Spinners

Spinners are rotary tank washers that contain slotted, flat-shaped spray orifices positioned such that the water jets generate the reaction forces necessary to produce the rotary motion. The spinners, made from stainless steel 316/316L or Hastelloy have a robust design. They utilise two ball bearing assemblies that make it possible to operate the nozzle in any orientation. This facilitates efficient 360° coverage. A spinner can also be introduced in a tank through a small flange hole. In the same way, the spinner can be fixed at different depths by means of a stainless steel lance (316 or 316L). The spinning of the tank washer is required in any mounted position. However, with time, wear to the roller bearings can cause the rotary heads to block under their own weight.

Spinners operate at pressures of 1-3 bars, with a maximum of 7-10 bars. With Mini-spinners the impact cleaning radius and the wetting radius are, respectively, 0.8-1.4 m and 2-3 m. They can be used in small-sized tanks of 100-10000 l (1-2 internal diameter). With Maxi-spinners the impact cleaning radius and the wetting radius are 1.9-3 m and 3.5-4 m, respectively. They can be used in large-sized tanks of 5000-50000 l (3-4 internal diameter). Both spinner types operate at an optimum of 95°C (with a maximum of 140°C).

Rokon™ tank washer

Unlike conventional fluid-driven rotating nozzles where the cleaning efficiency decreases as the pressure increases, the Rokon™ rotary tank washing nozzle increases its cleaning impact as the fluid pressure increases. Conventional fluid-driven rotating nozzles, that use the reactionary forces at the nozzle orifices to drive the spray head, spin at too fast a rate, breaking open the fluid streams to small droplets that have a much smaller impact. However, the Rokon™ tank washers that use the momentum of the liquid flow to drive the spray head contain a differential speed reduction unit. As a consequence, they rotate at a constant speed of approximately 10 rpm even when the fluid pressure is up to 20 bar.

The Rokon™ tank washer body is constructed of stainless steel 316 / 316L or chemical- and corrosion resistant KYNAR® (PVDF), with TEFLON® seals and stainless steel elliptic flat spray orifice inserts. The Rokon™ rotary tank washing nozzle can clean tanks up to 4-7.5 m. The flow rates range from 25-100 l/min at pressures up to 16 bar (max. 20 bar). The maximum permitted liquid temperature is 70°C.