Using ultrasound to evaluate dough properties

- Like

- Digg

- Del

- Tumblr

- VKontakte

- Buffer

- Love This

- Odnoklassniki

- Meneame

- Blogger

- Amazon

- Yahoo Mail

- Gmail

- AOL

- Newsvine

- HackerNews

- Evernote

- MySpace

- Mail.ru

- Viadeo

- Line

- Comments

- Yummly

- SMS

- Viber

- Telegram

- Subscribe

- Skype

- Facebook Messenger

- Kakao

- LiveJournal

- Yammer

- Edgar

- Fintel

- Mix

- Instapaper

- Copy Link

Posted: 16 November 2007 | Martin G Scanlon, John H Page, M Nabil Bassim, Harry D Sapirstein,Guillermo G Bellido, Hussein M Elmehdi, Yuanzhong Fan, Valentin Leroy, Keyur L Mehta, G Moses Owolabi, Food Science, Physics & Astronomy, Mechanical & Manufacturing Engineering - University of Manitoba, Winnipeg, Manitoba, Canada | No comments yet

Bread, and the dough from which it is made from, can be viewed as a two-phase system of gas cells and matrix[1]. Both phases ordain the properties of the dough or the bread crumb, and both phases change considerably during the various operations that comprise the breadmaking process. In the history of gas cells, three important stages occur[2,3], namely gas cell nucleation, gas cell growth, and gas cell interconnectivity. But, this history is actually foretold by the numerous physical, chemical and biological events that take place in the dough matrix, one example being the fermentation of sugars to ethanol and carbon dioxide by the activities of the yeast.

Bread, and the dough from which it is made from, can be viewed as a two-phase system of gas cells and matrix[1]. Both phases ordain the properties of the dough or the bread crumb, and both phases change considerably during the various operations that comprise the breadmaking process. In the history of gas cells, three important stages occur[2,3], namely gas cell nucleation, gas cell growth, and gas cell interconnectivity. But, this history is actually foretold by the numerous physical, chemical and biological events that take place in the dough matrix, one example being the fermentation of sugars to ethanol and carbon dioxide by the activities of the yeast.

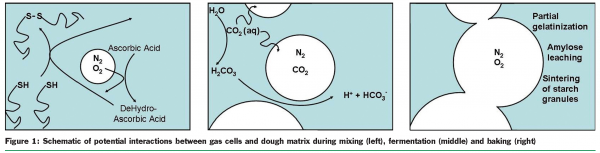

Bread, and the dough from which it is made from, can be viewed as a two-phase system of gas cells and matrix[1]. Both phases ordain the properties of the dough or the bread crumb, and both phases change considerably during the various operations that comprise the breadmaking process. In the history of gas cells, three important stages occur[2,3], namely gas cell nucleation, gas cell growth, and gas cell interconnectivity. But, this history is actually foretold by the numerous physical, chemical and biological events that take place in the dough matrix, one example being the fermentation of sugars to ethanol and carbon dioxide by the activities of the yeast. This is shown schematically in Figure 1.

Because events occur in the dough matrix concurrently with changes in the gas cells, it is useful if we have a technique that can evaluate both the properties of the matrix and the gas cells, and quantify their individual contributions to the overall properties of the dough. Low-intensity ultrasound is such a technique, and thus it has the potential to become a comprehensive process control tool for the baking industry. The emphasis on low intensity is to delineate this ultrasonic technique from power ultrasound that also has bakery applications, for example, in slicing of bread4.

Benefits of ultrasound for assessing the properties of breadmaking doughs

A number of advantages make ultrasound particularly suitable for evaluating the properties of dough.

- Ultrasound is very sensitive to the presence of gas cells. This is due to the large differences in the densities of the gases and the dough matrix.

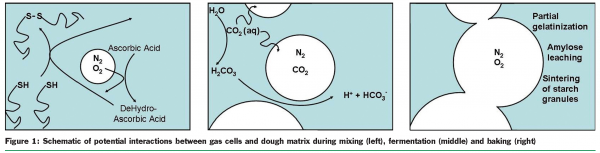

- Ultrasound is unaffected by the opacity of dough. Dough properties can thus be evaluated without diluting the dough, as would be the case for optical techniques such as light scattering (Figure 2).

- Ultrasonic transducers covering a wide range of frequencies are available. As a result, ultrasound can probe dough properties at various length scales, an evident advantage for probing a material undergoing substantial changes in gas cell sizes during breadmaking.

- Ultrasonic transducers and associated electronic equipment tend to be robust. Accordingly, ultrasound is amenable to on-line deployment in breadmaking operations.

Some of these points will be examined in the following sections using examples taken from recent studies conducted at the University of Manitoba, in a project funded by NSERC Canada and eight international industrial partners. Although ultrasonic measurements can provide a number of parameters that will interrogate the mechanical and structural properties of dough, in this article we will simply relate changes in dough systems to measurements of ultrasonic velocity (v) and attenuation coefficient (α). The former assesses how fast ultrasonic pulses propagate in the dough, while the latter is a measure of how effectively the sound is absorbed.

Ingredient effects and dough mixing

A number of ingredients are included in a dough formulation in minor amounts to improve the quality of the resulting loaf of bread5. Some of these ingredients are surface-active, and so are expected to partition at the interface between the gas cell and matrix phases. We wanted to know if ultrasound could tell us something about the surface-active efficacy of these ingredients, particularly in relation to gas cell nucleation during mixing of the dough.

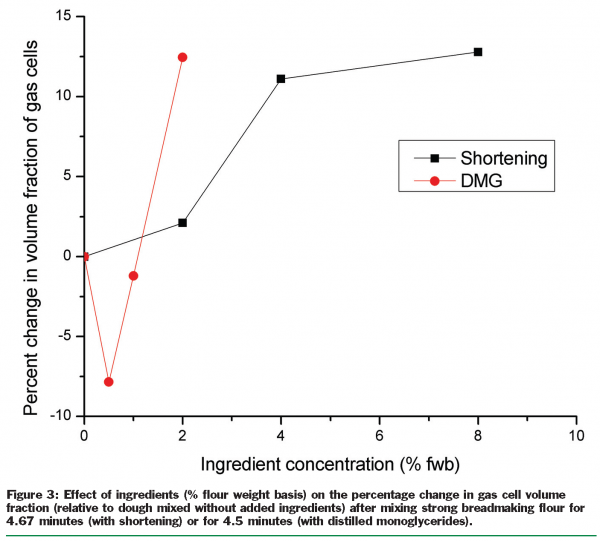

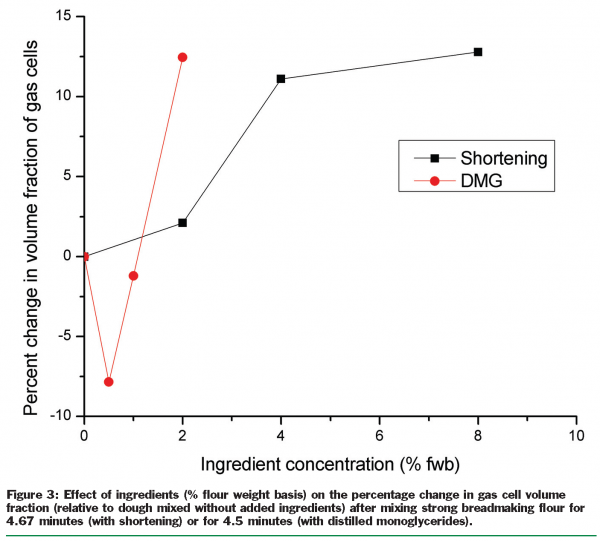

We compared the properties of doughs formulated with a high melting point vegetable shortening versus those made with a distilled monoglyceride (DMG). Gas entrainment capacity of the dough was expressed as volume fraction of gas cells determined from density measurements6. Not unexpectedly, the higher the ingredient concentration, the more gas that was entrained, with the DMG perhaps being more effective than the shortening on an equal weight basis (Figure 3).

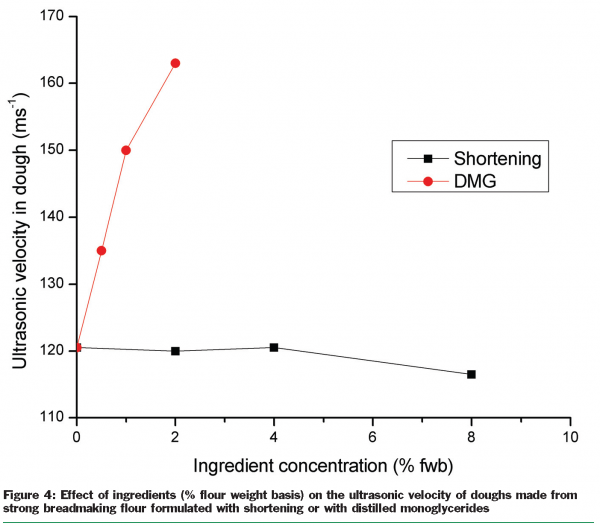

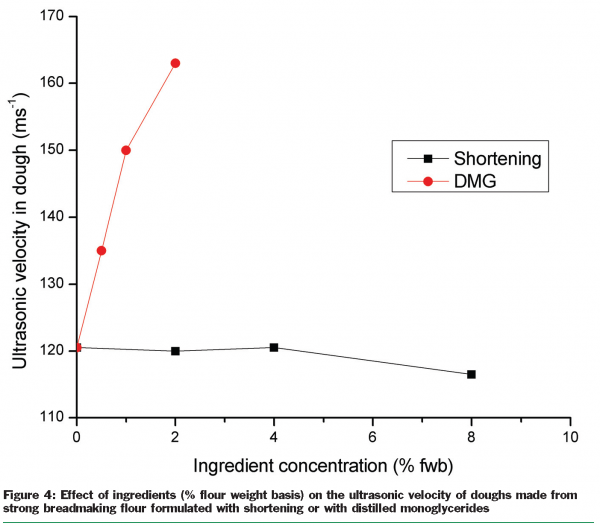

In examining the ultrasonic velocity of these doughs, we used a frequency of 50kHz, a frequency that probes the properties of the dough as a whole7, and where the velocity is dominated by the compressibility of the gas cells. We observe that the two ingredients have different effects on the ultrasonic velocity (Figure 4). So, despite having more gas, doughs formulated with DMG are less compressible, an effect we can attribute to enhanced stiffening of the dough matrix by the DMG8. Therefore, ultrasound is sensitive to the different mode of action of these ingredients, and perhaps it is also a useful probe of the structuring of water in the dough.

Ingredients effects during dough fermentation

We have previously seen pronounced changes in the properties of dough as a result of the action of yeast that cannot be ascribed to gas cell growth9. One issue in studying dough fermentation is the complex array of metabolic by-products that are produced by the yeast in addition to the carbon dioxide that causes the gas cells to grow. Chemical leavening systems have the advantage of producing a much more restricted number of chemicals than yeast, as illustrated for the sodium bicarbonate/sodium acid pyrophosphate (SAPP) system at alkaline pHs.

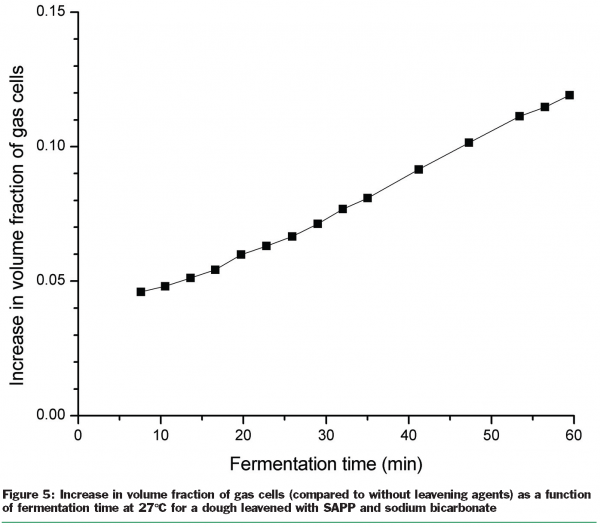

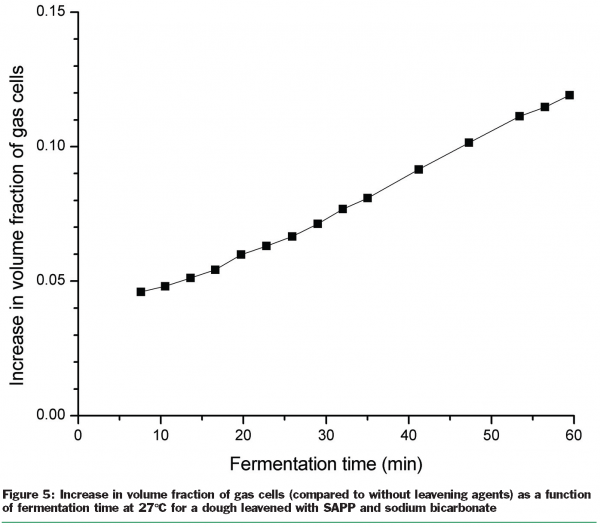

The carbon dioxide generated in the dough matrix by the leavening reaction diffuses to the gas cells and they grow as the time of reaction proceeds (Figure 5). All of the species on both the left and right hand side of these equations can be expected to alter the properties of the dough matrix, due, for example, to how such ions alter the structure of water around the gluten polymers.

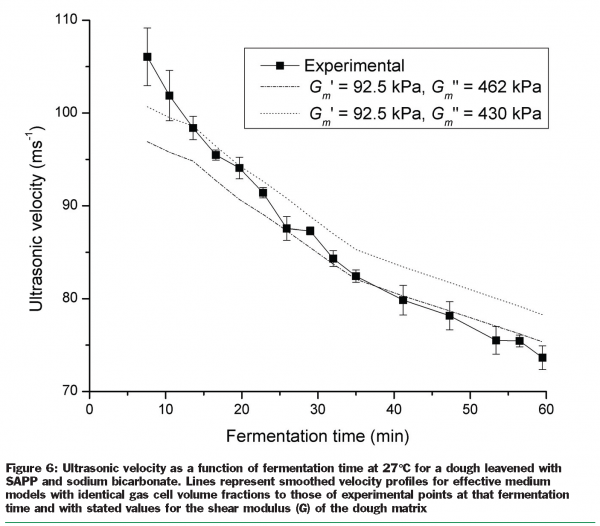

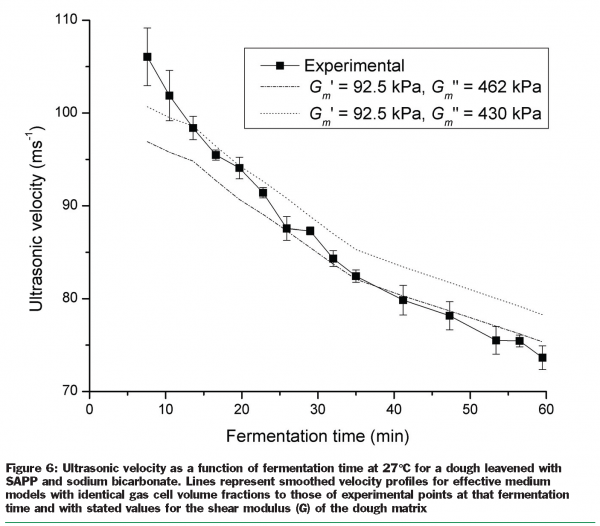

Ultrasonic examination of the effect of these leavening species on the properties of the dough matrix is complicated by the dynamic nature of the leavening process. One theoretical framework that helps cope with this complexity is the use of effective medium models10. These allow us to predict the properties of the dough as a whole based on knowledge of the properties of the gas and matrix phases. In our case, we wanted to see if we could predict the ultrasonic velocity of the dough for all fermentation times by selecting appropriate values for the shear modulus of the dough matrix. The effectiveness of this approach is illustrated for the SAPP system in Figure 6. As the gas cells grow, the velocity drops, but we are only able to predict the correct form of this velocity change by employing a variable value for the shear modulus of the dough matrix (lines represent a significant change in the imaginary part of the matrix shear modulus). We would ascribe this change in dough matrix properties to changes arising from the decreasing concentration of acidulant and sodium bicarbonate and the increasing concentration of salt.

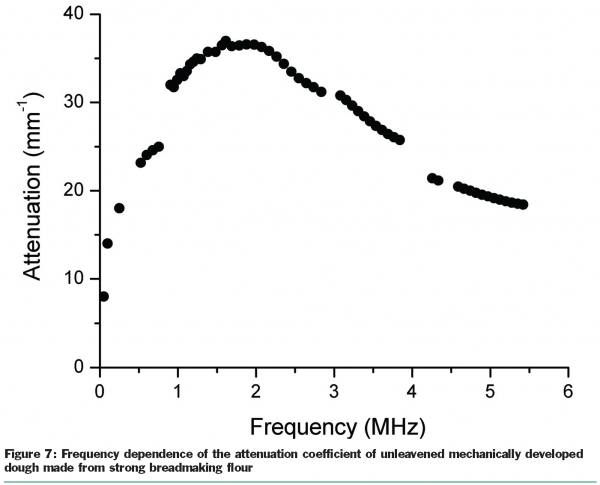

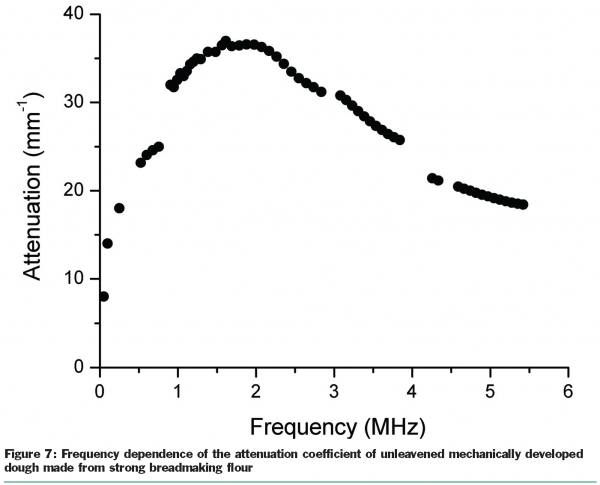

Probing dough properties at various length scales

By employing transducers that cover a range of frequencies, the different wavelengths act as a mechanical spectroscope. This is illustrated in Figure 7 for the ultrasonic attenuation of dough measured with seven transducers over the frequency range of 50kHz to 5MHz11. The two previous examples used a frequency in the left hand region of Figure 7, where attenuation (and velocity) were low. In the right hand region of Figure 7, wavelengths were small, and ultrasonic attenuation is largely affected by the properties of the dough matrix12.

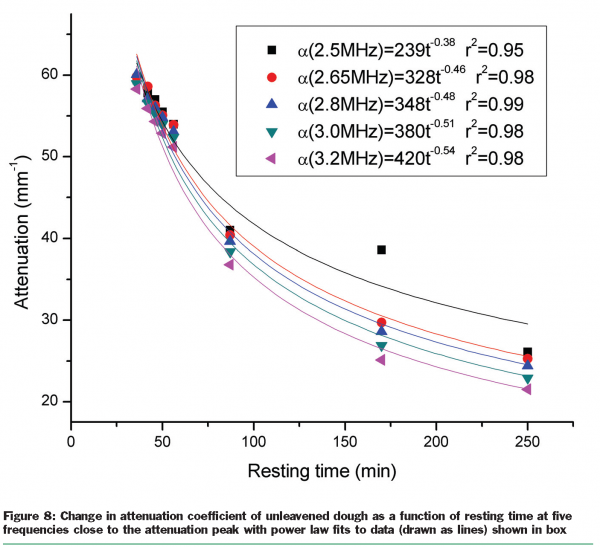

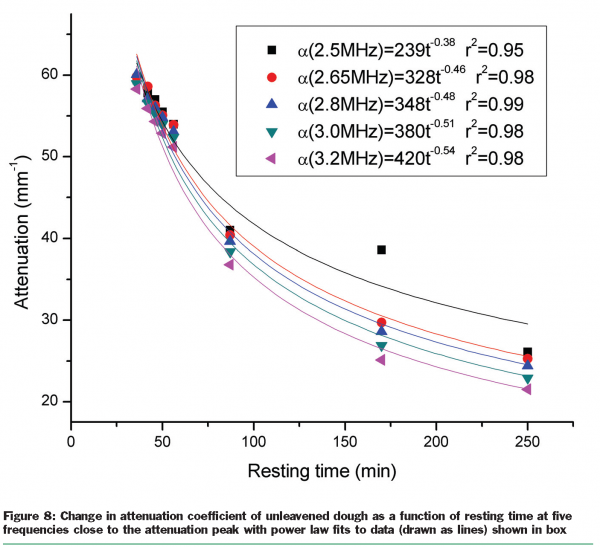

The most notable feature in Figure 7 is the broad peak at approximately 2MHz, where there is an increase in attenuation associated with resonance of the gas cells in the dough. This resonance occurs when ultrasound of a specific wavelength interacts with gas cells of a given size11. We can therefore use the frequency dependence of this peak to investigate gas cell sizes in the dough. Using data taken from a series of dough samples formulated without leavening agents using different transducers13, we examined changes in attenuation versus time of aging of the dough at frequencies just to the right of the peak frequency (Figure 8). In this system, we expect substantial disproportionation of gas cells because of pressure differences inside gas cells of different size14. The time-dependent changes in attenuation marked on Figure 8 are best fits to power law distributions as the attenuation peak shifts to lower frequency (i.e., resonance is induced at a longer wavelength, compatible with a time-dependent coarsening of the gas cells). The square-root time dependence of the attenuation hints at a diffusively driven process14, and this would be expected if ultrasound was accurately following the disproportionation of gas cells in the dough. A more quantitative assessment, where the median and the distribution of gas cell sizes are extracted from the frequency dependence of velocity and attenuation is currently under way15.

Potential on-line deployment

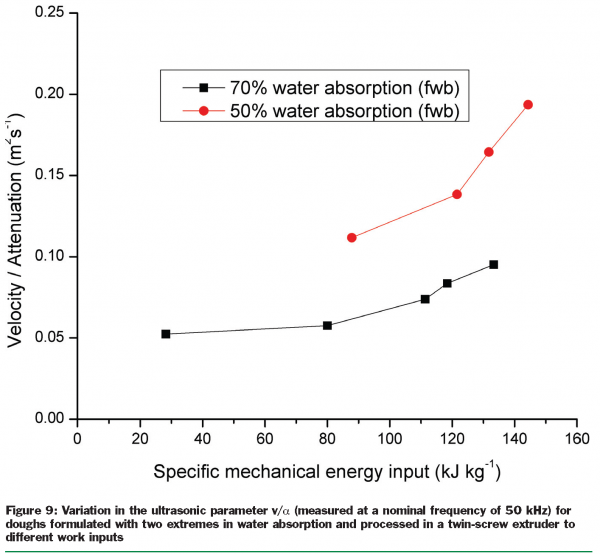

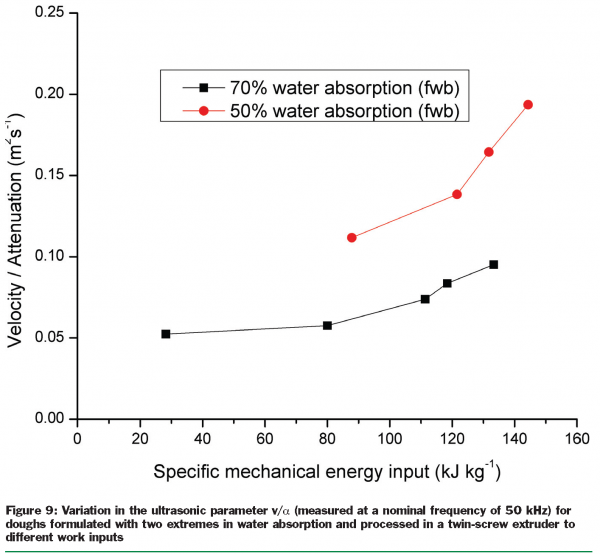

Creating dough that will exhibit good gas retention properties requires optimal development of the dough, and in many cases this is brought about by input of a specific amount of mechanical energy5. Although not used extensively for dough formation, twin-screw extrusion technology is able to continuously control the amount of work input administered to the dough accurately16. As with standard breadmaking processes, manipulating gas cell characteristics and dough matrix properties are pre-requisites for optimising extruded dough quality. Based on the results above, any changes in gas cell and matrix will be expected to affect ultrasonic velocity (v) and attenuation (α).

For two extremes in dough water content17, provided that the SME is not too low, the parameter v/α is sensitive to specific mechanical energy (SME) input for doughs extruded at 40°C (Figure 9). Accordingly, installing ultrasound on-line within a dough extrusion process (as in aerated synthetic polymer extrusion systems18), offers the possibility of using ultrasound to monitor and control the work input that controls the development of the dough.

Conclusion

Low intensity ultrasound is a versatile technique that provides information on ingredient effects on dough matrix properties, both during mixing and during fermentation. Using a range of ultrasonic frequencies allows changes in gas cell populations and sizes to be monitored, an objective that is difficult to attain in this opaque material using other techniques. The potential for on-line utilisation augurs well for integration of ultrasound within process control options planned for wheat flour dough processing systems.

References

- Scanlon, M.G. and Zghal, M.C. 2001. Bread properties and crumb structure. Food Research International 34: 841-864.

- Shah, P., Campbell, G.M., Dale, C. and Rudder, A. 1999. Modelling bubble growth during proving of bread dough: predicting the output from the Chopin rheofermentometer. In G. M. Campbell, C. Webb, S. S. Pandiella & K. Niranjan (Eds.), Bubbles in Food (pp. 95–106). St. Paul, MN: Eagan Press.

- Babin, P., Della Valle, G., Chiron, H., Cloetens, P., Hoszowska, J., Pernot, P., Réguerre, A.L., Salvo, L. and Dendievel, R. 2007. In situ fast X-ray tomography study of the evolution of cellular structure in bread dough during proofing and baking. In G. M. Campbell, M. G. Scanlon, D. L. Pyle & K. Niranjan (Eds.), Bubbles in Food 2: Novelty, Health and Luxury (in press). St. Paul, MN: AACC Press.

- Zahn, S., Schneider, Y. and Rohm, H. 2006. Ultrasonic cutting of foods: effects of excitation magnitude and cutting velocity on the reduction of cutting work. Innovative Food Science & Emerging Technologies 7: 288-293.

- Brown, J. 1993. Advances in breadmaking technology. In B. S. Kamel & C. E. Stauffer (Eds.), Advances in Baking Technology (pp. 38–87). Glasgow: Blackie Academic and Professional.

- Mehta, K. 2006. The use of low intensity ultrasound to investigate the effect of mixing time and ingredients on the mechanical properties of bread dough. M.Sc. Thesis, Food Science. Winnipeg, MB: University of Manitoba.

- Elmehdi, H.M., Page, J.H. and Scanlon, M.G. 2004. Ultrasonic investigation of the effect of mixing under reduced pressure on the mechanical properties of bread dough. Cereal Chemistry 81: 504-510.

- Krog, N. 1981. Theoretical aspects of surfactants in relation to their use in breadmaking. Cereal Chemistry 58: 158-164.

- Scanlon, M.G., Elmehdi, H.M. and Page, J.H. 2002. Probing gluten interactions with low intensity ultrasound. In P. K. W. Ng & C. W. Wrigley (Eds.), Wheat Quality Elucidation: The Bushuk Legacy (pp. 170-182). St. Paul, MN: AACC Press.

- Page, J.H., Sheng, P., Schriemer, H.P., Jones, I., Jing, X.D. and Weitz, D.A. 1996. Group velocity in strongly scattering media. Science 271: 634-637.

- Elmehdi, H.M., Page, J.H. and Scanlon, M.G. 2005. Investigating the porosity of dough using ultrasound. In S. P. Cauvain, S. S. Salmon & L. S. Young (Eds.), Using Cereal Science and Technology for the Benefit of Consumers (pp. 188 192). Cambridge: Woodhead Publishing Limited.

- Létang, C., Piau, M., Verdier, C. and Lefebvre, L. 2001. Characterization of wheat-flour-water doughs: a new method using ultrasound. Ultrasonics 39: 133-141.

- Fan, Y. 2007. Assessment of relaxation phenomena in wheat flour dough using ultrasound of different frequencies. M.Sc. Thesis, Physics & Astronomy. Winnipeg, MB: University of Manitoba.

- van Vliet, T. 1999. Physical factors determining gas cell stability in a dough during bread making. In G. M. Campbell, C. Webb, S. S. Pandiella, & K. Niranjan (Eds.), Bubbles in Food (pp. 121–127). St. Paul, MN: Eagan Press.

- Leroy, V., Fan, Y., Strybulevych, A.L., Bellido, G.G., Page, J.H. and Scanlon, M.G. 2007. Investigating the bubble size distribution in dough using ultrasound. In G. M. Campbell, M. G. Scanlon, D. L. Pyle & K. Niranjan (Eds.), Bubbles in Food 2: Novelty, Health and Luxury (in press). St. Paul, MN: AACC Press.

- Miller, R.C. 1993. Extrusion of baked products. In B. S. Kamel & C. E. Stauffer (Eds.), Advances in Baking Technology (pp. 316–335). Glasgow: Blackie Academic and Professional.

- Owolabi, G.M., Bassim, M.N., Page, J.H. and Scanlon, M.G. 2008. The influence of specific mechanical energy on the ultrasonic characteristics of extruded dough. Journal of Food Engineering (in press).

- Sahnoune, A., Tatibouet, J., Gendron, R., Hamel, A. and Piche, L. 2001. Application of ultrasonic sensors in the study of physical foaming agents for foam extrusion. Journal of Cellular Plastics 37: 429-454.