Improving the mould free shelf life of bakery products

- Like

- Digg

- Del

- Tumblr

- VKontakte

- Buffer

- Love This

- Odnoklassniki

- Meneame

- Blogger

- Amazon

- Yahoo Mail

- Gmail

- AOL

- Newsvine

- HackerNews

- Evernote

- MySpace

- Mail.ru

- Viadeo

- Line

- Comments

- Yummly

- SMS

- Viber

- Telegram

- Subscribe

- Skype

- Facebook Messenger

- Kakao

- LiveJournal

- Yammer

- Edgar

- Fintel

- Mix

- Instapaper

- Copy Link

Posted: 24 August 2016 | Michael Adams, Bakery Science Section Manager, Campden BRI and Nicole Maher, Senior Bakery Scientist, Campden BRI | 1 comment

Mould free shelf life (MFSL) is a critical parameter in the bakery industry. Formulation and parameters such as Aw and the use of preservatives such as propionates and sorbates are traditionally used to ensure the length of MFSL is acceptable to consumers, retailers and manufacturers.

However, the current trend to reduce or eliminate the use of ‘artificial’ preservatives and the rise of organic foods is challenging the traditional methodologies.

A number of new technologies and processes can help bakers extend their MFSL without the use of preservatives, or with reduced quantities. These include infra red, ultra violet light, vacuum cooling, cold plasma and sourdough systems. This article will examine each technology/ process in turn and discuss the associated benefits and drawbacks.

Vacuum cooling

Vacuum cooling is a rapid evaporative technique that can be used for various foods and vegetables1. The major characteristic of vacuum cooling that benefits MFSL is that the product can be cooled extremely quickly whilst enclosed in a chamber.

It works according to the principle that when liquid evaporates, it needs to absorb heat to reach the higher energy level of molecular movement in the gaseous phase2. The amount of energy required is called latent heat. Water boils at 100°C at a pressure of 1 atmosphere, however a pressure reduction will cause the water to boil at a lower temperature. The resulting vapour generated during vacuum cooling is then removed by vacuum pump3.

Most vacuum cooling apparatus are operated in batch-wise processes. Products with a raised temperature are placed in a vacuum chamber soon after baking. When the vacuum pump is switched on, air is evacuated and the chamber pressure starts to decrease. As soon as the saturation vapour pressure corresponds to the temperature of the product, water inside the product begins to boil and latent heat is released. This causes the temperature of the product to decrease rapidly.

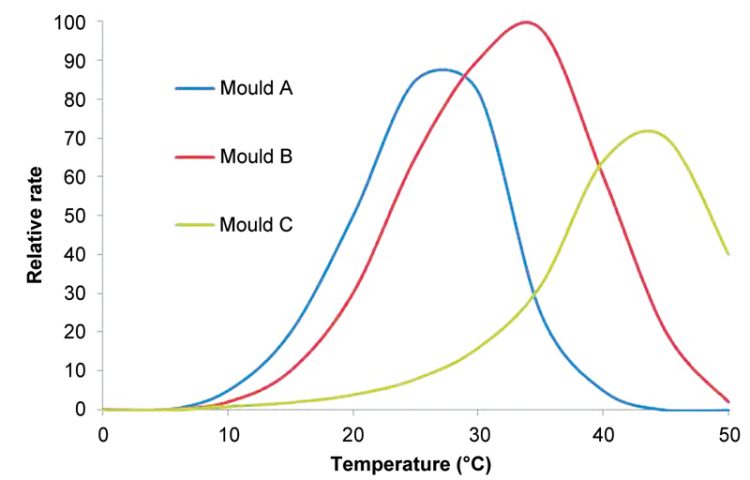

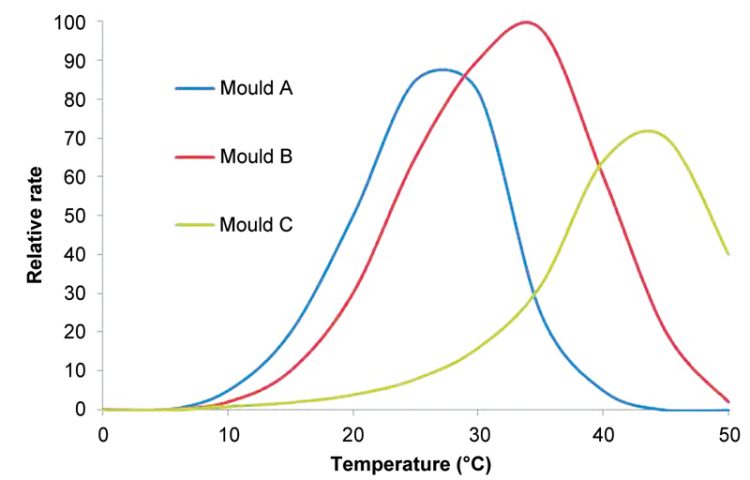

The major advantage of vacuum cooling over other conventional cooling techniques is the reduction in time required to cool a product to a given temperature. This decreases the amount of time a baked product spends in the key mould growth temperature range, which varies between species, but the most common bakery moulds have their highest relative growth rates above 28°C. It also reduces the time between exiting the oven and being packaged; typically the most common time that contamination with fungal spores occurs (Figure 1, below).

Figure 1: An illustrative chart indicating typical growth kinetics for bakery spoilage moulds

The cost of vacuum cooling is comparable to the cost of other cooling processes even though the initial capital investment is high. The energy consumption of vacuum cooling installations has been found to be lower than other methods of cooling, with high energy use coefficients (sensible heat/electrical energy) of 2.65 compared to 0.52 and 1.2 for air-blast and hydrocooling, respectively.

There are a number of disadvantages to vacuum cooling over traditional bakery cooling technologies; with product weight loss due to moisture removal being a particular issue. Vacuum cooling is also a highly product specific process and suitable for moist and porous structures only, as well as batch systems due to the engineering complexities of continuous systems.

Ultraviolet light (UV-C)

The use of ultraviolet light is well established in water treatment, air disinfection and surface decontamination. Increased public concern over non–clean label ingredients has improved its appeal in the food industry, especially as it is now considered as a safe processing method according to the US Food and Drug Administration (FDA) and US Department of Agriculture (USDA)4.

Short wave ultraviolet light (UV-C, 254nm) can be used as a method to increase the mould free shelf life of bakery products as it can reduce the microbial load in the air or on hard surfaces. Over the UV radiation range of 250–260nm most micro-organisms are inactivated due to damage to their DNA through dimer formation. The changes to DNA mean that the micro-organisms cannot reproduce, which reduces the risk of spoilage. This technique is used in the bakery industry to prevent mould growth by decontaminating the surface of the product5. UV lamps are added to bread production lines – usually before slicing – to minimise contamination from airborne moulds and mould growth in packaging6. It has also been used to prolong the shelf life of par-baked baguettes by reducing post baking contamination7.

The advantage offered by UV light is that it is a non thermal method of surface decontamination. This prevents any physical (such as changes in the crust) or chemical (such as acrylamide formation) changes in the bread. It also has the potential to allow a reduction in the use of artificial preservatives in the product.

Disadvantages include the capital cost of installing the system; potential Health and Safety concerns around controlling exposure to UV lights; and its effectiveness on certain products. UV-C is a line of sight disinfectant so products that do not have a smooth outer crust or shell require careful attention to ensure that no shadowing occurs, as this can significantly reduce effectiveness. UV-C light could also catalyse certain oxidation pathways resulting in an increased risk of rancidity.

Cold atmospheric plasma

Plasmas are commonly referred to as the 4th state of matter. A plasma state can be achieved when sufficient energy is applied to a gas. Plasmas can be generated using electrical energy. Applying a voltage to a gas generates an electric field that can accelerate any free electrons in the gas. Accelerated electrons will collide with neutral gas atoms, resulting in excitation or ionisation. This ionisation will release more free electrons to be accelerated, causing an ‘avalanche effect’ and generating a rich abundance of highly reactive, short-lived chemical species that are capable of inactivating a wide range of microorganisms, including food borne pathogens and spoilage organisms.

Typically, noble gases such as helium or argon are used to generate plasmas, because lower voltages are required. Other gases can be added (such as oxygen or nitrogen) to provide the type of reaction chemistries required. With the correct electrode configuration and power supply, plasmas can also be generated using air as the operating gas, reducing the need for expensive gases.

Studies have shown the potential for CAP to increase the MFSL of fresh produce by up to three days8. Recent advancements have tested technical solutions for sterilisation in pack. A number of different approaches are being trialled that allow for the generation of plasmas within a sealed pack (Polypropelene and low density polyethylene). This is potentially a huge advantage over other techniques, given the elimination of potential recontamination post-treatment and pre-packaging, inherent in other treatment methods (such as UV).

One disadvantage of this technology is the potential for CAP to modify the surface of baked products. Whilst some of the modifications seen, such as increasing the hydrophobicity of the surface9, could be potentially beneficial to a process, more detailed study of the mechanisms are required, as the potential for rapid oxidative damage to lipids means shelf life could be compromised in certain bakery applications.

Infra-red

Surface decontamination of bakery products with infra red radiation (IRR) is already relatively common within the industry. It offers a number of advantages over a comparable technology, such as UV, whilst also having drawbacks. One of the main advantages of IRR is that it offers a wide spectrum of activity, due to the fact that its primary mechanism is heat based. This means that the activity penetrates much further into a product than UV-C and does not suffer the effects of shadowing (although care must be taken that the entire surface of the product reaches the correct temperature). Due to the need to prevent recontamination after treatment, a potential issue when using IRR treatment is that items can hold residual heat post packaging. This can lead to condensation forming within the packaging, potentially causing quality issues. Another issue is the potential for the alteration of surface textures due to the application of heat.

Sourdough systems

By definition sourdough is dough made from cereal products, liquids and microorganisms that are metabolically active, or can be reactivated. Metabolites, such as organic acids, are produced by fermentation after the addition of flour and water. Sourdoughs are classified according to three groups, depending on the kind of technology used in their production:

- Type I sourdoughs or traditional sourdoughs

- Type II sourdoughs or accelerated sourdoughs

- Type III sourdoughs or dried sourdoughs

Type I sourdoughs are produced using traditional methods and are characterised by continuous, daily refreshments to keep the microorganisms in an active state, which is indicated by a high metabolic activity expressed by gas production. Type I sourdoughs are difficult to implement in a plant bakery owing to the high levels of manual intervention.

Type II sourdoughs are semi-fluid preparations, which have been developed to meet industry’s need for a faster, efficient and more controlled large scale fermentation process. Several modified, accelerated fermentation processes exist, such as continuous propagation and long one-stage fermentation. They have been found to ensure more production reliability and flexibility.

Type III sourdoughs are dried preparations containing lactic acid bacteria (LAB) resistant to the drying process. They are used as acidifier supplements and aroma carriers during bread making. The drying process (e.g. spray or drum drying) also has the advantage of increasing the shelf life of the sourdough. Dried sourdoughs are convenient materials to use in plant bakeries and result in greater consistency of the end products.

The bacterial flora in any fermented food is dependent on the pH, mineral concentration, gas concentration, incubation temperature and composition of the product. It has been noted in microbiological studies that sourdoughs are made up of more than 50 species of lactic acid bacteria (LAB)10.

LAB produce a variety of antimicrobial compounds during fermentation, such as lactic acid and acetic acid, which act to reduce the pH and produce hydrogen peroxide, formic acid, propionic acid and diacetyl. These compounds can have a synergistic antifungal effect working together to inhibit mould growth. In order to be considered useful the bacteria producing the antifungal effect must not adversely affect the leavening power of the yeast, Saccharomyces cerevisiae11.

Multiple studies have been conducted looking at potential strains of LAB and their ability to increase the MFSL of bread12,13. Whilst these studies show an improvement over bread made without any preservatives, sourdough systems have been shown to not be as effective as artificial preservatives. However, used in conjunction they allow a much lower level of proprionate than typically used14.

There are cost implications, however, in buying the sourdough as a pre ferment, as well as increased manual intervention in the process.

Conclusion

There are multiple technologies available to bakeries in order to maintain, or indeed extend, MFSL. While the use of artificial preservatives is still commonplace in the market, the trend towards ‘clean label’ and ‘preservative free’ products mean that new technologies and methods are needed to ensure that product shelf life and quality are not impacted.

The above article has considered a number of technologies that could be adopted to help reduce the reliance on additives, such as sorbates and propionates. It is our opinion that none of the technologies mentioned are capable of replacing artificial preservatives by them- selves; but innovative use of technology, coupled with insightful product design and ingredient choices can certainly work together to increase mould free shelf life in bakery products.

About the authors

Nicole Maher is Senior Bakery Scientist in the Bakery and Cereals Processing Department at Campden BRI and joined in 2011. Nicole studied Food Science at University College Cork (UCC). In her role at Campden BRI Nicole is involved in many areas of the department. She has experience of test baking, new product development and working on research projects. Her main areas of interest include gluten free, high fibre baking, dough fermentations, and the use of interfacial techniques to characterise bakery systems.

References

- McDonald, K. & Sun, D.-W. 2000, “Vacuum cooling technology for the food processing industry: a review.” Journal of Food Engineering, vol. 45, no. 2, pp. 55-65

- Drummond, L., Zheng, L., & Sun, D.-W. 2014, “Vacuum cooling of foods.” in Emerging Technologies for Food Processing, Academic Press, pp. 477-494

- Zheng, L. & Sun, D.-W. 2004, “Vacuum cooling for the food industry – a review of recent research advances”, Trends in Food Science and Technology, vol. 15, no. 12, pp. 555-568

- Koutchma, T. & Stewart, C. Applications and Efficacy of UV; Light for Foods. Click here for source. 2016

- BIntsis, T., Litopoulou-Tzanetaki, E., & Robinson, R. K. 2000, “Existing and potential applications of ultraviolet light in the food industry – a critical review”, Journal of the Science of Food and Agriculture, vol. 80, pp. 637-645

- Arvanitoyannis, I. S. & Bosinas, K. Bakery Products. 2016

- Doulia, D., Katsinis, G., & Mougin, B. 2000, “Prolongation of the microbial shelf life of wrapped part baked baguettes”, International Journal of Food Properties, vol. 3, no. 3, pp. 447-457

- Bayliss, D., Snipe, T., Bennington, M, Staniforth, L., Everis, L., & Leadley, C. 2014, “Cold Atmospheric Plasma” in R&D Report 377, Campden BRI

- Misra, N.N., Tiwari, B.K., Raghavarao, K.S.M.S. & Cullen, P.J. 2011, “Nonthermal plasma inactivation of food-borne pathogens.”, Food Engineering Reviews, 3 (3-4), 159-170

- Arendt, E. K., Ryan, L. A. M., & Dal Bello, F. 2007, “Impact of sourdough on the texture of bread.”, Food Microbiology, vol. 24, pp. 166-174

- Schnürer, J. & Magnusson, J. 2005, “Antifungal lactic acid bacteria as biopreservatives”, Trends in Food Science and Technology, vol. 16, pp. 70-78

- Dal Bello, F., Clarke, C. I., Ryan, L. A. M., Ulmer, H., Schober, T. J., Ström, K., Sjögren, J., van Sinderen, D., Schnürer, J., & Arendt, E. K. 2007, “Improvement of the quality and shelf life of wheat bread by fermentation with the antifungal strain Lactobacillus plantarum PST 1.7“, Journal of Cereal Science, vol. 45, pp. 307-318

- Ryan, L. A. M., Dal Bello, F., & Arendt, E. K. 2008, “The use of sourdough fermented by antifungal LAB to reduce the amount of calcium propionate in bread”, International Journal of Food Microbiology, vol. 125, pp. 274-278

- Gerez, C. L., Torino, M. I., Rollan, G., & de Valdez, G. F. 2009, “Prevention of bread mould spoilage by using lactic acid bacteria with antifungal properties”, Food Control, vol. 20, pp. 144-148.

i find this article quite informative.