A farm to fork approach to lower acrylamide in food

- Like

- Digg

- Del

- Tumblr

- VKontakte

- Buffer

- Love This

- Odnoklassniki

- Meneame

- Blogger

- Amazon

- Yahoo Mail

- Gmail

- AOL

- Newsvine

- HackerNews

- Evernote

- MySpace

- Mail.ru

- Viadeo

- Line

- Comments

- Yummly

- SMS

- Viber

- Telegram

- Subscribe

- Skype

- Facebook Messenger

- Kakao

- LiveJournal

- Yammer

- Edgar

- Fintel

- Mix

- Instapaper

- Copy Link

Posted: 13 June 2008 | Frédéric Mestdagh and Bruno De Meulenaer, Department of Food Safety and Food Quality, Faculty of Bioscience Engineering, Ghent University, Belgium | No comments yet

In 2002, Swedish researchers discovered that within certain foods, significant levels of acrylamide, a probable human carcinogen formed during heating processes such as frying, roasting or baking. Free asparagine and reducing sugars were indicated as the most important precursors. Over the past few years, significant progress has been made to reduce acrylamide formation. Foodstuffs contributing […]

In 2002, Swedish researchers discovered that within certain foods, significant levels of acrylamide, a probable human carcinogen formed during heating processes such as frying, roasting or baking. Free asparagine and reducing sugars were indicated as the most important precursors. Over the past few years, significant progress has been made to reduce acrylamide formation.

Foodstuffs contributing the most to the daily acrylamide intake are fried potatoes, roasted cereal products such as bread and biscuits, and products composed of roasted beans such as chocolate and coffee (Mestdagh et al., 2007). There is still much ambiguity surrounding the risks associated with the carcinogenicity of acrylamide intake in humans. Nevertheless, in comparison with other food contaminates such as benzo(a)pyrene, a polyaromatic hydrocarbon, and a well known carcinogen formed in charbroiled food, acrylamide was indicated to pose a higher risk to human health, due to its abundance in so many food products consumed daily (FAO/WHO, 2005). A recent study observed increased risks of postmenopausal endometrial and ovarian cancer with increasing dietary acrylamide intake (Hogervorst et al., 2007)5,6,7.

Whilst potatoes are not the only food products which have a major contribution to the dietary acrylamide intake, the following article specifically looks at the mitigation of acrylamide in potato products. The main reason for this is due to the large efforts, already undertaken by stakeholders, not at least by the industry, to reduce the acrylamide formation within these products.

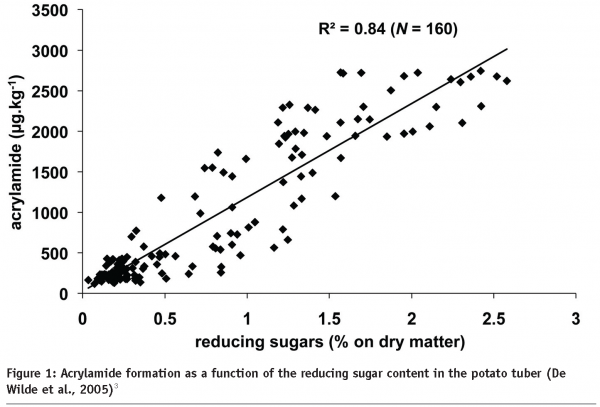

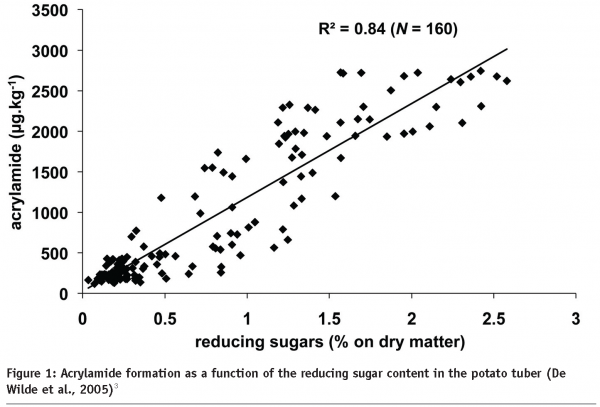

The strong susceptibility of potatoes can be attributed to the abundance of free asparagine, which is present in the tuber in considerable excess compared to the amount of reducing sugars. As a result, the reducing sugar content can be considered as the limiting factor for acrylamide formation. Several studies demonstrate a strong linear correlation between acrylamide formation and reducing sugar content, as illustrated in Figure 1. In general, potatoes used for frying should contain less than 0.5% reducing sugars (on dry matter).

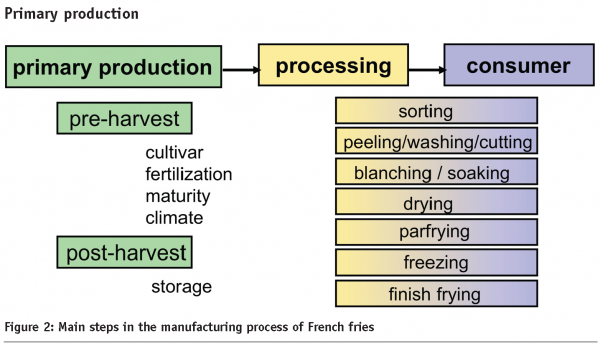

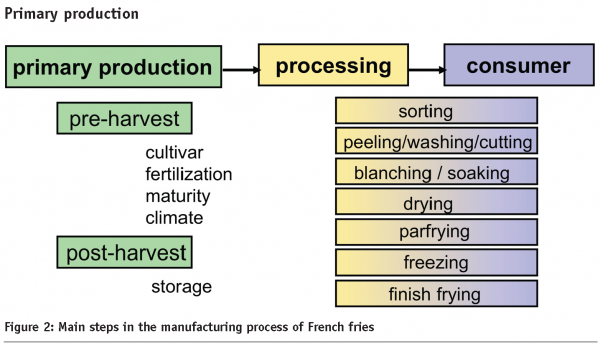

The industrial production process of French fries can be divided into three main stages, as shown in Figure 2. Numerous steps have an impact on the reducing sugar content of the raw material and thus on acrylamide formation upon subsequent frying. Besides the sugar content, acrylamide formation can be controlled by many other parameters, as discussed later on in the article. Due to the range of factors, there is a big variability in acrylamide contamination even within the same batch of processed potatoes.

Primary production

Different potato cultivars may have a different chemical composition. Some varieties, such as Tebina and Quincy, are considered to be unsuitable for frying purposes, due to their extremely high reducing sugar content. Cultivars used for the production of potato crisps, such as Saturna and Lady Claire, are bred and selected for low sugar content and are therefore less susceptible to acrylamide formation upon frying.

However, it is obvious that other factors have a considerable impact on the reducing sugar content of the tuber, such as the level of fertilisation. Increased nitrogen fertilisation reduces the amount of reducing sugars in the harvested tubers. Considering the environmental impact, it thus seems important to find an appropriate balance in the volume of fertiliser applied (De Wilde et al., 2006)4.

Furthermore, potato growers are confronted with the variability in climatological conditions. In this respect, it was observed that exceptional warm and dry summers gave rise to lower reducing sugar contents and thus a lower susceptibility for acrylamide generation during subsequent frying. Exceptionally low rainfall in the final stages of the growth season gave rise to lower dry matter and increased reducing sugar content (De Meulenaer et al., 2008). These climatological conditions may also influence the harvest time and maturity of the tuber at harvest. It is known that immature and therefore smaller tubers have a higher potential to form acrylamide upon frying2.

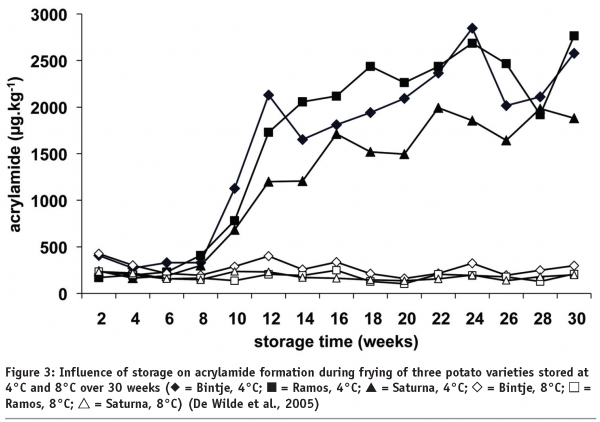

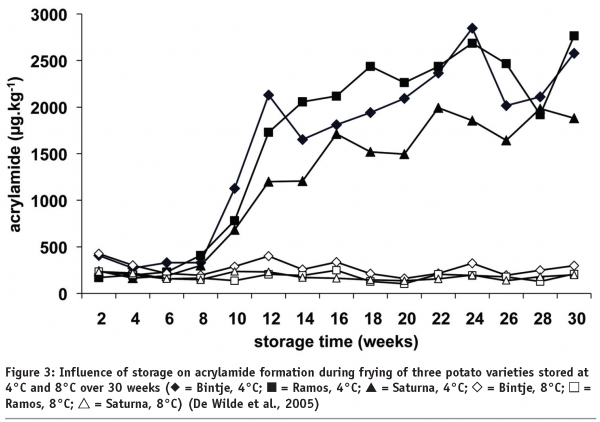

After harvest, potatoes are usually stored at 8°C. This storage temperature does not significantly influence the reducing sugar content, although some varieties are susceptible to senescent sweetening upon long-term storage, involving a gradual enzymatic starch hydrolysis and thus increase in the tubers’ reducing sugar content. Due to climatological conditions or to avoid sprouting, the tubers might be stored at temperatures below 8°C. This induces a so-called low temperature sweetening and dramatically increases the formation of acrylamide upon subsequent frying. As seen in Figure 3 see page 50, this susceptibility is cultivar dependent. Unlike senescent sweetening, low temperature sweetening is at least partially reversible when storing the tubers, by doing so for a period of 3 weeks at 15°C.

It can therefore be concluded that several agronomical parameters influence the reducing sugar content in the tuber. Unfortunately some of these are uncontrollable, such as the climatological conditions. However, several factors later on in the production process can be adjusted in order to (further) decrease the potential of acrylamide formation during frying.

Processing

The potatoes entering the potato frying factory are first graded according to size (Figure 2). As indicated above, smaller tubers tend to form more acrylamide upon frying. After peeling, cutting and washing, the strips undergo a blanching (or soaking) treatment in order to obtain a more uniform colour after frying, to inactivate enzymes and to form a layer of gelatinised starch that limits oil absorption and improves texture. This process also extracts reducing sugars from the potato strips, leading to less acrylamide. It was shown that the blanching temperature had a more significant impact on the sugar extraction compared to the blanching time, as evaluated in a 0-35 minute time range and a 45-85°C temperature range. Furthermore, an adequate refreshment of the water also increased the extraction efficiency (Mestdagh et al., 2008a)8.

Food-grade additives can be dissolved into the blanching solutions in order to further lower the potential of acrylamide formation. Organic acids such as acetic, lactic or citric acid are known to efficiently lower the pH and thus the amount of acrylamide. Furthermore, pyrophosphate, already used in the industrial French fry production to reduce darkening of the blanched potato cuts, reduces acrylamide. In addition, several salts such as Na+, Ca2+ or Mg2+ are indicated as efficient acrylamide reducing agents. Unfortunately, these treatments may also have an impact on the sensorial product quality. A careful dosage of the additives is required in order to avoid a sour, bitter or too pale end product (Mestdagh et al., 2008b). These and other practical considerations make the implication of additives in the production process of French fries, for example, a challenge.

During the (two step) frying operation, the Maillard reaction creates unique aroma and colour components. Several studies revealed a relationship between Maillard browning and acrylamide (Viklund et al., 2007). Generally, a darker-coloured product contains more acrylamide. Consequently, a more intensive frying operation produces more acrylamide. Therefore, it was suggested to limit the frying temperature to 170-175°C and to fry until the French fries have a light-yellow colour9,10.

Catering and consumer

As discussed in the previous paragraphs, both the agricultural and food processing industry have a big responsibility to lower the overall acrylamide exposure. Clearly, the catering industry also plays a major role. Due to a considerable raise in out of home eating over the last decennia, the role of caterers has further increased. Even if agricultural and processing practices are optimal, large amounts of acrylamide can still be formed in the final product when not respecting the finish frying time and/or temperature.

Consumers should also take their responsibility in order to prepare qualitative and safe food. Besides the frying instructions, the consumer is generally advised to follow a diverse dietary pattern composed of foods from many sources, low in fried foodstuffs, but rich in fruits and vegetables (Mestdagh et al., 2007).

To conclude, it can be stated that a farm to fork approach is needed in order to control acrylamide formation in heated foodstuffs in general and in fried potatoes in particular. To communicate new findings to all stakeholders, an acrylamide “toolbox” was composed by and published on the European Confederation of the food and drink industries (CIAA) website and on the website of the DG Health and Consumer Protection (for the website links, see references). Only through this kind of cooperation, safer (fried) foodstuffs can be obtained, keeping in mind the total product quality.1

References

- Acrylamide toolbox. http://www.ciaa.be/documents/brochures/CIAA_Acrylamide_Toolbox_Oct2006.pdf and on http://ec.europa.eu/food/food/chemicalsafety/contaminants/acrylamide_en.htm

- De Meulenaer, B. et al. (2008). Comparison of potato varieties between seasons and their potential for acrylamide formation. Journal of the Science of Food and Agriculture, 88, 313-318.

- De Wilde, T. et al. (2005). Influence of storage practices on acrylamide formation during potato frying. Journal of Agricultural and Food Chemistry, 53, 6550-6557.

- De Wilde, T. et al. (2006). Influence of Fertilization on Acrylamide Formation during Frying of Potatoes Harvested in 2003. Journal of Agricultural and Food Chemistry, 54, 404-408.

- FAO/WHO (2005). Joint FAO/WHO Expert Committee on Food Additives: Summary and conclusions report from sixty-fourth meeting, Rome, 8-17 February 2005.

- Hogervorst, J.H. et al. (2007). A prospective study of dietary acrylamide intake and the risk of endometrial ovarian, and breast cancer. Cancer Epidemiology Biomarkers & Prevention, 16, 2304-2313.

- Mestdagh, F. et al. (2007). Importance of a canteen lunch on the dietary intake of acrylamide. Molecular Nutrition and Food Research, 51, 509-516.

- Mestdagh, F. et al. (2008a). Optimization of the blanching process to reduce acrylamide in fried potatoes. LWT – Food Science and Technology. Accepted for Publication, doi: 10.1016/j.lwt.2007.10.007.

- Mestdagh, F. et al. (2008b). Impact of chemical pre-treatments on the acrylamide formation and sensorial quality of potato crisps. Food Chemistry, 106, 914-922.

- Viklund, G. et al. (2007). An experimental set-up for studying acrylamide formation in potato crisps. LWT – Food Science and Technology, 40, 1066–1071.