Pulsed Electric Field processing of foods

- Like

- Digg

- Del

- Tumblr

- VKontakte

- Buffer

- Love This

- Odnoklassniki

- Meneame

- Blogger

- Amazon

- Yahoo Mail

- Gmail

- AOL

- Newsvine

- HackerNews

- Evernote

- MySpace

- Mail.ru

- Viadeo

- Line

- Comments

- Yummly

- SMS

- Viber

- Telegram

- Subscribe

- Skype

- Facebook Messenger

- Kakao

- LiveJournal

- Yammer

- Edgar

- Fintel

- Mix

- Instapaper

- Copy Link

Posted: 4 September 2007 | Stefan Toepfl and Volker Heinz, German Institute of Food Technology (DIL) | 3 comments

Pulsed Electric Field (PEF) applications can be utilised to achieve disintegration of biological tissues or microbes. Various applications have been identified such as improvement of mass transfer during extraction or drying as well as gentle food preservation. The first commercial applications of the technique have been achieved. By development of equipment based on state of the semiconductor, equipment reliability and cost effectiveness of the equipment has been improved. The technology is heading for wider industrial application.

Among novel, emerging techniques PEF is one of the most promising in order to achieve a gentle, non thermal pasteurisation or cell disintegration. First applications of pulsed electric fields were suggested in the 1960s1. In the 1980s first attempts to realise industrial equipment were made, but it took until 2005 to achieve the first commercial use2. By exposure to external electrical fields pores can be induced in microbial, plant or animal cells, an effect termed electroporation. The technique can be applied continuously and hardly needs a residence time. In contrast to other electrical techniques such as ohmic heating, the underlying mechanism is based on a non-thermal effect. The timescale required to achieve a pore induction is a range of microseconds, allowing the short pulsed energy required to reduce the electrical power consumption.

Pulsed Electric Field Equipment

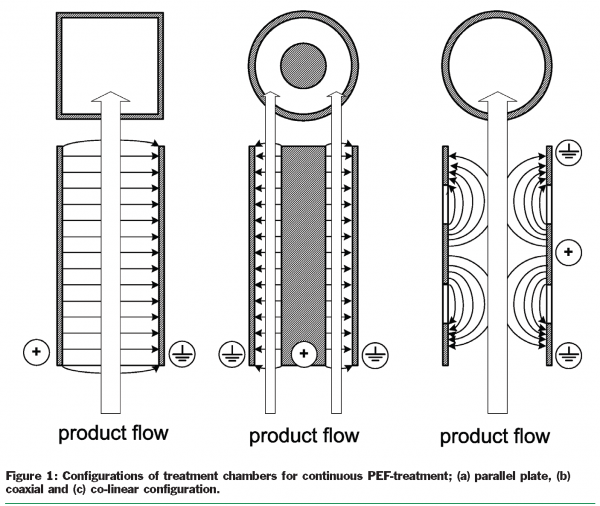

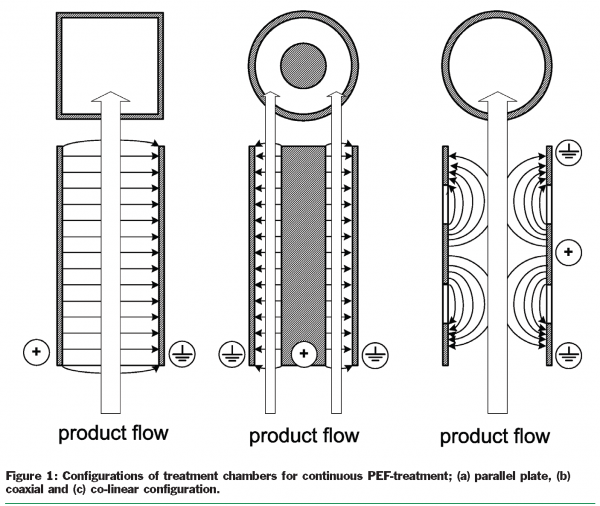

For a PEF treatment, a pulse modulator and a treatment chamber to expose the food to the electric fields is required. The pulse modulator is transforming the sinusoidal alternating current from the power line to pulses with sufficient peak voltage and pulse energy. For disintegration of plant or animal cells, typically 1kV/cm electric field strength is required, whereas microbial inactivation occurs above the critical field strength of 15kV/cm. The voltage used is in a range of 20 to 50kV, the energy per pulse between 1 and 100J at repetition rates up to kHz range. At present around 25 research groups are working on PEF applications for food treatment and pilot scale equipment is available at Ohio State University, USA, Stork Food Systems, The Netherlands, Berlin University of Technology, Germany and the German Institute of Food Technology, Germany. Pulse generation is achieved by charging a capacitor bank and discharging the stored energy across a high voltage switch into the treatment chamber. Mainly three treatment chamber designs have been suggested for liquid food treatment, parallel plate electrodes or coaxial or collinear configurations of cylindrical electrodes (see Figure 1). An example of a treatment chamber with a diameter of 60mm and a maximum treatment capacity of 5t/h is shown in Figure 2.

Potential applications

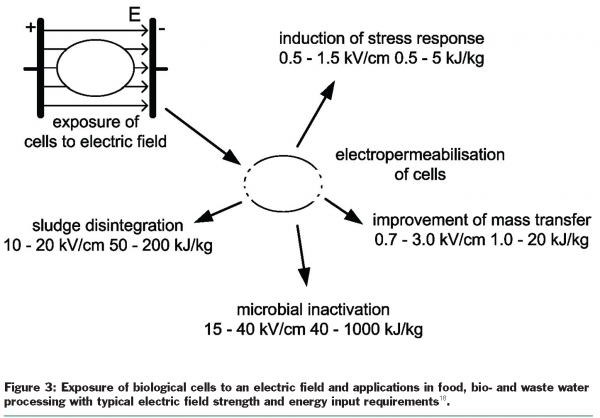

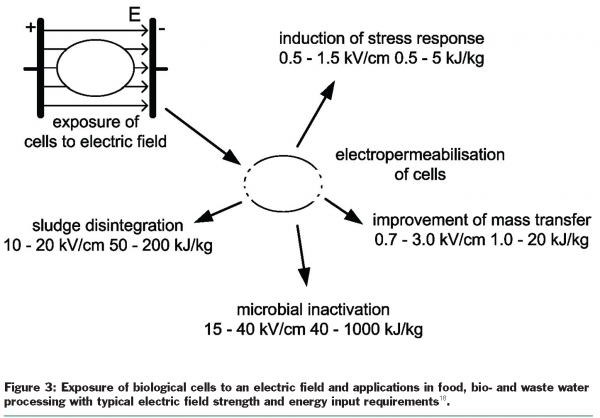

The technique’s ability to enhance extraction of intracellular compounds from fruits and vegetables; to improve drying rates of potatoes and meat products and to achieve a gentle decontamination of liquid foods has been investigated in lab and pilot scales tests3-5. In the following sections examples will be presented. An overview of potential applications in food and bioprocessing is shown in Figure 3 along with typical processing parameters.

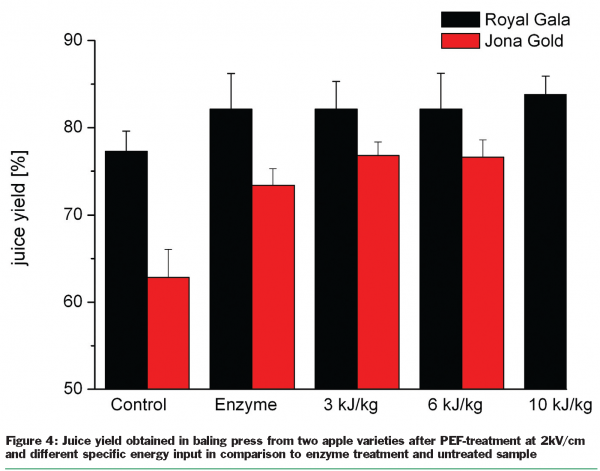

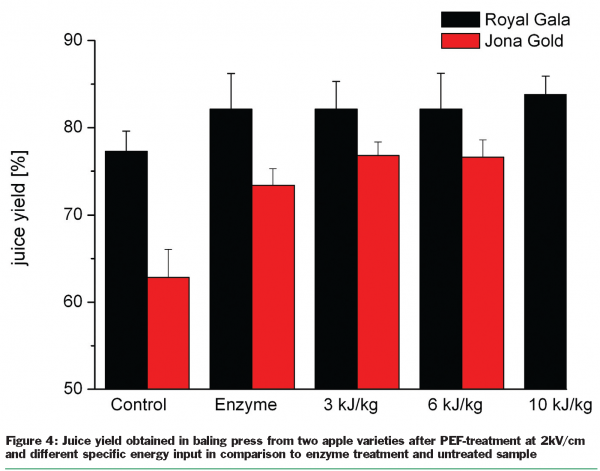

Improvement of juice extraction

Cell disintegration is often a crucial prerequisite prior to liquid-solid separation during extraction of fruit and vegetable juices. Conventionally, an enzymatic maceration is applied, requiring residence times of 30 to 60 minutes and holding tanks. The applicability of a short-time, continuous PEF treatment to induce cell disintegration was investigated using a juice press with a capacity of 50kg (see Figure 4). Dependent on apple variety and PEF treatment intensity, an increase in juice yield was found, similar or higher than after an enzymatic treatment. A specific energy input of 3kJ/kg was sufficient to achieve an increase in juice yield. Higher treatment intensities resulted in a further disintegration of apple mash, which could – dependent on press type – cause difficulties during liquid-solid separation. As a PEF application does not cause a depolymerisation or de-esterfication of hydrocolloids a potential to extract native structured pectin from pomace is provided. A first industrial prototype for this application was installed in a German fruit juice producing company in 2006.

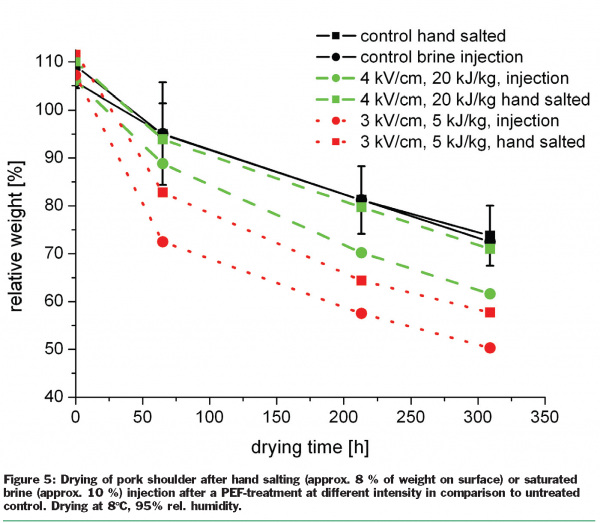

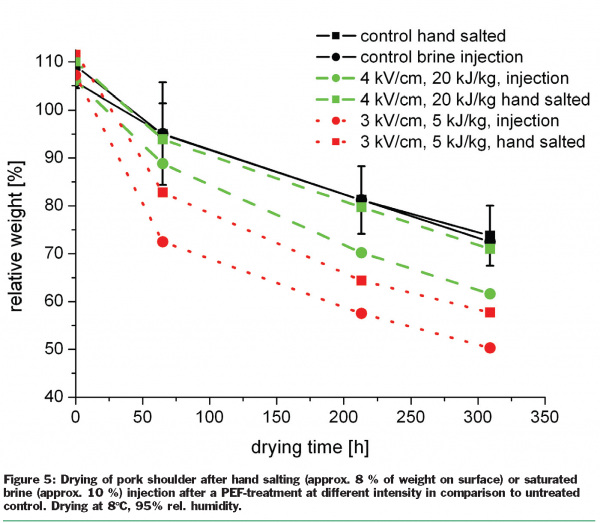

Improvement of drying

Drying of foodstuffs often significantly contributes to production costs and time requirements due to limited moisture diffusion from product core to its surface. Water removal from product surface can be improved by various drying conditions, but high removal will cause the formation of a dry crust inhibiting further moisture supply from the centre. Enhancement of drying of several fruit and vegetable products after a PEF application has been shown6-9, allowing for a reduction of drying times of up to 30 per cent for potato cubes. Though the energy required for water evaporation will not be changed by a PEF application, significant energy savings can be expected due to faster moisture transport and increased production capacities of existing lines10.

Production of dry cured ham and sausages requires the application of gentle drying conditions and drying times in a range of up to 30 days. The potential to enhance drying rates of dry cured ham was investigated subjecting samples of pork shoulder to a treatment at a field strength of 3 and 4kV/cm and a specific energy input of 5 and 20kJ/kg (see Figure 5). Shortest drying times were achieved after a PEF treatment and brine injection, emphasising the technique’s potential to improve moisture transport in meat tissue. An application of hand salting in combination with PEF caused formation of a dry, denatured meat surface, particularly after a treatment at 4kV/cm and 20kJ/kg. This pronounced effect might be related to the high treatment intensity and to the drying conditions applied, as the air velocity (approx. 4m/s) was not variable in the climatic cabinet and higher than applied during conventional cured ham processing. In case of pile salting, two mass transport processes will occur, a diffusion of water out of the tissue, as well as salt diffusion into the tissue. A pre-treatment by PEF application could as well be utilised to improve uptake of salt and nitrite/nitrate.

Gentle liquid decontamination

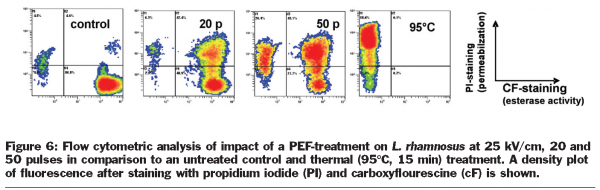

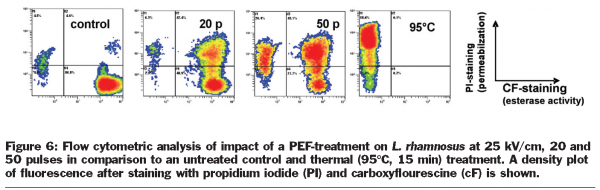

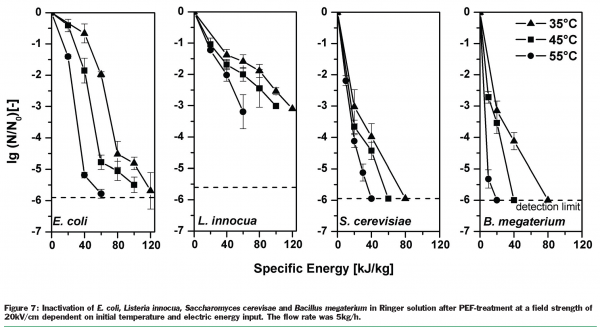

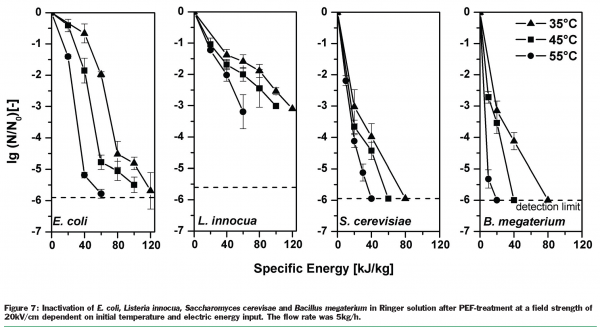

Induction of membrane pores by PEF can also be utilised for inactivation of microorganisms11. Loss of membrane barrier function and leakage of intracellular liquid will cause cell death. Membrane permeabilisation can be visualised using fluorescent cell staining and flow cytometric analysis. In Figure 6, staining of L. rhamnosus by propidium iodide (PI) and carboxy-flourescine (cF) is shown. PI is a membrane-impermeant probe which will not penetrate cells with intact membranes. After a PEF-treatment, PI diffuses into and stains the cells. The second probe, cF, is used primarily for the evaluation of cellular enzymatic activity. Dependent on number of pulses applied, membrane permeabilisation increases, whereas cellular esterase activity is maintained in contrast to a thermal treatment at 95°C. Successful inactivation of 5 to 7 log cycles of microbial cells has been shown in tap water, fruit juices, milk and cream and beer as well as vitamin solutions or nutrient media12-16. As an example, the inactivation of four microbial strains in Ringer solution is shown in Figure 7. It is noteworthy that a PEF treatment is only effective on vegetative organisms, whereas spores, viruses or enzymes are mostly unaffected by the electric field, as the primary target – the cell membrane – is missing. Process variables to improve energy efficiency are electric field strength, specific energy input and treatment temperature. Combining application of PEF and mild heat a microbial inactivation can be achieved with a low consumption of electrical energy while operating at lower maximum temperature and residence time in comparison to thermal processing14. A first commercial application for preservation of premium fruit juices was achieved in the US at the end of 20052. Products are distributed while chilled to prevent degradation by residual enzyme activity. Retaining enzyme activity – a potential disadvantage during juice processing by PEF – might be an advantage in media where a microbial decontamination, but no enzyme or protein denaturation is desired. Production of raw milk cheese and treatment of enzyme or protein preparations of egg yolk are examples where a reduction of microbial load could be performed without heat application and related changes in protein structure. It was shown that activity of lipid peroxidase, a component of native antimicrobial system can be retained after a microbial decontamination of milk17. A reduction of maximum temperatures during decontamination of liquids containing proteins could also help to minimise fouling at heat exchanger surfaces.

Industrial feasibility and costs of treatment

In general, the technique is feasible on an industrial scale by increasing treatment chamber size, pulse peak voltage and average power within certain technical limits. Lack of reliable and affordable industrial size equipment and a lack of innovation due to well established, conventional processing have limited the industrial exploitations in the past. Successful implications of the technique will require the identification of a cost or quality benefit to justify the costs of investment, which are in a range of between ?200 and ?250,000 for a 30kW pulse modulator. Dependent on type of application, this average power is sufficient for 10 to 15t/h of plant or meat tissue or, due to higher energy requirements, 1 to 2t/h liquid media decontamination. Breaking down the costs to a ton of product and including energy and maintenance, a typical total cost range is between €1 and €2/t for cell disintegration and 1 to 2ct/l for preservation. Recent developments in solid state semiconductor technology allow the design of compact, reliable and modular pulse modulators, as performed at the German Institute of Food Technology. A circuit typology based on a low voltage switching and pulse transformation was developed to limit stress on power modulator components. Prototypes with a power of 3 and 30kW are available.

Summary

The technique’s potential to achieve a disintegration of plant, animal or microbial cells has been shown, pre-treatment of tissue prior to extraction or drying and preservation of premium, chilled products or media containing proteins have been identified as promising applications. The technique can be called up to industrial size; prototype equipment is being developed at the German Institute of Food Technology.

References

- Doevenspeck, H. Influencing cells and cell walls by electrostatic impulses. Fleischwirtschaft, 1961. 13(12): p. 968-987.

- Clark, P. Pulsed Electric Field Processing. Food Technology, 2006. 60: p. 66-67.

- Knorr, D. and A. Angersbach. Impact of high-intensity electric field pulses on plant membrane permeabilization. Trends in Food Science & Technology, 1998. 9: p. 185-191.

- Barbosa-Cánovas, G.V., et al., Preservation of foods with pulsed electric fields. Food science and technology, ed. S.L. Taylor. 1999, San Diego: Academic Press.

- Toepfl, S., V. Heinz, and D. Knorr. Applications of pulsed electric field technology for the food industry, in: Pulsed electric field technology for the food industry, J. Raso and V. Heinz, Editors. 2006, Springer: Berlin. p. 197-221.

- Angersbach, A. and D. Knorr. Anwendung elektrischer Hochspannungsimpulse als Vorbehandlungsverfahren zur Beeinflussung der Trocknungscharakteristika und Rehydrationseigenschaften von Kartoffelwürfeln. Nahrung, 1997. 41: p. 194-200.

- Ade-Omowaye, B.I.O., et al. Use of pulsed electric field treatment to improve dehydration characteristics of plant based foods. Trends in Food Science and Technology, 2001. 12: p. 285-295.

- Lebovka, N.I., N.V. Shynkaryk, and E. Vorobiev. Pulsed electric field enhanced drying of potato tissue. Journal of Food Engineering, 2006: p. in press.

- Arevalo, P., et al. Impact of Pulsed Electric Fields on the Dehydration and Physical Properties of Apple and Potato Slices. Drying Technology, 2004. 22(5): p. 1233-1246.

- Toepfl, S. and D. Knorr. Pulsed electric fields as a pretreatment in drying processes. Stewart Postharvesting Reviews, 2006(8): p. 4:3 doi: 10.2212/spr.2006.4.3.

- Sale, A.J. and W.A. Hamilton. Effect of high electric fields on micro-organisms. I. Killing of bacteria and yeast. II. Mechanism of action of the lethal effect. Biochimica Biophysica Acta, 1967. 148: p. 781-800.

- Sepulveda, D.D., et al. Production of extended shelf-life milk by processing pasteurized milk with pulsed electric fields. Journal of Food Engineering, 2005. 67: p. 81-86.

- Sampedro, F., et al. Quality and safety aspects of PEF application in milk and milk products. Critical Reviews in Food Science and Nutrition, 2005. 45: p. 25-47.

- Heinz, V., S. Toepfl, and D. Knorr. Impact of temperature on lethality and energy efficiency of apple juice pasteurization by pulsed electric fields treatment. Innovative Food Science and Emerging Technologies, 2003. 4(2): p. 167-175.

- Yeom, H.W., et al. Effects of Pulsed Electric Fields on the Quality of Orange Juice and Comparison with Heat Pasteurization. Journal of Agricultural Food Chemistry, 2000. 48: p. 4597-4605.

- Toepfl, S. Pulsed Electric Fields (PEF) for Permeabilization of Cell Membranes in Food- and Bioprocessing – Applications, Process and Equipment Design and Cost Analysis., in: Food Biotechnology and Food Process Engineering. 2006, Technische Universität Berlin: Berlin.

- Toepfl, S., et al. Neues Verfahren zur Haltbarmachung von Milch. Deutsche Molkerei Zeitung, 2006. 127(2): p. 24-28.

- Toepfl, S., V. Heinz, and D. Knorr. Overview of Pulsed Electric Field Processing for Food, in: Emerging Technologies for Food Processing, D.-W. Sun, Editor. 2005, Elsevier: Oxford. p. 67-97.

Issue

Related topics

Equipment, Food Safety, Lab techniques, Technology & Innovation

apakah saya dapat mengetahui proses

jarak antara electrode serta waktu?

saya akan mencoba menggunakannya untuk extraksi

terimakasih

(Translation:

can i know the process

the distance between the electrode and the time?

I will try to use it for extraction

thank you)

pls update

Hi there, we’ll contact the original author and see if they’d like to update this article!