New tools to optimise spray dryers

- Like

- Digg

- Del

- Tumblr

- VKontakte

- Buffer

- Love This

- Odnoklassniki

- Meneame

- Blogger

- Amazon

- Yahoo Mail

- Gmail

- AOL

- Newsvine

- HackerNews

- Evernote

- MySpace

- Mail.ru

- Viadeo

- Line

- Comments

- Yummly

- SMS

- Viber

- Telegram

- Subscribe

- Skype

- Facebook Messenger

- Kakao

- LiveJournal

- Yammer

- Edgar

- Fintel

- Mix

- Instapaper

- Copy Link

Posted: 23 May 2007 | M. Verschueren, J. Straatsma, M. Schutyser, C. Akkerman, P. de Jong, NIZO food research, Ede, the Netherlands | No comments yet

Spray drying is an essential unit operation for the manufacture of many products with specific powder properties. It is characterised by atomisation of a solution or suspension into droplets, followed by subsequent drying of these droplets by evaporation of water or other solvents. Spray drying is used for the manufacture of many consumer and industrial products such as instant food products, laundry detergents, pharmaceuticals, ceramics and agrochemicals. The best known example of an instant food product is milk powder, but instant beverages such as coffee can also be produced by spray drying.

Spray drying is an essential unit operation for the manufacture of many products with specific powder properties. It is characterised by atomisation of a solution or suspension into droplets, followed by subsequent drying of these droplets by evaporation of water or other solvents. Spray drying is used for the manufacture of many consumer and industrial products such as instant food products, laundry detergents, pharmaceuticals, ceramics and agrochemicals. The best known example of an instant food product is milk powder, but instant beverages such as coffee can also be produced by spray drying.

Spray drying is an essential unit operation for the manufacture of many products with specific powder properties. It is characterised by atomisation of a solution or suspension into droplets, followed by subsequent drying of these droplets by evaporation of water or other solvents. Spray drying is used for the manufacture of many consumer and industrial products such as instant food products, laundry detergents, pharmaceuticals, ceramics and agrochemicals. The best known example of an instant food product is milk powder, but instant beverages such as coffee can also be produced by spray drying.

Conventional spray drying processes and particularly the agglomeration process taking place during spray drying are optimised by trial-and-error methods. This, however, is a time-consuming and costly process. In collaboration with a number of industrial and academic partners, NIZO food research has developed several tools for optimising spray drying processes avoiding expensive and time-consuming trial-and-error experiments:

- Within the framework of a European project entitled EDECAD a Computational Fluid Dynamics (CFD) tool was developed that enables efficient optimisation of drying processes with respect to processing costs and powder properties.

- Together with CFD software vendor CD-Adapco, NIZO food research has also developed es-spraydry: an expert tool that allows non-CFD experts to evaluate and optimise their spray drying processes with CFD.

- More recently, NIZO food research has collaborated with Delft University to evaluate a new experimental method based on attractor comparison methods to accurately measure dynamic sticky-points of food powders.

Spray drying equipment

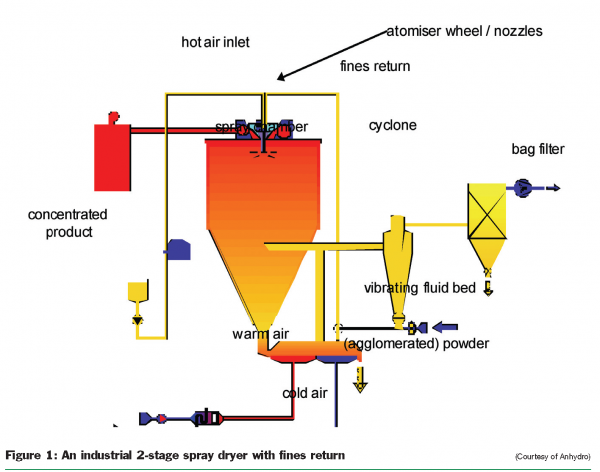

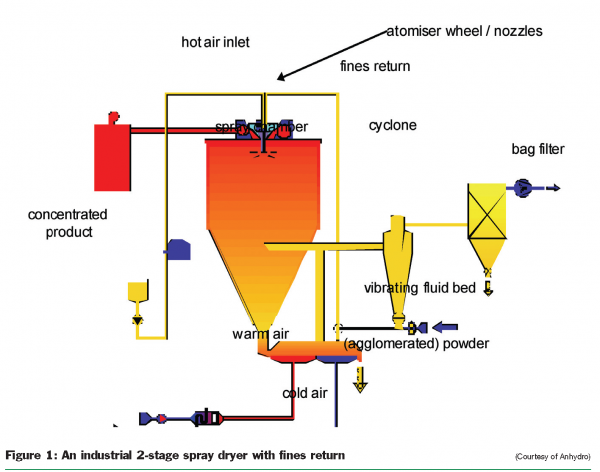

Figure 1 schematically shows an example of an industrial spray dryer for the production of agglomerated powder. In the spray chamber the incoming product is atomised by rotary wheel atomisers or pressure nozzles and dried by the hot air introduced at the top. The powder particles leave the spray dryer at the bottom of the fluid bed, where further drying takes place. Most of the air leaves the spray chamber through the air outlet. Powder particles in the outlet air (small dry particles) are separated by a cyclone and can be reintroduced into the spray chamber (fines return) or into the fluid bed to enhance the agglomeration process.

Drying and fouling

The primary goal of spray drying is removing water. Under normal operating conditions the powder particles are dry enough before they hit the walls of the spray dryer, such that they do not stick to the walls. The drying behavior strongly depends on the spray characteristics and the feed composition. Stickiness is related to the drying state of the particles. Incorrect operating conditions, which do not match the drying behavior of the particles, can therefore lead to fouling.

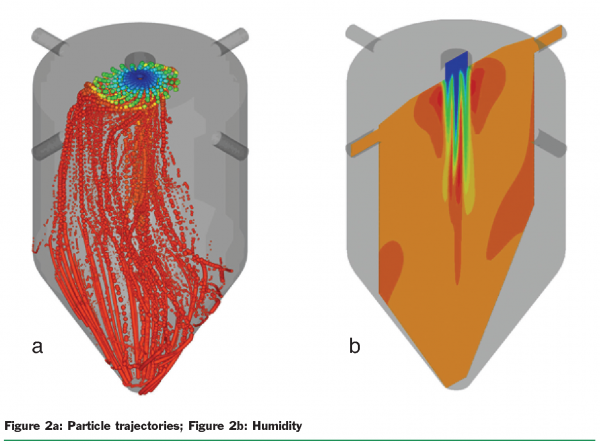

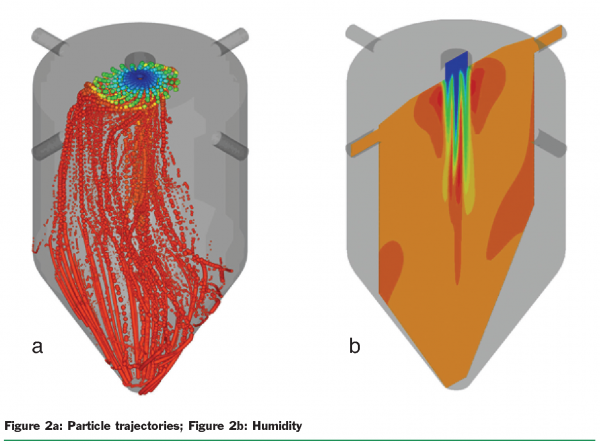

The airflow field, the particle trajectories (Figure 2a) and the local temperature and humidity (Figure 2b) inside the spray dryer can be computed by using Euler-Lagrange CFD techniques, taking into account the coupling for mass, momentum and energy. The difference from other spray calculations (e.g. diesel sprays) mainly concerns the drying part: stickiness primarily depends on the drying state of the outer layer of the particles. Additional sub-models for moisture diffusion inside the particles and for the relation between the drying state and stickiness are therefore required to be able to compute the drying and fouling behavior of spray drying systems.

To enhance the accessibility of CFD knowledge, CD adapco and NIZO food research have cooperated to develop an expert system for predicting the drying and fouling behavior of spray dryers: es-spraydry. An easy-to-use GUI guides the user through defining the spray drying system, defining the product characteristics, setting up the processing conditions, mesh generation, running the calculations and post-processing the results. The es-spraydry tool can be used to design spray dryers, to check whether a specific dryer is suitable for a specific product or to investigate the effect of changes in processing conditions on the drying and fouling behavior of dryers.

Agglomeration

Some powder properties (e.g. the insolubility index) can be related to the moisture content and the temperature-time history of the particles. For these properties the modeling techniques described above can be used. Many powder quality properties, however, are related to the degree of agglomeration. Agglomeration is a size enlargement process of powders, where small particles combine to form large relatively permanent structures, in which the original particles are still identifiable.

Agglomeration facilitates the handling of powders (free flowing powders without dust formation) and enhances the instant properties of powders (a quick dissolution and dispersion without the formation of lumps). The improved instant properties are a result of the open porous structure of the agglomerates, allowing water to penetrate and disperse throughout to its original constituting particle, forcing the particle to sink.

In a spray dryer, agglomeration can take place within the spray of an atomiser, between sprays of various atomisers and between sprays and dry material being introduced into the drying chamber (fines return, see Figure 1). The latter technique is the most effective way to achieve and control agglomeration in spray dryers.

The EDECAD project

Agglomeration during spray drying is considered to be a difficult process to control. The main cause of this is the complex interaction of the process variables: the atomisation process, the mixing of spray and hot air, the drying of suspension droplets and the collision of particles which might lead to coalescence or agglomeration. As a consequence, agglomeration during spray drying is operated by trial-and-error. In 2001 an EC-sponsored project started, coordinated by NIZO food research, entitled EDECAD (Efficient DEsign and Control of Agglomeration in spray Drying machines, www.edecad.com).

The aim of the project is to develop an industrially validated CFD model to predict agglomeration processes in spray drying machines. The modeling technique used is an extension of the Euler-Lagrange model for the drying and fouling behavior of spray dryers described above. Besides the drying model, additional models for collision and agglomeration are required. The initial spray conditions were measured and the sub-models for drying, collision and agglomeration were developed and validated by the academic partners in the project.

A stochastic collision model is used to predict the collision probability and impact details. When a collision occurs, the drying state of the particles and the impact details determine whether the particles rebound, coalesce or agglomerate. Agglomeration occurs when particles are sticky. For many food products stickiness is strongly related to glass transition. The particle composition and the moisture content of the outer layer determine the glass transition temperature and thereby the stickiness of the particle, which influences the agglomeration process.

All sub-models were integrated in the CFD model. Pilot plant validation trials and industrial scale experiments were carried out by the industrial partners in the project to produce validation data for the CFD model.

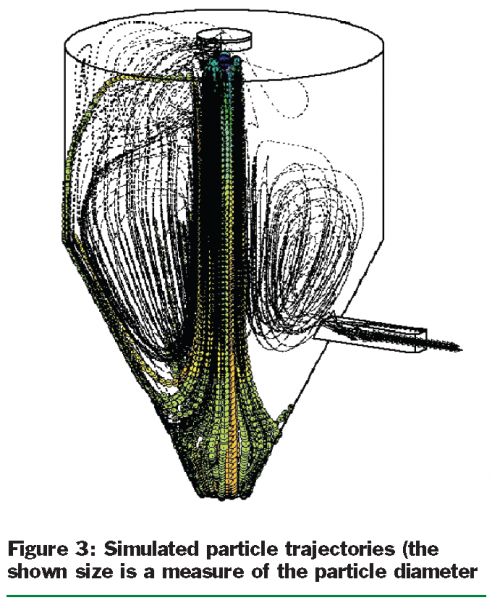

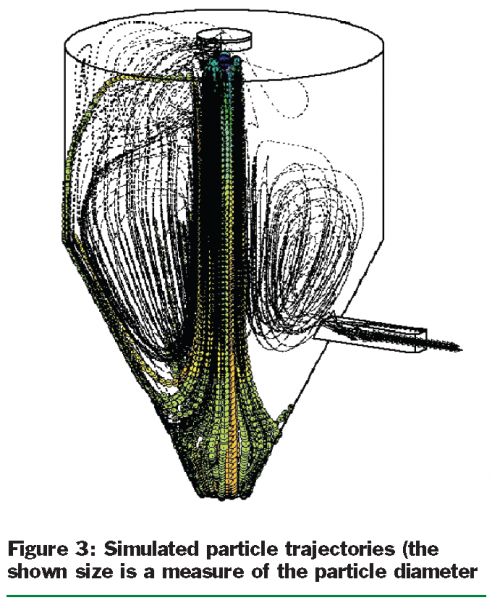

Figure 3 shows a typical simulation result for the particle trajectories in the pilot plant dryer which was also used for the validation trials. The size of the particles shown in Figure 3 is a measure for the particle diameter. The results clearly show that the smaller particles (fines) leave the dryer through the air outlet, whereas the majority of the larger particles leave the dryer through the bottom. The results also show large recirculation pattern in the dryer, which is not unusual especially for relatively small particles.

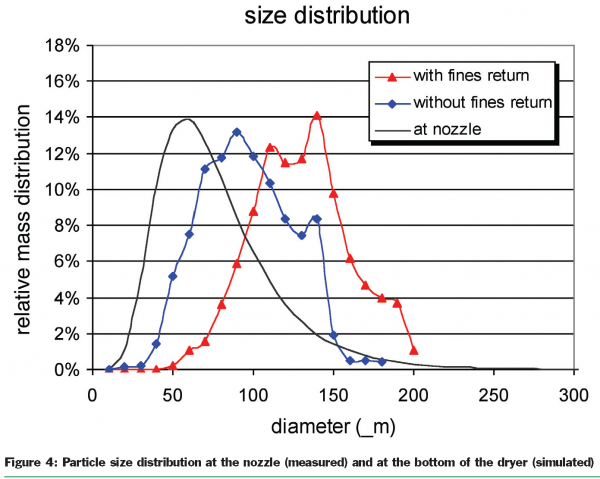

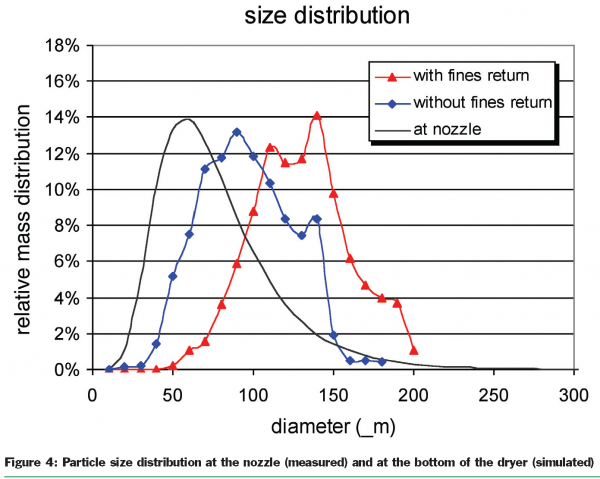

Figure 4 shows the initial particle size distribution at the nozzle and the computed size distribution at the bottom of the dryer.

Dynamic sticky-point measurements

Agglomeration takes place when two sticky particles, or a sticky and a dry particle, collide and form a liquid bridge that is strong enough to resist mechanical deformations, while the integrity of the particles is maintained. The temperature at which particles stick together is called the sticky point temperature. As mentioned above, the sticky point temperature can be related to the glass transition temperature. However, this relation is dependent on product composition and, moreover, sticky points can further deviate from glass transition points, for instance because also the dynamics of colliding particles are also relevant. Direct measurement of sticky points under dynamic conditions yields valuable information that can be applied to optimise fluidised bed and spray drying processes.

In collaboration with Delft University, NIZO food research has evaluated a new method to measure stickiness under dynamic conditions. The method is based on a technique called attractor comparison, which was developed by Delft University (for details see Van Ommen et al). It can detect small hydrodynamic changes due to agglomeration taking place in fluid beds by analysing high frequency pressure measurements by attractor comparison methods. Since the method is very sensitive to small changes in the hydrodynamics, it is much more suitable for monitoring stickiness than by conventional parameters such as the pressure drop over the bed or visual inspection. In the latter case, one is observing the consequences of agglomeration (bed collapse), whereas the attractor comparison method is directly monitoring particle agglomeration.

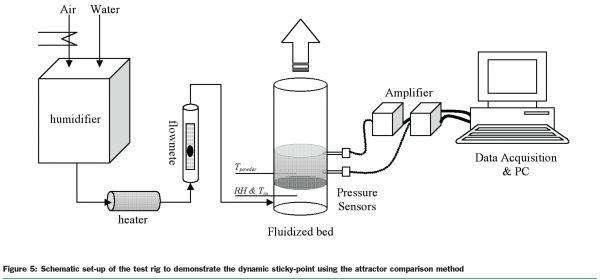

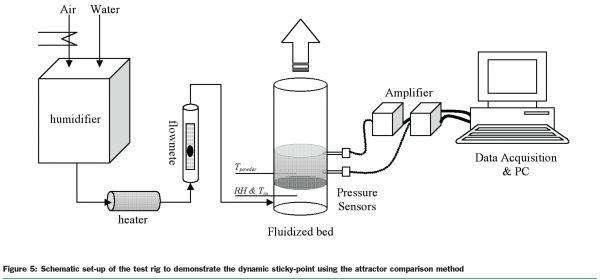

The dynamic sticky-point of a powder can be determined by fluidising a powder in an experimental fluid bed (see Figure 5). This fluid bed is composed of a sintered distributor plate and a cylinder. The air that is fluidising the powder can be heated and humidified. Two pressure probes, each containing a high frequency pressure sensor, are connected to the fluid bed. The sensors are connected to a data acquisition system which is used to analyse the pressure signals.

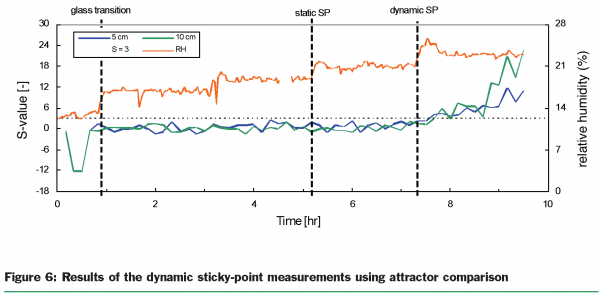

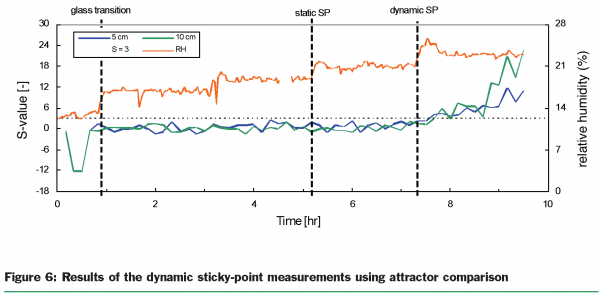

During an experiment, the relative humidity of the air is step-wise increased at constant air flow rate and temperature. The high frequency pressure signals are automatically analysed during the experiment by determining the so-called S-values: i.e. the statistical deviation of the attractor with respect to a ‘dry’ reference state in which no agglomeration occurs. By repeating this procedure at different temperatures, a dynamic stickiness line can be constructed.

Figure 6 shows the results of the dynamic stickiness measurements by attractor comparison. The red line corresponds to the relative humidity of the inlet air, which is step-wise increased. The blue and the green line represent the S-values for each pressure probe. For S less than three there is no significant change in the hydrodynamics of the system. The horizontal dotted line in Figure 6 corresponds to S is equal to three. It can be seen that the S-values for both pressure probes exceed three at a RH of about 22 per cent. This matches with the conventionally determined value of the dynamic sticky point.

Measuring the dynamic sticky point yields valuable information that can be applied to optimise fluidised bed and spray drying processes. This could involve not only optimisation of existing drying processes, but also for new product development (i.e. varying ingredient composition and processing conditions). Measuring dynamic sticky points is especially interesting for products that exhibit strong sticky behaviour during drying, such as products that contain high amounts of sugars or organic acids (e.g. hydrolysed or acid whey). Sticky behaviour of powders during drying leads to fouling on the walls, loss of powder quality, unwanted agglomeration and clumping, operational problems and product losses.

NIZO food research is looking for partners in the food industry that are interested in the application of dynamic sticky point measurements. A large project with industrial partners is currently being set-up, which is aimed at further development of the Dymont system for specific powdered food products. The first phase will include tests with a new well controlled fluidised bed lab-scale facility equipped with the Dymont system. In this set-up we will perform an in-depth investigation of the dynamic behaviour of several sticky powder products and processing conditions. In addition, the effect of additives on the dynamic sticky point will be studied. The second phase is aimed at demonstration of the Dymont system on full industrial scale for in-line monitoring of dynamic sticky point. During the latter phase the system will be evaluated as an early-warning system to prevent process failure due to undesired sticky behaviour.

References

Verdurmen, R.E.M., P. Menn, J. Ritzert, S. Blei, G.C.S. Nhumaio, T. Sonne Sørensen, M. Gunsing, J. Straatsma, M. Verschueren, M. Sibeijn, G. Schulte, U. Fritsching, K. Bauckhage, C. Tropea, M. Sommerfeld, A.P. Watkins, A. Yule and H. Schønfeldt (2004), Simulation of agglomeration in spray drying installations: the EDECAD project, Drying Technology Vol. 22, pp. 1403-1461.

M. Verschueren, R.E.M. Verdurmen, G. van Houwelingen, A.C.P.M. Backx, J.E.A. van der Knaap, M. Bartels, J. Nijenhuis and J.R. van Ommen, Dynamic stickiness measurements by attractor comparison: a feasibility study, Proc. Int. Conf. Liquid Atomisation and Spray Systems (ICLASS), Aug 27 – Sept 1, 2007, Kyoto, Japan.

Van Ommen, J. R., Coppens, M.O., Van den Bleek, C.M., Schouten, J.C., 2000. ‘Early warning of agglomeration in fluidised beds by attractor comparison’. AIChE J., 46, 2183-2197.