The benchmark in quality for dehydrated food products

- Like

- Digg

- Del

- Tumblr

- VKontakte

- Buffer

- Love This

- Odnoklassniki

- Meneame

- Blogger

- Amazon

- Yahoo Mail

- Gmail

- AOL

- Newsvine

- HackerNews

- Evernote

- MySpace

- Mail.ru

- Viadeo

- Line

- Comments

- Yummly

- SMS

- Viber

- Telegram

- Subscribe

- Skype

- Facebook Messenger

- Kakao

- LiveJournal

- Yammer

- Edgar

- Fintel

- Mix

- Instapaper

- Copy Link

Posted: 30 June 2010 | Daniel Donhowe, Expert Engineer, Nestlé PTC Marysville | No comments yet

Freeze drying is considered the benchmark in quality for many dehydrated food products. But is it worth the higher cost compared to cheaper air drying technologies such as spray or fluid bed drying? Freeze drying is a process that usually provides several benefits over competing technologies, such as improved flavour and aroma, better retention of nutrients (vitamins, bioactive compounds, etc), ‘natural’ or attractive shape, more natural colour after rehydration, better rehydration – especially for large pieces (e.g. fruits and vegetables) and better solubility for larger particles (e.g. instant coffee).

Freeze drying is considered the benchmark in quality for many dehydrated food products. But is it worth the higher cost compared to cheaper air drying technologies such as spray or fluid bed drying? Freeze drying is a process that usually provides several benefits over competing technologies, such as improved flavour and aroma, better retention of nutrients (vitamins, bioactive compounds, etc), ‘natural’ or attractive shape, more natural colour after rehydration, better rehydration – especially for large pieces (e.g. fruits and vegetables) and better solubility for larger particles (e.g. instant coffee).

Freeze drying is considered the benchmark in quality for many dehydrated food products. But is it worth the higher cost compared to cheaper air drying technologies such as spray or fluid bed drying? Freeze drying is a process that usually provides several benefits over competing technologies, such as improved flavour and aroma, better retention of nutrients (vitamins, bioactive compounds, etc), ‘natural’ or attractive shape, more natural colour after rehydration, better rehydration – especially for large pieces (e.g. fruits and vegetables) and better solubility for larger particles (e.g. instant coffee).

Some of the drawbacks for this process include a higher cost (capital and operating) than competing technologies, increased suscepti – bility to oxidation for some products (due to a highly open structure) and some products can be very brittle and prone to breakdown. The reason behind these benefits will be discussed in the next section on basic principles. We will then review some product applications, look at some industrial equipment options and finally take a brief look to the future.

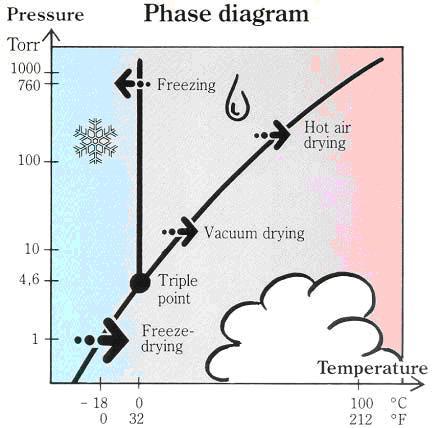

Figure 1 Basic principles of freeze drying Copyright: GEA Niro

Basic principles

Freeze drying is a process where water is first frozen and then removed from a substance at a pressure below the triple point of water (4.6 Torr or 6.1 mbar, less than 1/100th normal atmospheric pressure). The bulk of the water is removed in a primary drying phase where ice is sublimated to water vapour. A secondary drying phase involves desorption of unfrozen water in the product and tends to overlap completion of the primary drying phase. Specific aspects of the freezing and drying phases will be discussed in further detail below.

A freeze dryer is basically a pressure vessel that contains these components:

» A receptacle to hold the material being dried (for foods this is usually an aluminium or stainless steel tray)

» A method of heating the tray. Heating is usually provided by recirculating warm water or oil through heated plates, with the trays separated from the plates by small gaps. Thus, radiation is the predominant heat transfer mechanism. Sometimes the trays are placed directly on the heating plates which results in increased heat transfer by conduction, though with risk of overheating and non-uniform product

» A system to generate a vacuum (typically a vacuum pump or jet eductors)

» A condenser (cold trap) to re-sublimate the water molecules. This greatly increases the performance of the vacuum system

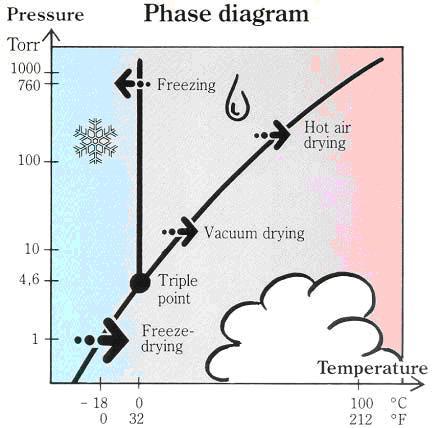

Figure 2 CONRAD™ dryers are fitted with a continuous de-icing system (CDI) Copyright: GEA Niro

As heat is supplied to the material, water is removed by sublimation of the ice crystals in the outer layer of the food and collects as ice on the condensers. This results in a ‘sublimation front’ where ice is removed progressively inward in the particles as the drying proceeds, until finally all ice is removed.

Meanwhile, behind the sublimation front, there is normally still a significant amount of unfrozen water to remove. This water starts to desorb while sublimation is still occurring, and so final drying follows the sublimation front inward until the desired average final moisture content is achieved.

As freeze drying is a relatively slow process (typically several hours), the pressures inside the food product are often close to the bulk pressure in the dryer. Therefore, the product temperature can often be adjusted colder simply by lowering the pressure in the vacuum chamber, though this often results in some loss of heat transfer (gas conduction) and drying rate. Product temperatures will tend to rise above 0°C only towards the end of drying once the ice is largely removed, when the secondary drying phase becomes dominant. This very gentle temperature treatment is a major factor in the superior quality and nutritional retention of many freeze-dried food products. The excellent shape retention (low shrinkage) compared to other dehydration methods results from the combination of low product temperature, slow drying and the progressive removal of ice, since the ice keeps the product very rigid until the latter drying phase.

The ice crystal structure formed during freezing has a large impact on drying performance (cost) and product quality. As ice crystals are removed by sublimation, voids or pores are created in the product. This tends to increase mass transfer by creating open passages for water vapour to flow to the surface, and increased surface area. However, heat transfer is often reduced since ice conducts heat faster than the dry, porous food material. On balance, the voids created by the removed ice crystals assist the drying process since mass transfer is often the limiting factor.

The voids created by the sublimed ice also can greatly assist rehydration or dissolution of the dry food product, which can be a critical factor for larger dry food pieces. The volume of these ice voids directly affects the final product density which can be very important for final product use and packaging. A food with very low solids content before freezing results in a very light freeze-dried product.

One issue with freeze drying is that during the freezing process, the unfrozen food material becomes concentrated. While this solid concentration of course happens for all drying processes, the combination of longer times and low temperatures may cause specific issues (e.g. slow freezing of living organisms may result in loss of viability).

Product applications

The largest industrial food application of freeze drying is production of instant coffee. Freeze dried instant coffee typically has superior flavour and aroma compared to product made from other technologies (e.g. spray drying).

Additional applications include production of high quality freeze-dried ingredients (e.g. dehydrated vegetables and fruits, meats, herbs) for food products such as breakfast cereals, or to make complete lightweight meals (e.g. for backpacking).

Freeze drying is also extensively used in the pharmaceutical industry.

Solid foods

In general, solid foods containing a significant amount of water (e.g. fruit and vegetables) can be placed directly in the freeze dryer and very slowly frozen and freeze-dried, and this practice is sometimes still followed. However, it is much more efficient to individually quick freeze the food pieces prior to loading into the dryer. While these products are sometimes dried in whole, native form, more typically they are cut or sliced to the desired dimension to reduce drying time. This may also enhance product appearance and functionality (especially rehydration and colour). Commercially, these products are typically dried in flat, open aluminium trays.

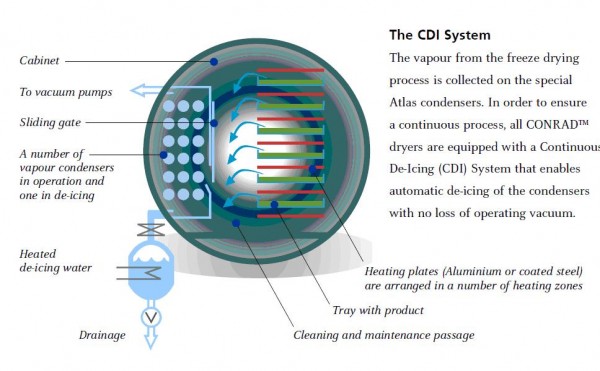

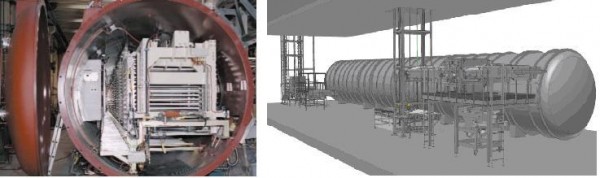

Figure 3 An example of a batch freeze dryer Copyright: Cuddon Freeze Dry

Liquids

Liquid food products such as coffee extract can also be freeze-dried. The liquid is often con centrated prior to freezing to reduce the amount of water to be removed during drying. The liquid is then normally frozen as a layer on a cold belt or drum and cut into particles of desired form for the product application. The frozen particles are loaded into a freeze drying tray (at subfreezing temperature to avoid melting of ice) and subjected to the usual freeze drying. The increased surface area from this particulation process allows much higher mass transfer rates during drying, while the smaller critical dimension (maximum distance from surface to centre of the product) allows more aggressive heating of the product without causing imbalance between heat transfer and mass transfer.

Industrial equipment

Commercial equipment is typically either ‘batch’ or ‘semi-batch/semi-continuous’ operation.

For batch dryers, a stack of cold, loaded trays are pushed into the freeze dryer, the dryer door is quickly closed and vacuum pulled on the dryer before the product can start to melt. Plate temperatures and chamber vacuum are adjusted for the optimal drying of the product, with flexibility to adjust both as needed during the process. Completion of drying is typically indicated from monitoring product temperature, or by a loss in weight scale. Larger batch freeze dryers may allow loading of trays from both ends for higher throughput.

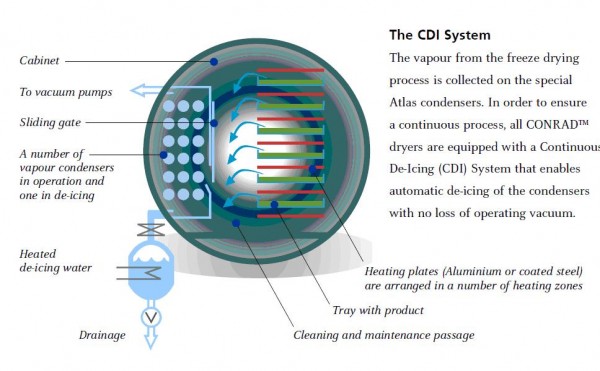

Semi-continuous dryers are similar to batch dryers, with the key difference being inter – mittent insertion and withdrawal of product. Trays are continually inserted (one at a time) into the freeze dryer through a small airlock. Machinery inside the vacuum chamber builds the trays into a stack, and the stack is then pushed through several heating zones and usually a final cooling zone. On the discharge end the trays are removed from the stack and then from the chamber again from a small airlock.

For larger installations, automatic tray filling, product removal from trays, tray washing (if necessary) and tray cooling are often provided. A full freeze-drying plant of course comprises much more processing and may include producing the original feed material (e.g. extract), concentrating, freezing, cutting and sieving, and final dry product handling.

There are also numerous contract freeze drying companies who can dry a wide range of products.

In comparison to other commercial drying technologies, freeze drying has among the highest equipment cost per unit of capacity, and also has high energy costs due to the need for freezing, maintaining equipment in a cold environment, and maintaining a vacuum.

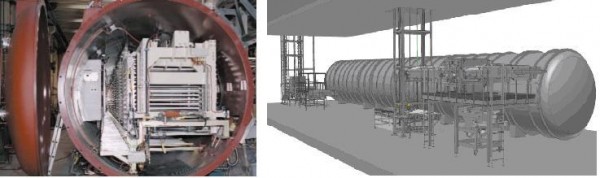

Figure 4 GEA Atlas Conrad freeze drying process Copyright: GEA Niro

Future technology

There have been two alternative technologies closely linked with traditional freeze drying, that are primarily focused on cost reduction.

Atmospheric freeze drying comprises flowing of high volumes of low humidity air over a bed of frozen particles or pieces. No vacuum is drawn on the chamber, which saves money both operationally and by avoiding the need for a pressure vessel. Quality is generally not as good as traditional freeze drying under vacuum, since sublimation will not keep the product cool. In fact melting of the ice will occur so the process is really low temperature air dehydration. Published and patented applications include fruit chips and green peas.

Microwave freeze drying has long promised to increase drying rates by bulk heating of the product, but with very limited success. Main issues include blockage of internal water vapour by ice still in the external layers of the particles, and the problem can be further compounded if the pressure increases to the point where ice is melted, since water is heated much more efficiently by microwaves than ice. The other issue has been uneven energy transfer to the product. However, for the final drying of unfrozen water, it has the potential to deliver energy especially to higher moisture regions in the product. New dryer designs with more uniform energy distribution, coupled with adjustment of microwave frequency for greater penetration depth, could be beneficial for some freeze drying applications.

Summary

Freeze drying is fundamentally a process that keeps product temperature low and separates out much of the water in pure form. It therefore offers many quality advantages over other dehydration technologies. However, this is at a considerably higher cost than conventional air drying technologies. While there are some new (and old) ideas to address this issue, whether they can bridge the gap sufficiently to make freeze drying an attractive option for more products remains to be seen.

About the Author

Daniel Donhowe

Daniel Donhowe graduated form the University of Wisconsin with a BS Che, MS and PhD in Food Engineering. Before joining Nestlé in 2000, Daniel worked on spray drying and fluid bed design/applications at Swenson and spray drying contract manufacturing at Spray-Tek. He currently leads the freeze drying and texturisation team.