Extrusion of precooked pasta

- Like

- Digg

- Del

- Tumblr

- VKontakte

- Buffer

- Love This

- Odnoklassniki

- Meneame

- Blogger

- Amazon

- Yahoo Mail

- Gmail

- AOL

- Newsvine

- HackerNews

- Evernote

- MySpace

- Mail.ru

- Viadeo

- Line

- Comments

- Yummly

- SMS

- Viber

- Telegram

- Subscribe

- Skype

- Facebook Messenger

- Kakao

- LiveJournal

- Yammer

- Edgar

- Fintel

- Mix

- Instapaper

- Copy Link

Posted: 1 May 2012 | Mian N. Riaz, Head Extrusion Technology Program, Food Protein R&D Center, Texas A&M University and Brian Plattner, Process Engineering Manager, Wenger Manufacturing Co | 1 comment

Pasta is a common source of carbohydrates in our diet today. Production and consumption of pasta products vary depending on the region of the world and culinary traditions within a society. Italy ranks as the highest consumer of pasta in the world at nearly 26 kilograms per capita, which is nearly double its next closest competitor, Venezuela1.

Most pasta products on the market, outside of instant noodles, are made from durum wheat semolina, and are processed via low temp – erature extrusion (less than 50°C)2. After extrusion and drying, these traditional pasta products have very low starch gelatinisation levels (less than 50 per cent) and must be cooked before serving. These products can also be treated to produce precooked pasta. This is accomplished after the conventional extrusion press process by a cooking stage in which the formed pasta is subjected to a steam or water bath followed by drying.

Another way to make a fully cooked pasta product without additional treatment is with extrusion cooking3. Typically, a twin screw extruder is used to wet the dough and cook and extrude it under high pressures and temperatures ranging from 90 to 110°C. This results in pasta products that can be rehydrated in three to eight minutes and they resemble the texture of those products made via a conventional process.

Pasta is a common source of carbohydrates in our diet today. Production and consumption of pasta products vary depending on the region of the world and culinary traditions within a society. Italy ranks as the highest consumer of pasta in the world at nearly 26 kilograms per capita, which is nearly double its next closest competitor, Venezuela1.

Most pasta products on the market, outside of instant noodles, are made from durum wheat semolina, and are processed via low temp – erature extrusion (less than 50°C)2. After extrusion and drying, these traditional pasta products have very low starch gelatinisation levels (less than 50 per cent) and must be cooked before serving. These products can also be treated to produce precooked pasta. This is accomplished after the conventional extrusion press process by a cooking stage in which the formed pasta is subjected to a steam or water bath followed by drying.

Another way to make a fully cooked pasta product without additional treatment is with extrusion cooking3. Typically, a twin screw extruder is used to wet the dough and cook and extrude it under high pressures and temperatures ranging from 90 to 110°C. This results in pasta products that can be rehydrated in three to eight minutes and they resemble the texture of those products made via a conventional process.

The extrusion cooked pasta method offers several advantages over the conventional process. First, it produces a fully cooked product that only needs to be rehydrated before consuming. Second, it allows many nontraditional ingredients to be used in the recipe such as soft wheat, rice, corn, and legumes. Extrusion cooked pasta can be dried in a much shorter time than traditional products. The biggest disadvantage is that a monoglyceride must be added to the recipe of extrusion cooked pasta products to protect the starch from being over sheared and damaged. In addition, regulations in many parts of the world prohibit the addition of monoglyceride in pasta and products made in this manner cannot be labelled as ‘pasta’.

Principles of extrusion cooking

Extrusion cooking has been defined as the process by which moistened, expansile, starchy and/or proteinaceous materials are plasticised in a tube by a combination of moisture, pressure, heat and mechanical shear. This results in the gelatinisation of the starch, denaturisation of the protein and the exothermic expansion of the extrudate4.

The extrusion system must accomplish a number of steps in a very short time under controlled, continuous, steady state conditions5. This includes tempering, feeding, mixing, cooking and shaping.

Feeding and tempering: the raw materials are fed uniformly into a preconditioner where they are mixed and tempered with water and steam. This results in a uniform moistened mixture entering the extruder and is critical for producing a high quality final product.

Cooking: through the addition of moisture, energy and time, the starch portion of the recipe is cooked or gelatinised and the proteins are denatured.

Mixing: the extrusion system provides a homogeneous, irreversible, bonded dispersion of all ingredients. This not only ensures uniformity of all ingredients such as dyes throughout the product, but also provides a means whereby minor ingredients can be intimately associated with potential reaction sites promoting desirable chemical and physical modifications of the starch and protein fractions of the raw ingredients.

Shaping and sizing of the final extruded product: precooked pasta must be properly shaped and sized during extrusion. This allows it to be placed in convenient and transportable sized portions prior to packaging for the retail and institutional marketplace. The pasta exiting the extruder die can be shaped and sized into both traditional and unique shapes. However, care must be taken so ensure quick and uniform hydration during final preparation. Selection of the proper raw materials and system configuration are essential for producing an acceptable final product.

Raw materials

The raw materials used for the production of extruded precooked pasta are both the most expensive and important consideration of the process6. There are several important raw material characteristics that require attention. These include the protein, starch, oil, fibre and particle size of each ingredient.

In any extrusion process, the particle size of the raw material is important. Large particles are difficult to hydrate and may require additional preconditioning or additional mechanical energy input in order to plasticise and disperse the entire particle. In some cases, very fine, floury particles are also detrimental because they tend to agglomerate in the preconditioner and then are difficult to re-disperse in the extruder barrel.

A wide variety of cereal grain and legume flours can be used as a base for the recipe. However, each flour type imparts its own textural, flavour and colour characteristics to the final product. The single largest advantage that extrusion precooked pasta has over traditional pasta processing is its ability to handle nontraditional ingredients. Traditional pasta relies on the binding of a good quality protein to develop the structure and hold the product together during and after processing. This often limits the ingredients to durum semolina flour or other high protein wheat flours. Inadequate quality protein can result in poor quality product after drying and cooling.

Products made via the extrusion cooking process are bound together by the gelatinised starch instead of an activated protein. Pasta-like products can be produced from blends of soft and hard wheat flours, as well as any other material that contains a significant level of starch. Blends of starch based ingredients such as corn, rice, and sorghum can be used to make gluten free pasta products.

Protein-based ingredients such as beans, peas, lentils and soy can be added to produce protein-enhanced products as well as glutenfree products. Other specialty pasta-like products for those requiring low protein diets can be produced from wheat or corn starch. Also, combinations of fibre and proteins can be added to produce a product having a lower glycaemic index. The flexibility of the extrusion cooking process allows these ingredients to be processed and converted into acceptable final products.

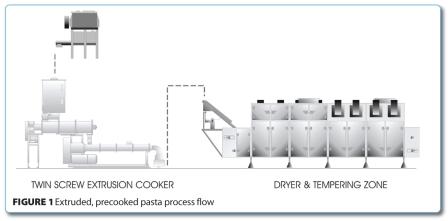

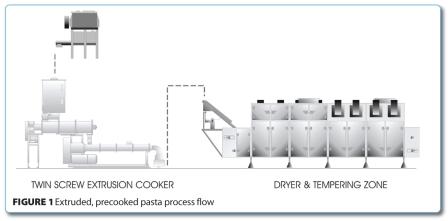

Extruded, precooked pasta production system

A typical process flow diagram for the production of extruded precooked pasta is shown in Figure 1. Raw materials are supplied either in bulk as shown or in bags. After mixing, the raw materials are conveyed to the live bin of the extrusion portion of the system.

The extrusion portion of the system includes a live bin/feeder, preconditioner, extrusion cooker and die/knife assembly as shown in Figure 2.

The design of each of these components is engineered to accomplish a specific function in the process. Within the design features, the operating conditions are adjusted to ensure complete cooking and to vary the properties of the finished product.

Live-bottom holding bin / feeder

The live bin/feeder provides a means of uniformly metering the raw materials (typically floury in nature) into the preconditioner and subsequently into the extruder. This flow of raw material must be uninterrupted and rate controllable. The live bin/feeder controls the product rate or throughput of the entire system. The live bin/feeder system can be controlled in a volumetric or gravimetric manner. In a volumetric setup, the feeder delivers a constant volume of feed to the preconditioner. When operating under gravimetric, or loss-in-weight (LIW), conditions the feeder delivers a set mass flow rate of raw material to the preconditioner.

Preconditioner

Preconditioning is required to provide uniform and complete moisture penetration of raw ingredients. This significantly improves the stability of the extruder and enhances final product quality. In the atmospheric pre – conditioner, moisture is uniformly applied in the form of water and steam to achieve a uniformly moistened mass. The retention time in the precondition is controlled and mixing of the added materials is accomplished by mixing and conveying elements consisting of rotating shafts with radially attached pitched paddles. The orientation and design of these elements allows the processor to optimise the initial hydration and heating portion of the process.

Preconditioning also begins the cooking of the starch. Typical moisture contents of 30 to 35 per cent and temperatures of 85 to 90°C allow for this initial cooking to take place prior to extrusion. By completely plasticising and hydrating the raw material particles prior to their introduction into the extruder barrel, extruder wear caused by the abrasive raw material particles is greatly reduced. In addition, flavours, colouring agents and other liquid additives may be introduced at this phase of the process insuring thorough and continuous mixing of all the foodstuffs prior to entering extruder barrel.

Extruder

Extruders used for the manufacture of precooked pasta are most commonly twin screw in design. The impact on final product characteristics such as texture, rehydration and density is produced by screw and barrel profile, screw speed, processing conditions (temp – erature, moisture and retention time), raw material characteristics and die selection.

As the moistened and partially cooked material leaves the preconditioner, it directly enters the extruder assembly consisting of the barrel and screw configuration. The initial section of the extruder barrel is designed to act as a feeding or metering zone to convey the preconditioned flour away from the inlet zone of the extruder. The material then enters a processing zone where the amorphous, free flowing flour is worked into elastic dough. The compression ratio of the screw profile is increased in this stage to assist in blending water or steam with the raw material. The temperature of the moist dough is increased though the addition of mechanical energy via the extruder screws and direct steam injection into the product. The remainder of the starch is gelatinised in this portion of the extruder barrel.

Following the cooking step, the material is passed into a venting zone and then a forming extrusion zone which cools and densifies the cooked material. The venting zone is usually equipped with vacuum assist to remove the excess energy and a screw stuffer to prevent any particles from plugging the vent opening. The temperature of the dough is lowered to prevent expansion and bubble formation as the product exits the die. The forming portion of the extrusion process contains a low shear configuration with minimal restrictions. The forming zone is usually characterised by positive forward transport screw elements comple – mented by maximum barrel cooling which further reduces the product temperature to 85 to 95°C. The cooled elastic product is then shaped by the final forming die into the final shape and size desired. The control of the moisture content, mechanical shear addition and the overall product temperature allows the product properties to be adjusted and optimised based on the formulation.

Die

The extrusion chamber is capped with a die apparatus. The die offers restriction to product flow and shapes the extrudate. Dies for extruded, precooked pasta are typically face dies. For many short cut products such as shells, elbows and wavy pasta, the die is in a horizontal position. For long cut goods such as rotini and ziti, the die is designed in a vertical orientation (parallel with the floor to allow these products to be shaped and cut evenly). Both die designs are fitted with variable speed cutting device to size the pasta.

Drying of pasta

As with most extruded products, extruded precooked pasta must be subjected to drying to make the product shelf stable. Since the pasta products are extremely dense, they must be carefully dried to prevent case hardening or cracking. To accomplish this, the drying rate is artificially reduced by injecting live steam, which raises the humidity in the dryer, through – out the drying process. Typical drying times are 30 to 45 minutes, but can vary depending on the wall thickness of the pasta products. After drying the pasta is cooled, fines are removed and the product is segregated into the appropriate size ranges and then sent to holding bins prior to packaging.

Final product specifications

After the processing steps are completed, the next step is rehydrating or reconstituting the extruded precooked pasta product. This step can be performed either by the consumer or the pasta may be rehydrated and added to a convenience food product.

Extruded, precooked pasta requires approxi – mately four to 10 minutes of preparation time as opposed to the 15 to 20 minutes necessary to completely prepare uncooked traditional pasta. Figure 3 shows an example of dry extruded rice and Figure 4 shows a sample of a prepared dish of extruded pasta.

The texture of the prepared precooked pasta will be affected by the preparation pro – cedure as well as the recipe. The preparation methods are somewhat flexible. The pasta products simply require rehydration to 58 to 60 per cent moisture in order to be edible. The following procedures have shown to give good results:

- Add equal volumes of precooked pasta and cold water to a container. Then cover and allow to set for two hours for complete rehydration

- Put equal volumes of precooked pasta and water in a microwave safe container. Microwave on high until the water begins to boil. Cover the container and wait for 10 minutes for complete rehydration

- Boil the precooked pasta product for four to eight minutes in excess water. The water should be boiling before the pasta is added. Remove the heat and drain off the excess water. The amount of time required for boiling will depend on the wall thickness of the pasta

Conclusion

Extrusion cooking can offer some unique opportunities for making precooked pasta-like products. While these products may not exactly duplicate the texture and quality of traditional pasta products, the flexibility of the extrusion process allows one to design new and inno – vative products based on nutrition, available ingredients and convenience.

References

1. UNAFPA. October 2011. http://www.pastaunafpa. org/ingstatistics4.htm

2. Wojtowicz A. and L. Moscicki. 2009. Influence of Extrusion-Cooking Parameters on Some Quality Aspects of Precooked Pasta-like Products. J. Food Sci. Vol. 74(5)226-233

3. Huber G. 1988. Extrusion cooking applications for precooked pasta products. Northern Crops Institute. Fargo, North Dakota

4. Smith, O.B. 1975. Textured Vegetable Proteins, presented at the World Soybean Research Conference, University of Illinois, August 3-8

5. Hauck, B.W. 1988. The Application of Co-rotating Fully Intermeshing Twin Screw Extruders with Conical Final Screw Elements in the Food Processing industry. Second International Symposium on Twin Screw Extruders for the Food Industry. Tokyo, Japan

6. Plattner, B. 2007. Applied Extrusion Workshop, University of Nebraska-Lincoln

About the author

Dr. Mian N. Riaz is Director for the Food Protein R&D Center, Head of the Extrusion Program and Graduate Faculty in the Food Science and Technology Program at Texas A&M University, College Station, Texas. Dr. Riaz has published five books and three of them are in the area of extrusion technology (Extruder in Food Application, Extruders and Expanders in Pet Food, Aquatic and Livestock Feeds and Extrusion Problem Solved) and one in the area of soybeans (Soy Application in Food). He also published 17 chapters in different books including some chapters in the area of extrusion. He offers four short courses in the area of extrusion annually, two courses are in feed extrusion and two courses are in food extrusion.

Thank you very much ‘ your information is very useful for me

I want to make ‘Macaroni plant’

Please can you send me how I make or manufactur a complete plant of macroni pasta

Thanks