Utilisation of durum wheat for yellow alkaline noodles

- Like

- Digg

- Del

- Tumblr

- VKontakte

- Buffer

- Love This

- Odnoklassniki

- Meneame

- Blogger

- Amazon

- Yahoo Mail

- Gmail

- AOL

- Newsvine

- HackerNews

- Evernote

- MySpace

- Mail.ru

- Viadeo

- Line

- Comments

- Yummly

- SMS

- Viber

- Telegram

- Subscribe

- Skype

- Facebook Messenger

- Kakao

- LiveJournal

- Yammer

- Edgar

- Fintel

- Mix

- Instapaper

- Copy Link

Posted: 13 June 2008 | David W. Hatcher and James E. Dexter, Canadian Grain Commission Grain Research Laboratory | No comments yet

Durum wheat (Triticum durum Desf) is a tetraploid wheat that is believed to have arisen from ancient emmer wheat (Triticum dicoccum) in the Mediterranean areas of Asia, Africa and Europe (Abdel-Aal et al, 1998) in approximately 300 B.C. Durum wheat has hard kernels and is usually milled into coarse flour, known as semolina, primarily for the manufacture of pasta (Feillet and Dexter, 1996). Durum wheat is also used for couscous, bulgur and specialty bread products, particularly in Mediterranean countries (Quaglia, 1988). There is an advantage in having developed alternative uses for durum wheat to increase its marketability in years of high production. Most previous efforts to increase durum’s marketability have centred on its bread making capabilities (Edwards et al., 2007 and references therein).

Durum wheat (Triticum durum Desf) is a tetraploid wheat that is believed to have arisen from ancient emmer wheat (Triticum dicoccum) in the Mediterranean areas of Asia, Africa and Europe (Abdel-Aal et al, 1998) in approximately 300 B.C. Durum wheat has hard kernels and is usually milled into coarse flour, known as semolina, primarily for the manufacture of pasta (Feillet and Dexter, 1996). Durum wheat is also used for couscous, bulgur and specialty bread products, particularly in Mediterranean countries (Quaglia, 1988). There is an advantage in having developed alternative uses for durum wheat to increase its marketability in years of high production. Most previous efforts to increase durum’s marketability have centred on its bread making capabilities (Edwards et al., 2007 and references therein).

Durum wheat (Triticum durum Desf) is a tetraploid wheat that is believed to have arisen from ancient emmer wheat (Triticum dicoccum) in the Mediterranean areas of Asia, Africa and Europe (Abdel-Aal et al, 1998) in approximately 300 B.C. Durum wheat has hard kernels and is usually milled into coarse flour, known as semolina, primarily for the manufacture of pasta (Feillet and Dexter, 1996). Durum wheat is also used for couscous, bulgur and specialty bread products, particularly in Mediterranean countries (Quaglia, 1988). There is an advantage in having developed alternative uses for durum wheat to increase its marketability in years of high production. Most previous efforts to increase durum’s marketability have centred on its bread making capabilities (Edwards et al., 2007 and references therein).

Durum wheat breeders select new lines for high yellow pigment and low levels of oxidative enzymes to assure a satisfactory bright yellow colour in pasta. Breeders also select for strong gluten and high protein content to assure that cooked pasta is firm and resilient (Dexter, 2004). Similar quality attributes are desirable for high quality yellow alkaline noodles (YAN), a major component of Asian diets (Hatcher, 2001). Although YAN is made from hexaploid common (bread-making) wheat (Triticum aestivum L) flour, the processing and formula are quite different. YAN is sheeted and usually marketed fresh, whereas pasta is extruded and usually marketed dried (Dexter, 2004). YAN contain alkaline salts, usually 0.3 to 1.0% w/w, with sodium and potassium carbonates in various ratios being the most common. Endogenous flavonoids in flour, which are colourless at neutral pH, undergo a chromophoric shift at alkaline pH, and are the primary cause of yellowness in YAN (Asenstofer et al, 2006). Yellow pigment in common wheat flour is a secondary contributor to YAN yellowness. However, the high yellow pigment levels in durum wheat, predominately the hydroxylated carotenoid lutein (Humphries et al, 2004), should enhance YAN yellowness. Fu et al (2006) recently drew attention to the potential of using durum wheat flour for yellow alkaline noodles.

Composition of durum wheat and common wheat flour

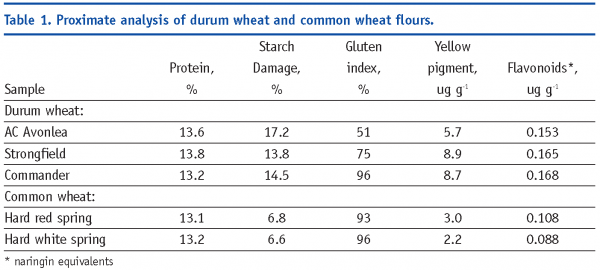

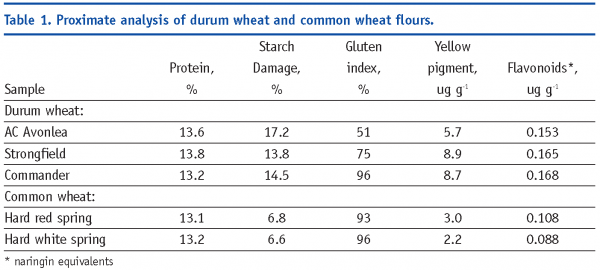

We have assessed the YAN quality of diverse durum wheat genotypes and compared these to the usual raw materials, hard white spring and hard red spring wheat flour (Hatcher et al, 2008a and 2008b). In this article, we will summarise the results from three Canadian durum wheat genotypes of diverse gluten strength and yellow pigment content. The durum wheat genotypes were grown in test plots in western Canada. The common wheat samples, used for comparative controls, were commercially produced Canada Western Red Spring wheat and Canada Western Hard White Spring wheat. All of the wheat samples were roller milled to give a flour yield of approximately 75% (on a clean wheat basis). Common wheat flours were obtained directly using a tandem Buhler mill (Martin and Dexter, 1981), whereas the durum wheat flour was derived by gradually reducing semolina particle size (Hatcher et al, 2008a). Comparisons between durum wheat and common wheat flours for some components associated with YAN colour and texture are summarised in Table 1.

The hard kernel texture of the durum wheat causes higher flour starch damage during roller mill grinding than the common wheat. High starch damage affects dough water absorption, and can negatively impact cooked noodle surface characteristics and texture (Hatcher et al, 2002 and 2008c). However, reduction of semolina to finer particle size is necessary to achieve satisfactory YAN. Fu et al (2006) found that YAN prepared from the coarser durum wheat semolina exhibited a rough streaky surface, due to incomplete hydration of coarse particles.

Texture of cooked YAN is related to protein content (Miskelly 1984, Dexter 2004), but the narrow range exhibited among the various flours (13.1-13.8%) should have a minimal impact on YAN textural attributes. Gluten index, a widely used durum wheat gluten strength specification (Cubadda et al, 1992), ranked the durum wheat genotypes from moderate strength for Avonlea, to comparable in strength to that of the common wheat samples for Commander. The durum wheat genotypes exhibited a range in yellow pigment content, although all contained far greater pigment (~2-3 fold) than either of the common wheat flours. Flavonoid contents were also significantly higher in the durum wheat flours than in the common wheat flours.

Fresh YAN Properties

Flour was mixed with a one per cent w/w kansui (9:1 sodium:potassium carbonate) solution to form a crumbly dough, using an asymmetrical speed mixer as described by Hatcher and Preston (2004), and then sheeted on a laboratory machine according to Kruger et al (1994). Optimum water absorption, as determined by sheeting characteristics, was 34% for the common wheat flours, and slightly higher (36%) for the durum wheat flours, due to higher starch damage. Aside from adjustment of water absorption, processing of durum wheat flour into YAN presented no difficulties; dough hydrated uniformly and the YAN surface was smooth, uniform in colour and non-sticky.

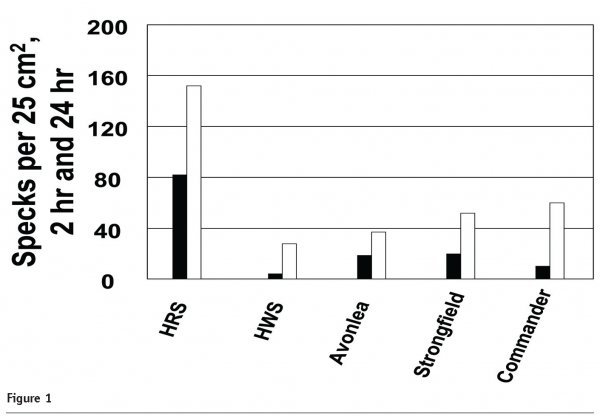

Common wheat with a red seed coat is widely used for YAN, but when it is available, common wheat with a white seed coat is preferred because bran specks in fresh noodles are less conspicuous (Ambalamaatil et al, 2002). Noodles with fewer bran specks offer a significant marketing advantage. In our laboratory, image analysis is used to objectively measure visible bran specks in noodles (Hatcher and Symons, 2000). As expected, fresh YAN prepared from the hard white spring wheat had far fewer visible specks than hard red spring wheat YAN two hours after preparation. This advantage was retained over the 24 hour storage period (Figure 1). Durum wheat breeders select white seed coat lines because visible bran specks are also considered a defect in pasta. All of the durum wheat genotypes demonstrated a low incidence of visible specks in YAN at both two hour and 24 hour after preparation.

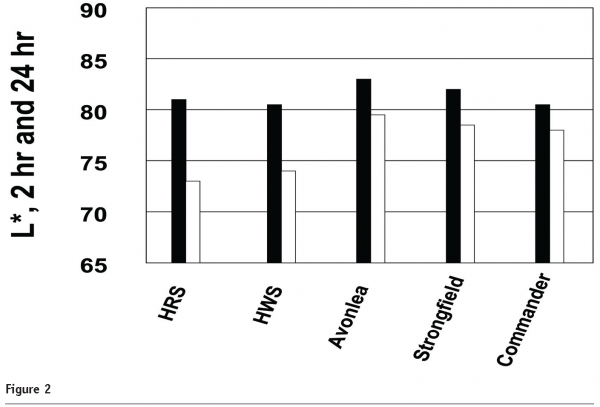

CIE 1976 L*, a*, and b* colour coordinates, determined by a spectrocolorimeter, were used to measure raw noodle colour. As seen in Figure 2 on page 38, the durum wheat YAN brightness (L*) were comparable to, or better than, the common wheat YAN in brightness two hour after processing. The durum wheat YAN also retained brightness (L*) much better than common wheat YAN over the 24 hour storage period. The better colour stability of the durum wheat YAN is consistent with lower levels of the oxidative enzymes peroxidase and polyphenol oxidase. Peroxidase activities in all durum wheat flours were at the minimum detection level, with values ranging from 4.3 to 12.2 purpuogallin units/g/min compared to values near 300 purpuogallin units/g/min for the hard red spring and hard white spring wheat flours (Hatcher et al, 2008a). Polyphenol oxidase (PPO) activity was not detectable in any of the durum wheat flours. Activities near 20 nmoles O2/g/min however were detected in the hard red spring and hard white spring wheat flours (Hatcher et al, 2008a).

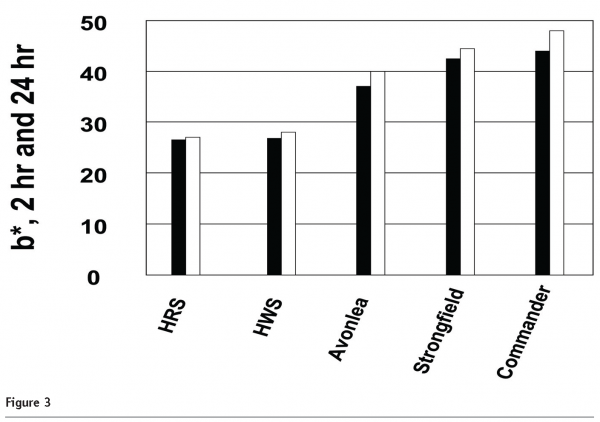

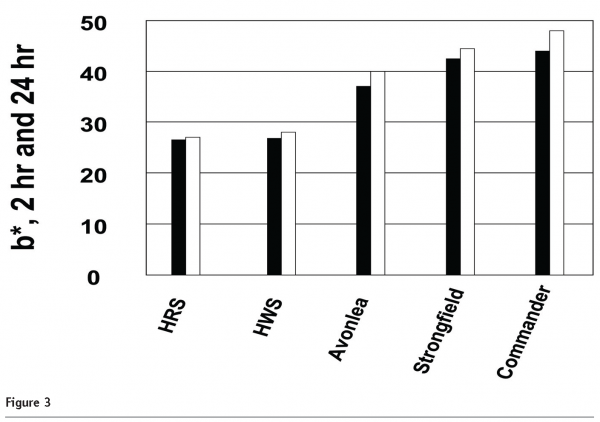

The durum wheat YAN offered no advantage in redness (a*) over the common wheat YAN (results not shown). However, the combined impact of higher flavonoid levels and higher yellow pigment levels in the durum wheat flours resulted in substantially yellower YAN as indicated by higher b* (yellowness) values at both 2 hour and 24 hour after processing (Figure 3). The contribution of the yellow pigment levels in the durum wheat to b* values is evident, as the increased durum YAN b* values correspond to their flours elevated yellow pigment content.

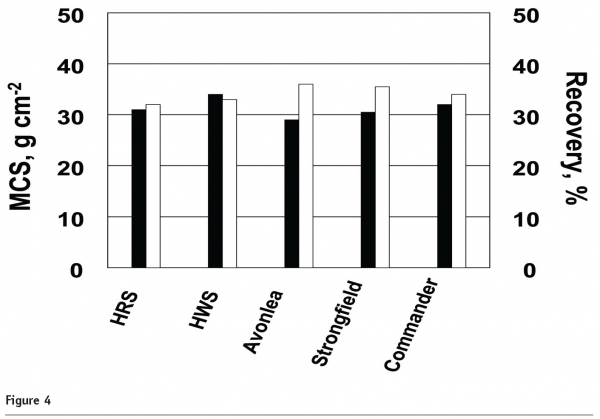

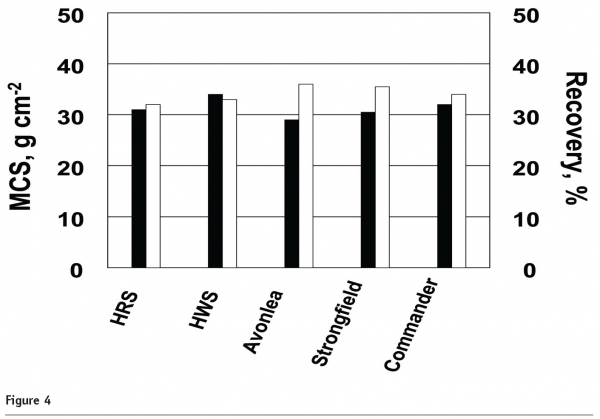

Cooked YAN texture quality was determined instrumentally using a TA-XT2i (Texture Technologies, Scarsdale, NY) with fixtures and procedures similar to those described by Oh et al (1983). Durum wheat cooked noodles displayed a smooth and non-sticky surface. Values for maximum cutting stress (an indication of noodle firmness) and recovery (an indication of noodle resilience during chewing) are shown in Figure 4 opposite. The textural measurements of the cooked YAN noodles were equal to or superior to the common wheat noodles. The high starch damage associated with durum wheat flour does not appear to be detrimental to YAN texture. This is consistent with our findings that the impact of starch damage on the texture of YAN prepared with alkaline salts is slight (Hatcher et al, 2008b). Durum wheat may not be suitable for YAN when NaOH is the alkaline agent (i.e.: Malaysia), because high starch damage in the presence of NaOH promotes liquefaction of starch, thereby increasing cooking loss and reducing cooked YAN firmness and resilience (Hatcher et al, 2008c).

Conclusions

Durum wheat is a relatively small international commodity. Durum wheat production worldwide averages only approximately 35 million metric tonnes, and durum wheat trade is only approximately seven million metric tonnes (International Grains Council 2007). Production today is erratic because durum wheat is primarily grown in areas prone to drought, resulting in inconsistent supply and price volatility. More stability and greater durum wheat market demand would be of great beneficial to producers.

During years of adequate production, when prices are competitive to common wheat, durum wheat would be a very attractive YAN raw material, offering a viable marketing option in addition to pasta. The Asian consumer’s preference for the degree of yellowness in YAN varies according to region, and YAN made from 100% durum wheat may not be acceptable everywhere. However, durum’s colour stability due to low oxidative enzymes and minimal bran speckiness will be appreciated in all markets. Recent results in our laboratory have shown that fresh durum wheat YAN retained colour stability over seven days, under refrigeration (Hatcher et al, 2008b).

Durum wheat flour could be blended in various proportions with common wheat flour to achieve the most desirable colour intensity for a given region. The desirable characteristics of durum wheat YAN have been recognised in Japan where the product is now commercially available (Hatcher et al, 2008b).

References

Abdel-Aal, E.-S. M., Sosulski, F. W. and Hucl, P. 1998. Origins, characteristics, and potentials of ancient wheats. Cereal Foods World, 48, 708-715.

Ambalamaatil, S., Lukow, O. M., Hatcher, D. W., Dexter, J. E., Malcolmson, L. J., Watts, B. M. 2002. Milling and quality evaluation of Canadian hard white spring wheats. Cereal Foods World 4, 319-327.

Asenstorfer, R. E., Wang, Y. and Mares, D. J. 2006. Chemical structure of flavonoid compounds in wheat (Triticum aestivum L.) flour that contribute to the yellow colour of Asian alkaline noodles. Journal of Cereal Science, 43, 108-119.

Cubadda, R., Carcea, M. and Pasqui, L. 1992. Suitability of the gluten index for assessing gluten strength in durum wheat and semolina. Cereal Foods World, 37, 866-869.

Dexter, J. E. 2004. Grain, paste products: Pasta and Asian noodles. Pages 249-271 in: Food Processing: Principles and Applications. J. S. Smith and Y. H. Hui, eds. Blackwell Publishing, Ames, Iowa.

Edwards, N. M., Preston, K. R., Paulley, F. G., Gianibelli, M. C., McCaig, T. N., Clarke, J. M., Ames, N. P. and Dexter, J. E. 2007. Hearth bread baking quality of durum wheat varying in protein composition and physical dough properties. Journal of the Science of Food and Agriculture, 87, 2000-2011.

Feillet, P. and Dexter, J. E. 1996. Quality requirements of durum wheat for semolina milling and pasta production. Pages 95-131 in: Pasta and Noodle Technology. J. E. Kruger, R. R. Matsuo and J. W. Dick, eds. American Association of Cereal Chemists, St. Paul, MN.

Fu, B. X., Assefaw, E. G., Sarkar, A. K. and Carson, G. R. 2006. Evaluation of durum wheat fine flour for alkaline noodle processing. Cereal Foods World, 51, 178-183.

Hatcher, D. W. 2001. Asian noodle processing. Pages 131-157 in: Cereals Processing Technology. G. Owens, ed., Woodhead Publishing, Cambridge, UK.

Hatcher, D. W. and Symons, S. J. 2000. Assessment of Oriental noodle appearance as a function of flour refinement and noodle type. Cereal Chemistry 77, 181-186.

Hatcher, D. W. and Preston, K. R. 2004. Investigation of a small-scale asymmetric centrifugal mixer for the evaluation of Asian noodles. Cereal Chemistry 81, 303-307.

Hatcher, D. W., Anderson, M. J., Desjardins, R. G., Edwards, N. M., and Dexter, J. E. 2002. Particle size and starch damage effect on the processing and quality of white salted noodles. Cereal Chemistry 79, 64-71.

Hatcher, D. W., Dexter, J. E. and Fu, B. X. 2008a. Investigation of amber durum wheat for production of yellow alkaline noodles. Journal of Cereal Science (accepted for publication).

Hatcher, D. W., Dexter, J. E. and Fu, B. X. 2008b. Refrigerated storage of yellow alkaline durum noodles: Impact on color and texture. Cereal Chemistry (accepted for publication).

Hatcher, D. W., Edwards, N. M. and Dexter, J. E. 2008c. Impact of flour particle size and starch damage and alkaline reagent on yellow alkaline noodle characteristics. Cereal Chemistry (accepted for publication).

Humphries, J. M., Graham, R. D. and Mares, D. J. 2004. Application of reflectance colour measurement to the estimation of carotene and lutein content in wheat and triticale. Journal of Cereal Science 40, 151–159.

International Grains Council. 2007. World Grain Statistics. International Grains Council, London, UK.

Kruger, J. E., Anderson, M. H. and Dexter, J. E. 1994. Effect of flour refinement on raw Cantonese noodle color and texture. Cereal Chemistry 71, 177-182.

Martin D.G., Dexter, J. E., 1991. A tandem Buhler laboratory mill: Its development and versatility. Association of Operative Millers Bulletin (April), 5855-5864.

Miskelly, D. M., 1984. Flour components affecting paste and noodle colour. Journal of the Science of Food and Agriculture 35, 463-471.

Oh, N. H., Seib, P. A., Deyoe, C. W. and Ward, A. B. 1983. Noodles I. Measuring the textural characteristics of cooked noodles. Cereal Chemistry 60, 433-438.

Quaglia, G. B. 1988. Other wheat products. Pages 263-282 in: Durum Wheat: Chemistry and Technology. G. Fabiani and C. Lintas, eds. American Association of Cereal Chemists, St. Paul, MN.